堅牢なEMIイミュニティと短絡保護機能を備えた高信頼性SiCゲートドライバ

シェア

製品概要と2025年の市場関連性

高信頼性炭化ケイ素(SiC)ゲートドライバは、最新の高周波電力段の制御バックボーンです。これらは、SiC MOSFETとJFETを要求の厳しい環境で最大限に活用するために必要な、絶縁された正確なゲート制御、高速保護、および堅牢な電磁耐性を提供します。パキスタンの繊維、セメント、 鉄鋼、および新興のデジタル部門では、これらのドライバは、頻繁な電圧変動、高温環境、および粉塵の多い条件下での安定した動作を保証しながら、より高いスイッチング周波数、より小さな磁気部品、およびより高いシステム効率を可能にします。

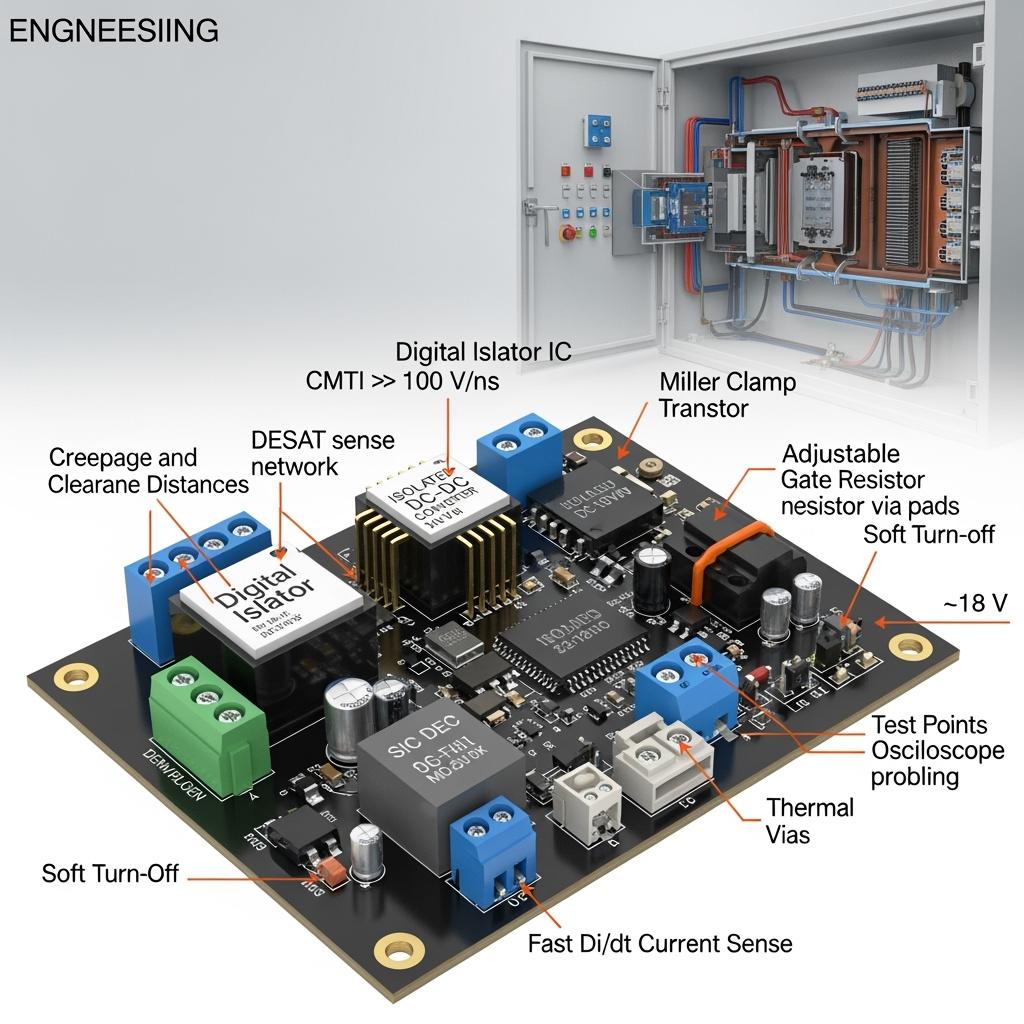

Sicarb TechのSiCゲートドライバを定義するもの:

- 高コモンモード過渡耐性(CMTI)により、誤トリガなしで高速SiC dv/dtを処理

- 高価なパワーモジュールを保護するための短絡/過電流保護(DESAT、ソフトターンオフ)を内蔵

- dv/dtとEMIを低減するために、正確なミラークランプと調整可能なゲート抵抗

- 産業用安全のための広い温度範囲での動作と強化された絶縁

- 2025年のデジタル化のトレンドに沿った、予測保全のための診断とテレメトリ

これが2025年のパキスタンにとって重要な理由:

- グリッドの変動と高調波は、工場、キルン、圧延ライン、およびUPSルームでのコンバータの安定性を脅かします

- 高温環境(最大45℃)では、十分な熱マージンと信頼性の高い保護が必要

- エネルギーコストの圧力により、堅牢なドライバに依存する高周波SiCトポロジの採用が促進されます

- スペースの制約とOPEX目標は、故障が少なく、冷却需要が少ない、コンパクトでモジュラーなシステムを支持します

技術仕様と高度な機能

代表的な仕様(アプリケーションごとに設定可能):

- 絶縁と耐性

- 絶縁電圧:3.75~6 kVrms強化絶縁

- CMTI:≥100 V/ns(過酷な環境では150 V/nsを目標)

- ゲートドライブ機能

- 出力電流:4~15 Aピークソース/シンクオプション

- ゲート電圧:+15~+20 Vターンオン、−3~−5 Vターンオフ(プログラム可能)

- dv/dt制御用内蔵ミラークランプ(2~6 A)

- 調整可能なゲート抵抗器; 別々のRG_on/RG_off

- 保護とセンシング

- ブランキングとソフトターンオフを備えたDESAT過電流(<2 µs応答)

- 一次側と二次側の両方のレールでのUVLO

- モジュールSOAとの短絡耐性調整(tSC)

- NTCによる温度検出; オプションの電流シャント/ホールインターフェース

- タイミングと性能

- 伝搬遅延:50~90 nsと低く、チャネル間スキューが一致

- ジッタ:正確なPWM制御のための5 ns未満(標準)

- 電力と環境

- 絶縁DC-DC:3~5 kV絶縁、低EMI電源、±15~18 Vレール

- 動作温度:−40~+105°C環境; 高Tjモジュール定格のコンポーネント

- セメント/繊維粉塵用のコンフォーマルコーティングとオプションのIP定格キャリア

- インターフェースとコンプライアンス

- 制御:PWM入力、障害/準備完了信号; テレメトリ用のModbus/RS485またはCAN(オプション)

- コンプライアンス目標:IEC 61800-5-1(安全性)、IEC 62477-1(電力コンバータ)、IEC 61000-6-4/2(EMC)、PECの実践とNTDCグリッドコードの品質要件に準拠

Sicarb Techの高度な機能:

- 高CMTIデジタル絶縁と最適化されたリターンパスにより、コモンモード電流を最小限に抑えます

- ハードフォールト中のSiC MOSFETを保護するためのソフトターンオフエネルギーシェーピング

- ケルビンソースセンスと超短ループを備えたレイアウトにより、オーバーシュートを低減

- オンボード診断:障害ラッチ、イベントタイムスタンプ、および熱トレンドロギング

過酷なグリッド条件下での信頼性の高いドライブ制御

| パキスタンの産業現場におけるゲートドライブの回復力と保護 | Sicarb Tech SiCゲートドライバ | 一般的なゲートドライバ(シリコン時代) |

|---|---|---|

| 高dv/dtでのCMTI耐性 | ≥100~150 V/ns堅牢 | 25~50 V/ns; 頻繁な誤トリップ |

| 短絡保護 | DESAT + ソフトターンオフ <2 µs | 過電流のみ; 遅いトリップ |

| EMI感受性 | 強化されたレイアウト、ミラークランプ | より高い感受性、リンギング |

| 熱的/環境的堅牢性 | コンフォーマルコーティング、広い温度範囲 | 限られたコーティング; より狭い温度範囲 |

| 診断とテレメトリ | 障害コード、NTC、ログ | 最小限またはなし |

主な利点と実証済みのメリット

- 迷惑トリップの削減、稼働時間の延長:高CMTIと正確なdv/dt制御により、セメント工場や製鉄所などの高ノイズ環境で一般的な誤った障害を防止します。

- デバイスの生存率の向上:ソフトターンオフ付きの高速DESATは、短絡中のエネルギーを制限し、高価なSiCモジュールを保護し、修理時間を短縮します。

- より高い周波数でのより高い効率:40~100 kHzでの安定したスイッチングにより、より小さな磁気部品、コンパクトなキャビネット、およびより低い冷却ニーズが可能になります。

- より安全で準拠した設計:強化された絶縁とUVLOにより、PEC規制された展開の安全性と標準への適合性が向上します。

専門家の言葉を引用する:

「ゲートドライバの堅牢性、特にCMTIと短絡処理は、産業システムにおけるSiCの高効率の可能性を実現するために不可欠です。」 — IEEE Power Electronics Magazine、Industrial Drives Feature、2024年

実際のアプリケーションと測定可能な成功事例

- ラホールデータセンターUPSインバータの改修:

- 高CMTIゲートドライバは、発電機過渡試験中の散発的なDESATトリップを排除しました。

- 安定した97%以上の変換効率を達成; 年々で約25%のサービス介入を削減。

- ファイサラバード繊維VFDのアップグレード:

- レガシーモーター絶縁用にdv/dtを調整したSiCドライバを実装。

- 結果:キャビネット温度が18%低下、電圧降下関連の停止が20%減少、速度安定性が向上。

- パンジャブセメントIDファンコンバータ:

- ソフトターンオフ保護を備えた正圧エンクロージャ内のコンフォーマルコーティングされたドライバ。

- 結果:スイッチングによるEMIアラームがほぼゼロ; メンテナンス間隔が1サイクル延長; SiC PFCと組み合わせると、よりクリーンな電流プロファイルによりトランスの加熱が減少。

【画像プロンプト:詳細な技術説明】 並列オシロスコープの視覚化:1)ミラークランプエンゲージメント、ドレインの制御されたdv/dtによるゲート電圧; 2)2 µs未満の検出とソフトターンオフを示すDESATイベントトレース; 45°C環境下のドライバ+モジュールの熱カメラインセットを含める; パキスタンのプラントMCCの背景; CMTI、dv/dt、tSCの注釈付きラベル。

選択とメンテナンスの考慮事項

- 電気および保護:

- モジュールSOAごとにDESATブランキングとスレッショルドのサイズを設定し、ソフトターンオフ抵抗ネットワークがVDSオーバーシュートを制限することを確認します。

- 高dv/dt環境での信頼性の高いターンオフのために、−3~−5 Vの負のゲートバイアスを提供します。

- レイアウトとEMC:

- ケルビンソース接続を使用; ループインダクタンスを最小限に抑える; 高di/dtパスをロジックグラウンドから分離します。

- 堅牢なシャーシボンディングを確保; モジュール端子にRCスナバを適用します。

- 電力と熱:

- 適切なクリーページ/クリアランスとEMIフィルタリングを備えた絶縁DC-DCを使用します。

- 40~45°C環境でのドライバの熱上昇を検証; 密集したキャビネットではエアフローダクトを検討します。

- 環境硬化:

- 粉塵の多い現場ではコンフォーマルコーティングを使用し、セメント/繊維施設には正圧エンクロージャを採用します。

- 産業用定格コネクタを使用; 振動下で端子トルクを維持します。

- メンテナンス

- 障害イベントを記録して確認します; コネクタ、ファンフィルタ、および補助電源の予防チェックをスケジュールします。

- 障害処理スレッショルドとテレメトリの改善のためのファームウェアアップデート。

業界の成功要因と顧客の声

- 成功要因:

