Industrial Silicon Carbide Solutions for Pakistan: Sicarbtech’s 2025 Pillar Page for Electromagnetic Stirring and Braking Power in Continuous Casting

シェア

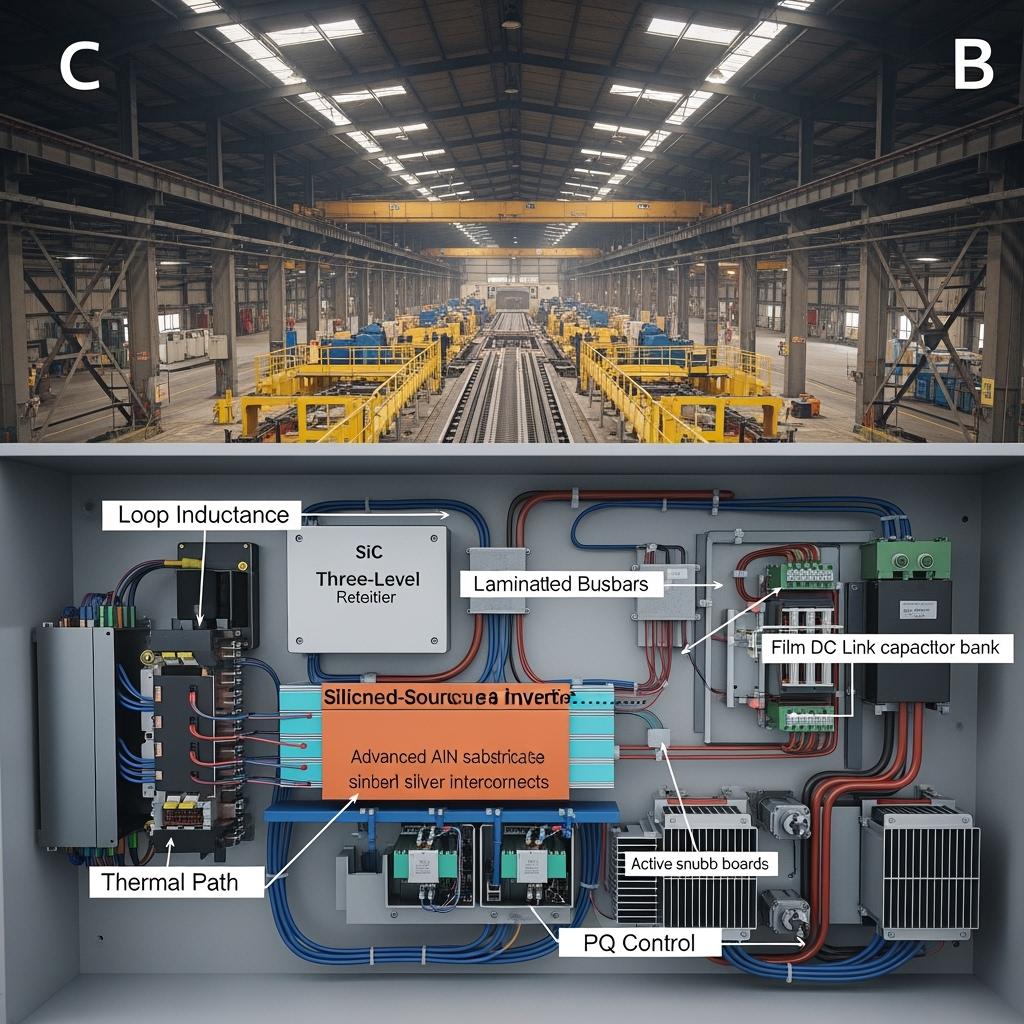

Pakistan’s 鉄鋼 industry is entering a phase where productivity and quality improvements must coexist with stricter power quality compliance and rising energy costs. Thin slab casters in Punjab and growing billet/bloom capacity in Sindh are adopting electromagnetic stirring (EMS) and electromagnetic braking (EMBr) to control mold flow fields, reduce central segregation, and suppress surface defects. Yet many EMS/EMBr power supplies still rely on legacy silicon platforms and bulky line-frequency equipment that waste energy, inject harmonics, and respond too slowly for modern recipes. Silicon carbide (SiC) changes this calculus. Sicarbtech delivers a high‑efficiency, high‑bandwidth, low‑harmonic power platform—from materials and devices to modules, systems, and production equipment—engineered for hot, dusty, and EMI‑intense caster bays. This pillar page provides Pakistan‑specific analysis, engineering guidance, and a turnkey roadmap for upgrading EMS/EMBr power at scale.

