通信、エッジコンピューティング、および産業用DCグリッド向けの高周波、高密度SiC DC電力システム

シェア

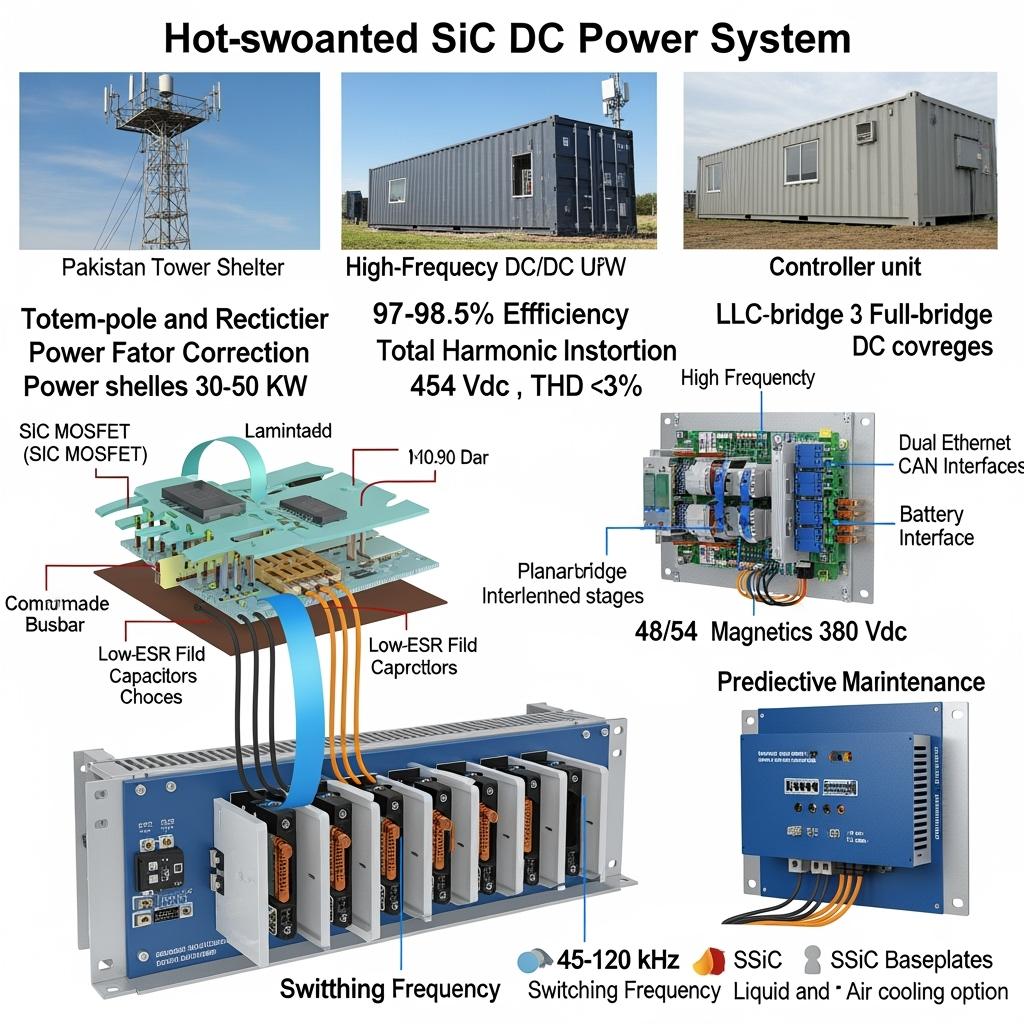

製品概要と2025年の市場関連性

高周波、高密度炭化ケイ素(SiC)DC電力システムは、SiC MOSFETとダイオードを高度な磁気素子、デジタル制御、および堅牢な熱パッケージングと統合し、通信サイト、エッジコンピューティングノード、および産業用DCグリッド向けのコンパクトで効率的なDC変換を提供します。パキスタンで一般的な周囲温度の上昇とグリッド障害の下で確実に動作するこれらのシステムは、48〜54 Vdc(通信)、380〜400 Vdc(HVDC配電)、およびドライブとプロセス機器用のカスタムDCバスを厳密に調整します。

