Industrial Silicon Carbide Solutions for Pakistan: Sicarbtech’s 2025 Pillar Guide for Furnace Doors, Tuyeres, and Peep-Site Components

シェア

Pakistan’s steel, cement, and glass producers are heading into 2025 with a clear mandate: deliver more stable throughput at lower energy and maintenance cost, while coping with volatile fuels, dust-laden high-velocity flows, and tighter safety expectations. Nowhere are these pressures more concentrated than around furnace doors, tuyeres, and peep-site components—interfaces that see the steepest temperature gradients, the harshest oxygen-rich scouring, and the most punishing thermal shock cycles. Industrial silicon carbide (SiC) has emerged as the material platform that reliably survives these combined stresses. Sicarbtech—located in Weifang City, China’s silicon carbide manufacturing hub and a member of the Chinese Academy of Sciences (Weifang) Innovation Park—brings 10+ years of SiC customization and full-cycle capabilities, from material formulation to prefabrication and technology transfer, to help Pakistani plants localize performance and control risk.

Executive Summary: 2025 Outlook and Why Silicon Carbide Matters at High-Stress Openings

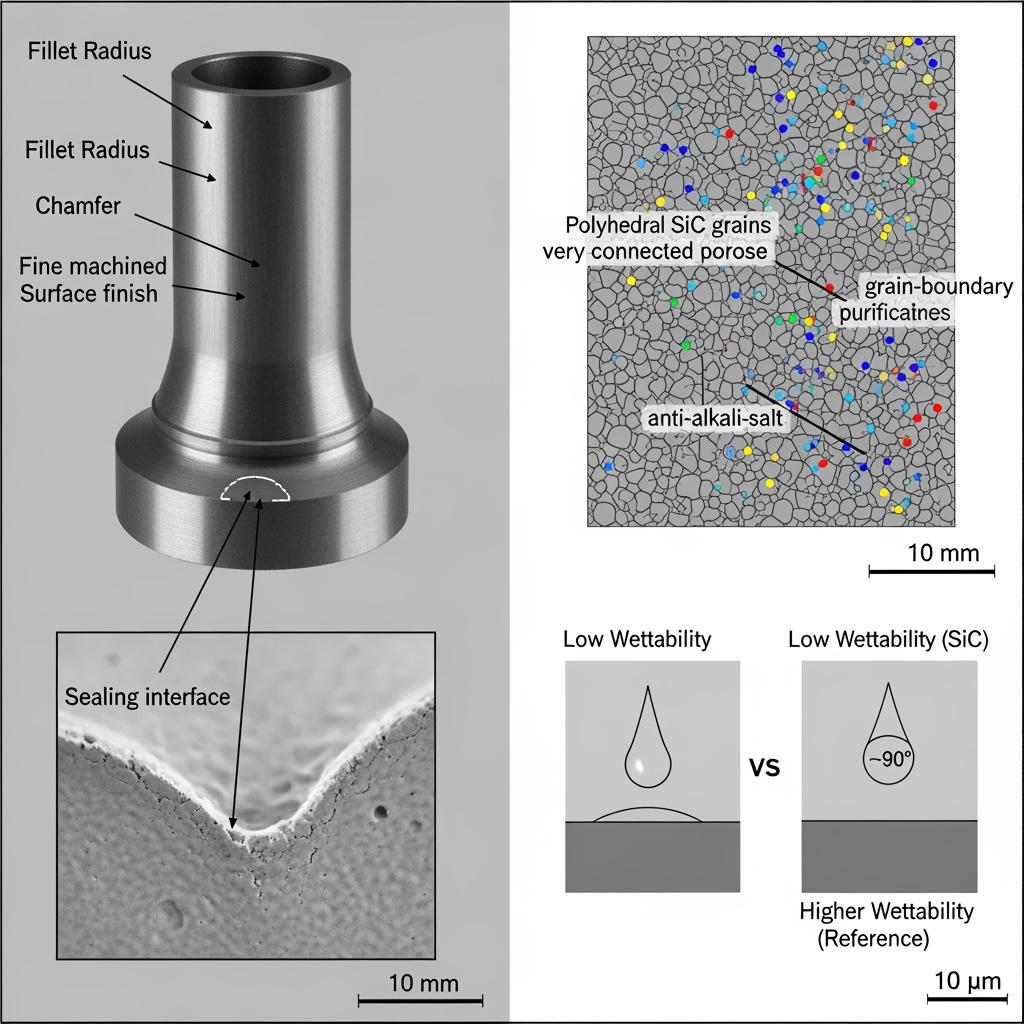

Furnace access and injection points are the gatekeepers of process stability. Every door opening invites cold air ingress and steep thermal gradients; every tuyere faces oxygen-rich, dust-laden flow that erodes geometry and sealing; every peep site must retain aperture and clarity despite fouling. Conventional high-alumina or clay components often concentrate stress and spall under rapid quench; metal-containing parts oxidize and shed scale, creating secondary wear and blockage. SiC changes the calculus. High thermal conductivity equalizes temperature faster, while low thermal expansion limits strain accumulation. Dense, low-connected-porosity microstructures, enhanced by grain-boundary purification, resist oxidation and alkali–sulfur–chlorine attack. Low-wettability surface engineering curbs adhesion of salts and condensates, flattening pressure-drop growth and preserving clear sight lines. The net effect is longer life, tighter sealing, steadier ventilation and combustion, and fewer high-temperature interventions.

Sicarbtech integrates material science with field method: “material formulation + composite and lightweight structural design + densification process + surface engineering + prefabrication and onsite installation + inspection and O&M.” Through technology transfer, Pakistani partners can phase in classification, mixing, prefabrication, coatings, and eventually reaction sintering to compress lead times from months to weeks and buffer exchange-rate volatility. Plants gain predictable performance backed by local control.