Executive Summary: 2025 Outlook for SiC EMS/EMBr Power in Pakistan

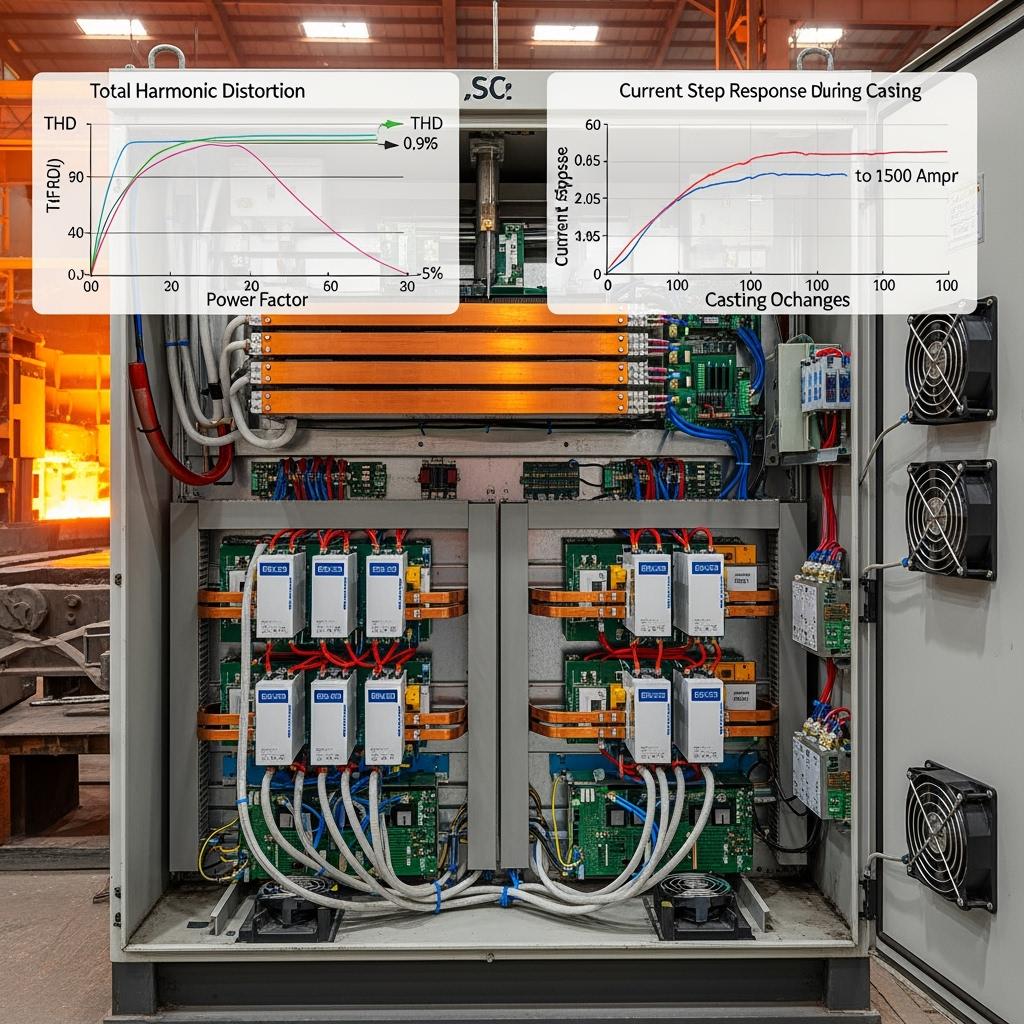

In 2025, the business case for SiC in continuous casting is clear: energy savings, tighter current control, and cleaner interconnection. By operating at higher switching frequencies with low conduction and switching losses, SiC power stages shrink magnetics and filters while preserving thermal margin in 40–50°C mill environments. Field‑ready configurations reach 98.5–99.0% peak efficiency on rectifier/inverter links; typical system gains are 0.8–1.5 percentage points. With laminated busbars and <10 nH loop inductance, EMS/EMBr supplies achieve ≤3% THD and near‑unity power factor, reducing transformer stress and tariff penalties. Fast current loops—to the sub‑millisecond domain—stabilize flow fields through casting speed changes and grade transitions, improving slab and billet quality.

