自動供給用、耐粉塵低粉塵取り扱いを備えた高吸収性コーティング炭化ケイ素顆粒

シェア

パキスタンの 鉄鋼 mills, where energy is dear and shop-floor stability is the new competitive edge, the handling quality of alloy additions matters as much as their chemistry. High-Absorption Coated Silicon Carbide Granules with Anti-Powdering Low-Dust Handling for Automated Feeding were engineered by Sicarbtech for precisely this environment. By pairing high-activity SiC with advanced hydrophobic coatings and densified granulation, these granules deliver fast, predictable dissolution with minimal dust, enabling reliable automated feeding—from EAF bath conditioning and converter tapping to ladle refining. The operational impact is immediate: steadier silicon absorption, cleaner inclusion behavior, lower aluminum wire dependency, and safer, compliant addition points aligned with Pakistan’s PEQS-driven dust expectations.

High-Absorption Coated Silicon Carbide Granules with Anti-Powdering Low-Dust Handling for Automated Feeding product overview and 2025 market relevance

Pakistan’s 2025 melt shop reality blends higher scrap ratios with tighter cleanliness targets and rising pressure to automate. Manual charging introduces variability; open handling elevates dust; and long logistics from Karachi to upcountry mills challenge moisture control. High-Absorption Coated Silicon Carbide Granules with Anti-Powdering Low-Dust Handling for Automated Feeding address all three. The SiC is produced through carbothermal reduction and refined via high-purity classification to keep sulfur and phosphorus low. A thin, oxidation-resistant, hydrophobic coating then protects reactivity and prevents caking, while densified granulation preserves flowability for enclosed feeders and pneumatic lines. Furthermore, trace-element tailoring—such as calcium or barium domains—lets the same granule act as an inclusion modifier, easing alumina-related nozzle issues. As Dr. Nadia Rehman, a continuous casting specialist, often reminds clients, “Predictability at the addition point is what buys you peace in the tundish” (Steel Process Insights Pakistan, 2024). These granules were built for that predictability, while ensuring safer, lower-dust operations that EHS teams endorse.

High-Absorption Coated Silicon Carbide Granules with Anti-Powdering Low-Dust Handling for Automated Feeding technical specifications and advanced features

