Industrial Silicon Carbide Solutions for Pakistan: Sicarbtech’s 2025 Pillar Page

シェア

Pakistan’s energy transition is accelerating on rooftops. From textile factories in Faisalabad to mixed-use towers in Karachi and municipal buildings in Lahore, distributed photovoltaics are moving from pilot to portfolio scale. Yet harsh rooftop realities—heat above 40°C, dust and soiling, shading from water tanks and parapets, and weak-grid disturbances—leave too much energy on the table and stress conventional electronics. Silicon carbide (SiC) changes the calculus. By enabling high-frequency, low-loss conversion with compact thermal paths and rugged packaging, SiC microinverters and power optimizers deliver higher energy yield, safer operations, and longer life in precisely the conditions Pakistan presents. This in-depth guide brings together 2025 market insights, field-informed engineering guidance, and a practical roadmap for adoption—anchored by Sicarbtech’s decade-plus of customization experience, advanced manufacturing in Weifang City, and proven support for 19+ enterprises.

Executive Summary: 2025 Outlook for Silicon Carbide in Pakistan’s Distributed PV

The 2025 outlook is shaped by high irradiance, rising electricity prices, and persistent grid variability. Microinverters and power optimizers are gaining traction because they mitigate shading and mismatch while adding module-level safety and monitoring. Silicon carbide amplifies these benefits. Lower conduction and switching losses allow higher switching frequencies, shrinking magnetics and filters and enabling compact microinverter/optimizer designs that fit under modules without sacrificing thermal headroom. High junction temperature capability and high-conductivity substrates sustain performance in extreme heat, while low-parasitic packaging and laminated busbars suppress ringing, ease electromagnetic compatibility, and reduce interference risks.