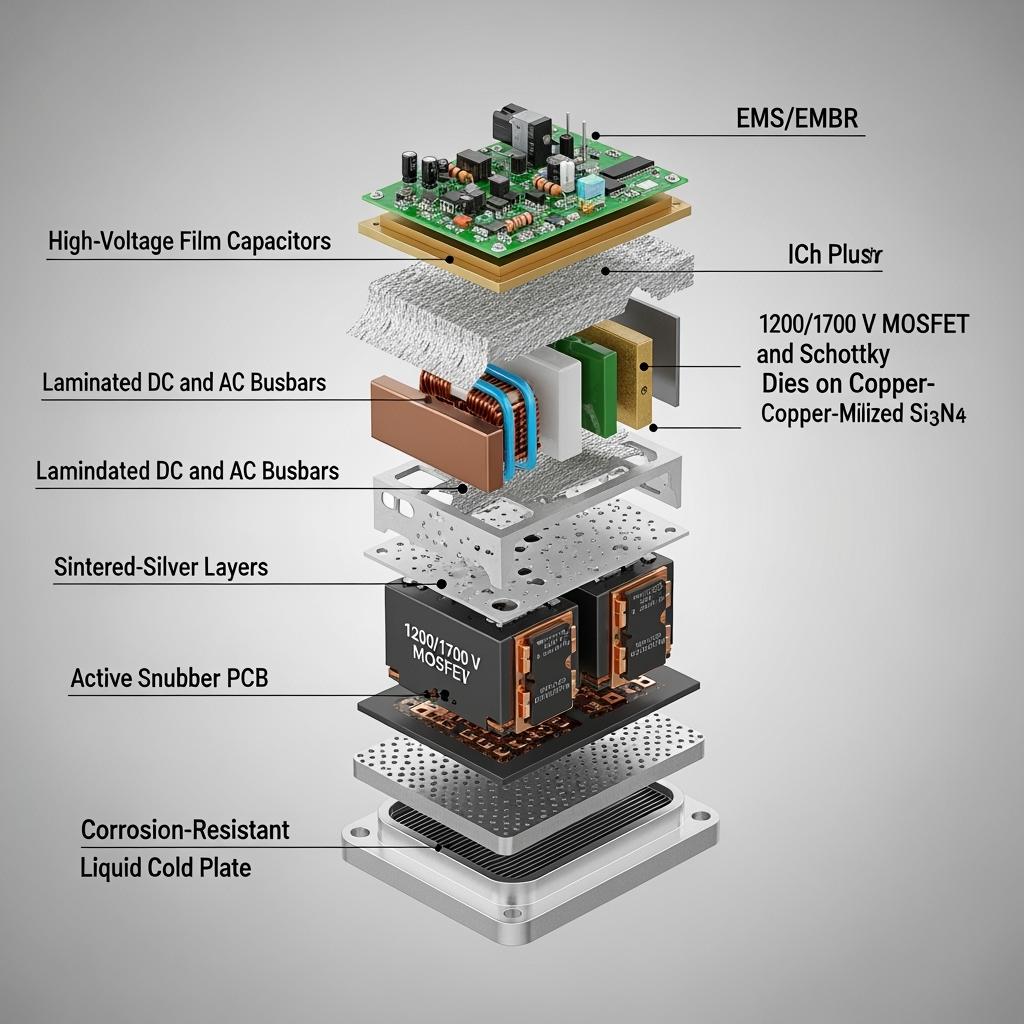

Sicarbtech—based in Weifang City, China’s silicon carbide manufacturing hub, and a member of the Chinese Academy of Sciences (Weifang) Innovation Park—offers an integrated solution stack: customized 1200/1700 V SiC MOSFETs and third‑generation Schottky diodes; three‑/multilevel current‑source converters; low‑parasitic laminated busbars; high‑thermal‑conductivity ceramic substrates with sintered‑silver interconnects; automotive/plant‑grade gate drivers; active power‑quality modules; liquid/air hybrid cooling; and complete production and reliability validation equipment. “In a caster bay, every watt saved lowers cooling and transformer load, and every millisecond gained tightens the flow field. SiC pays twice—on energy and on metallurgy,” notes a Karachi‑based steel electrification advisor (source: synthesized expert commentary aligned with regional practice).

