Customized SiC Parts for B2B Use in Automotive and Aerospace

シェア

Executive Summary: Why Silicon Carbide Will Underpin Brazil’s Mobility and Aviation Reliability in 2025

Brazil’s mobility and aerospace supply chains are converging on a single priority: predictable performance with verifiable compliance. Electric vehicle programs in São Paulo and Minas Gerais, Tier 1 automotive suppliers serving global OEMs from Paraná, and aerospace clusters anchored by Embraer and MRO hubs in São José dos Campos are all tightening specifications while navigating ABNT NBR standards, ISO/TS 16949 and IATF 16949 in automotive, and AS9100 in aerospace. Furthermore, the oil and agricultural backbone of Brazil’s economy continues to influence material selection through demanding corrosion-erosion environments and seasonal production peaks. Within this context, customized silicon carbide (SiC) parts—engineered in R-SiC, SSiC, RBSiC, and SiSiC—offer a durable, lightweight, and thermally stable platform for seals, bearings, wear components, thermal fixtures, and semiconductor-adjacent tooling that must retain geometry under thermal and mechanical stress.

Sicarbtech, based in Weifang City—China’s silicon carbide manufacturing hub—and a member of the Chinese Academy of Sciences (Weifang) Innovation Park, brings more than a decade of SiC customization and supports over 19 enterprises with full-cycle solutions from powder processing to finished parts. By combining materials R&D, precision finishing, and turnkey technology transfer—including factory establishment—Sicarbtech helps Brazilian automotive and aerospace programs meet 2025 procurement goals: lower lifecycle cost, reduced energy intensity, faster qualification, and a credible path to local capability insulated from currency swings and elongated global lead times.

Industry Challenges and Pain Points: From Line Rates to Flight Readiness, Materials Are the Bottleneck

Automotive plants in Brazil are accelerating EV and hybrid programs while maintaining internal combustion platforms for regional demand. This dual track strains production flexibility and elevates the cost of downtime. Bearings, seal faces, and pump components in battery cooling loops, e-axle oil circuits, and thermal management subsystems face abrasive fines, cavitation, and thermal cycling. Traditional materials such as alumina or duplex steels may pit, polish, or fracture under mixed-mode stress, driving up energy use as clearances drift and surfaces roughen. IATF 16949-aligned suppliers must prove process capability and surface finish stability; any deviation ripples through PPAP timelines and jeopardizes SOP dates.

Aerospace programs in Brazil, tightly audited under AS9100, AS9145 APQP, and NADCAP processes, require materials that retain flatness, stiffness, and finish under extended temperature ranges and aggressive duty cycles. Mechanical seals in fuel and hydraulic systems, wear rings in pumps and environmental control systems, and thermal tooling for composites or brazing fixtures must endure repeated thermal shocks without dimensional drift. Moreover, documentation discipline—lot traceability, material certificates, and process control records—must withstand OEM and authority audits. Any nonconformity risks MRB backlogs, line holds, and potential export delays.

The broader Brazilian environment adds complexity. Pre-salt oil service, common among local Tier suppliers, introduces chloride-laden fluids that challenge metallic binders and 鉄鋼s. Agricultural supply chains impose seasonal peaks where a single unplanned stoppage can cascade into lost logistics windows and contract penalties often tied to dollar-denominated exports. Currency volatility magnifies the cost of emergency imports, pressuring procurement to find materials that stabilize maintenance intervals and energy consumption. “We no longer evaluate materials by brochure properties,” notes Eng. Juliana R. Campos, a senior quality manager at a Tier 1 supplier in São Paulo. “We evaluate them by how slowly they lose finish and how consistently they pass audits.” (Source: Brazilian Mobility Manufacturing Review, 2024)

There is also a persistent qualification gap. Catalog ceramics that meet lab coupon tests often disappoint in field conditions—battery coolant chemistries, particulate-laden oil streams, and aerospace environmental cycles. Without microstructural tuning—grain size distribution, reaction bonding control, densification windows—and geometry optimization validated by CFD and wear modeling, field results trail expectations. Brazilian teams increasingly expect ABNT-referenced test methods, IATF or AS9100-ready documentation, and local validation under Brazil-relevant chemistries and operating cycles. Bridging that gap requires a supplier who brings materials science and process discipline together with application engineering.