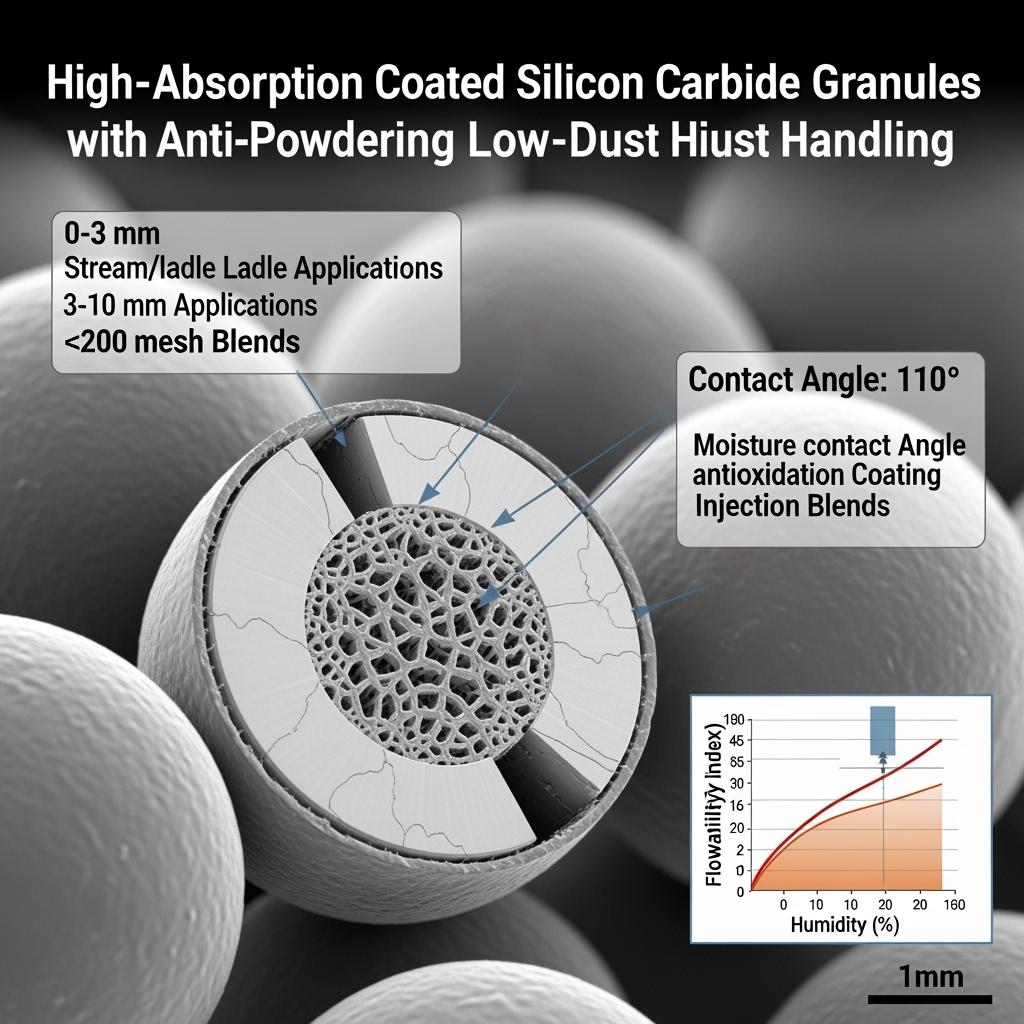

The performance of High-Absorption Coated Silicon Carbide Granules with Anti-Powdering Low-Dust Handling for Automated Feeding comes from the interplay of composition control, morphology, and surface engineering. Typical SiC content ranges from eighty-nine to ninety-seven percent, while free carbon is tuned between one and eight percent to reinforce the dual deoxidation path and stabilize heat balance. Free silicon is deliberately kept low—often 0.5 to 1.5 percent—to minimize secondary oxidation. Harmful impurities stay tightly managed, with sulfur and phosphorus each at or below 0.02 percent. Particle size is matched to the addition point: 0–3 mm for fast dissolution at the teeming stream or early ladle stages; 3–10 mm where residence time allows; and <200 mesh for pneumatic injection blends. The hydrophobic coating reduces water uptake during monsoon logistics and mitigates dust generation, while densified granulation resists powdering in handling systems, preserving flow and dosing accuracy in automated feeders.

Steelmaking outcomes comparison for High-Absorption Coated Silicon Carbide Granules with Anti-Powdering Low-Dust Handling for Automated Feeding

| Tapping, refining, and casting KPIs | 自動供給用、耐粉塵低粉塵取り扱いを備えた高吸収性コーティング炭化ケイ素顆粒 | High-purity SiC without coating | FeSi + aluminum wire reference |

|---|---|---|---|

| Silicon absorption improvement vs baseline | +プラス3-8%ポイント | +2–6 percentage points | Baseline; variable |

| Total oxygen reduction after refining (ppm) | -5 to -15 | -4 to -12 | 可変;アルミナスパイク |

| Nozzle clogging incidents per 100 heats | -20-40% | -15-30% | 参考 |

| Dust at addition points | Low; enclosed feeding friendly | Moderate; prone to powdering | Wire handling and open-charge dust |

| Tapping temperature drop (°C) | -2 to -6 | -2 to -5 | 0 to -2 |

| Heat time change | -0.5-2% | -0.5-1.5% | 参考 |

Material and handling attributes of High-Absorption Coated Silicon Carbide Granules with Anti-Powdering Low-Dust Handling for Automated Feeding

| 属性 | 自動供給用、耐粉塵低粉塵取り扱いを備えた高吸収性コーティング炭化ケイ素顆粒 | パキスタンにおける事業意義 |

|---|---|---|

| SiC含有量 | 89–97% | Strong silicon source with carbon synergy |

| フリー・カーボン | 1-8% | Dual deoxidation and thermal support |

| フリーシリコン | 0.5–1.5% | Limits secondary oxidation |

| S、P(各) | ≤0.02% | Clean steel for export requirements |

| Particle size options | 0–3 mm; 3–10 mm; <200 mesh | Stream/ladle/injection flexibility |

| コーティング | Hydrophobic, anti-oxidation, anti-powdering | Moisture resistance, low dust, stable flow |

| 貯蔵安定性 | ≥6ヶ月以上 | Karachi-to-upcountry inventories |

| Flowability index | High in humid conditions | Accurate automated metering |

High-Absorption Coated Silicon Carbide Granules with Anti-Powdering Low-Dust Handling for Automated Feeding performance comparison with alternatives

| Cost, energy, and EHS metrics | 自動供給用、耐粉塵低粉塵取り扱いを備えた高吸収性コーティング炭化ケイ素顆粒 | Separate carburizer + silicon source | High-aluminum deoxidation |

|---|---|---|---|

| 鋼材1トン当たりの合金コスト | -1–5% vs reference | +0–2% volatility | Variable; higher Al input |

| Energy/time impact | -0.5–2% heat time | Minor reduction | 参考 |

| Dust and housekeeping | Low; enclosed metering | Higher; open charging | Wire feed dust |

| Sequence stability | Higher; fewer interventions | 中程度 | Lower; Al2O3-related risk |

