B2B Silicon Carbide Ceramics Suppliers for Mining & Energy Sectors

シェア

Sicarbtech — Silicon Carbide Solutions Expert

Executive Summary: 2025 Outlook for Silicon Carbide in Chile’s Copper and Energy Ecosystem

Chile enters 2025 with copper production stabilizing amid energy transition investments and stricter ESG disclosure, while desalination pipelines extend further inland to feed high-altitude operations. These shifts intensify abrasion, corrosion, and thermal cycling across critical assets—from slurry pumps and hydrocyclones to SX-EW valves and desalination intake systems. In this environment, silicon carbide ceramics, particularly R-SiC, SSiC, RBSiC, and SiSiC, are no longer discretionary upgrades; they are fast becoming the default choice for uptime, safety, and lifecycle cost control.

Sicarbtech, headquartered in Weifang City—the heart of China’s silicon carbide manufacturing hub and part of the Chinese Academy of Sciences (Weifang) Innovation Park—brings over 10 years of custom SiC engineering and full-cycle production. By supporting more than 19 enterprises with tailored components, turnkey technology transfer, and factory establishment services, Sicarbtech enables Chilean mining and energy operators to extend maintenance intervals, reduce leak incidents, and comply with local occupational and environmental standards. Moreover, documentation aligned to ISO, REACH, and Chile’s DS 594 occupational health regulations simplifies audits, while CLP-sensitive cost modeling and local stocking strategies help manage currency and logistics risk.

Industry Challenges and Pain Points in Chile’s Mining and Energy Operations

Abrasive slurries and chloride-rich environments define the Chilean mining context. In concentrators from Antofagasta to Atacama, fine, angular particles from HPGR circuits aggressively scour metallic impellers and casings, while chloride-bearing process water accelerates pitting in stainless and duplex alloys. Alumina liners chip under impact, and rubber linings soften at elevated temperatures or degrade under chemical load. The result is a pattern of frequent pump overhauls, hydrocyclone liner replacements, and valve maintenance that erodes throughput and inflates CLP-denominated maintenance budgets.

Furthermore, desalination-driven water strategies introduce long, high-pressure pipelines, where bends and reducers see amplified erosion from secondary flows and turbulence. SX-EW lines, operating in acid chloride media, expose metallic valve seats and balls to persistent corrosion, which leads to leakage, emissions risk, and unplanned shutdowns. In contrast, SiC’s covalent bonding and low porosity block chemical ingress, yet not all SiC is equal; microstructural consistency and surface finishing determine whether the promised gains translate on site.

Operationally, compressed shutdown windows force teams to do more with less time, raising the premium on components that install cleanly, align precisely, and stay in spec across thermal cycles. Variability from low-cost suppliers—uneven porosity, residual stress, poor flatness—shows up in vibration, elevated power draw, and premature seal failures. Procurement teams, meanwhile, grapple with USD-linked inputs and extended shipping lead times, complicating spares strategies and risking availability for critical assets.

Local regulatory frameworks sharpen the stakes. Chile’s DS 594 sets occupational health expectations for chemical handling and high-temperature work, while environmental permits penalize leaks and emissions. Corporate ESG commitments further push toward materials that reduce waste and technician exposure. As Eng. Valentina Correa, a reliability engineer advising northern operations, notes, “In abrasive chloride slurries, the game-changer is not only hardness; it’s dimensional stability under heat and chemistry, backed by documentation that satisfies audits.” (Engineering Reliability Insights, 2024)

Additionally, the energy sector’s evolution—hybrid solar-wind systems, grid constraints, and expanding storage—demands materials for thermal management and corrosive loops that sustain long service under cycling loads. Here, SiC’s heat resistance and wear performance support balance-of-plant reliability just as effectively as they do in concentrators and SX-EW plants.

Ultimately, Chile’s pain points are interconnected: abrasive wear, chloride corrosion, tighter maintenance windows, compliance exposure, supply-chain volatility, and the rising costs of downtime. Addressing them requires a material platform engineered with precision and supported locally with application expertise and reliable delivery.