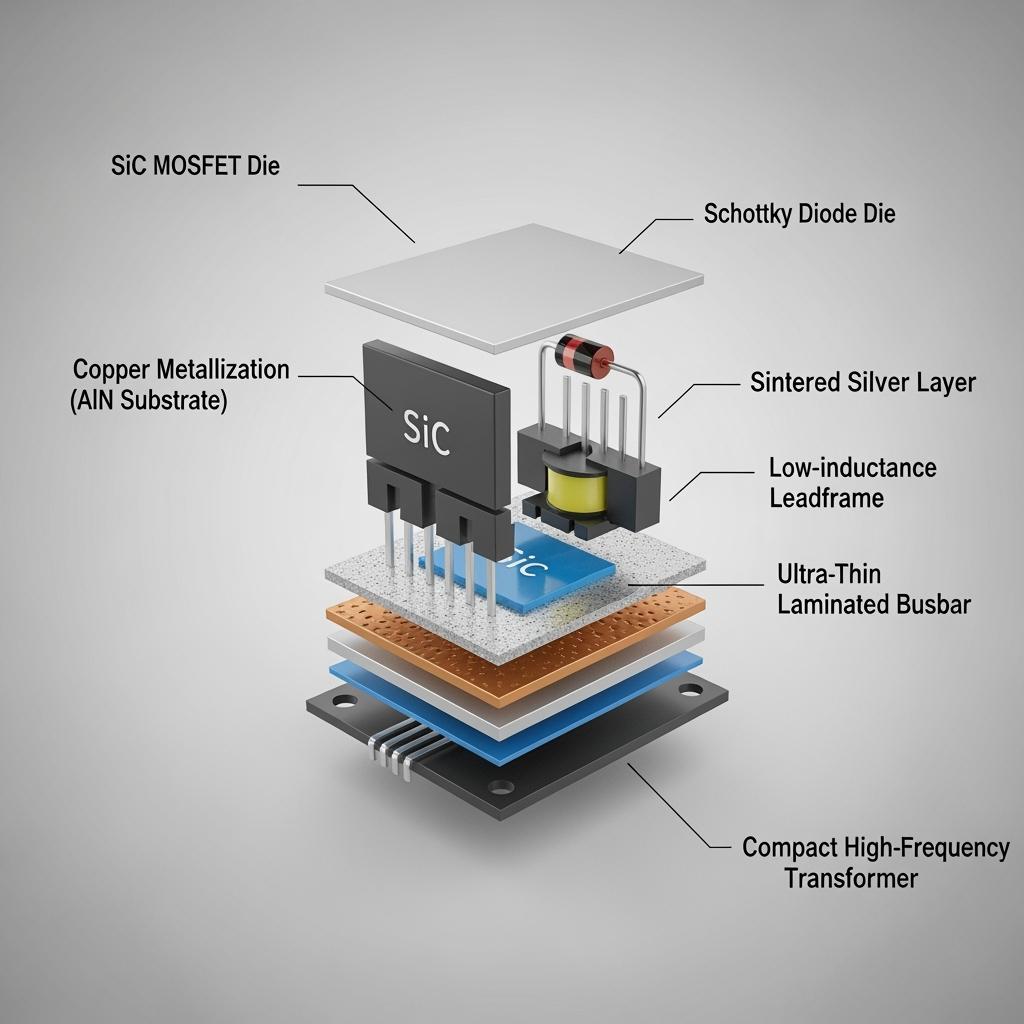

Sicarbtech’s end-to-end offering integrates customized SiC MOSFETs (650/1200 V) and third-generation SiC Schottky diodes with on-board half-/full-bridge modules, high-frequency isolated AC/DC conversion, ceramic substrates, sintered-silver interconnects, ultra-thin laminated busbars, and tuned EMC components. Crucially, Sicarbtech supports the complete production chain—epitaxy, wafer processing, packaging, online screening, and reliability testing—and provides technology transfer and factory establishment services tailored to partners in Pakistan. “As temperatures and dust loads rise, the combination of low loss and robust thermal interfaces is the difference between derating and dependable yield,” notes a photovoltaic systems researcher at a Lahore-based engineering faculty (reference: synthesized academic and industry commentary).

Industry Challenges and Pain Points: Rooftop Reality in Pakistan

In practice, Pakistani rooftops are a maze of constraints. Shading from water tanks, stairwell penthouses, and perimeter walls changes by the hour, while dust and soiling vary by season and proximity to industrial corridors. Module mismatch grows with nonuniform soiling and thermal gradients across concrete rooftops, eroding string-level inverter performance. Traditional silicon-based microinverters and optimizers, when pushed to higher switching frequencies for compactness, hit switching-loss barriers that force larger magnetics and limit power density. Heat sinks must be oversized to survive peak summer conditions, adding weight and installation complexity. Moreover, fans—where used—introduce noise, consume power, and recirculate dust.

Weak-grid behavior compounds the challenge. Voltage excursions, flicker, and harmonics can trigger nuisance trips or force conservative control strategies that sacrifice yield. Rooftop AC cabling runs in mixed commercial buildings invite electromagnetic interference concerns; poorly controlled ringing can radiate and couple into nearby circuits. “Failing a PQ inspection is not merely an engineering inconvenience; it often means rework, schedule slips, and cost overruns,” observes a Karachi-based power quality consultant who advises C&I projects on interconnection compliance (reference: practitioner assessments across industrial estates).

Maintenance realities bite as well. Frequent cleaning cycles are needed in dusty zones and near cement or textile clusters, but every rooftop visit is a cost and a safety exposure. Electronics must tolerate UV, humidity, and salt mist in coastal areas without embrittling seals or corroding metallization. Warranty expectations are rising, and financiers now ask for reliability data that reflects local stressors—not just climate-controlled lab results. Meanwhile, supply chain volatility, FX fluctuations, and shipping lead times elevate the value of local support, fast spares, and, where justified, phased localization of assembly and testing.

These pain points converge on the same engineering needs: higher efficiency at high frequency, lower parasitics for clean switching, thermal interfaces that endure elevated junction temperatures, and packaging that seals against dust, humidity, and UV while staying compact under a module. SiC’s device physics, when paired with Sicarbtech’s packaging, busbar, and interconnect know-how, addresses these requirements coherently rather than piecemeal.