High-Absorption Coated Silicon Carbide Granules with Anti-Powdering Low-Dust Handling for Automated Feeding advantages and proven benefits with expert perspective

The decisive benefit of High-Absorption Coated Silicon Carbide Granules with Anti-Powdering Low-Dust Handling for Automated Feeding is operational calm. When granules flow consistently through feeders, land in the melt without powdering, and dissolve with a predictable profile, silicon targets align without last-minute wire corrections. Additionally, coatings reduce oxidation loss pre-contact and help keep inclusion populations fine and floatable, improving nozzle openness and sequence length. Prof. Li Wei of CAS Weifang Innovation Park captures the essence: “Coating is not cosmetics; it’s kinetics control. It preserves activity in logistics—and unleashes it in the melt” (CAS Materials Review, 2023). For Pakistani mills, that translates directly into fewer unplanned pauses and narrower KPI bands.

High-Absorption Coated Silicon Carbide Granules with Anti-Powdering Low-Dust Handling for Automated Feeding real-world applications and measurable success stories

At a Karachi-adjacent EAF mill producing billets for construction grades, switching to High-Absorption Coated Silicon Carbide Granules with Anti-Powdering Low-Dust Handling for Automated Feeding stabilized silicon pickup and trimmed aluminum wire by twelve percent. Over eight weeks, silicon absorption rose by five percentage points, total oxygen dropped by eight ppm, and nozzle clogging incidents fell by thirty-one percent per hundred heats. Dust readings at the addition point decreased sufficiently to simplify PEQS reporting, and the shop reported fewer housekeeping interventions. Meanwhile, in a Punjab converter facility, early ladle additions using 0–3 mm granules produced a three-degree Celsius advantage in tapping temperature drop and shaved roughly one percent from heat time, translating to more than one percent effective capacity gain over the quarter.

High-Absorption Coated Silicon Carbide Granules with Anti-Powdering Low-Dust Handling for Automated Feeding selection and maintenance considerations

Selection begins with the addition point. For teeming stream applications, 0–3 mm High-Absorption Coated Silicon Carbide Granules with Anti-Powdering Low-Dust Handling for Automated Feeding dissolve rapidly without excessive fume loss, especially when tapping temperatures hover at typical Pakistani ranges. Early ladle additions benefit from the same fraction when residence time is limited; otherwise, 3–10 mm provides a steadier release. For injection, <200 mesh blends can be prepared to match pneumatic systems. Composition tuning should follow your grade mix: maintain free silicon toward the lower end when pursuing low-al pathways for casting stability, and consider calcium-bearing variants when alumina inclusions challenge nozzle openness. To retain flowability through the monsoon season, enclosed silos and dry transfer points remain best practice even with hydrophobic coatings, with periodic flowability and moisture checks reinforcing consistency.

High-Absorption Coated Silicon Carbide Granules with Anti-Powdering Low-Dust Handling for Automated Feeding industry success factors and customer testimonials

Sicarbtech’s field teams in Pakistan consistently find that pairing High-Absorption Coated Silicon Carbide Granules with Anti-Powdering Low-Dust Handling for Automated Feeding with online metering and oxygen-activity-linked dosing yields the best results. A QA manager in the North Region described the shift succinctly: “The tundish team stopped calling for nozzle checks every other heat. The silicon curve flattened—in a good way.” That calm on the radio often correlates with measurable KPI stability and better operator focus where it matters.

