予測メンテナンスとリモートテレメトリを備えたSiC電力システム監視および診断モジュール

シェア

製品概要と2025年の市場関連性

SiC電力システム監視および診断モジュールは、SiCベースの整流器、インバーター、UPS、およびDC電力シェルフを計測し、リアルタイムテレメトリ、予測保全、およびリモートライフサイクル管理を提供するインテリジェントなアドオンおよび組み込みユニットです。高周波および高温で動作するワイドバンドギャップパワートレイン向けに特別に設計されたこれらのモジュールは、シリコン時代のモニターでは見逃しがちな、高速電気過渡現象、熱勾配、スイッチング健全性、およびグリッド品質パラメータを捕捉します。

2025年のパキスタンにおけるこの重要性:

- グリッドの不安定性と熱:頻繁な電圧降下、サージ、高調波が、40〜45℃の周囲温度と組み合わさって、コンポーネントの経年劣化を加速させます。予測分析は、繊維、セメント、および 鉄鋼 施設における計画外のダウンタイムを防止し、データセンター/金融機械室のSLAを保護します。

- OPEXと人員配置:自動化された分析は、手動検査を削減し、スペアを最適化し、分散した通信および産業サイト全体でMTTRを短縮します。

- コンプライアンスとESG:継続的なPF/THDレポート、効率追跡、およびイベント監査は、NTDCグリッドコードの整合性と持続可能性ダッシュボードをサポートします。

Sicarb Techは、以下の監視モジュールを提供しています。

- SiC PFC/UPS/DCシステムへの組み込み基板(工場統合)。

- 既存の電力キャビネット用レトロフィットキット(DINレールまたはメザニン)。

- 安全なリモートアクセス、アラーム、およびAPI統合(SNMP/Modbus/CAN/REST)を備えたクラウド/エッジ分析スタック。

技術仕様と高度な機能

計測とデータ収集:

- 電気センシング

- 最大1 kV rms(グリッド)、1.2 kVdc(バス)の相電圧/電流、16〜24ビットADC、チャネルあたり最大500 kS/s

- SiCスイッチングノード用の高CMTI絶縁プローブ(≥100 V/ns)

- IEC 61000メソッドに準拠したPF/THD計算(最大50次高調波)

- 熱的および機械的

- マルチポイント熱入力:NTC/RTD、ダイ近傍センサー、オプションのファイバーブラッグ格子ポート

- ファン/ポンプRPM、振動(MEMS)、粉塵/粒子(オプション)、湿度センサー

- 予測保全モデル

- コンデンサESR/静電容量ドリフト推定と残存寿命(RUL)

- SiCモジュール用インダクタホットスポットエージングモデルとパワーサイクリングストレス

- ファン/ポンプベアリング寿命予測(L10)、コネクタの熱上昇検出

- 制御統合と安全性

- 読み取り専用タップとフェイルセーフ出力。ゲートドライバまたは保護を妨げません。

- 高速障害相関:DESATトリップ、過電流イベント、msレベルのタイムスタンプ付き過熱ログ

- 接続性とセキュリティ

- インターフェース:SNMPv3、Modbus-RTU/TCP、CAN、RESTful API。オプションのMQTTを使用してクラウドを保護

- デュアルイーサネット、RS-485、オプションのLTE/4G。TLS 1.2+、署名付きファームウェア、ロールベースのアクセス

- ソフトウェアと分析

- 異常検出のためのエッジ推論(電流/電圧のスペクトル分析)

- ダッシュボードKPI:PF、THD、効率、ΔTj推定、ステージ別のエネルギー損失、イベントヒートマップ

- ファームウェアOTAアップデート。30日以上のローカルバッファリングとストアアンドフォワード

- 環境とフォームファクター

- DINレールまたはメザニンカード。-20〜+70℃の周囲温度での動作。コンフォーマルコーティングオプション(IP54+エンクロージャ)

- コンプライアンスアライメント:IEC 61000-6-2/6-4(EMC)、IEC 62477-1(電力変換器)、IEC 62368(ICT機器)

Sicarb Techの差別化要因:

- 高速エッジ現象を捕捉するためのSiC対応サンプリング同期

- モデル調整用のパキスタン固有のグリッド障害プロファイルのライブラリ

- 変圧器容量、フィーダーインピーダンス、およびサイトSPDを統合する試運転ウィザード

SiCシステム向け、継続的な電力品質と健全性の可視化

| パキスタンのグリッドの可視性、精度、および稼働時間保護 | SiC監視および診断モジュール(Sicarb Tech) | 従来のキャビネットメーターとSCADAタップ |

|---|---|---|

| 高周波でのPF/THD精度 | 高調波50次までの高精度、SiCエッジセーフ | 限られた高調波範囲とノイズ耐性 |

| 熱/接合部の洞察 | ダイ近傍推論とマルチポイントセンシング | ヒートシンクのみの温度 |

| 予測保全 | アラート付きESR/インダクタ/ファンRUL | カレンダーベース、非予測型 |

| イベント相関 | 電源段階全体でのmsレベルのログ | 大まかなタイムスタンプとコンテキストの欠落 |

| リモートアップデート/セキュリティ | OTA、RBAC、TLS、署名付きイメージ | 基本的またはなし |

主な利点と実証済みのメリット

- 発生前に障害を防止:ESRの上昇、インダクタホットスポットドリフト、またはファンの劣化を数週間前に検出し、生産に合わせてメンテナンスをスケジュールします。

- 効率と電力品質を向上:ライブPF/THDとスイッチング損失テレメトリは、フィルタ調整と制御アップデートをガイドし、サイトコンプライアンスを強化し、OPEXを削減します。

- MTTRを短縮し、障害の繰り返しを回避:根本原因分析は、グリッドイベントとコンバータの応答を関連付け、トラブルシューティング時間を短縮します。

- 過酷な環境に対応:コーティングされた基板、粉塵センサー、および正圧ロジックは、セメント/繊維/製鉄所の状態に適応します。

専門家の言葉を引用する:

「高帯域幅センシングを備えた診断を組み込むことは、高周波でワイドバンドギャップデバイスを安全に活用するために不可欠です。予測保全は、もはやアドオンではなく、コア機能です。」— IEEE Power Electronics Magazine、Reliability of Wide-Bandgap Power Systems、2024年

実際のアプリケーションと測定可能な成功事例

- ラホールデータセンターUPSフリート:

- 200 kW SiC UPSモジュールに追加されたモニター。分析により、ESRとファンのRULの追跡が可能になりました。

- 結果:計画外の停止が12か月でゼロに減少。ファンカーブを最適化することにより、HVACエネルギーが7.9%削減。PF≥0.99、THD 2.3〜2.8%。

- ファイサラバード繊維VFDライン:

- SiCドライブでの振動および熱異常検出。

- 結果:夏季の迷惑トリップが26%削減。コンデンサの交換を事前に計画し、メンテナンス時間を18%削減。

- カラチセメントミルMCC:

- グリッド障害のタグ付けと自動制御調整の推奨事項。

- パフォーマンス:フィルタ再調整後、THDが6.8%から3.1%に低下。イベントヒートマップを使用して、故障発見時間が約40%短縮。

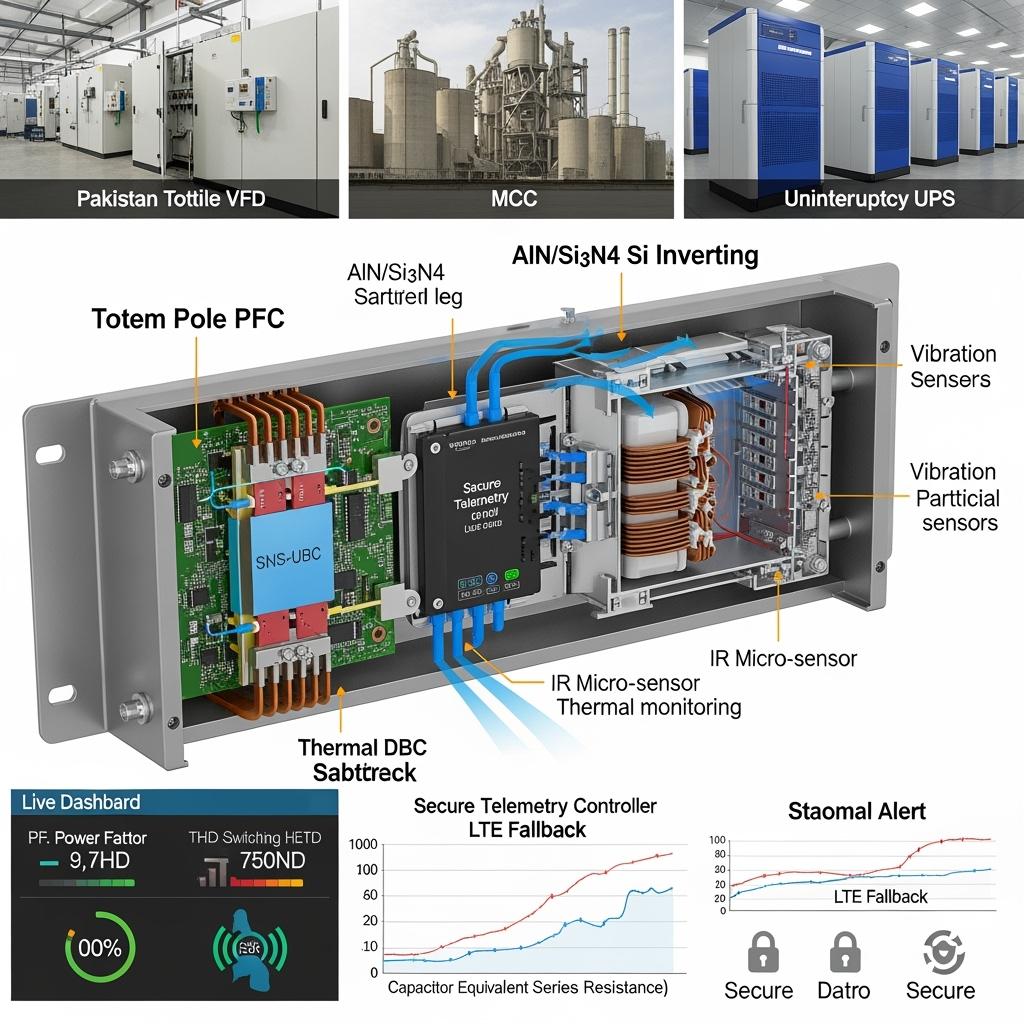

【画像プロンプト:詳細な技術説明】 3パネルダッシュボードの可視化:1)高調波バーとコンプライアンスフラグを備えたライブPF/THDスペクトル。2)コンデンサESRの上昇、インダクタホットスポットトレンド、およびファンRULを示すコンポーネント健全性タイムライン。3)グリッドサグをDESATトリップと熱スパイクにmsタイムスタンプで関連付けるイベント相関マップ。センサーコールアウト(電流プローブ、熱ダイオード、振動MEMS)を備えたキャビネット写真を含めます。写実的、4K。

選択とメンテナンスの考慮事項

- センサー戦略

- 電流/電圧センサーを、高CMTI絶縁を備えたスイッチングノードの近くに配置します。正確なΔTj推定のために、ダイ近傍の熱点を追加します。

- ミルおよび繊維サイトには、少なくとも1つの振動および粉塵センサーを含めます。

- ネットワークとサイバーセキュリティ

- 分離されたVLANまたはOTネットワークを使用します。RBACと証明書ベースの認証を適用します。安全なサイト向けにオフラインデータエクスポートパスを維持します。

- 分析調整

- サイトの負荷プロファイルとグリッド障害記録をインポートします。試運転後にESRベースラインを校正します。デバイスクラスごとにアラートしきい値(警告/クリティカル)を設定します。

- 環境保護

- コンフォーマルコーティングを適用します。粉塵がひどい場合は、IP54+エンクロージャと正圧を導入します。フィルタクリーニングアラートをスケジュールします。

- ライフサイクル計画

- KPIとトレンドドリフトの四半期レビュー。メンテナンスウィンドウでのファームウェアアップデート。迅速なフィールド交換のためにスペアセンサーキットを維持します。