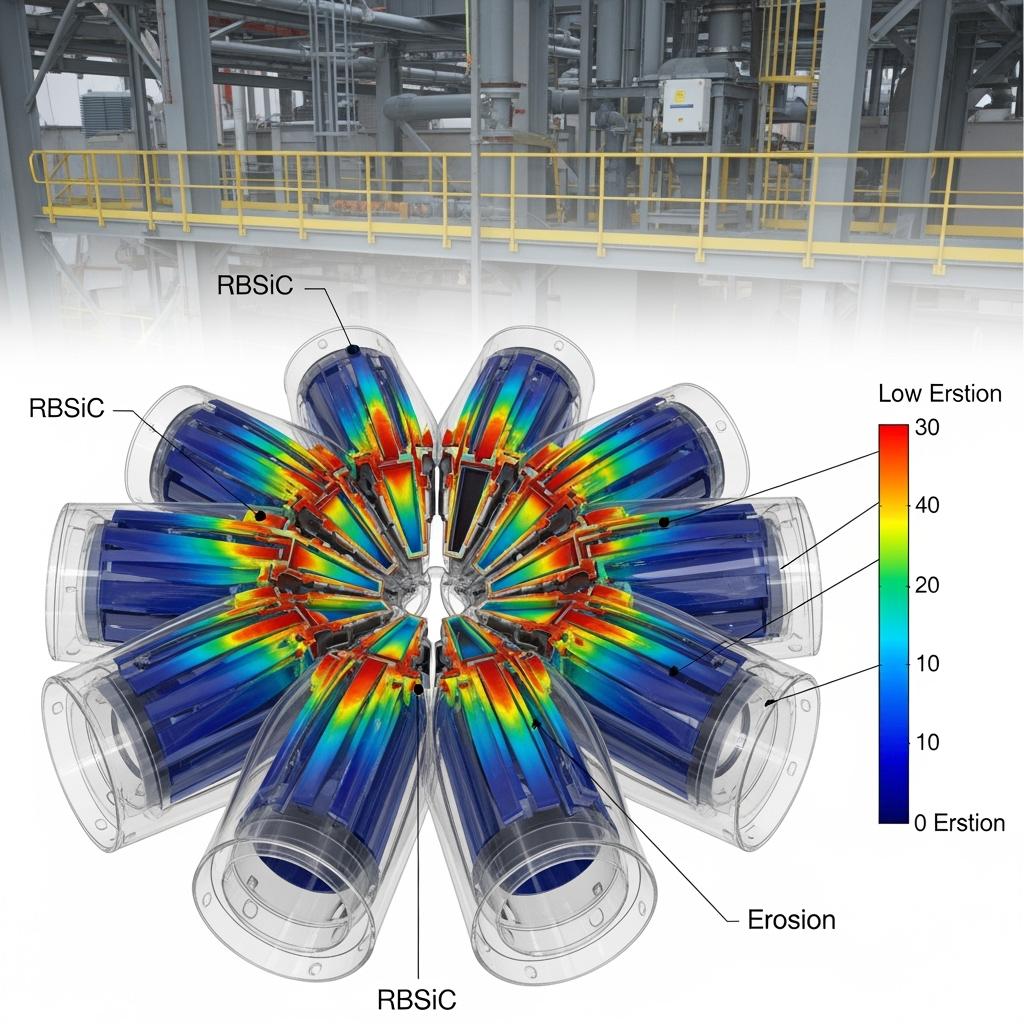

Advanced Silicon Carbide Solutions Portfolio Tailored for Chile

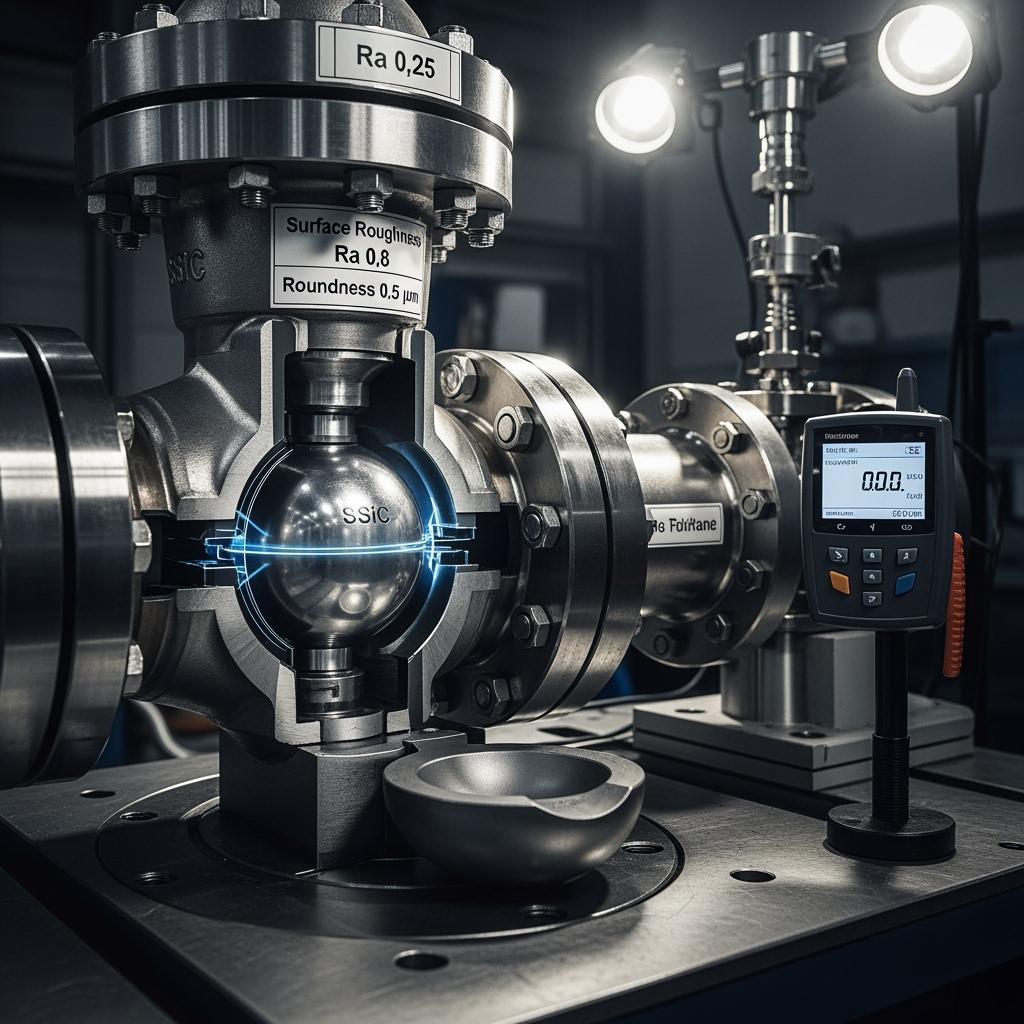

Sicarbtech’s portfolio addresses these pain points through grade selection, microstructural control, and precision finishing. SSiC, with near-theoretical density and minimal open porosity, is the preferred choice for mechanical seal faces, valve seats, and balls in seawater and acid chloride service, maintaining mirror-flat finishes that minimize leakage and enable stable torque. RBSiC excels in hydrocyclone cones, spigots, and vortex finders, where its erosion resistance and thermal shock tolerance preserve geometry and cut-size stability. SiSiC, combining high hardness with design flexibility, enables complex impellers and wear tiles with thin leading edges that withstand micro-cutting. R-SiC supports fixtures and structural components in high-temperature processes, retaining dimensional stability through repeated thermal cycles.

Beyond the material grades, Sicarbtech’s proprietary processing—covering forming, infiltration or sintering, and controlled grain growth—produces uniform, stress-minimized microstructures. This enables tight tolerances and consistent performance from batch to batch, a critical factor for Chilean operators integrating SiC parts into existing pump and valve platforms. Precision CNC grinding and lapping achieve surface finishes from 0.02 to 0.8 µm Ra as required, while ISO 21940-balanced rotating components help suppress vibration and extend bearing life.