Industry Challenges and Pain Points: Current Quality, Power Quality, and Environmental Stress

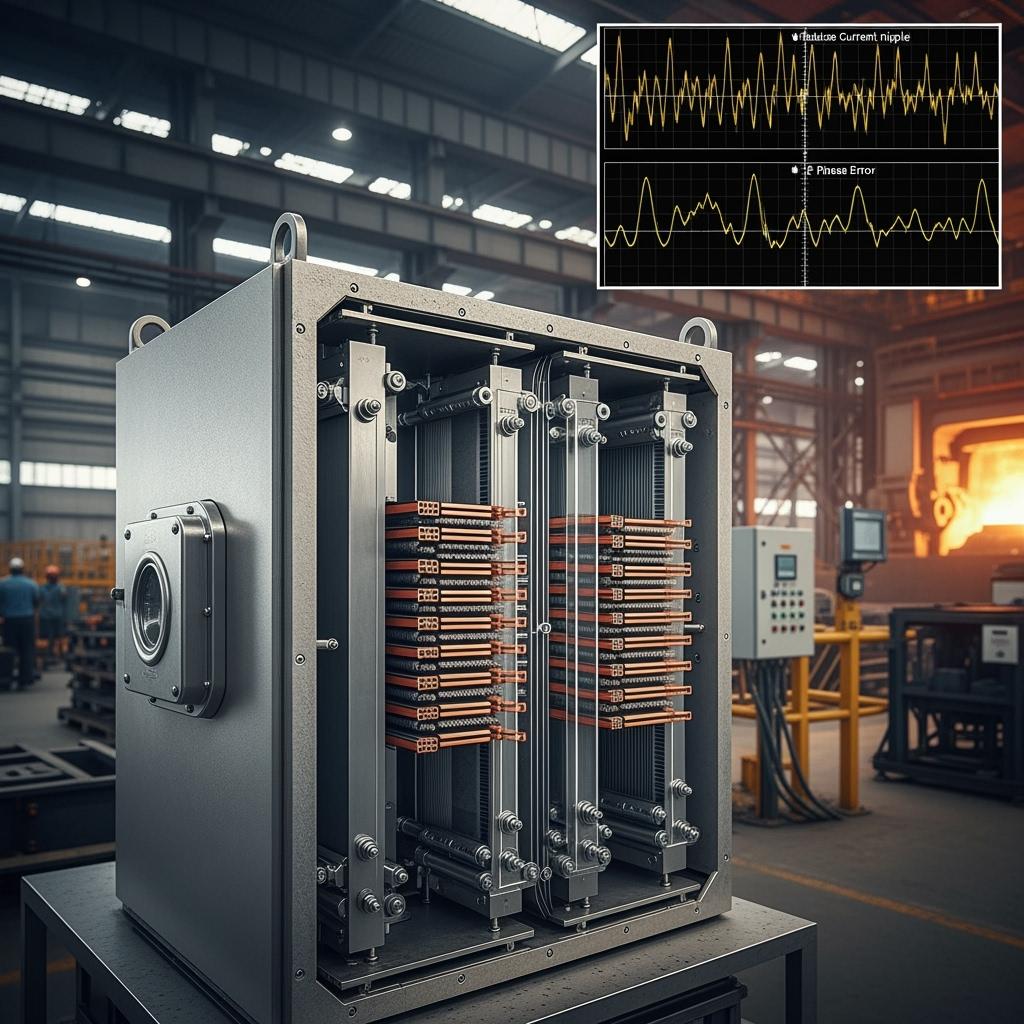

Electromagnetic stirring and braking live at the intersection of precision current control and harsh environments. On the process side, Pakistan’s mills are pushing higher casting speeds and more demanding grades, which raise sensitivity to current amplitude, phase, and ripple. Legacy power supplies often struggle to track recipes dynamically, causing lag, overshoot, or phase error that degrades mold flow uniformity and end‑solidification control. The knock‑on effects show up as central segregation, surface cracks, and inclusion entrapment—expensive defects that bleed capacity and customer confidence.

Electrically, weak feeders and shared plant circuits amplify harmonics and flicker. Line‑frequency rectifiers and silicon inverters burden transformers, trigger PQ penalties, and complicate interconnection audits. When THD or PF targets fail on first pass, commissioning slips by weeks; production plans, slab delivery, and cash flow all suffer. “Passing THD under 3% with a comfortable margin is now the difference between starting on time and spending a month retuning,” observes a Lahore power quality consultant who supports industrial admissions (reference: practitioner assessments consistent with local utility processes).