2025年がパキスタンで重要な理由:

- ネットワークの高密度化:4G/5Gの拡張とエッジコンピューティングには、高い信頼性と低いOPEXを備えたコンパクトな整流器とDC電力シェルフが必要です。

- 産業の近代化:繊維、セメント、および 鉄鋼 プラントは、より高い効率とより簡単なエネルギー貯蔵統合のために、DCマイクログリッドを採用することが増えています。

- 電力品質の課題:頻繁な電圧降下、サージ、高調波は、低THD、高PF、および安定したDCレールを維持するフロントエンドを必要とします。

- 持続可能性とコスト圧力:SiCの損失

Sicarb Techは、3kW整流ブリックから30~100kWラックモジュール、250kW以上のキャビネットシステムまで、ターンキーSiC DC電源プラットフォームを提供しており、トーテムポール/Viennaフロントエンド、高周波絶縁DC/DC段、および回復力とリモート管理のためのインテリジェント制御を特徴としています。

技術仕様と高度な機能

アプリケーション(通信、エッジ、産業用DCグリッド)ごとに設定可能:

- 電気定格

- AC入力:220/230Vac単相または380/400/415Vac三相、50Hz

- DC出力:

- 通信:48/54Vdc(±1%調整)、ブリックあたり60~300A、並列接続で3kA以上

- エッジ/IT DC:380~400Vdc HVDC配電、棚あたり5~50kW

- 産業用DCグリッド:350~800Vdc設定可能、キャビネットあたり30~250kW、MWまで並列接続可能

- PFCフロントエンド:PF≧0.99、入力THD≦3%(高調波補償あり)

- 効率と周波数

- 段効率:定格負荷で97.0~98.5%、20~30%負荷で96%以上

- スイッチング:45~120kHz PFC、60~150kHz DC/DC(LLC、位相シフトFB)

- 制御と保護

- デジタル制御(MCU/FPGA)、平均電流制御、適応デッドタイム、軽負荷効率のためのバースト/スキップ

- 保護:OCP、OVP/UVP、OTP、出力ORing、アクティブ突入電流制御、サージ耐性(IEC 61000-4シリーズ)

- バッテリー/ESSカップリングのためのライドスルー、ブラウンアウト回復、ソフトスタートシーケンス

- 熱的および機械的

- SSiC/RBSiCヒートスプレッダー、銀焼結アタッチ、AlN/Si3N4 DBC

- 空冷3~15kWブリック、30~250kW密度用の液冷棚/キャビネット

- ブラインドメイト電源/データ付きホットスワップ可能なモジュール、ほこりの多い場所向けのIP定格オプション

- モニタリングと統合

- SNMP、Modbus-RTU/TCP、CAN、リモートファームウェアアップデート、サイバーセキュリティで強化されたアクセス

- 分析:コンデンサESRドリフト、インダクタ温度、ファン/ポンプの健全性、入力歪みメトリック

- バッテリー/ESSインターフェース:48VまたはHV DCカップリング、BMS統合、ピークシェービング、ブラックスタート

- コンプライアンスの調整

- IEC 62368/60950(ICT安全性)、IEC 62477-1(電力変換器)、IEC 61000-3-2/3-12(高調波)、IEC 61000-6-2/6-4(EMC)

- 電力品質に関するPECおよびNTDCグリッドコードに準拠した慣行

Sicarb Techのオプション:

- 3kW~10kWブリックを備えた通信棚キット(19インチ/23インチ)

- LFP/LTOバッテリーカップリングを備えた380VdcエッジDC棚

- PV/BESSを統合するための双方向DC/DCを備えた産業用DCグリッドキャビネット

パキスタンのネットワークとプラントのためのクリーンな電力とコンパクトなフットプリント

| 通信/エッジ/産業用DCのための電力品質、密度、および回復力 | SiC高周波DC電源システム(Sicarb Tech) | 従来のシリコンDC電源システム |