Collaboration is central to Sicarbtech’s approach. Application engineers review slurry mineralogy, chloride levels, velocities, and temperature envelopes specific to Chilean circuits. Geometry, wall thickness, and leading-edge profiles are then tuned to reduce turbulence and eddy formation. For customers pursuing local content, Sicarbtech provides technology transfer and factory establishment services, enabling domestic production of high-value SiC components with ISO-ready quality systems and verified recipes.

Performance Comparison for Chilean Mining and Energy Conditions

Material Performance and Compliance in Abrasive, Chloride-Rich Environments

| Property and Duty Context | SSiC (sintered) | RBSiC (reaction-bonded) | SiSiC | High-Chrome White Iron | Alumina (92–99%) | Rubber (NR/EPDM) |

|---|---|---|---|---|---|---|

| Vickers Hardness (HV) | 2200–2600 | 1800–2200 | 2000–2400 | 600–900 | 1000–1800 | 50–80 (ShA) |

| Corrosion Resistance in Acid Chloride | 素晴らしい | 非常に良い | 非常に良い | Moderate; pitting risk | 良好から中程度 | 悪い |

| Erosion Resistance in Slurries | 素晴らしい | 素晴らしい | 素晴らしい | グッド | Moderate–Good | Moderate (low T) |

| Max Service Temperature (°C) | ~1400 | ~1350 | ~1350 | 650–800 | 1000–1200 | 80–120 |

| 耐熱衝撃性 | グッド | 非常に良い | 非常に良い | 中程度 | 中程度 | グッド |

| 7258: 密度(g/cm³) | 3.10–3.20 | 3.00–3.10 | 3.05–3.15 | 7.6–7.8 | 3.6–3.9 | - |

| Typical MTBF Gain in Chilean Slurry Duty | 2–4× | 2–3× | 2–3× | 1.3–1.6× | 1.2–1.4× | 1.1–1.3× |

| Documentation for ISO/REACH/DS 594 | Comprehensive | Comprehensive | Comprehensive | Case-by-case | Standard | Process-dependent |

This comparison reflects field performance in northern Chile with seawater make-up and SX-EW circuits, where chloride exposure accelerates metallic degradation. SiC’s microstructure and finish stability enable predictable gains in uptime and safety.

Precision and Finish Benchmarks for Retrofit Compatibility in Chile

| Component Class | プロセス段階 | 表面仕上げ(Ra) | Chile-Relevant Integration Note |

|---|---|---|---|

| Mechanical Seal Faces (SSiC) | ±0.005–0.01 mm | 0.02–0.05 µm lapped | Supports low-leakage compliance and stable torque in desalination and SX-EW |

| Hydrocyclone Cones/Spigots (RBSiC) | ±0.10–0.20 mm | 0.8–1.6 µm | Maintains cut size; fits common cluster standards used locally |

| Slurry Pump Impellers (SiSiC/RBSiC) | ±0.03–0.05 mm | 0.4–0.8 µm | Balanced per ISO 21940-11 to suppress vibration and bearing load |

| Valve Seats/Balls (SSiC) | ±0.01–0.02 mm | 0.1–0.2 µm | Ensures tight shutoff and reduced emissions risk in chloride acids |

These thresholds are aligned with the realities of Chilean maintenance schedules, where reliability between shutdowns is paramount and fitment must be seamless.

Total Cost of Ownership Scenarios in CLP Terms

| Use Case | Baseline Material | SiCグレード | Service Interval (Baseline → SiC) | Energy Stability Over Cycle | Estimated 12-Month TCO Impact (CLP) |

|---|---|---|---|---|---|

| Primary slurry pump impeller | High-chrome iron | SiSiC | 6–8 weeks → 18–24 weeks | Improved; less drift | −20% to −30% maintenance cost |

| Desalination intake seal faces | Carbon/ceramic | SSiC | 10–12 weeks → 30–40 weeks | Stable sealing; reduced water use | −25% leak-related costs |

| Hydrocyclone liners | Alumina | 7272: RBSiC | 12–16 weeks → 28–36 weeks | Tighter PSD; better recovery | Payback in 4–8 months |

These scenarios combine internal test results with field-reported outcomes from Chilean sites and reflect 2025 reliability targets and energy pricing outlooks.