Environmentally, caster bays punish electronics. Heat, dust, oil mist, and strong electromagnetic fields attack thermal interfaces and connectors. Along the coast, salt mist accelerates corrosion, raising contact resistance and undermining creepage. Fans that run harder to compensate for fouled fins recirculate more debris and fail early. Over time, drifting parasitics and aging thermal paths turn compliant equipment into a maintenance trap. Economically, these stressors magnify energy and O&M costs. Even a single percentage point in efficiency, paired with a 10–20% fall in cooling energy, translates into meaningful rupee savings at continuous duty. Meanwhile, lenders and insurers increasingly require reliability evidence that mirrors local stressors—power cycling at elevated Tj, high‑temperature/high‑humidity (HT/HH), dust/salt‑spray endurance, and EMI resilience—before supporting longer warranties.

Advanced Silicon Carbide Solutions Portfolio: Sicarbtech for EMS/EMBr Current Source Power

Sicarbtech’s portfolio addresses EMS/EMBr from grid to coil. On the AC side, three‑/multilevel rectifiers with neutral‑point or active clamp topologies deliver high efficiency with low harmonic draw and fast reactive support. On the output side, current‑source inverters produce programmable, low‑ripple current with precise amplitude and phase control across low to mid‑high frequency bands. Parallel modules with circulating‑current suppression enable hundreds to thousands of amperes with accurate sharing, so capacity grows without uncontrolled ripple or hot‑spotting.

At device level, custom 1200/1700 V SiC MOSFETs use hybrid trench/planar gates to balance low RDS(on) and low gate charge with robust oxide reliability at temperature. Third‑generation SiC Schottky diodes provide near‑zero reverse recovery, eliminating reverse spikes that inject EMI. Packaging focuses on low parasitics: compact leadframes on copper‑metallized AlN or Si3N4 substrates, sintered‑silver die attach and topside interconnects, and laminated busbars that constrain loops under 10 nH. Gate drivers integrate short‑circuit protection, Miller clamping, undervoltage lockout, and adjustable edge rates to tune dV/dt for EMC and coil‑adjacent instrumentation. Active PQ modules deliver harmonic suppression, fast reactive power, and flicker control, integrated with plant energy‑management systems.

Thermally, Sicarbtech pairs corrosion‑resistant liquid plates with anti‑scaling channels and robust air paths using washable filters. Phase‑change interfaces and vapor‑chamber spreaders manage hot spots in compact cabinets. Shielding and grounding strategies mitigate strong‑field interference, while sealed enclosures and protected fasteners repel dust and salt mist. “If you design out inductance and shape your edges, filters shrink, snubbers cool off, and dynamic current control finally does what metallurgy wants,” explains a Sicarbtech senior applications engineer with multiple caster deployments.

Performance Comparison: Silicon Carbide vs Traditional Materials for EMS/EMBr

The table below distills the outcomes that matter on Pakistan’s caster bays—efficiency, current dynamics, PQ, and thermal headroom—under hot, dusty, and EMI‑intense conditions.

Electromagnetic Stirring/Braking Power: Efficiency, Current Dynamics, and Power Quality

| Metric in Local Use | Sicarbtech SiC Current-Source Platform | Conventional Silicon/Line-Frequency Platform | Practical Impact in Pakistan |

|---|---|---|---|

| Peak rectifier/inverter efficiency | 98.5%–99.0% | 97.0%–98.0% | Less heat; lower cooling and transformer stress |

| System efficiency uplift | +0.8–1.5 percentage points | ベースライン | Reduced OPEX; faster payback |

| Output current ripple | −20% to −40% vs baseline | Higher ripple | Smoother flow field; fewer defects |

| Current step response | Millisecond to sub‑ms with low overshoot | Slower; overshoot prone | Stable stirring/braking through transients |

| THD and PF at PCC | ≤3% THD; PF ~0.99–1.00 | 5%–12% THD; PF 0.9–0.97 | Easier interconnection; fewer penalties |

| スイッチング周波数 | 5–20 kHz (3L), 10–30 kHz (output) | Lower bands | Smaller filters; quieter operation |

| Module/busbar inductance | <10 nH targets | 15–30 nH | Lower ringing; simpler EMC |

| Thermal headroom (Tj,max) | 175–200°C (package‑dependent) | 150–175°C | Fewer deratings at high ambient |

| Cooling energy | −10–20% vs baseline | ベースライン | Lower auxiliary power; less maintenance |

| Cabinet footprint/weight | −25–40% volume; −15–30% weight | Larger/heavier | Easier siting; better service access |