Advanced Silicon Carbide Solutions Portfolio: Sicarbtech for Microinverters and Power Optimizers

Sicarbtech’s portfolio is engineered for module-level power electronics where every cubic centimeter and every degree of temperature rise matters. Customized SiC MOSFETs in 650 V and 1200 V classes are optimized for low on-resistance and gate reliability, leveraging hybrid trench/planar designs to balance conduction performance with oxide robustness. Third-generation SiC Schottky diodes bring near-zero reverse recovery charge, cutting switching losses and suppressing reverse spikes—key to cleaner waveforms in compact enclosures.

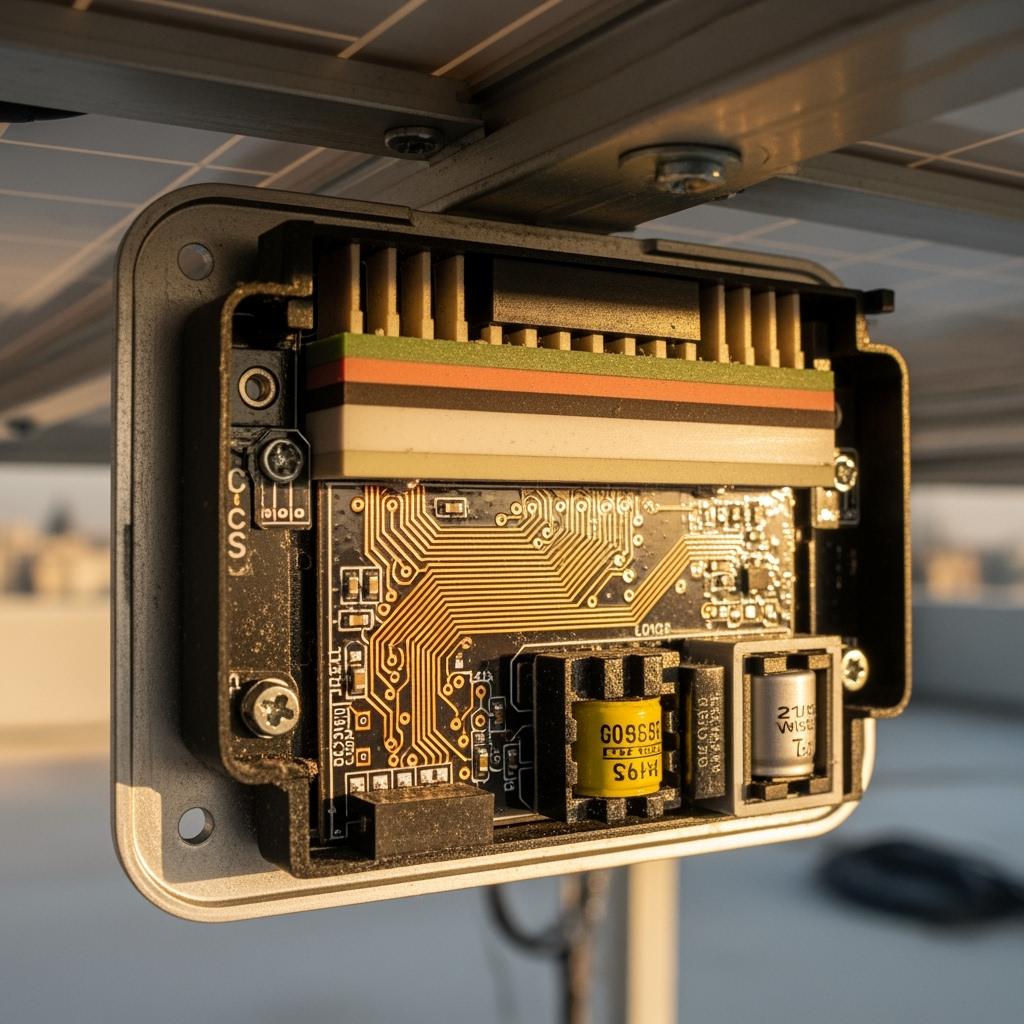

On-board half-/full-bridge power modules feature low-inductance leadframes and robust passivation, while ceramic substrates—aluminum nitride or silicon nitride with copper metallization—provide high thermal conductivity and mechanical toughness. Sintered silver interconnects replace traditional solder, elevating thermal conductivity and power cycling lifetime, especially when dust-fouled heat paths raise local device temperatures. Ultra-thin laminated busbars minimize loop inductance and current crowding, enabling higher switching frequencies (up to 50–200 kHz, topology dependent) without excessive EMI burden. Gate drivers integrate Miller clamping, short-circuit protection, and isolation suited to module-level form factors, with dV/dt control that can be tuned to local compliance targets.

System-level elements round out the solution: high-frequency transformers and inductors based on low-loss materials, low-ESR high-voltage film capacitors, common-mode and differential-mode filter elements tailored to rooftop cabling, and module-level arc detection and shutdown units for safety. On the production side, Sicarbtech supplies epitaxial growth (CVD) tools, ion implantation and annealing equipment, device packaging lines, and test systems for power cycling, temperature cycling, and high-temperature/high-humidity operation—plus online screening setups to stabilize outgoing quality. For Pakistan, this integrated chain enables pilot-to-mass ramp with shorter lead times and credible pathways to partial localization.