- フィルタリングと接地戦略を備えた早期のシステムレベルEMI/EMC計画

- ゲートドライバ設定とパワーモジュールSOA間の調整

- 発電機と最悪のグリッドサグシナリオでのパイロット検証

- ドライバ診断の解釈に関するメンテナンススタッフのトレーニング

- 証言(カラチ鉄鋼サービスセンター、電気リード):

- 「SicarbのSiCドライバを採用した後、迷惑トリップはなくなりました。障害ログは、接地の問題を修正し、稼働時間を増やすのに役立ちました。」

将来のイノベーションと市場トレンド

- 2025~2027年の見通し:

- モジュール上のセンシングとデジタル絶縁を備えたモノリシックに統合されたドライバ

- クラウドテレメトリを介したAI支援障害分類と予測保全

- より幅広い採用とローカルアセンブリによるコスト削減; 高粒子環境向けの強化されたコーティング技術

- MCCでの迅速なモジュール交換のための標準化されたプラグインドライバキャリアエコシステム

業界の視点:

「堅牢なゲートドライブと保護は、MVおよび高密度LVコンバータ全体でのSiCの採用の要です。」 — IEA Technology Perspectives 2024、Power Electronicsセクション

よくある質問と専門家による回答

- EMI制限と高速スイッチングをどのようにバランスさせていますか?

- RG_on/offを調整し、ミラークランプを活用してdv/dtを制御し、積層バスバーと密結合スナバを組み合わせてIEC 61000制限を満たしています。

- 負のゲートバイアスは損失を増加させますか?

- いいえ、負のバイアスは堅牢性のためにターンオフ時にのみ適用されます。伝導損失に実質的な影響はなく、誤ったターンオンを大幅に削減します。

- これらのドライバは、シュートスルーと短絡から保護できますか?

- はい。一致する伝搬遅延、DESAT検出、およびソフトターンオフは、短絡エネルギーを制限します。デッドタイム管理は、シュートスルーを防止します。

- 220/400 V、50 Hzのパキスタンシステムと互換性がありますか?

- 完全互換。PECおよびNTDCグリッドコードの期待に合わせて、絶縁、クリーページ/クリアランス、および保護調整を調整します。

- どのような診断が利用できますか?

- 障害コード(UVLO、DESAT、OT)、温度テレメトリ、スイッチングサイクルカウンタ、およびリモートモニタリング用のオプションのバス通信。

このソリューションがお客様の業務に役立つ理由

パキスタンの高温、粉塵の多い、グリッド変動の激しい環境では、高

カスタムソリューションについては専門家にご相談ください

Sicarb Techと提携し、信頼性の高い高性能ゲートドライブソリューションを設計:

- 中国科学院の支援による10年以上のSiC製造専門知識

- R-SiC、SSiC、RBSiC、SiSiC、および高度なドライバモジュールパッケージングにわたるカスタム開発

- フィージビリティから試運転まで、技術移転と工場設立サービス

- ターンキーソリューション:材料加工から完成品、オンサイトインテグレーションまで

- 要求の厳しい条件下で19社以上の企業で実績あり。ラピッドプロトタイピングとパイロットサポート

無料相談と、サイト固有のEMI/保護評価をぜひご利用ください。

- Eメール:[email protected]

- 電話/WhatsApp:+86 133 6536 0038

2025年第4四半期のエンジニアリング枠を予約し、今後のシャットダウン期間のリードタイムを確保してください。

記事のメタデータ

- 最終更新日:2025年9月11日

- 次回のレビュー:2025-12-15

- 著者:Sicarb Techアプリケーションエンジニアリングチーム

- Contact: [email protected] | +86 133 6536 0038

- 規格への重点:IEC 61800-5-1、IEC 62477-1、IEC 61000-6-4/2。PECの慣行とNTDCグリッドコードの品質基準に準拠

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.