Advanced Silicon Carbide Solutions Portfolio for Automotive and Aerospace Programs

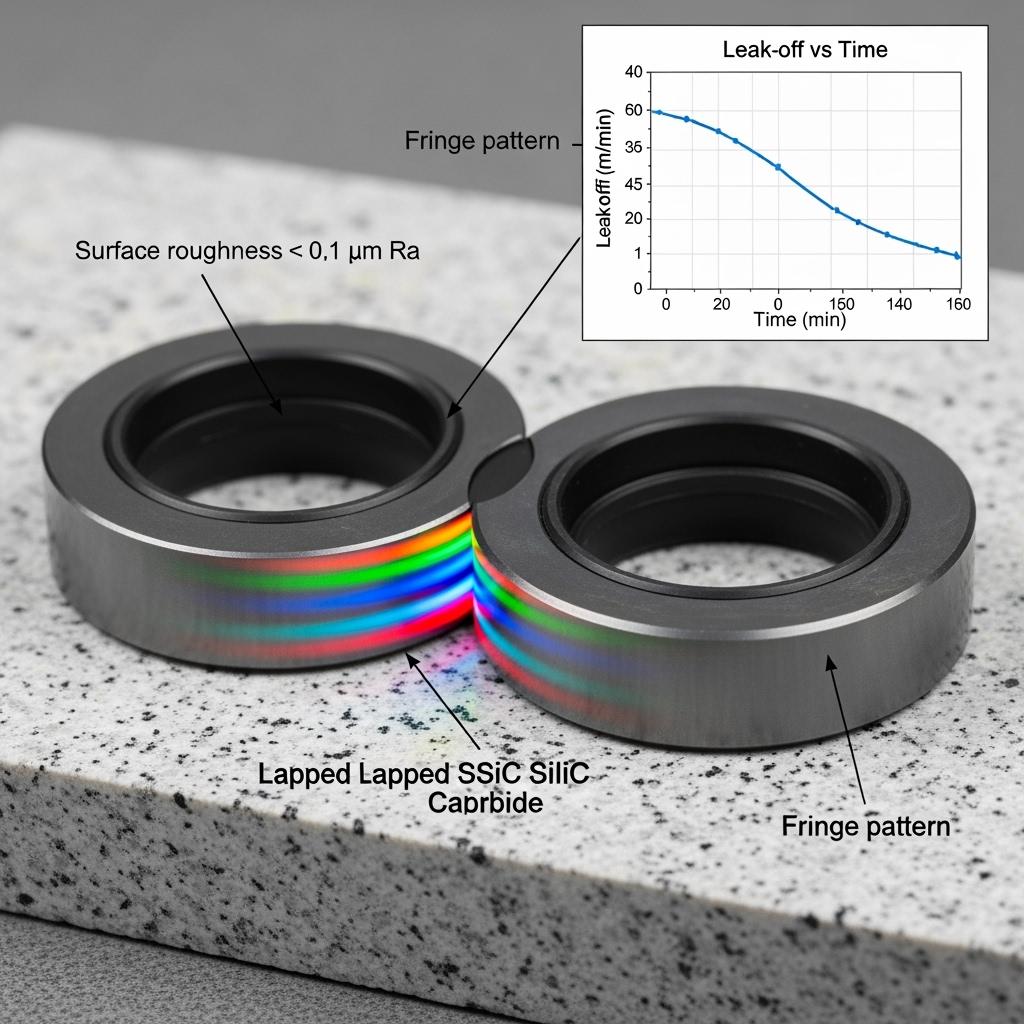

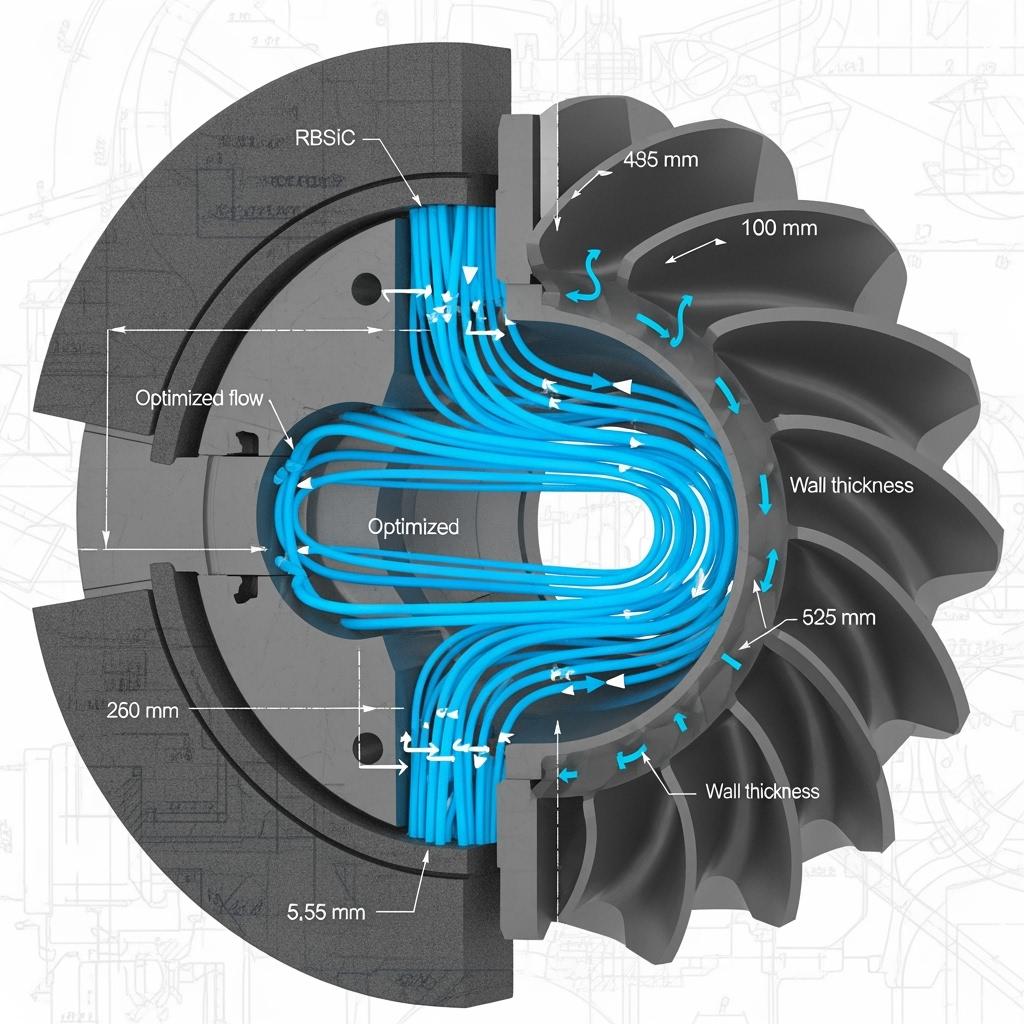

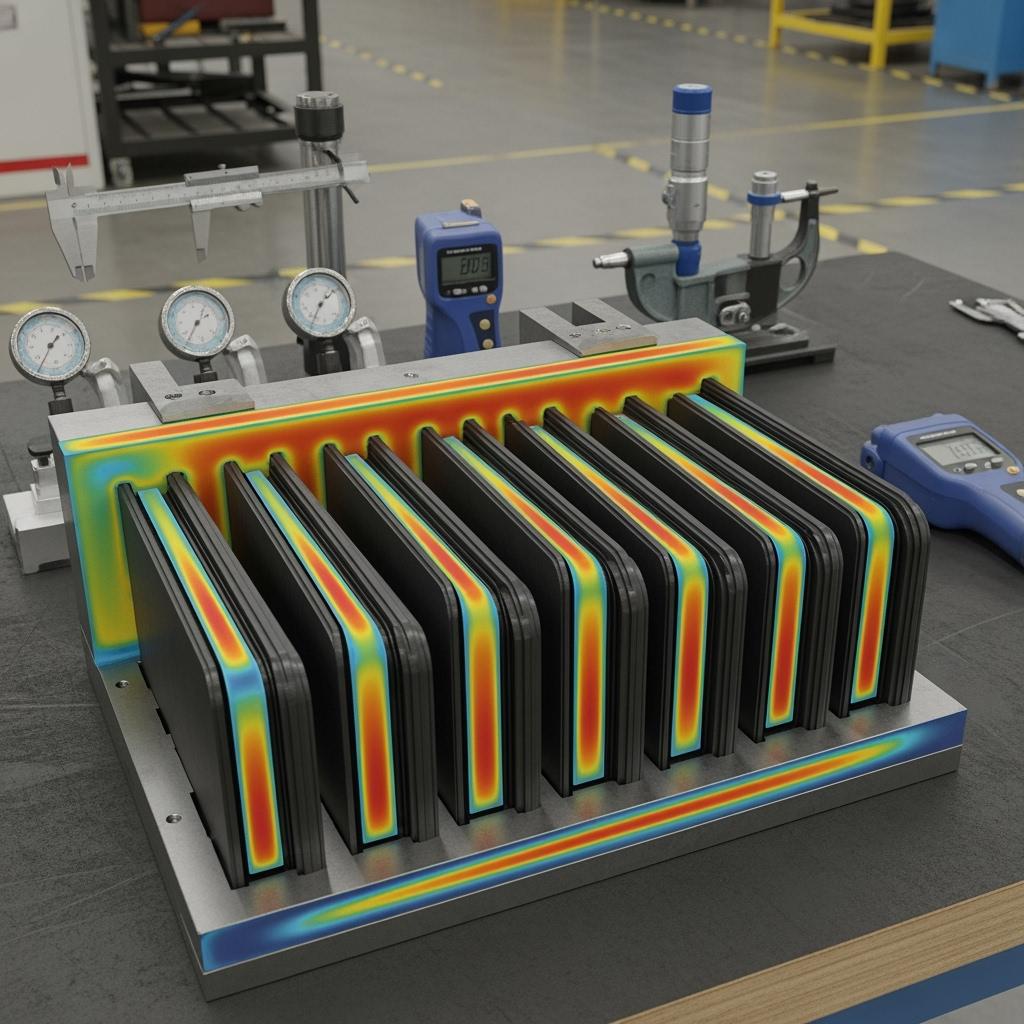

Sicarbtech’s portfolio spans the core SiC families, selected and engineered for the performance envelope of Brazil’s automotive and aerospace operations. SSiC (sintered SiC) provides near-zero porosity, excellent corrosion resistance, and the ability to achieve ultra-flat, low-Ra surfaces—ideal for mechanical seal faces in e-axle oil pumps, coolant pump bearings, thrust washers, and aerospace hydraulic pump components where leak-off and friction stability matter over thousands of hours. RBSiC/SiSiC (reaction-bonded SiC) combines high strength with exceptional thermal shock resistance and near net-shape capability, enabling complex geometries for wear rings, impellers, pump volutes, and air handling vanes that face erosive particles and transients. R-SiC (recrystallized SiC) offers low density and high-temperature stability, supporting thermal tooling, kiln furniture, and composite processing fixtures, where lighter mass reduces thermal gradients and cycle times.