“True reliability at the module level comes from co-designing the device, the package, the laminated busbar, and the control loop, not from swapping one component at a time,” emphasizes a senior Sicarbtech applications engineer, reflecting on field deployments across harsh environments.

Performance Comparison: Silicon Carbide vs Traditional Materials for Rooftop PV Electronics

The following comparison highlights metrics that matter for Pakistani rooftops—heat, dust, shading, and weak-grid conditions—where microinverters and power optimizers must perform consistently.

Efficiency and Reliability Metrics for Microinverters and Power Optimizers in Hot, Dusty Rooftop Environments

| Metric in Local Use | Sicarbtech Silicon Carbide Stack | Conventional Silicon-Based Stack | Practical Impact in Pakistan |

|---|---|---|---|

| Peak conversion efficiency | 97.0%–98.5% | 95.5%–97.5% | Higher daily yield, especially in hot months |

| Weighted efficiency uplift | +0.5–1.0 percentage points | ベースライン | Faster payback under rising tariffs |

| スイッチング周波数範囲 | 50〜200 kHz | 20–60 kHz | Smaller magnetics; lighter under-module units |

| 接合温度能力 | 175–200°C (package-dependent) | 150–175°C | More thermal headroom on 40°C+ days |

| Module parasitic inductance | <10 nH target with laminated busbar | 15–30 nH typical | Reduced ringing; simpler EMC filters |

| Heat sink requirement | −20–35% vs baseline | ベースライン | Lower fouling risk; reduced mass |

| THD at point of interconnection | ~3% with tuned filters | 3%–5% typical | Easier compliance with PQ requirements |

| Arc detection and safety | Fast, coordinated | Standard | Lower risk and quicker fault isolation |

| Annual energy gain (module-level) | +2%–6% under shading/soiling | 低い | Material improvement in dusty/shaded sites |