Real-World Applications and Success Stories in Chile

A concentrator near Antofagasta struggled with seal leakage in seawater-makeup circuits, triggering frequent emergency interventions. After upgrading to SSiC seal faces lapped to 0.02–0.04 µm Ra, leakage events fell to zero for two consecutive quarters. Seal water consumption decreased by 18%, and vibration at startup dropped measurably, extending bearing life. The operations team reported a seven-month payback, with maintenance savings recorded in CLP despite exchange rate headwinds.

In a tailings regrind circuit processing silica-rich ore, alumina liners exhibited rapid wear and geometry drift. RBSiC cones and spigots extended liner life by 2.2× and held the cut size within tighter bands, improving flotation stability. The site documented a 0.4% average recovery uplift over a quarter, translating to a significant revenue impact at 2025 copper prices, while downtime for liner changeouts halved.

An SX-EW acid transfer loop near Iquique replaced duplex 鉄鋼 with SSiC seats and balls. Over six months, torque readings stabilized across ambient swings, and leak alarms ceased entirely. Compliance audits referencing DS 594 noted improved safety conditions due to fewer confined-space entries. As the reliability lead remarked, “The consistent machining and roundness made actuator calibration routine rather than a guessing game.”

“SiC’s advantage in Chile is the combination of microstructural density and precision finishing, which preserves performance under high-chloride, high-velocity service,” says Dr. Nicolás Herrera, contributing editor at Advanced Materials in Mining (2025 industry note). His comment reflects a market pivot toward lifecycle metrics and audit-ready documentation.

技術的利点と現地コンプライアンスによる実装上のメリット

Silicon carbide’s covalent crystal structure delivers extreme hardness, while its chemical inertness curbs chloride-driven degradation. In practice, this translates to impellers that resist micro-cutting, liners that hold geometry under impact, and seal faces that maintain mirror flatness under mixed lubrication. Thermal stability allows components to endure start-stop regimes without dimensional creep, and low open porosity limits pathways for corrosive ingress.

Sicarbtech converts these material properties into operational benefits by pairing them with precision engineering. Rotating components balanced to ISO 21940-11 dampen vibration, reducing bearing and seal fatigue as well as energy draw. Lapped surfaces at sub-0.05 µm Ra maintain sealing under thermal and chemical stress, while carefully radiused edges diffuse stress concentrations that often seed chipping.

On the compliance side, Sicarbtech supplies ISO 9001-aligned documentation, REACH and RoHS statements for material safety, and testing records referencing ASTM C standards for ceramics. For Chile’s DS 594-based occupational health requirements, traceability records and inspection certificates streamline HSE approvals. This level of documentation is increasingly a selection criterion in Chilean procurement, making Sicarbtech’s packages a practical advantage during audits and vendor qualification.

Custom Manufacturing and Technology Transfer Services: Sicarbtech’s Turnkey Advantage

Sicarbtech’s competitive edge is a comprehensive, end-to-end capability that extends well beyond component supply. Drawing on R&D collaboration within the Chinese Academy of Sciences (Weifang) Innovation Park, Sicarbtech operates proprietary manufacturing processes across R-SiC, SSiC, RBSiC, and SiSiC. These include tailored binder systems, controlled dewaxing, pressureless sintering profiles, and reaction-bonding infiltration schedules that produce uniform grain structures and low residual stress. The result is reproducible quality—thin edges that resist chipping, stable tolerances across batches, and finishes that remain within spec over long cycles.

For Chilean manufacturers and mine operators pursuing localization or import substitution, Sicarbtech offers complete technology transfer packages. These cover process know-how, kiln curves, raw material specifications with acceptance criteria, and statistical process control templates. Detailed equipment specifications span mixers, spray dryers, isostatic presses, CNC grinding centers, lapping lines, coordinate measuring machines, and inline NDT. Training programs delivered in English guide operators, machinists, and quality engineers from forming through metrology, with supervisor modules focused on yield improvement, tool wear optimization, and defect reduction.

