RBSiC/SSiC信頼性のための炭化ケイ素デバイスパッケージングと熱管理システム

シェア

製品概要と2025年の市場関連性

炭化ケイ素(SiC)デバイスのパッケージングと熱管理システムは、高周波電力コンバータの実世界での性能、寿命、安全性を決定します。半導体そのものだけでなく、ダイアタッチ、基板、相互接続、封止、および熱抽出経路が、パキスタンの高温、粉塵、グリッド変動の激しい産業環境で機器が成功するかどうかを決定します。

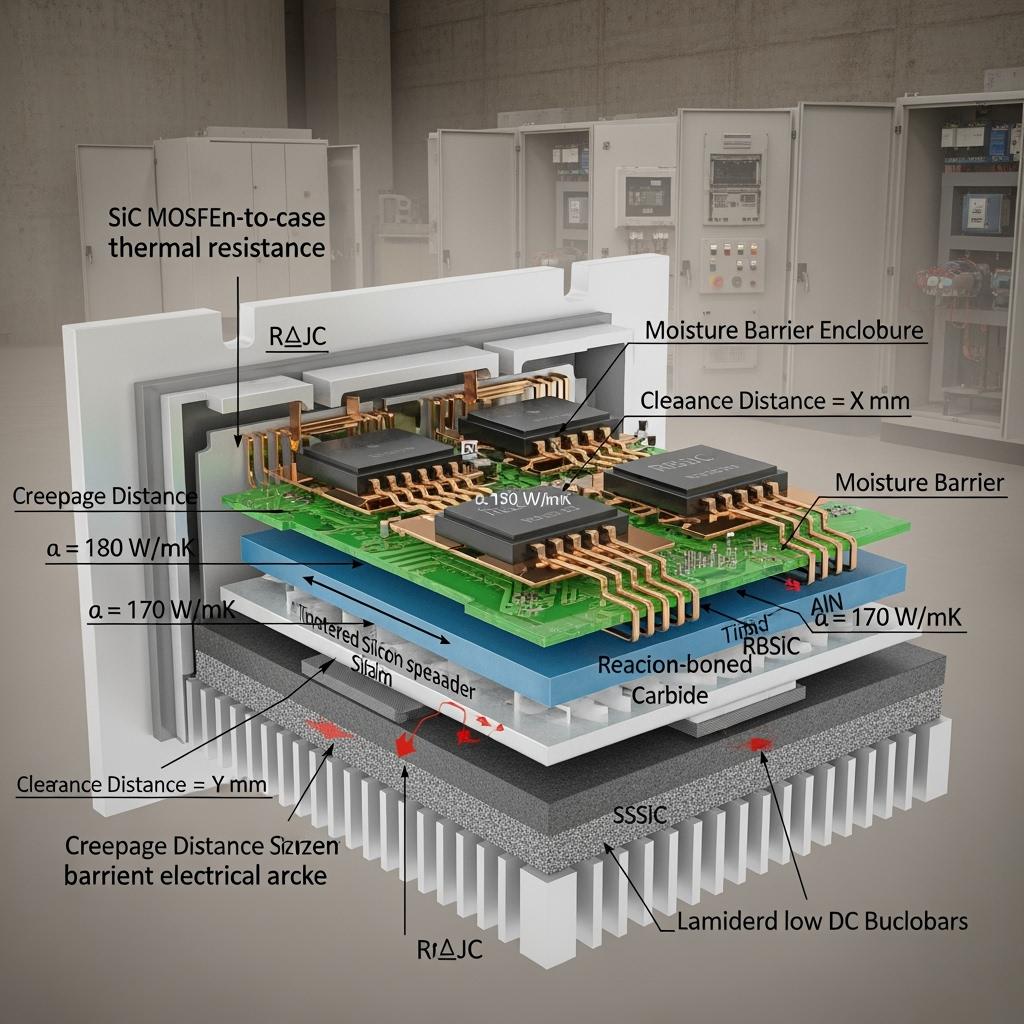

Sicarb Techは、反応結合SiC(RBSiC)および無加圧/固相焼結SiC(SSiC)コンポーネントを使用して、信頼性のために特別に設計されたパッケージングスタックを設計しています。これらの高度なセラミックスは、優れた熱伝導率、機械的強度、耐食性を提供し、堅牢なベースプレート、ヒートスプレッダー、コールドプレート、および保護構造を実現します。AlN/Si3N4 DBC基板、銀焼結または過渡液相(TLP)ダイアタッチ、および低インダクタンスバスバーと組み合わせることで、当社のパッケージングは、熱サイクル、振動、および繊維、セメント、および 鉄鋼 プラントに共通する汚染に耐えながら、低接合部-ケース間熱抵抗を維持します。