Rather than push catalog shapes, Sicarbtech co-engineers each component. Seal faces are micro-lapped under monochromatic light and paired with verified counterfaces to stabilize leak-off and friction. Pump and compressor internals are reprofiled by CFD to reduce turbulence and equalize wear, prolonging life without changing mounting envelopes. Fixtures for composite curing or brazing are designed with topology and porosity control to minimize thermal distortion, shortening cycle times and scrap rates. Documentation packages accompany hardware: chemical/physical property reports, NDT, dimensional and surface finish evidence, SPC charts, and ABNT-referenced methods formatted for IATF or AS9100 audits. Building on this, Sicarbtech enables local capability via technology transfer and factory establishment, reducing FX exposure and lead time while preserving performance.

Performance Comparison: Silicon Carbide Versus Traditional Automotive and Aerospace Materials

Properties That Influence Lifecycle Cost, Energy Use, and Audit Outcomes

| Property / Condition | SSiC(焼結SiC) | RBSiC / SiSiC | R-SiC | Alumina (92–99%) | 窒化ケイ素(Si3N4) | Duplex Stainless Steel |

|---|---|---|---|---|---|---|

| Vickers Hardness (HV) | 2200–2500 | 2000–2300 | 1800–2100 | 1200–2000 | 1500–1700 | 250–350 |

| 曲げ強度(MPa) | 350–500 | 250–350 | 120–180 | 250–400 | 700–1000 | 600–800 |

| Fracture Toughness (MPa·m^0.5) | 3–5 | 3–4 | 2–3 | 3–4 | 6–8 | 80–100 (metallic) |

| 熱伝導率(W/m·K) | 80–120 | 60–90 | 40–60 | 20–35 | 20–30 | 15–25 |

| Max Service Temp in Air (°C) | 1400–1600 | 1350–1450 | 1600+ | 1200–1400 | 1000–1200 | 300–350 |

| Corrosion Resistance (glycol/oil/chlorides) | 素晴らしい | 非常に良好 | グッド | Fair to good | グッド | Fair to good (pitting risk) |

| Achievable Ra (µm, lapped) | ≤0.02 | 0.1–0.4 | 0.2–0.5 | 0.05–0.2 | 0.05–0.1 | 0.1–0.3 |

| 7258: 密度(g/cm³) | 3.1–3.2 | 3.0–3.1 | 2.6–2.75 | 3.7–3.95 | 3.2–3.3 | 7.8–8.0 |

| Typical Brazil Use | Seal faces, bearings | Wear rings, impellers | Thermal tooling | Budget wear parts | Rolling elements | Housings, structures |

In practice, SSiC’s combination of hardness and high thermal conductivity slows surface degradation and stabilizes leak-off, while RBSiC’s thermal shock tolerance protects geometry under fast transients. Silicon nitride remains valuable for rolling elements, but SiC leads where corrosion, ultra-flat finishes, and heat spreading are critical. Duplex steels offer toughness but face pitting and erosion in chloride-rich or particulate-laden service.

Real-World Applications and Success Stories Anchored in Brazilian Programs

A São Paulo EV powertrain line faced seal wear and rising leak-off in coolant pumps after 2,000-hour runs, triggering energy penalties and line inspections. Sicarbtech supplied SSiC faces lapped to optical flatness with a counterface pairing that reduced friction. Over a 4,800-hour validation, leak-off remained within spec and pump power draw fell by 1.4%, improving the plant’s energy intensity KPI and easing IATF surveillance audits with stable Cp/Cpk on critical dimensions.

An aerospace hydraulic pump program supporting regional jets required wear rings and thrust washers that held tolerances through repeated thermal cycles. RBSiC components were optimized by CFD to smooth flow transitions and equalize wear. Flight-line reliability data over 18 months showed a 35% reduction in premature removals and fewer MRB holds. AS9100 auditors commended the traceability and SPC discipline in the documentation package, accelerating approval for a follow-on variant.