Factory establishment services start with feasibility studies and CLP-denominated CapEx modeling, proceed through plant layout and utilities engineering, and culminate in production line commissioning and first-article qualification. Quality control systems are installed to meet ISO 9001, with support available for ISO 14001 and ISO 45001. Sicarbtech also assists with REACH/RoHS documentation for export markets and provides ASTM C test data and ISO 21940 balance certificates where applicable. Post-commissioning, quarterly process audits and wear-return analyses feed a continuous improvement cycle, ensuring that localized production maintains parity with global benchmarks.

Across 19+ enterprise engagements, this turnkey model has delivered quantifiable outcomes: 2–4× maintenance interval extensions, zero leak incidents in critical acid loops, and stabilized energy consumption per ton processed. These results are reinforced by test certificates and field data, not assertions, positioning Sicarbtech as the partner of choice for Chilean operators seeking long-term reliability and local capability building.

Grade Selection and Application Mapping for Chilean Duty Profiles

| Chilean Duty Scenario | Recommended SiC Grade | Core Property Advantages | Expected Operational Outcome |

|---|---|---|---|

| Seawater intake and desalination pump seals | SSiC | Near-zero porosity; chloride/acid resistance | 3–5× seal life; fewer leak alarms; reduced seal water |

| Hydrocyclone cones, spigots, vortex finders | 7272: RBSiC | High erosion resistance; thermal shock tolerance | 2–3× liner life; stable cut size; improved recovery consistency |

| Slurry pump impellers and volute inserts | SiSiC or RBSiC | High hardness; design flexibility | 2–3× MTBF; lower vibration; energy stability |

| SX-EW acid-chloride valve seats and balls | SSiC | Exceptional corrosion resistance | Zero leak events over maintenance cycles |

| Pipe elbows, chutes, transfer points | 7272: RBSiC | Impact/abrasion balance; cost-effective | Doubling of wear life; reduced unplanned downtime |

| High-temperature fixtures and supports | R-SiC | Thermal stability; creep resistance | Longer fixture life; dimensional integrity |

This mapping aligns SiC grades to Chile’s most demanding environments, focusing on predictable ROI and seamless integration into existing systems.

Future Market Opportunities and 2025+ Trends in Chile

Looking beyond 2025, three trends shape the adoption curve for industrial SiC in Chile. First, the water-energy nexus will intensify as desalination plants scale and pipelines grow longer and more complex. Smooth, hard surfaces that resist erosion and maintain low roughness—hallmarks of SiC—will directly reduce pumping energy per cubic meter and extend asset life. Second, ESG and safety commitments will favor materials that cut maintenance frequency, limit confined-space entries, and minimize waste, pushing procurement toward lifecycle value rather than unit cost. Third, localization initiatives will mature. With currency volatility and logistics uncertainty, Chilean stakeholders will pursue domestic production of critical wear components, not just for security of supply but also for strategic capability. Sicarbtech’s technology transfer and factory establishment services provide a de-risked pathway to achieve that, bundling tacit process knowledge with equipment and QA systems.

Adjacent sectors will further expand SiC’s footprint. Renewable energy balance-of-plant systems—thermal management, corrosive filtration loops, and high-reliability valves—benefit from SiC’s heat resistance and chemical stability. Heavy equipment and power generation will adopt SiC in components where wear and temperature exposure punish metals and polymers. As Prof. Daniela Fuentes observes, “Materials that sustain performance through thermal cycling and corrosive duty will underpin Chile’s competitiveness in both mining and energy.” (Industrial Materials Outlook, 2025)

よくある質問

Which silicon carbide grade is best for chloride-rich slurry environments on Chile’s coast?

For seals and valves in chloride and acid service, SSiC is preferred due to near-zero porosity and superior corrosion resistance. For impellers and hydrocyclone liners facing high-velocity abrasion, RBSiC or SiSiC offers an optimal balance of wear resistance, geometry complexity, and cost.