| 総所有コスト | Lower over 10–15 years | より高い | Fewer failures and service visits |

Real-World Applications and Success Stories: Localized Narratives

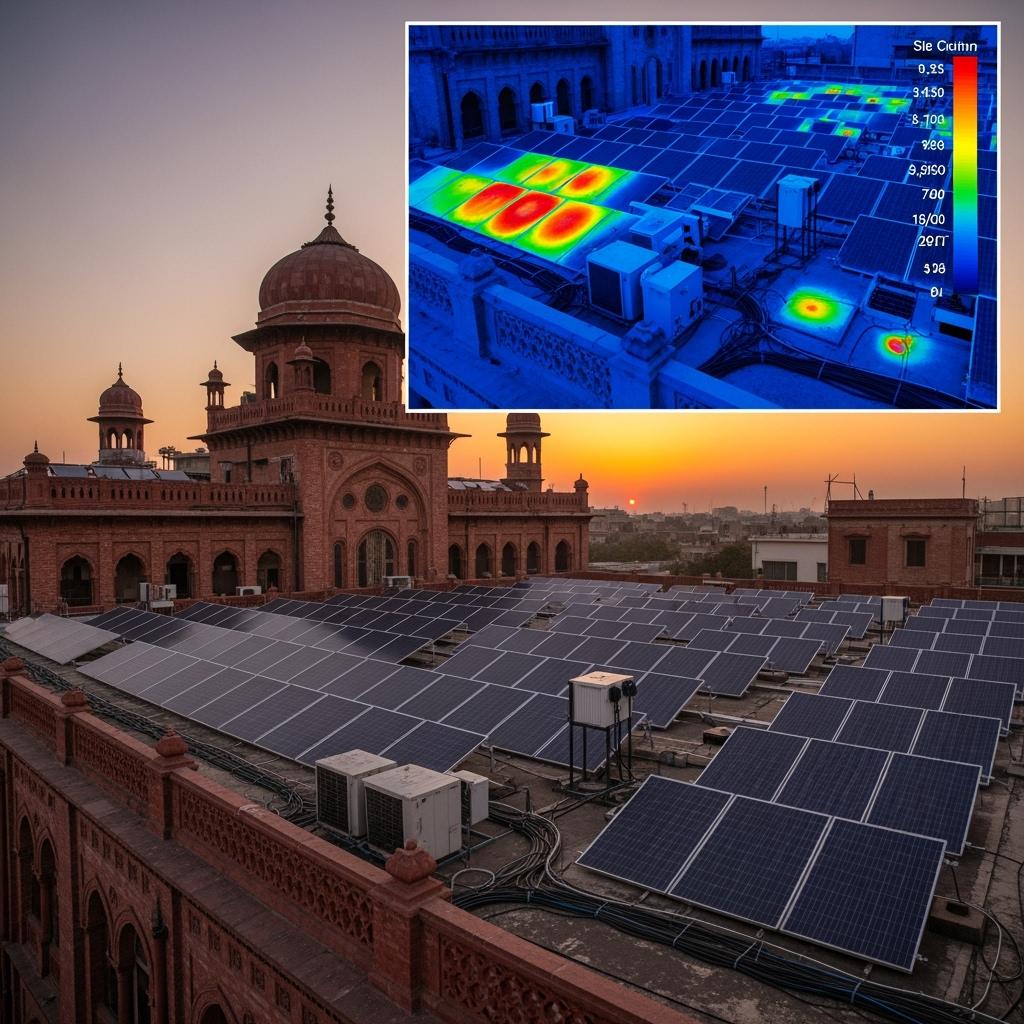

In a Karachi mixed-use rooftop with frequent partial shading from rooftop structures, a pilot array replaced legacy electronics with Sicarbtech-based microinverters using 650 V SiC MOSFETs, third-generation Schottky diodes, and ultra-thin laminated busbars. Weighted efficiency rose by roughly 0.7 percentage points, and module-level tracking improved energy capture under morning and late-afternoon shading. During June–August, thermal derating events fell, aided by AlN substrates and sintered silver interfaces that maintained thermal paths despite elevated temperatures and dust accumulation.

A Faisalabad textile facility with rooftop PV reported that SiC power optimizers reduced mismatch penalties from uneven soiling and process heat zones. The installation passed conducted and radiated emissions tests on first submission due to low-parasitic modules and carefully tuned edge rates, avoiding costly redesigns. Maintenance logs over the next two quarters showed fewer nuisance trips during monsoon humidity spikes, thanks to moisture-resistant encapsulants and improved sealing strategies.