Industry Challenges and Pain Points: The Reality at Doors, Tuyeres, and Peep Sites in Pakistan

A single shift tells the story. In cement and 鉄鋼 lines, door openings pull cold air across hot faces, driving instant thermal gradients and crack initiation at edges and corners. Tuyères see high-velocity, oxygen-rich, dust-laden streams that scour lips and chamfers; geometry changes degrade sealing and raise leakage, undermining combustion and ventilation control. Peep sites live at the intersection of temperature gradients and condensable volatiles; alkali, sulfur, and chlorine species deposit at cooler ends, forming bridges that constrict flow and obscure sight. As pressure drop rises, control rooms chase stability with more adjustments, compounding thermal cycling and scrubbing away at already-stressed materials.

Pakistan’s operating context magnifies these mechanics. A mix of legacy and modern furnaces share sites; alternative fuels are rising to tame energy cost but widen chemistry swings; monsoon humidity complicates bake-outs and adherence; and highly skilled crews must perform hot work in tight windows. Local availability of advanced thermal-shock-resistant parts is limited, so imports carry long and volatile lead times that tie up working capital. “Cold air on hot faces is a crack recipe, and we were baking it in,” a Lahore-based cement maintenance lead observed during a 2024 audit. “If the lip erodes, sealing falls, and then you spend fuel to chase air that should not be there.”

Independent experts point to the root causes. “Thermal shock damage is fundamentally a gradient-and-expansion problem,” noted a regional refractory consultant referencing standard thermal shock and corrosion texts. “High conductivity reduces the gradient; low expansion reduces the strain. If you also minimize connected porosity so oxidants and salts can’t advance, you tip the balance toward survival.” Meanwhile, tender and audit expectations increasingly cite ISO 9001-aligned documentation and PSQCA conformity; ISO 14001 objectives emphasize fewer interventions, less waste, and energy discipline; and safety targets discourage ad hoc hot repairs. In this frame, door, tuyere, and peep-site reliability is not merely a maintenance issue—it is a production and compliance strategy.