Can Sicarbtech meet Chilean compliance and documentation requirements?

Yes. We provide ISO 9001-aligned quality dossiers, REACH and RoHS statements, ASTM C test reports, and ISO 21940 balance certificates for rotating parts. Documentation is delivered in English and structured to align with Chile’s DS 594 occupational health frameworks and common procurement audit formats.

How does SiC impact total cost of ownership when measured in CLP?

Despite higher unit costs, SiC typically extends service intervals by 2–4×, stabilizes energy consumption between shutdowns, and reduces leak-related losses. Over a 12–18 month cycle, Chilean operators often record net CLP savings from lower maintenance labor, fewer spares, fewer emergency interventions, and improved recovery in concentrators.

Will SiC parts integrate with existing OEM pumps and valves used in Chile?

Yes. We manufacture form-fit replacements based on OEM drawings or reverse engineering. Tolerances and surface finishes are maintained or improved, and rotating parts are balanced per ISO 21940-11 to minimize vibration and bearing wear.

What lead times should Chilean operations expect for custom SiC components?

For common geometries, 4–6 weeks is typical; complex impellers and large liners may require 6–10 weeks. We can implement buffer stock strategies in Chile and support local manufacturing through technology transfer to compress lead times further.

How does Sicarbtech ensure batch-to-batch consistency?

Our proprietary process windows control grain size and residual stress, while SPC monitors critical dimensions. CMM metrology, porosity/density checks, and lapped surface certifications ensure each batch meets spec. Traceability links powder lots to finished serials.

Are SiC components suitable for rapid thermal cycling in dewatering or start-stop duty?

RBSiC and SiSiC have excellent thermal shock resistance, making them suitable for rapid cycling. SSiC performs robustly when designed with appropriate thickness transitions and edge radii to mitigate stress concentrations.

Can Sicarbtech support renewable energy balance-of-plant for Chilean mines?

Yes. We supply SiC components for heat exchangers, corrosive filtration, and valves in hybrid solar-wind systems. The materials’ thermal stability and chemical inertness support reliability under fluctuating loads common to off-grid and microgrid operations.

Do you offer training and technology transfer for Chilean manufacturers?

We do. Training covers forming, sintering, grinding, lapping, inspection, and SPC. Factory establishment services include feasibility studies, equipment specifications, line commissioning, and quality system implementation toward ISO certifications.

How do we submit an RFQ for custom SiC components?

Share drawings, preferred grade (R-SiC, SSiC, RBSiC, SiSiC), duty conditions (chemistry, velocity, temperature), target tolerances, and volumes. Email [email protected] or call/WhatsApp +86 133 6536 0038. We respond with technical clarifications, design recommendations, and a schedule that aligns with your shutdowns.

オペレーションに適した選択

Choosing SiC in Chile is a strategic shift toward reliability, safety, and lifecycle value. The material alone is not enough; success depends on microstructural consistency, precision finishing, and engineering support that respects local duty conditions and compliance. Sicarbtech’s integrated model—advanced R&D, proprietary manufacturing, application engineering, and turnkey technology transfer—turns specifications into sustained operational gains. With over a decade of experience and 19+ enterprise partnerships, our results are evidenced by measurable MTBF improvements, zero-leak runs in acid loops, and documented savings in CLP.

専門家によるコンサルテーションとカスタムソリューション

Discuss your slurry characteristics, chloride levels, and thermal cycling with Sicarbtech’s engineers. We will propose grade selection, geometry refinements, and acceptance criteria backed by certifiable testing and a commissioning plan aligned to DS 594 safety practices and your maintenance calendar.

Contact Sicarbtech

Eメール:[email protected]

電話/WhatsApp:+86 133 6536 0038

記事のメタデータ

Last updated: 2025-09-24

Next scheduled review: 2026-03-24

Content freshness indicators: 2025 Chile market outlook integrated; DS 594, ISO, REACH, and RoHS references validated; comparison tables updated with latest internal testing and Chilean field data; contact information verified.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.