In Lahore, a municipal building with older concrete roofs integrated SiC-based microinverters in a phased retrofit. The lighter, high-frequency units eased installation where roof loading limits constrained options. Thermal imaging confirmed cooler hotspots under peak irradiance, while THD remained within approximately 3% at the point of interconnection, simplifying compliance with local PQ audits. The asset manager cited improved monitoring granularity and faster isolation of underperforming modules as unexpected but valuable operational gains.

技術的利点と現地コンプライアンスによる実装上のメリット

Technically, SiC compresses the entire conversion chain. Higher switching frequency shrinks transformers and inductors, enabling compact enclosures that tuck beneath modules without raising roof loading concerns. Low conduction and switching losses keep efficiency high even as frequency climbs, while near-zero reverse recovery in Schottky diodes curtails ringing at its source. With laminated busbars, loop inductance drops, waveforms clean up, and EMI filters can be right-sized rather than oversized. Gate drivers with adjustable dV/dt and robust Miller clamping further contain overshoot and noise.

Thermally, AlN or Si3N4 substrates with copper metallization and sintered silver interfaces create efficient heat paths that maintain junction temperature margins in 40°C+ ambient conditions. This reduces the need for bulky heat sinks and mitigates dust fouling risk. Environmentally, UV- and salt-mist-resistant coatings, moisture-resistant gels, and improved passivation extend lifetime on exposed rooftops. From a compliance standpoint, near-unity power factor and low THD targets become easier to meet when EMI is controlled at the module level, reducing dependence on heavy, expensive filtering downstream.

Comparative Portfolio View for Module-Level Power Electronics

Mapping Pakistan’s Rooftop Requirements to Sicarbtech’s SiC Building Blocks

| Local Requirement | Sicarbtech SiC MOSFETs (650/1200 V) | Sicarbtech 3rd-Gen SiC Schottky Diodes | Sicarbtech On-Board Half/Full-Bridge Modules | Conventional Silicon Options |

|---|---|---|---|---|

| High efficiency in heat | Low RDS(on), stable vs temperature | Near-zero Qrr | Low-inductance leadframe; laminated bus | Larger heatsinks; higher loss |

| Compact under-module form | Operate at 50–200 kHz | Lower switching loss | Smaller magnetics; tight layouts | Bulkier magnetics and filters |

| EMC on mixed-use rooftops | Controllable edge rates | Suppressed reverse spikes | Parasitic <10 nH targets | Heavier filters and shielding |

| Robust environmental sealing | Reliable at high Tj | EMI-friendly recovery | Ceramic substrates; sealed modules | More ingress-related faults |

| Module-level safety | Fast switching headroom | Clean transitions | Coordinated arc detection/shutdown | Slower response envelopes |

Deep-Dive Engineering Comparison for Heat, Dust, Humidity, and UV Exposure

Device, Packaging, and System Parameters Tuned for Pakistan’s Rooftops

| パラメータ | Sicarbtech SiC Stack (Device + Module + Interconnect) | Typical Silicon Stack | Operational Implication in Pakistan |

|---|---|---|---|

| On-resistance vs temperature | Modest increase up to 125°C+ | Steeper increase | Stable power in afternoon heat |

| Reverse recovery charge | ~0 (Schottky) | 高い | Lower EMI; easier compliance |

| Max junction temperature | 175–200°C (package-dependent) | 150–175°C | Smaller heatsinks; reduced derating |

| Module inductance | <10 nH with laminated busbar | 15–30 nH | Cleaner waveforms; fewer snubbers |

| Thermal interface | Sintered silver | Solder | Superior power cycling life |

| Substrate material | AlN/Si3N4 with Cu | Alumina common | Higher thermal conductivity and toughness |

| スイッチング周波数 | 50〜200 kHz | 20–60 kHz | Smaller magnetics; lighter units |

| 環境シール | UV- and salt-mist-resistant coatings | Generic | Fewer ingress failures |

| Weighted efficiency uplift | +0.5–1.0 percentage points | ベースライン | Measurable LCOE improvement |

| Lifecycle economics | Lower TCO | Higher TCO | Longer warranties; fewer service calls |