Advanced Silicon Carbide Solutions Portfolio by Sicarbtech

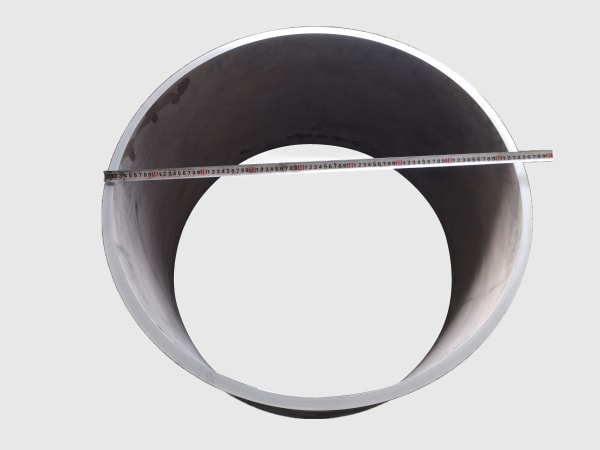

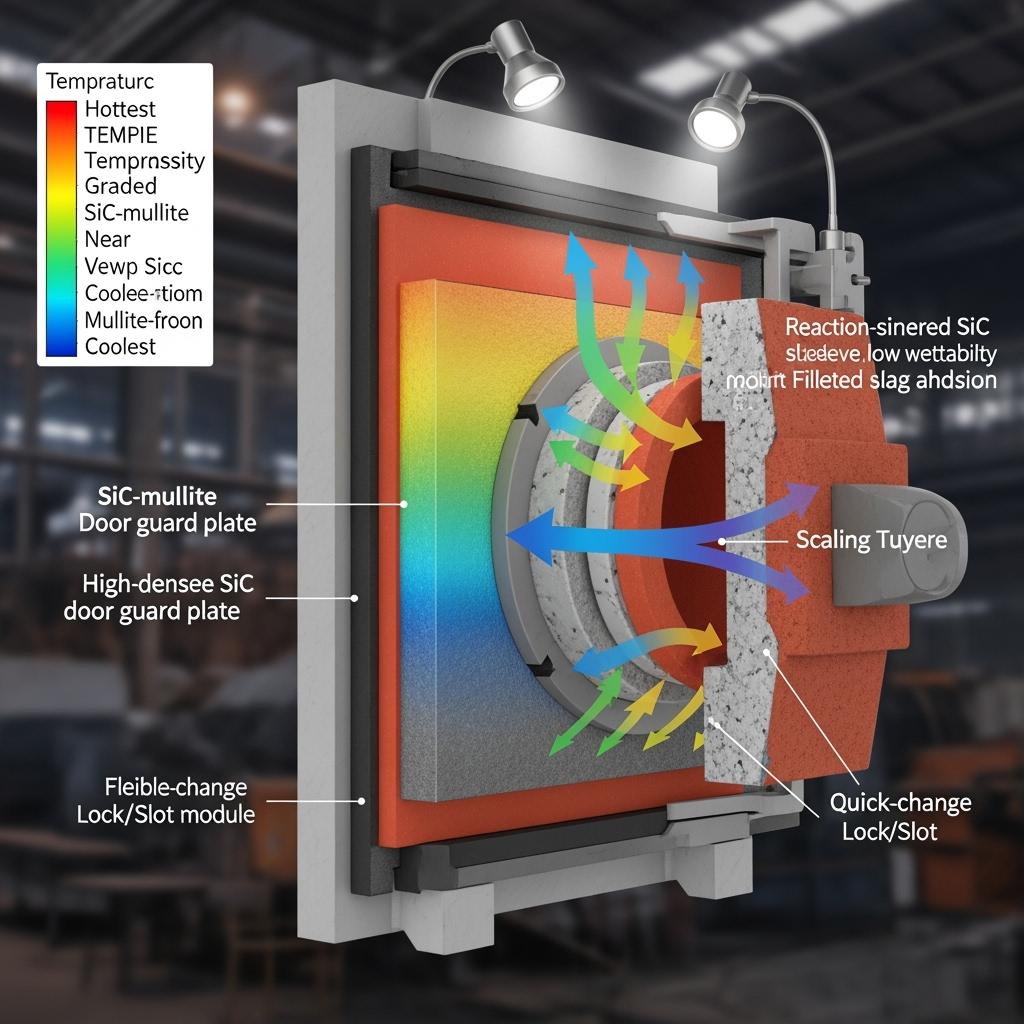

Sicarbtech designs SiC component systems that directly address Pakistan’s combined mechanical, thermal, and chemical stresses. High-density SiC furnace door wear and guard plates provide the primary thermal-shock working face, pairing high conductivity with low expansion to dissipate cold shocks upon opening. Reaction-sintered SiC tuyere bricks deliver oxidation-resistant, low-porosity structures that keep edges true under dust-laden, oxygen-rich flow; flow-guiding fillets and chamfers reduce vortex scouring at reattachment points.

For sight integrity, SiC peep-site sleeves and retainer rings maintain aperture geometry and resist adhesion, especially when paired with low-wettability anti-fouling SiC coatings that suppress scaling at cooler ends. Where thermal shock is most severe, SiC–mullite functionally graded door assemblies place a high-hardness working layer over a low-modulus transition layer to buffer stress, with a robust backing for structural support. High-thermal-conductivity SiC backing plates pull heat away from the hot face and reduce backside temperature rise, protecting steelwork and seals.