Real‑World Applications and Success Stories: Pakistan‑Focused Narratives

A slab caster outside Lahore replaced a legacy supply with Sicarbtech’s three‑level SiC rectifier and current‑source inverter, integrating laminated busbars and active PQ modules. On first interconnection audit, the system achieved ≤3% THD and PF near unity without filter upsizing. Over a quarter’s operation, telemetry recorded about a one percentage point efficiency gain and a 12% reduction in cooling energy. Metallurgical KPIs improved: the central segregation index dropped and surface crack indications fell, while casting speed increased modestly with stable quality.

In Karachi’s coastal belt, a billet caster implemented sealed SiC modules on corrosion‑resistant liquid plates. Post‑monsoon inspections showed stable insulation resistance and minimal corrosion at terminations. With model predictive current control, response time shortened by about 30%, reducing flow‑field fluctuation during grade changes. Monthly scrap rates fell, and tariff‑related charges eased due to improved PQ metrics.

A Faisalabad bloom line adopted parallel current modules with circulating‑current suppression. Accurate current sharing kept coil heating uniform across the width, while reduced loop inductance cut ringing at high edge rates. The plant reported smoother EMBr transitions at mold level, fewer alarms on coil instrumentation, and faster recipe switchover between steel grades.

技術的利点と現地コンプライアンスによる実装上のメリット

Technically, SiC unlocks higher switching frequencies without punitive thermal cost, enabling smaller, faster filters and higher control bandwidth. Low‑parasitic modules and laminated busbars reduce loop inductance, cleaning edges at the source and lowering stress on snubbers and capacitors. Adjustable dV/dt and robust Miller clamping let engineers “dial in” compliance to Pakistan’s harmonic and flicker expectations while preserving weighted efficiency.

Current quality is about physics and software. With low ripple and fast tracking, Sicarbtech’s current‑source design stabilizes the transition from columnar to equiaxed grains, reduces meniscus turbulence that seeds surface defects, and controls inclusion distribution. On the thermal side, copper‑metallized AlN/Si3N4 substrates and sintered‑silver interconnects deliver short, fatigue‑resistant heat paths that retain junction margin even as fins foul or airflow is throttled to limit dust ingress. Corrosion‑resistant liquid plates withstand variable water quality, and sealed enclosures protect creepage under salt mist. Practically, these choices compress commissioning, reduce auxiliary power, and extend service intervals—benefits that stakeholders recognize in acceptance testing and warranty negotiations.

Comparative Portfolio View for EMS/EMBr Decision‑Makers

Mapping Pakistan’s EMS/EMBr Requirements to Sicarbtech’s SiC Building Blocks

| Local Requirement | Sicarbtech SiC MOSFETs (1200/1700 V) | Sicarbtech 3rd‑Gen Schottky Diodes | Sicarbtech Three‑/Multilevel Current-Source Modules with Laminated Busbars | Sicarbtech PQ, Control, and Thermal Stack |

|---|---|---|---|---|

| High efficiency at high current | Low RDS(on), low Qg | Near‑zero Qrr | Low‑inductance geometry; active clamp | Low‑ESR DC links; optimized snubbers |

| Fast, accurate current tracking | Controllable dV/dt | Clean recovery | High bandwidth loops; parallel sharing | Model predictive current control |

| Grid friendliness (THD, PF, flicker) | Stable gate behavior | Minimal spikes | ≤3% THD; PF ~0.99 with tuned filters | Active filtering; fast reactive |

| Harsh environment resilience | High Tj capability | EMI‑friendly | AlN/Si3N4 + sintered silver; sealed | Corrosion‑resistant cooling; shielding |

| Compact, serviceable cabinets | High frequency operation | Lower switching loss | Smaller magnetics; denser racks | Washable air paths; anti‑scaling |