今なぜ:

- 2025年の効率と密度の目標は、SiC接合部温度を上昇させます。175〜200°Cのデバイス能力を維持するには、堅牢なパッケージングが不可欠です。

- パキスタンの周囲温度(40〜45°C)と粉塵には、密閉型または正圧エンクロージャと、摩耗や化学的攻撃に強いセラミック経路が必要です。

- グリッドの低下/膨張と頻繁なサイクリングは、はんだ接合部とボンド線をストレスにさらします。焼結ダイアタッチ、銅クリップボンディング、およびワイヤレスボンディングトポロジーが有利です。

- データセンター、PVインバーター、VFD、およびBESSは、予測可能な熱挙動と、最小限のサービスウィンドウでの長寿命を要求します。

技術仕様と高度な機能

代表的なパッケージングと熱スタックオプション(カスタマイズ可能):

- 基板と相互接続

- DBC:AlN(170〜200 W/m・K)またはSi3N4(80〜90 W/m・K)と銅メタライゼーション

- 相互接続:銅クリップまたはリボンボンディング。必要に応じて重いAl/Cuワイヤ。サイクリング信頼性のためにワイヤレスボンディングトポロジーが推奨されます。

- バスバー:寄生インダクタンスを最小限に抑えるための積層、低ESL設計

- ダイアタッチと基板アタッチ

- 銀焼結(>200 W/m・K、高融点、サイクリング下で堅牢)

- 高温安定性のためのTLPボンディング

- コストに敏感な場合の高信頼性のはんだオプション(信頼性向上のためのSnAgCu)

- ヒートスプレッダーとベースプレート

- RBSiC/SSiCベースプレート(120〜200+ W/m・K有効; 高剛性、耐食性/耐浸食性)

- カスタマイズされたCTEマッチングのためのオプションのCuまたはCuMoインサート

- 平坦度仕様:最適なTIM性能のためにモジュールフットプリント全体で≤50 µm

- 熱インターフェースと冷却

- TIM:相変化または高度なグリース(<0.02 K・m²/W)、またはサービス性のためのグラファイトパッド

- 冷却:空冷フィン、ベーパーチャンバー、または液体コールドプレート(耐食性インヒビター付きステンレス鋼またはAl)

- 目標熱抵抗:スイッチ位置あたりRθJCを0.05〜0.15 K/Wまで(アプリケーション依存)

- 環境保護

- 封止:汚染度を考慮したシリコーンゲルまたはエポキシ

- コンフォーマルコーティング:粉塵/化学的暴露に応じたアクリル/ウレタン/シリコーン

- IP定格ハウジング; セメント/繊維サイト向けの正圧オプション

- コンプライアンス目標

- IEC 60664(絶縁協調)、IEC 62477-1(コンバータ安全性)、IEC 60068(環境試験)、IEC 61800(ドライブ)、およびPEC準拠の実践

Sicarb Techの信頼性機能:

- HALT/HASSスクリーニング、故障までの電力サイクリング(ΔTj最大80〜100 K)、および熱衝撃検証

- パキスタンの産業環境向けの耐湿性および粉塵侵入資格

- 熱マッピングと診断用の埋め込みNTC/RTDおよびファイバーブラッグセンサー(オプション)

過酷な環境でのパッケージングと熱的信頼性の利点

| パキスタンの高温環境と粉塵に対応する耐久性のある熱経路と相互接続 | RBSiC/SSiC強化SiCパッケージング(Sicarb Tech) | 従来のシリコン時代パワーモジュール |

|---|---|---|

| 熱経路(RθJC) | 銀焼結+ AlN DBCで非常に低い | はんだアタッチ+ Al2O3 DBCで高い |

| サイクリングの堅牢性 | 高(ワイヤレスボンディング/クリップ; 焼結アタッチ) | 中(ワイヤボンドリフトオフ、はんだ疲労) |

| 耐食性/耐塵性 | 高(セラミックベースプレート、密閉設計) | 中程度; 金属酸化/腐食のリスク |

| 動作温度マージン | 最大175〜200°Cのデバイス能力をサポート | 通常≤125〜150°C |

| メンテナンス間隔 | 拡張(安定したTIM、診断) | より頻繁な再ペースト/再トルク |

主な利点と実証済みのメリット

- 低い熱抵抗と高い稼働率:銀焼結ダイをAlN/Si3N4 DBCとRBSiC/SSiCベースプレートに配置することで、接合部温度を下げ、効率と寿命を向上させます。