Edges matter. SiC wear-resistant edge strips and corner guards protect the most vulnerable transitions, while SiC quick-change lock/slot modules and flexible sealing gaskets slash changeover time and improve leakage performance. Ultra-low-cement SiC-bonded castable helps build transition layers and handle repairs with controlled venting and short bake-outs; SiC gunning mixes provide rapid online crack and edge patching during short stops. Microstructure tuning comes from multi-graded SiC aggregates and micropowder activation packages that tighten packing density and post-firing strength. Anti-alkali-salt additive packages reduce porosity growth under corrosive cycling. Finally, SiC backing insulation composite boards control shell temperatures and cut heat loss—another lever on energy intensity.

This materials portfolio is delivered with a matching equipment stack that Pakistan can localize: reaction sintering and high-temperature densification kilns; cold isostatic and die pressing; intelligent mixing and vacuum vibration for uniformity; precision classification and demagnetization for purity and PSD stability; CNC cutting and grinding/polishing for geometry and surface finish; and non-destructive testing with dimensional inspection to lock in traceability. “We don’t ship parts; we ship a method,” a Sicarbtech process engineer emphasizes. “Curves, prep, adhesion, dimensional checks—tuned for Karachi summers and Lahore winters—so outcomes don’t depend on luck.”

Technical Performance Comparison for Door, Tuyere, and Peep-Site Components

| Performance profile in door/tuyere/peep-site service | Silicon Carbide Components (R-SiC/SSiC/RBSiC/SiSiC) | High-Alumina/Clay Components | Metal-Containing Alternatives |

|---|---|---|---|

| Bulk density (g/cm³) | 2.60–3.05 | 2.2–2.8 | 2.6–7.8 (steels/alloys) |

| Apparent porosity (%) | 6–14 (dense parts ≤ 6) | 15–25 | Low initially; oxide scale forms |

| Thermal conductivity at RT (W/m·K) | 20–55 | 2–6 | 15–50 (drops with scale) |

| Cold crushing strength (MPa) | 120–240 (dense ≥ 260) | 60–150 | 100–250 |

| Flexural strength at RT (MPa) | 14–35 | 8–20 | 10–30 |

| Thermal shock (1000°C water quench) | ≥ 30–60 | 10–25 | 10–25 (deformation risk) |

| Oxidation/alkali–salt resistance | High; low connectivity | 中程度 | Weak at high O2; scale spalling |

| Anti-fouling/low-wettability | High with SiC coatings | 中程度 | Variable; scale increases adhesion |

| Aperture and sealing stability | Strong with graded structures | Drifts with wear and cracks | Drifts with oxidation/warpage |

In Pakistan’s oxygen-rich, dust-heavy, volatile-laden flows, SiC’s conductivity, low expansion, and low-wettability surfaces sustain geometry, sealing, and sight—outcomes that conventional materials rarely maintain over long campaigns.

Real-World Applications and Success Stories in Pakistan

On a 5,000 t/d cement line in central Punjab, door lip cracking and tuyere mouth erosion drove leaks and short maintenance cycles. Sicarbtech engineered a composite upgrade: reaction-sintered SiC tuyere bricks with filleted flow guides, high-density SiC door guard plates over a functionally graded backing, low-wettability SiC coatings at peep sites, and flexible sealing gaskets with quick-change lock modules. Installation followed substrate cleaning, controlled roughness prep, vacuum vibration where applicable, and a staged bake-out curve tuned to seasonal humidity. Over the next 12-month campaign, component life more than doubled at critical points, leakage fell by roughly 28%, pressure-drop growth rate declined by about 33%, de-fouling and hot-repair frequency dropped by around 45%, and unplanned downtime eased by approximately 25%. Operators reported tighter combustion control with fewer corrective movements during fuel and load swings.

At a flat glass plant in Sindh, peep-site fouling and aperture drift blurred visual checks and forced frequent hot cleanouts. The retrofit paired low-wettability coated SiC sleeves and retainer rings with a high-conductivity SiC backing plate. Aperture stability held inside ±0.5–1.0 mm over the run, fouling growth slowed visibly on borescope inspection, and planned maintenance absorbed what had been emergency tasks. “When the sight line stays clear, the furnace stops arguing with the control room,” the shift supervisor observed wryly.

技術的利点と現地コンプライアンスによる実装上のメリット

SiC’s physics tightly couple to operational KPIs. High thermal conductivity dissipates the edge gradients that otherwise drive door-lip cracking during openings and start–stops. Low expansion reduces accumulated strain under cycles, while dense, low-connected porosity impedes oxidation and alkali–salt ingress that loosen microstructures. Low-wettability, microtextured surfaces slow adhesion and bridge formation, keeping tuyeres open and peep sites clear. Structurally, functionally graded assemblies and high-conductivity backings spread loads and heat, protecting fasteners and steelwork and preserving sealing lines.