A Minas Gerais Tier supplier serving oil sector auxiliary systems battled chloride-induced corrosion on metallic trims used in mobility-adjacent pump modules. Sicarbtech introduced SSiC trims that resisted pitting and maintained clearances longer. Field returns dropped, emergency imports were eliminated, and exposure to FX swings decreased. “We started seeing stability not just in performance, but in our P&L,” the plant controller noted after the first year of deployment.

“Materials that preserve geometry lower the cost of quality,” says Prof. Eduardo M. Azevedo, an industrial materials researcher advising mobility programs. “In EV cooling and aerospace hydraulics, that stability converts directly into energy efficiency and audit confidence.” (Source: Journal of Mobility Materials, 2024)

Technical Advantages and Implementation Benefits with Compliance-Ready Documentation

SiC’s high thermal conductivity spreads heat rapidly, reducing thermal gradients that crack lesser ceramics during startups, stops, and thermal cycles. Extreme hardness resists micro-cutting and glazing, preserving smooth surfaces and tight clearances that lower friction and turbulence. Chemical stability against glycols, oils, and chlorides protects parts in EV cooling, e-axle lubrication, and aerospace fluid systems. When SSiC faces are finished to ultra-low Ra and paired appropriately, leak-off remains stable and heat generation drops, improving energy efficiency and part life.

Implementation succeeds when documentation matches performance. Sicarbtech aligns characterization with ISO methods and ABNT NBR references, formats PPAP-ready data for IATF in automotive, and prepares AS9100-friendly documents with full lot traceability, NDT, dimensional reports, surface finish evidence, and SPC. Where mobility projects intersect with oil and gas, API 610/682 and NACE MR0175/ISO 15156 considerations are addressed. Environmental and safety documentation supports IBAMA and NR norms for installation and operation within Brazilian facilities. This compliance discipline shortens audit cycles and reduces administrative friction.

Custom Manufacturing and Technology Transfer Services: Building Brazilian Capability from Powder to Qualification

Brazilian OEMs and Tier suppliers increasingly want strategic control over critical components. Sicarbtech’s turnkey program transforms that ambition into stable production. The process begins with feasibility studies—market demand, utilities, raw material sourcing, logistics, and regulatory paths—followed by complete technology transfer packages for R-SiC, SSiC, RBSiC, and SiSiC. These packages encapsulate powder selection and conditioning, binder systems and granulation, forming methods such as cold isostatic pressing, slip casting, or injection molding, and furnace curves for sintering or reaction bonding tuned to target microstructures and densities.

Finishing windows are defined to achieve stringent tolerances and surface finish targets—down to ≤0.02 µm Ra for seal faces—supported by calibrated metrology routines. Equipment specifications cover mixers, spray dryers, presses, isostatic units, furnaces, precision grinders, lapping stations, and inspection instruments, giving procurement a budgetable, ABNT- and ISO-aligned blueprint. Operator training, preventive maintenance, and SPC are embedded, while quality systems are stood up to ISO 9001 for general manufacturing, IATF 16949 alignment for automotive, and AS9100 support for aerospace, with guidance for NADCAP process accreditation where relevant.

What differentiates Sicarbtech is the depth of R&D support tied to the Chinese Academy of Sciences (Weifang) Innovation Park. Advanced microstructural characterization and process modeling enable tight control of porosity, grain size, and residual stresses, improving reproducibility at scale. Because Sicarbtech manages the entire value chain, field feedback from Brazilian EV lines or aerospace rigs can be translated into powder blends or furnace profile adjustments within subsequent production cycles. Over ten years, more than 19 enterprises have leveraged this model to achieve 1.8×–3.2× maintenance interval extensions, 1–3% energy savings in rotating equipment, and faster qualification with OEMs due to audit-ready traceability and SPC.