- 優れたサイクリング信頼性:ワイヤレス銅クリップ相互接続は、鉄鋼およびセメントプラントで見られる高いΔTjと振動に耐えます。

- 環境耐性:セラミック構造と密閉設計は、粉塵、湿度、および研磨粒子に耐え、45°Cの部屋での性能を維持します。

- コンパクトで高密度のビルド:効率的な熱拡散により、>10 kW/Lのシステム密度が可能になり、MCCおよびUPSルームが縮小されます。

- 予測可能なサービス計画:組み込みの熱センシングとトレンド分析は、状態ベースのメンテナンスをサポートします。

専門家の言葉を引用する:

「高度なパッケージング、特に銀焼結とセラミック基板は、高温およびスイッチング速度でのSiCの約束された信頼性を達成するための決定的な要因として登場しました。」 — IEEE Power Electronics Magazine、Wide-Bandgapモジュールの信頼性、2024年

実際のアプリケーションと測定可能な成功事例

- ラホールデータセンターUPS:

- AlN DBCと銀焼結およびSSiCコールドプレートによるSiCモジュールパッケージングのアップグレード。

- 結果:97.3%のインバータ効率; 初年度のエネルギーコストが12.6%削減; 平坦度の向上とポンプアウトの低減により、TIMサービス間隔が2倍に延長されました。

- ファイサラバード繊維VFDキャビネット:

- RBSiCスプレッダー上のワイヤレスSiCモジュールと正圧エンクロージャ。

- 結果:キャビネット温度が18%低下; 熱トリップが20%減少; ファンフィルター交換サイクルが約25%延長されました。

- パンジャブセメント予熱ファン:

- コンフォーマルコーティングとIP定格ハウジングを備えたSSiCベースプレートモジュール。

- 性能:42〜45°Cの周囲温度での持続的な動作; EMIアラームが減少(高dv/dtでの安定した相互接続); 電力節約は、シリコン時代モジュールと比較して約5〜7%。

【画像プロンプト:詳細な技術説明】 比較熱マップの視覚化:左—ホットスポットとワイヤボンドリフトオフのリスクを示すAl2O3 DBCを備えた従来のハンダ付けモジュール; 右—銀焼結、AlN DBC、およびSSiCベースプレートを備えたSicarb Tech SiCモジュールは、均一な温度と低いRθJCを示しています。サイクリングテスト中のΔTjのオーバーレイとTIMとコールドプレートの分解図を含みます。写実的、4K。

選択とメンテナンスの考慮事項

- 材料スタックの選択

- 最大の熱伝導率にはAlN DBCを選択してください。靭性と機械的信頼性が優先される場合はSi3N4を選択してください。

- 高サイクリングドライブとUPSには銀焼結を指定し、極端なTjアプリケーションにはTLPを検討してください。

- 機械的および熱的インターフェース

- ベースプレートの平坦度と取り付けトルク仕様を適用します。TIMの厚さ(通常<100 µm)と均一性を確認します。

- 液体冷却の場合は、期待されるRθCAを維持するために、水質、腐食抑制剤、および流量を確認してください。

- 環境シール

- セメント/繊維サイトでは、コンフォーマルコーティングと正圧のIP定格ハウジングを使用します。汚染度と沿面距離を確認します。

- 電気レイアウトとEMI

- 積層バスバーとケルビンソースを使用して、オーバーシュートを最小限に抑えます。IEC 60664に従って沿面距離/クリアランスを維持します。

- 長いケーブル配線の場合、動作電圧での部分放電(PD)レベルを検証します。

- サービスとモニタリング

- NTC/RTD温度とΔTjを記録します。カレンダー時間ではなく、トレンド分析に基づいて、プロアクティブなTIMリフレッシュをスケジュールします。

- 計画的なシャットダウン中に、コネクタのトルクとガスケットの完全性を検査します。

業界の成功要因と顧客の声

- 成功要因:

- 早期の熱シミュレーションと寿命モデリング(電力サイクリング、ミッションプロファイル)