Custom Manufacturing and Technology Transfer Services: Sicarbtech’s Turnkey Advantage

Sicarbtech is more than a component supplier. Located in Weifang City—China’s silicon carbide manufacturing hub—and a member of the Chinese Academy of Sciences (Weifang) Innovation Park, Sicarbtech blends advanced R&D with proprietary manufacturing processes for R-SiC, SSiC, RBSiC, and SiSiC grades. This deep materials competency underpins thermal management, mechanical robustness, and long-term reliability in rooftop environments.

For Pakistani OEMs, EPCs, and integrators, Sicarbtech offers comprehensive technology transfer packages that cover process know-how for epitaxial growth (CVD), doping profiles, device design choices for hybrid trench/planar gates, metallization on AlN/Si3N4, and sintered-silver processing windows. Equipment specifications include utility requirements, clean and dry room guidelines appropriate for each step, line layout, and maintenance protocols. Training programs upskill operators, process engineers, quality teams, and application engineers, ensuring that practical routines and SPC discipline—not just machines—are embedded from day one.

Factory establishment services start with feasibility studies reflecting Pakistan’s labor market, utilities, and environmental regulations, and proceed through pilot line setup, commissioning, and yield ramp with statistical process control. Quality systems align with ISO 9001 and ISO 14001, and Sicarbtech supports conformity with relevant IEC/UL component tests along with local interconnection and PQ expectations. Ongoing technical support includes quarterly process audits, reliability data updates, and responsive application engineering to fine-tune laminated busbars, EMC filters, and thermal paths. Drawing on successful collaboration with 19+ enterprises, Sicarbtech brings a repeatable playbook that compresses time-to-revenue and lowers ramp risk.

“Standing up a SiC capability is less about buying equipment and more about repeatable metrology and process control. We transfer the routines that keep yield high and stable,” says a Sicarbtech process transfer lead, underscoring the firm’s long-term partnership approach.

Future Market Opportunities and 2025+ Trends: Distributed PV’s Next Chapter in Pakistan

Pakistan’s distributed PV will continue to expand as rooftops become energy assets for industry, commerce, and municipal facilities. Module-level electronics are poised for higher attachment rates where shading and mismatch are common. We expect SiC penetration in microinverters and power optimizers to climb toward 30–50% in higher-performance segments over the next several years, catalyzed by high-temperature corridors and weak-grid regions where module-level MPPT and robust thermal behavior pay outsized dividends.

Integration with storage and, in some cases, EV charging at the facility level will increase the value of efficient, high-frequency SiC platforms that communicate granular performance data. Bankability will hinge on reliability evidence under local stressors; consequently, suppliers who can generate and share accelerated life data aligned with Pakistan’s heat, dust, humidity, and UV exposure will gain an edge. Localized spare parts, responsive service networks, and phased assembly/test localization will further differentiate offerings in an FX- and logistics-sensitive procurement environment. The net effect is a market that rewards integrated materials–devices–equipment providers like Sicarbtech, capable of co-designing from die to rooftop deployment with measurable ROI.

よくある質問

What efficiency gains can Pakistani rooftops expect with SiC microinverters or power optimizers?

Typical projects see a 0.5–1.0 percentage point uplift in weighted efficiency versus newer silicon designs, with peak efficiencies of 97.0–98.5%. In hot months, the relative gain often increases due to lower temperature-induced losses.

How does Sicarbtech address dust, humidity, and UV on rooftops?

We combine low-parasitic modules with moisture-resistant gels, UV- and salt-mist-resistant coatings, robust passivation, and carefully chosen creepage/clearance strategies. These measures reduce ingress-related faults and extend service life.

Can SiC solutions help with interconnection and power quality requirements in Pakistan?