High-Absorption Coated Silicon Carbide Granules with Anti-Powdering Low-Dust Handling for Automated Feeding future innovations and market trends

Through 2025 and into the next cycle, Pakistani mills will push further into automated alloying and data-linked dosing. High-Absorption Coated Silicon Carbide Granules with Anti-Powdering Low-Dust Handling for Automated Feeding are evolving accordingly. Sicarbtech is refining coating chemistries for stronger moisture barriers and tailored dissolution under varying slag carry-over, while developing microstructured granules that deliver a two-stage release—an initial fast response to oxygen spikes, followed by a controlled tail for absorption stability. Moreover, as import substitution gains momentum, Sicarbtech’s technology transfer for powder synthesis, classification, granulation, and coating lines enables local production of these coated granules, cutting lead times and allowing faster recipe iteration against real plant data.

よくある質問と専門家の回答

How do High-Absorption Coated Silicon Carbide Granules with Anti-Powdering Low-Dust Handling for Automated Feeding reduce dust compared with standard SiC?

The hydrophobic, anti-powdering coating and densified granulation significantly limit fines generation during transport and feeding. In enclosed metering systems, this combination keeps dust low and improves compliance with PEQS-aligned targets.

Can High-Absorption Coated Silicon Carbide Granules with Anti-Powdering Low-Dust Handling for Automated Feeding help us cut aluminum wire without risking inclusions?

Yes. By providing silicon and carbon early and consistently, High-Absorption Coated Silicon Carbide Granules with Anti-Powdering Low-Dust Handling for Automated Feeding reduce the need for late wire corrections. Inclusion populations tend to be finer and more floatable, which supports nozzle openness.

What particle size of High-Absorption Coated Silicon Carbide Granules with Anti-Powdering Low-Dust Handling for Automated Feeding should we select for teeming stream vs ladle?

For the stream and early ladle, 0–3 mm delivers fast dissolution. When residence time allows in the ladle, 3–10 mm offers a steadier release. Sicarbtech will match grading to your tapping temperature and flow regime.

Are calcium or barium variants of High-Absorption Coated Silicon Carbide Granules with Anti-Powdering Low-Dust Handling for Automated Feeding available for inclusion control?

They are. Microdomain additions of calcium or barium can be incorporated to promote conversion of alumina to more deformable calcium aluminates, coordinated with your slag practice to maintain stability.

How does Sicarbtech guarantee batch-to-batch consistency for High-Absorption Coated Silicon Carbide Granules with Anti-Powdering Low-Dust Handling for Automated Feeding?

Each batch of High-Absorption Coated Silicon Carbide Granules with Anti-Powdering Low-Dust Handling for Automated Feeding is validated under Sicarbtech’s in-situ quality monitoring and traceability system for SiC %, free carbon/silicon, particle size distribution, coating performance, moisture, and flowability, with records tied to shipment IDs.

Why High-Absorption Coated Silicon Carbide Granules with Anti-Powdering Low-Dust Handling for Automated Feeding work for your operations

Because they turn a difficult corner—materials logistics—into a performance advantage. High-Absorption Coated Silicon Carbide Granules with Anti-Powdering Low-Dust Handling for Automated Feeding preserve activity during transport, meter cleanly into the melt, and dissolve in a profile that defends silicon targets and casting stability. In Pakistan’s mills, where the cost of unpredictability is paid in time and yield, that combination is the most direct route to calmer metallurgy and stronger financials.

カスタムソリューションのスペシャリストと連携

Sicarbtech backs High-Absorption Coated Silicon Carbide Granules with Anti-Powdering Low-Dust Handling for Automated Feeding with more than a decade of silicon carbide manufacturing expertise and Chinese Academy of Sciences–supported innovation. Beyond delivering coated SiC tuned to your grades, Sicarbtech develops custom R-SiC, SSiC, RBSiC, and SiSiC products and offers technology transfer and factory establishment services to localize powder synthesis, classification, granulation, coating, and online feeding. With turnkey solutions proven across nineteen-plus enterprises, we can design a no-cost pilot aligned to your oxygen activity data, tapping temperatures, and slag practice, with clear KPIs for alloy cost per ton, cleanliness, and sequence stability. If you want to de-risk your melt shop and make automated feeding a true advantage, we’re ready to help now.

無料相談と、データに裏打ちされた迅速なご提案については、こちらまでご連絡ください:

Eメール:[email protected]

電話/WhatsApp:+86 133 6536 0038

記事のメタデータ

最終更新日: 2025年9月15日

次回審査予定2025-12-15

著者Sicarbtechアプリケーション・エンジニアリング・チーム

Region focus: Pakistan (EAF and converter routes; billets, bars, flats)

Timeliness note: Content aligned to 2025 scrap ratio trends, PEQS-aligned dust control practices, and closed-loop automated feeding advancements

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.