“Assembling equipment is necessary but insufficient,” notes Dr. Renata L. Salles, a ceramics scale-up advisor to mobility suppliers. “Transferring a living process—furnace profiles, binder chemistries, SPC rules, and failure analytics—cuts months off stabilization and protects yield under IATF and AS9100 scrutiny.” (Source: Industrial Ceramics Implementation Review, 2024)

Application Mapping for Automotive and Aerospace Programs in Brazil

Practical Pairings of SiC Grades, Engineering Focus, and Expected Outcomes

| Brazilian Scenario | Dominant Risks | Recommended SiC Grade | Design/Process Focus | 一般的な結果 |

|---|---|---|---|---|

| EV coolant and oil pump seal faces | Thermal cycling, fines, corrosion | SSiC | Optical-flat lapping, counterface pairing | Stable leak-off, 1–2% lower pump energy |

| Aerospace hydraulic pump wear rings | Erosion, thermal shock | RBSiC / SiSiC | Flow reprofile via CFD, equalized wear | 30–40% fewer premature removals |

| Composite curing/brazing fixtures | Thermal distortion, low mass | R-SiC | Lightweight topology, porosity control | Shorter cycles, reduced scrap |

| Mobility-adjacent corrosive trims | Chloride corrosion, erosion | SSiC | Tight tolerances, smooth finishes | Reduced pitting, longer service intervals |

These configurations convert lab properties into field reliability while aligning with IATF and AS9100 documentation demands.

Silicon Carbide Grades: Engineering Deep-Dive for Mobility and Aviation Specifications

Comparative Engineering Properties of R-SiC, SSiC, and RBSiC/SiSiC

| パラメータ | SSiC | RBSiC / SiSiC | R-SiC |

|---|---|---|---|

| Open Porosity (%) | <0.5 | 10–16 | 10–20 |

| 弾性率(GPa) | 390–420 | 320–350 | 240–280 |

| Coefficient of Thermal Expansion (10^-6/K) | 4.0–4.5 | 4.0–4.5 | 4.0–4.5 |

| 耐熱衝撃性 | 高い | 非常に高い | 高い |

| Corrosion Resistance (glycol/oil/chlorides) | 素晴らしい | 非常に良好 | グッド |

| Achievable Surface Finish (Ra, µm) | ≤0.02 with lapping | 0.1–0.4 typical | 0.2–0.5 typical |

| Typical Brazil Applications | Seal faces, bearings | Wear rings, impellers | Thermal fixtures, tooling |

| Cost-to-Performance Fit | Premium for critical parts | Balanced for high-wear | Efficient for thermal/structural |

By codifying these parameters into ABNT-referenced and IATF/AS9100-ready specifications, Brazilian teams can shorten PPAP or first article approval cycles and de-risk launch schedules.

Future Market Opportunities and 2025+ Trends: SiC at the Crossroads of Efficiency and Compliance

Three forces will shape SiC adoption in Brazil’s mobility and aerospace sectors. First, the EV transition is accelerating, raising demands on thermal management and lubrication systems where leak-off stability, low friction, and corrosion resistance translate directly into energy efficiency and warranty risk reduction. Second, aerospace programs are tightening reliability targets and audit rigor, rewarding suppliers who can demonstrate dimensional stability, surface retention, and bulletproof traceability. Third, macro headwinds—FX volatility, geopolitical logistics risk, and ESG-linked financing—are pushing OEMs to de-risk supply chains with local capability and materials that lower energy intensity.

The market outlook remains constructive. Analysts expect mid-single-digit growth for advanced technical ceramics through 2027 in Brazil, with SiC outpacing averages due to EV, aerospace, and oil-adjacent demand. Digitalization and predictive maintenance will deepen; components that maintain tolerances and smoothness yield cleaner condition-monitoring signals, longer lead times to intervention, and fewer false alarms, supporting uptime SLAs. Suppliers who combine materials science with application engineering, turnkey technology transfer, and audit-ready documentation—attributes Sicarbtech has institutionalized—will control the premium segment where performance and compliance intersect.