業界の成功要因と顧客の声

- 成功要因:

- KPIと閾値を調整するために、UPS/ドライブ制御チームとの早期統合

- 熱モデルを検証するために、ピーク夏にパイロットを実施

- 施設ワークフローに関連付けられた明確なエスカレーションランブックとオンコールアラート

- ダッシュボードとAPIに関する施設/OTスタッフのトレーニング

- テストモニアル(カラチ金融機械室の施設長):

- 「予測アラートにより、故障したファンモジュールを交換する数週間前に通知を受けました。バイパスイベントを回避し、その過程で冷却エネルギーを削減しました。」

将来のイノベーションと市場トレンド

- 2025~2027年の見通し:

- SiCスイッチングシグネチャの異常分類のためのエッジAI

- より厳密なΔTj推定のための組み込みファイバーブラッグセンサーとダイ上温度プロキシ

- ライフタイム予測のためのテレメトリとミッションプロファイルを融合したデジタルツインモデル

- ESGレポートとグリッドサービス対応性を備えた、マルチサイトフリート全体の安全なクラウド集約

業界の視点:

「ワイドバンドギャップシステムの信頼性リーダーシップは、デバイス物理学からフリート運用までを閉じる組み込みの監視と分析にかかっています。」— IEA Technology Perspectives 2024、Power Electronicsの章

よくある質問と専門家による回答

- 監視は保護または制御ループに干渉しますか?

- いいえ。当社のモジュールは、制御信号をロードまたは変更しない、絶縁された読み取り専用センシングと時間調整されたサンプリングを使用しています。

- 接合部温度の推定精度はどのくらいですか?

- ダイ近傍センサーと校正された熱モデルを使用すると、ΔTj推定は通常、IRサーモグラフィベンチマークの±5〜8 K以内になります。

- 既存のシリコンベースのキャビネットを改造できますか?

- はい。DINレールキットはレガシーシステムをサポートします。分析は依然として価値を追加し、SiC対応モデルを選択的に有効にします。

- リモートサイトではどのような接続がサポートされていますか?

- デュアルイーサネット、RS‑485、およびオプションのLTE/4G(VPN/TLS付き)。ストアアンドフォワードにより、バックホール停止中のデータ損失が保証されます。

- 典型的なROIはどのくらいですか?

- 9〜24か月(ダウンタイムの回避、緊急呼び出しの削減、冷却の最適化から)。24時間365日のUPSおよびプロセスに不可欠なラインの場合は、より高速です。

このソリューションがお客様の業務に役立つ理由

Sicarb Techの監視および診断モジュールは、高速SiCデバイスの動作を実用的な洞察に変換します。障害を予測し、効率を最適化し、パキスタンの熱と粉塵の影響を受けやすい環境でのコンプライアンスを文書化します。その結果、可用性が向上し、OPEXが削減され、データセンター、通信ネットワーク、重工業全体でSiCテクノロジーを自信を持って拡張できます。

カスタムソリューションについては専門家にご相談ください

Sicarb Techで信頼性を変革:

- 中国科学院の支援による10年以上のSiC製造専門知識

- 堅牢な熱スタックのためのR‑SiC、SSiC、RBSiC、およびSiSiC全体でのカスタム開発

- 生産とテストを現地化するための技術移転と工場設立サービス

- 材料から完成したシステムまでのターンキーソリューション(監視、分析、コンプライアンスドキュメントを含む)

- 19以上の企業での実績。迅速なパイロット、KPI設計、およびROIモデリング

無料の監視準備評価と予測保全ROI計画をリクエストしてください。

- Eメール:[email protected]

- 電話/WhatsApp:+86 133 6536 0038

Q4 2025の統合スロットを予約して、シャットダウンウィンドウとピークシーズンの信頼性目標に合わせます。

記事のメタデータ

- 最終更新日:2025年9月11日

- 次回のレビュー:2025-12-15

- 著者:Sicarb Tech Reliability & Analytics Team

- Contact: [email protected] | +86 133 6536 0038

- 規格の焦点:IEC 62477-1、IEC 61000-6-2/6-4、IEC 62368。PECの慣行およびNTDCグリッドコードの電力品質基準に準拠

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.