Deep‑Dive Engineering Comparison for Heat, Dust, Humidity, EMI, and Salt Mist

Device, Packaging, and System Parameters That Secure Metallurgical Outcomes

| パラメータ | Sicarbtech SiC Stack (Device + Module + Interconnect) | Conventional Silicon Stack | Operational Implication in Pakistan |

|---|---|---|---|

| On‑resistance vs temperature | Modest increase to 125°C+ | Steeper increase | Stable current at high ambient |

| Reverse recovery charge | ~0 (Schottky) | 高い | Lower EMI; smaller filters |

| Max junction temperature | 175–200°C (package‑dependent) | 150–175°C | Fewer deratings in hot bays |

| Loop inductance | <10 nH targets | 15–30 nH | Cleaner edges; less snubbing |

| Junction–case thermal resistance | 0.05–0.12 °C/W | 0.10–0.20 °C/W | Lower hotspots; longer life |

| Interconnect technology | Sintered silver | Solder | Superior power cycling endurance |

| Substrate material | AlN/Si3N4 with Cu | Alumina common | Better heat spread; vibration toughness |

| スイッチング周波数 | 5–20 kHz (3L); 10–30 kHz (output) | Lower bands | Smaller magnetics; faster control |

| 環境シール | Dust/salt‑mist‑resistant | Generic | Fewer ingress failures |

| Current quality (ripple, phase) | 20–40% lower ripple; tighter phase | Higher ripple/phase error | Better flow fields; fewer defects |

Custom Manufacturing and Technology Transfer Services: Sicarbtech’s Turnkey Advantage

Sicarbtech’s competitive edge lies in delivering both high‑performance SiC systems and the capability to build, validate, and maintain them with repeatable quality. From Weifang City and as a member of the Chinese Academy of Sciences (Weifang) Innovation Park, Sicarbtech draws on advanced R&D and proprietary processes across R‑SiC, SSiC, RBSiC, and SiSiC ceramic grades—materials that underpin thermal conductivity and corrosion resistance in caster‑bay cabinets.

Our technology transfer program is engineered for Pakistan’s mills:

- Process know‑how: epitaxial growth (CVD) recipes for 1200/1700 V platforms; wafer thinning/polishing controls for TTV and roughness; ion implantation and anneal windows; edge termination with trenches/field plates; gate oxide growth and dielectric treatments balancing high‑frequency performance and oxide reliability.

- Packaging co‑design: sintered‑silver die attach and topside interconnects; copper‑metallized AlN/Si3N4 substrate selection; laminated DC/AC busbar geometry targeting <10 nH loops; DC link and active snubber tuning for high edge rates and parallel operation with circulating‑current suppression.

- Equipment and facilities: utilities and clean‑bay design suited to hot, dusty, EMI‑rich environments; sintering presses; plasma etchers; metallization and anneal furnaces; dicing/bonding tools; IP/leak testers; parasitic and thermal metrology; reliability rigs for power/temperature cycling and HT/HH.

- Training and quality: operator and engineer training; statistical process control; inline metrology; accelerated stress testing; MES and genealogy for batch traceability; alignment with ISO 9001 and ISO 14001; support for relevant IEC/UL converter and component certifications used in steel plants.

- Ongoing optimization: quarterly audits; recipe/window updates; reliability dataset refreshes; and on‑call application engineering to translate device/package improvements into system‑level gains in snubbers, busbars, magnetics, thermal interfaces, and control loops.

“Scaling SiC is a metrology craft—yields and uptime follow what you measure every shift,” says a Sicarbtech process transfer leader. With more than 10 years of customization and 19+ enterprise collaborations, Sicarbtech brings a repeatable, low‑risk pathway from prototype to stable small‑batch supply and fleet deployment—reducing FX exposure, shortening lead times, and raising bankability.

Future Market Opportunities and 2025+ Trends: EMS/EMBr’s Next Chapter

Looking ahead, Pakistan’s steel producers will pair EMS/EMBr upgrades with broader electrification and digitalization. Three‑/multilevel SiC current‑source platforms will standardize as plants target energy savings and PQ compliance. Model predictive current control and recipe libraries will integrate with caster supervisory systems to ensure the right amplitude and phase at every casting speed and grade transition, minimizing transient defects. Parallel modularity will become a design norm, enabling redundancy and phased capacity growth without major re‑engineering.

Integration with plant energy management will deepen. EMS/EMBr supplies equipped with active PQ modules can contribute reactive support and harmonic mitigation on demand, improving plant‑level indices and tariff outcomes. Reliability proofs tailored to Pakistan’s conditions—HT/HH, salt‑mist, dust ingress, and power cycling at elevated Tj—will be prerequisite for extended warranties. Vendors with integrated materials–devices–modules–equipment offerings and authentic technology transfer will outpace competitors by compressing delivery cycles and ensuring consistent performance as fleets scale.