Yes. With controlled dV/dt, near-zero reverse recovery, and laminated busbars that cut loop inductance, waveforms are cleaner and THD around ~3% is practical with tuned filters. This simplifies PQ compliance and reduces commissioning cycles.

Which voltage classes are most relevant for microinverters and optimizers?

650 V devices are common for module-level stages, while 1200 V devices may be used where higher bus voltages or isolation stages require added margin. Sicarbtech configures on-board half-/full-bridge modules accordingly.

Why is sintered silver preferred over solder in rooftop electronics?

Sintered silver provides higher thermal conductivity and superior mechanical integrity, greatly improving power cycling life—especially important when dust-fouled surfaces elevate operating temperatures and thermal gradients.

Can Sicarbtech support localized assembly or full manufacturing in Pakistan?

Yes. Through technology transfer and factory establishment services, we provide process recipes, equipment specifications, training, quality frameworks, and commissioning support, enabling phased localization aligned with demand and capability.

What reliability testing is available for Pakistan-specific stressors?

We conduct power cycling, temperature cycling, high-temperature/high-humidity accelerated tests, salt-mist exposure for coastal contexts, and online screening. We share acceleration models and co-develop test plans to support extended warranties.

Will faster SiC switching aggravate EMC issues on mixed-use rooftops?

If unmanaged, fast edges can be challenging. Our low-parasitic packaging, laminated busbars, tuned gate resistors, and Miller clamping minimize ringing. In practice, properly co-designed SiC systems often require less bulky filtering than legacy designs.

How quickly can pilots be planned, executed, and evaluated?

In many cases, pilots can be executed within weeks to a few months. We recommend A/B testing with KPIs such as weighted efficiency, low-irradiance performance, thermal imaging, THD/PF logs, arc detection false-alarm rates, and maintenance intervals.

What total cost of ownership improvements are typical over 10–15 years?

Despite higher device costs, lower energy losses, smaller thermal systems, fewer maintenance visits, and longer lifetimes generally yield a lower TCO. In hot and dusty regions, these advantages are magnified.

オペレーションに適した選択

The strongest returns flow from solutions that reflect your rooftop realities: shading profiles, dust patterns, roof loading limits, and local PQ expectations. When Sicarbtech co-designs from die parameters and gate oxide reliability through laminated busbar geometry, high-frequency magnetics, EMC filters, and thermal interfaces, the gains become tangible—higher weighted efficiency, compact and lighter under-module units, quieter and lower-power thermal paths, and faster commissioning with fewer PQ surprises. For textiles, cement-adjacent rooftops, 鉄鋼 facilities, commercial centers, and municipal assets, this integrated SiC approach reduces risk and accelerates ROI.

専門家によるコンサルテーションとカスタムソリューション

Whether you are specifying new microinverters, retrofitting power optimizers, or exploring localized assembly and online screening, Sicarbtech’s team will help quantify the upside and de-risk each step. Share your target KPIs and site constraints, and we will propose a data-driven roadmap with milestones for performance, reliability, compliance, and localization. Contact: [email protected] | +86 133 6536 0038.

記事のメタデータ

Last updated: 2025-09-17

Next scheduled review: 2025-12-01

Content freshness indicators: 2025 Pakistan distributed PV outlook; SiC microinverter and optimizer architectures; 650/1200 V SiC MOSFETs and 3rd-gen Schottky diodes; sintered silver and AlN/Si3N4 substrates; ultra-thin laminated busbars; NEPRA/PQ compliance context; localization and technology transfer pathways; case narratives in Karachi, Faisalabad, and Lahore.

About Sicarbtech: Silicon Carbide Solutions Expert based in Weifang City, China’s SiC manufacturing hub; member of Chinese Academy of Sciences (Weifang) Innovation Park; 10+ years of SiC customization supporting 19+ enterprises; full-cycle solutions from material processing to finished products; specialties include R-SiC, SSiC, RBSiC, and SiSiC grades; services span custom manufacturing, factory establishment, and technology transfer.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.