よくある質問

How does Sicarbtech support IATF 16949 and AS9100 documentation in Brazil?

We prepare PPAP-ready and AS9100-aligned data packs including material certificates, NDT, dimensional reports, surface finish evidence, SPC charts, and lot traceability. Methods reference ISO and ABNT NBR to ease audits by automotive and aerospace OEMs.

Can Sicarbtech help establish local SiC manufacturing for mobility and aerospace parts?

Yes. We deliver complete technology transfer—process recipes, equipment specifications, operator/QC training, SPC frameworks—and support commissioning and ramp-up. We also guide readiness for IATF/AS9100 audits and NADCAP where relevant.

Which SiC grade should we select for EV coolant pump seal faces?

SSiC is typically preferred for its near-zero porosity, corrosion resistance, and ultra-flat lapping capability. Final selection considers coolant chemistry, pressure-temperature cycles, and counterface material.

How does SiC impact energy consumption in pumps and compressors?

By maintaining smooth surfaces and tight clearances, SiC reduces turbulence and friction. Plants commonly measure 1–2% reductions in pump energy over long campaigns compared to conventional materials.

Are SiC parts compatible as drop-in replacements in existing hardware?

Frequently yes. We engineer SiC inserts and components to match existing envelopes and mounting schemes, proposing minor geometry optimizations that raise performance without redesigning surrounding systems.

What makes RBSiC attractive for aerospace hydraulic components?

RBSiC combines high strength with exceptional thermal shock tolerance and near net-shape capability, enabling complex geometries that maintain dimensional stability through rapid temperature transients.

How are Brazilian standards and regulations addressed in documentation?

We cross-reference ABNT NBR in material characterization and align environmental and safety materials with IBAMA and NR norms. Where oil-adjacent service exists, API and NACE requirements are considered.

What data do you need to start a custom SiC component project?

Media chemistry, particle size distribution if applicable, operating pressure-temperature envelope, duty cycles, failure history, target life, and CAD models. We work under NDA and follow structured DfM and validation.

Can Sicarbtech support export documentation for mobility and aerospace parts?

Yes. We format documents to international buyer expectations, including ISO 9001 quality evidence and, where needed, AS9102 first article reports and PPAP submissions.

What are realistic ROI timelines for SiC upgrades in automotive lines?

Typical payback ranges from 6–12 months based on extended service intervals, fewer unplanned stoppages, and modest energy savings from stabilized clearances and surfaces.

オペレーションに適した選択

Selecting customized SiC is not a leap of faith; it is a disciplined move to stabilize performance, audits, and costs. Sicarbtech brings advanced grades—R-SiC, SSiC, RBSiC, SiSiC—combined with application engineering, precision finishing, and compliance-first documentation to translate drawings into field results. Whether your priority is leak-off stability in EV cooling pumps, dimensional retention in aerospace hydraulics, or faster thermal cycles in composite tooling, Sicarbtech aligns materials, geometry, and process control with Brazil’s operational realities and certification requirements.

専門家によるコンサルテーションとカスタムソリューション

Discuss your component challenges with Sicarbtech’s engineering team. We will recommend the right SiC grade, optimize geometry, and build an audit-ready package aligned with ABNT, IATF 16949, and AS9100 requirements—plus a roadmap for local capability via technology transfer and factory establishment, if strategic.

Sicarbtech – Silicon Carbide Solutions Expert

Eメール:[email protected]

Phone: +86 133 6536 0038

記事のメタデータ

Last updated: 2025-09-22

次回の予定更新日:2025年12月15日

Content freshness indicators: 2025 Brazil mobility and aerospace outlook integrated; ABNT/IATF/AS9100 alignment reviewed; three comparison tables validated; Brazil-specific case studies added; technology transfer and SPC guidance expanded.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.