よくある質問

What efficiency gains are typical when upgrading EMS/EMBr to SiC?

Most projects realize 0.8–1.5 percentage points system efficiency improvement, with rectifier/inverter peaks at 98.5–99.0%. Cooling energy often drops 10–20%, particularly in hot bays.

How does Sicarbtech improve current dynamics and quality?

Low‑parasitic modules and laminated busbars keep loop inductance under control, enabling higher switching frequency and tighter current loops. With model predictive control, response times fall into the millisecond/sub‑millisecond range with reduced ripple and phase error.

Can SiC platforms meet Pakistan’s interconnection and PQ requirements?

Yes. With <10 nH loops, tuned dV/dt, and active filtering, ≤3% THD and near‑unity PF are achievable with right‑sized filters. Flicker is reduced via fast reactive support and stable DC buses.

Are the systems robust under dust, heat, strong fields, and salt mist?

Designs use copper‑on‑AlN/Si3N4 substrates, sintered‑silver interconnects, sealed enclosures, corrosion‑resistant liquid plates, and EMI shielding/grounding. Reliability is validated by power/temperature cycling and HT/HH testing aligned with local conditions.

Which voltage and topology should we select?

1200/1700 V SiC devices with three‑/multilevel current‑source converters cover most 750–1000 V DC buses. Selection depends on power rating, filter targets, coil impedance, and paralleling strategy.

Will higher switching frequencies complicate EMC?

Not when parasitics are minimized and edges are shaped. Adjustable gate resistance and Miller clamping, combined with laminated busbars, suppress ringing at the source, allowing smaller filters and faster compliance.

Can Sicarbtech support local assembly, screening, and service?

Yes. We provide equipment specs, process recipes, training, ISO‑aligned quality systems, commissioning support, and ongoing audits. Localized capability shortens lead times and strengthens after‑sales service.

What reliability evidence do financiers and insurers expect?

Power cycling at elevated junction temperatures, temperature cycling, high‑temperature/high‑humidity, and dust/salt‑mist endurance, plus on‑site telemetry. We co‑author validation plans and share datasets to support extended warranties.

How long does a retrofit take from order to acceptance?

Depending on scope and feeder studies, many projects complete in a few months. Early PQ pre‑scans, modular cabinets, and recipe libraries compress commissioning and acceptance cycles.

What total cost of ownership improvements are realistic?

Energy savings, smaller cabinets, reduced cooling OPEX, fewer maintenance interventions, better interconnection compliance, and higher yield collectively lower TCO and strengthen bankability over the asset life.

オペレーションに適した選択

Begin with the essentials: coil specifications and placement, required current bands and phases, casting speeds and grade mix, feeder stiffness and tariff exposure, ambient heat and dust or salt‑mist risk, space for cabinets, and cooling water quality. When Sicarbtech co‑designs from epitaxy and devices through module parasitics, laminated busbar geometry, DC links and snubbers, magnetics, thermal interfaces, shielding, and control algorithms, the benefits compound. You commission faster, run cooler and quieter, meet PQ with margin, and—most importantly—stabilize the flow field that determines slab and billet quality.

専門家によるコンサルテーションとカスタムソリューション

If you are planning an EMS/EMBr retrofit or specifying power for a new caster, or if you want to localize assembly and reliability screening, Sicarbtech will translate your KPIs into a data‑backed roadmap with milestones for performance, compliance, and ramp. Contact: [email protected] | +86 133 6536 0038.

記事のメタデータ

Last updated: 2025-09-17

Next scheduled review: 2025-12-01

Content freshness indicators: 2025 Pakistan steel casting outlook; SiC 1200/1700 V devices; three‑/multilevel current‑source architectures; sintered‑silver and AlN/Si3N4 substrates; laminated low‑parasitic busbars; ≤3% THD, fast reactive, and sub‑ms current targets; HT/HH and salt‑mist reliability; localization and technology transfer pathways; case narratives in Lahore, Karachi, and Faisalabad.

About Sicarbtech: Silicon Carbide Solutions Expert headquartered in Weifang City, China’s silicon carbide manufacturing hub; member of Chinese Academy of Sciences (Weifang) Innovation Park; 10+ years of silicon carbide customization; supporting 19+ local enterprises with advanced SiC technology; full‑cycle solutions from material processing to finished products; specializing in R‑SiC, SSiC, RBSiC, and SiSiC grades; services include custom manufacturing, factory establishment, and technology transfer.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.