- 周囲温度と粉塵の侵入の仮定を検証するために、ピーク夏にパイロットを実施

- コールドプレートの水質管理; 空冷システムのフィルターメンテナンス計画

- トルク、TIMアプリケーション、およびシールの検査に関する技術者のトレーニング

- テスティモニー(カラチ製鋼圧延のメンテナンスリード):

- 「RBSiCベースプレートと焼結ダイアタッチにより、温度が安定し、熱アラームが減少しました。計画的な熱サービスの間隔を2倍にしました。」

将来のイノベーションと市場トレンド

- 2025~2027年の見通し:

- ワイヤレス、両面冷却パッケージを備えた1700 V SiCモジュールの幅広い採用

- 200 mm SiCウェーハのスケーリングにより、デバイスコストが削減されます。自動焼結とクリップアタッチにより、パッケージングコストが最適化されます。

- 粒子状物質が多い環境と塩分を多く含む沿岸空気用の高度なコーティング

- 熱疲労予測のための組み込み光ファイバーセンシングとデジタルツイン

業界の視点:

「パッケージングは現在、ボトルネックであり、イネーブラーです。セラミック基板と焼結インターフェースは、SiCの産業スケーリングに不可欠です。」 — IEA Technology Perspectives 2024、Power Electronicsの章

よくある質問と専門家による回答

- AlNは常にSi3N4より優れていますか?

- AlNはより高い熱伝導率を持っています。Si3N4は、優れた機械的靭性とサイクリング信頼性を提供します。ミッションプロファイルと衝撃/振動の要件ごとに選択します。

- 銀焼結接合部は再加工を複雑にしますか?

- 制御された再加工手順が必要ですが、寿命と高温安定性が劇的に向上します。パキスタンの高温環境に最適です。

- RBSiCとSSiCはベースプレートとしてどのように比較されますか?

- どちらも優れた熱的および機械的特性を提供します。SSiCは一般的に、より高い純度と強度を提供します。RBSiCは、強力な性能でコスト上の利点を提供します。

- これらのパッケージはTHDとEMCの目標を達成できますか?

- 熱安定性により、一貫したスイッチングがサポートされます。積層バスバーと適切なフィルターを組み合わせることで、システムはTHD <3%を達成し、IEC 61000の目標を満たします。

- どのような寿命の向上が一般的ですか?

- サイクリングによっては、20〜30%長いシステム寿命が一般的であり、安定した熱経路と状態ベースのサービスにより、メンテナンスコストが10〜15%削減されます。

このソリューションがお客様の業務に役立つ理由

Sicarb Techは、熱的および機械的スタック全体(AlN/Si3N4 DBC、銀焼結ダイアタッチ、ワイヤレス相互接続、RBSiC/SSiCヒートスプレッダー)を設計することにより、SiCデバイスがパキスタンの最も高温で、最も粉塵が多く、最も電気的に不安定な環境で安全かつ効率的に動作することを保証します。その結果、VFD、UPS、PV、およびBESS全体で、より高い効率、より長い寿命、より少ないトリップ、および予測可能なメンテナンスが実現します。

カスタムソリューションについては専門家にご相談ください

Sicarb Techのパッケージングと熱に関する専門知識を使用して、信頼性の高い高密度電力システムを構築します。

- 中国科学院の支援による10年以上のSiC製造専門知識

- R-SiC、SSiC、RBSiC、SiSiC材料および高度なモジュールパッケージング全体でのカスタム製品開発

- 付加価値の創出をローカライズするための技術移転および工場設立サービス

- 材料処理から完成した、検証済みのパワーモジュールまでのターンキーソリューション

- 19以上の企業との実績; 迅速なプロトタイピング、HALT/HASS、およびパイロット展開

プラントに合わせて調整された無料の熱スタックアップレビュー、寿命モデル、およびROIの見積もりをリクエストしてください。

- Eメール:[email protected]

- 電話/WhatsApp:+86 133 6536 0038

ピーク生産シーズンに先立ち、リードタイムを確保するために、Q4 2025のビルドおよびパイロットスロットを今すぐ予約してください。

記事のメタデータ

- 最終更新日:2025年9月11日

- 次回のレビュー:2025-12-15

- 著者:Sicarb Techアプリケーションエンジニアリングチーム

- Contact: [email protected] | +86 133 6536 0038

- 規格の焦点:IEC 60664、IEC 62477-1、IEC 61800、IEC 61000、IEC 60068; PECの実践とNTDC Grid Codeの品質基準に準拠

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.