|---|---|---|

| 段効率(定格) | 97.0~98.5% | 91〜94% |

| 電力密度 | 10kW/L以上実現可能 | 4~6 kW/L |

| 入力電力品質 | PF ≥0.99、THD ≤3% | PF 0.95〜0.98、THD 5〜10% |

| 環境への耐性 | 40~45℃で定格削減計画で信頼性あり | 35~40℃以上で大幅な定格削減 |

| メンテナンス | 予測可能、ホットスワップ可能 | 定期的な手動およびより長いMTTR |

主な利点と実証済みのメリット

- エネルギーと冷却の節約:損失の削減と小型ヒートシンクにより、シェルターとエッジコンテナのHVAC需要が減少します。

- スペース効率:高密度化により、ラック/キャビネットのスペースが無線機またはIT負荷のために解放され、サイトのCAPEXが削減されます。

- 電力品質と稼働時間:ほぼ1のPFと低いTHDにより、フィーダーが安定し、誤トリップと変圧器の加熱が減少します。

- 厳しい環境での信頼性:セラミック熱経路、コンフォーマルコーティング、防塵メカニズムは、セメント、繊維、鉄鋼の現場に適しています。

専門家の言葉を引用する:

「SiCベースの整流器とDC/DCコンバータは、高い周波数で高効率を達成し、優れた電力品質を備えたコンパクトなDC電源棚を実現します。これは、通信およびエッジ展開に最適です。」— IEEE Power Electronics Magazine、ICT向け高密度DC電源、2024年

実際のアプリケーションと測定可能な成功事例

- カラチメトロセルサイト(通信シェルター):

- 19インチ棚に3kW SiC整流ブリック、54Vdc出力。

- 結果:サイトエネルギーが約8%削減、PF≧0.99、THDが7%から2.5%に削減、ファンデューティが45℃の環境で30%削減。

- ラホールエッジマイクロデータセンター:

- 液冷およびESSカップリングを備えた30kW 380Vdc SiC棚。

- パフォーマンス:DCバス効率98.1%、フットプリントが28%削減、2回のサグイベント中の自律的なライドスルー、ITダウンタイムゼロ。

- ファイサラバード繊維DCグリッドパイロット:

- 複数のVFDとプロセス負荷に供給する250kW産業用DCキャビネット。

- 結果:プロセスエネルギーが5.6%削減、ケーブル/変圧器の温度が低下、熱応力の低下によりメンテナンス間隔が1シーズン延長。

【画像プロンプト:詳細な技術説明】 3つのシーンのインフォグラフィック:1)ホットスワップ可能な3~5kW SiCブリック、54Vdcバスバーを備えた通信19インチ棚、2)液冷棚とESSを備えたエッジデータセンター380Vdcラック、3)PV/BESSカップリングと双方向DC/DCを備えた産業用DCキャビネット。オーバーレイは、PF≧0.99、THD≦3%、97~98.5%の効率、45~120kHzのスイッチング、および環境45℃の熱マップを示しています。フォトリアリスティック、4K。

選択とメンテナンスの考慮事項

- 電圧とトポロジー

- RANサイトには48/54Vテレパワー棚を選択、エッジ/ITには380~400Vdc、産業用DCバスには350~800Vdcを選択。

- フロントエンドにはトーテムポール/Vienna PFC、絶縁と高効率にはLLCまたは位相シフトFB。

- 熱戦略

- 3~10kWブリックと適度な環境には空冷、30~250kWシステムまたは限られた部屋には液冷を推奨。

- TIMの選択とベースプレートの平坦性を検証し、ホットスポットの緩和にはSSiC/RBSiCスプレッダーを検討してください。

- EMCとグリッドインターフェース

- ローカルインピーダンスに合わせてフィルタを調整し、IEC 61000に準拠したエミッション/イミュニティを現場で検証します。

- サージ保護(MOV/TVS)を施設のSPD階層と連携させます。

- 信頼性とサービス

- コンデンサ、インダクタ、ファン/ポンプの健全性に関する予測分析を有効にします。

- ホットスワップスペアを在庫し、コネクタとフィルタの四半期ごとの検査、ほこりの多いプラントの場合は月次検査を計画します。

- 統合と制御

- SCADA/DCIM接続(SNMP、Modbus、CAN)を確保し、安全なリモートファームウェアアップデートを行います。

- 夏のピークと高度に応じて、定格削減曲線を設定します。

業界の成功要因と顧客の声

- 成功要因:

- 展開前の高調波調査と変圧器負荷分析

- 高周波動作のための磁気部品と熱設計の共同設計

- 定格削減とファンカーブを最終決定するために、最も暑い月にパイロットを実施

- ホットスワップ手順とリモート診断に関する従業員トレーニング

- 推奨の声(ネットワークパワーマネージャー、主要通信事業者):

- 「SiC棚はフィーダーPFとTHDを安定させ、シェルターエネルギーを削減しました。ホットスワップ可能なブリックと分析により、MTTRが削減されました。」

将来のイノベーションと市場トレンド

- 2025~2027年の見通し:

- エッジサイトでのピークシェービング、急速充電、およびグリッドサービスのためのBESSを備えた統合DC電源

- さらなるCMTIと低いEMIのための共パッケージ化されたドライバとセンシング

- 200mm SiCウェーハの経済性により、kWあたりのコストが削減され、リードタイムを短縮するためのローカルアセンブリパートナーシップ

- グリッド歪みと熱ドリフトにリアルタイムで対応するAI駆動の適応制御

業界の視点:

「DC配電とワイドバンドギャップ変換は、効率的なエッジおよび産業用電力アーキテクチャの中心です。」— IEA Technology Perspectives 2024、電力電子章

よくある質問と専門家による回答

- 歪んだフィーダーでPF≧0.99およびTHD≦3%を維持できますか?

- はい。当社のSiCフロントエンドは、高調波補償と堅牢な制御を使用して、典型的なパキスタンのグリッド歪みプロファイル全体で目標を達成します。

- どれくらいのスペースとエネルギーを節約できますか?

- 負荷率と冷却に応じて、サイトレベルで20〜35%のフットプリント削減と5〜10%のエネルギー節約を期待できます。

- システムはホットスワップ可能でスケーラブルですか?

- はい。ブリックと棚はホットスワップ可能であり、キャビネットはアクティブ電流共有によりMWスケールにシームレスに並列接続できます。

- 高密度化には液冷が必須ですか?

- 必ずしもそうではありません。空冷ブリックはそれぞれ約10kWで十分です。30〜250kWの棚/キャビネットまたは狭い熱エンベロープには液冷が推奨されます。

- バッテリーとPVとの統合についてはどうですか?

- BESSカップリングとPV対応入力用の双方向DC/DCを提供し、ライドスルー、ピークシェービング、ブラックスタートを可能にします。

このソリューションがお客様の業務に役立つ理由

Sicarb Techの高周波SiC DC電源システムは、パキスタンの熱とグリッドの変動に強い、クリーンで効率的でコンパクトなDC電源を提供します。ほぼ1のPF、低いTHD、および予測メンテナンスが組み込まれているため、OPEXを削減し、キャビネットを縮小し、稼働時間を改善します。これは、通信タワー、エッジデータセンター、および繊維、セメント、鉄鋼環境の産業用DCグリッドに最適です。

カスタムソリューションについては専門家にご相談ください

Sicarb TechでDC電源を最新化:

- 中国科学院の支援による10年以上のSiC製造専門知識

- 優れた熱力学のためのR-SiC、SSiC、RBSiC、およびSiSiCのカスタム開発

- 生産とテストを現地化するための技術移転と工場設立サービス

- コンプライアンスドキュメントを備えた、材料から完成したDC電源棚およびキャビネットまでのターンキーデリバリー

- 19社以上の企業との実績:ラピッドプロトタイピング、フィールドパイロット、ROIモデリング

通信、エッジ、または産業用DCグリッド向けの無料のDC電源監査とサイト固有のROIモデルをリクエストしてください。

- Eメール:[email protected]

- 電話/WhatsApp:+86 133 6536 0038

ピークロールアウトシーズンに先立って納品を確保するために、2025年第4四半期のエンジニアリングおよび製造スロットを今すぐ予約してください。

記事のメタデータ

- 最終更新日:2025年9月11日

- 次回のレビュー:2025-12-15

- 著者:Sicarb Techアプリケーションエンジニアリングチーム

- Contact: [email protected] | +86 133 6536 0038

- 標準への焦点:IEC 62368、IEC 62477-1、IEC 61000-3-2/3-12、IEC 61000-6-2/6-4、PECの慣行およびNTDCグリッドコード品質基準に準拠

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.