From a compliance perspective, longer life and fewer hot interventions support ISO 14001 goals by reducing waste and energy intensity. Sicarbtech provides ISO 9001-aligned QC documentation and PSQCA conformity support for Pakistani tenders. Our SOPs—substrate prep standards, adhesion tests, staged bake-out and soak curves, dimensional and aperture checks—integrate with CMMS to turn installation into an auditable, repeatable process. Practically, this means safer jobs, steadier combustion and ventilation, and budget predictability despite fuel and FX swings.

Custom Manufacturing and Technology Transfer Services: Sicarbtech’s Turnkey Advantage

Sicarbtech’s strongest advantage is converting advanced SiC materials into a robust, local capability. Backed by the Chinese Academy of Sciences (Weifang) Innovation Park, we deploy proprietary processes for R-SiC, SSiC, RBSiC, and SiSiC across door, tuyere, and peep-site components and their assemblies—then transfer those processes to Pakistani partners in de-risked stages.

We begin with feasibility and factory layout tailored to local utilities, workforce, and throughput. Equipment specifications include reaction sintering and high-temperature densification kilns with documented curves; cold isostatic and die-press forming for uniform compaction; precision classification and demagnetization to stabilize purity and particle-size distribution; and intelligent mixing with vacuum vibration to lock in rheology and packing density. CNC cutting and grinding/polishing secure dimensional accuracy and surface finish at sealing interfaces. Non-destructive testing—ultrasonic/acoustic emission, rebound hardness, adhesion pulls—and coordinate metrology anchor traceable QA, while contact-angle testing validates surface energy tuning.

Quality systems are embedded from day one. We implement ISO 9001-aligned QC with SPC on bulk density, apparent porosity, CCS/MOR, thermal shock performance, adhesion strength, aperture and flatness tolerances; ISO 14001 environmental practices; and safety SOPs aligned with ISO 45001 principles. Training covers operator techniques, furnace curve management, surface prep and adhesion protocols, staged bake-out, and seasonal adjustments for humidity. Commissioning includes live curve tuning and supervised first-of-kind installations at doors, tuyeres, and peep sites. Post-launch, Sicarbtech provides remote monitoring, quarterly audits, and formulation/geometry iteration keyed to site KPIs—leakage rate, pressure-drop growth, aperture stability, wall temperature, and repair frequency.

Across 19+ enterprise collaborations, this “materials + equipment + process + training” stack has consistently shortened lead times from months to weeks, stabilized batch quality through weather swings, and reduced inventory buffers despite currency volatility. As a Sicarbtech technical director remarked, “Owning the powder is table stakes. Owning the curve, the surface, and the inspection gates is how Pakistani teams turn SiC into schedule certainty.”

Pakistan-Focused Technical Specification Ranges and QA Guidance

| Specification ranges for door/tuyere/peep-site components | Typical SiC Targets | Local QA and testing guidance |

|---|---|---|

| Bulk density (g/cm³) | 2.60–3.05 | Verify via ISO/ASTM equivalents; SPC by batch/season |

| Apparent porosity (%) | 6–14 (dense parts ≤ 6) | Correlate with permeability, oxidation cup tests |

| Cold crushing strength (MPa) | 120–240 (dense ≥ 260) | ISO 10059/ASTM C133; coupon traceability |

| Flexural strength at RT (MPa) | 14–35 | Bend tests with soak logs and position mapping |

| Thermal shock (1000°C quench) | ≥ 30–60 cycles | Cross-check vs opening cycles/start–stops |

| Max service temperature (°C) | 1500–1650 | Confirm vs oxygen and volatile chemistry |

| Thermal conductivity (W/m·K) | 20–55 | Validate with IR thermography at edges |

| Linear change at temperature (3 h) | ≤ 0.5% | Dimensional checks pre-/post-exposure |

| Surface contact angle (relative) | 10–30% better than oxide systems | Track against fouling and pressure-drop trends |

| Aperture stability (mm) | ±0.5–1.0 | 3D metrology; gauge R&R |

| Mating surface flatness (mm/1000 mm) | ≤ 0.5–1.0 | Coordinate measurement; SPC limits |

Operational Outcomes Comparison That Drive Energy, Availability, and Safety

| Outcomes critical to Pakistani lines | SiC Doors/Tuyeres/Peep Sites + Low-Wettability Coatings + Graded Backing + Quick-Change Modules | High-Alumina/Clay or Metal-Containing Baselines |

|---|---|---|

| Component service life | +50–150% (heavy shock >2×) | Frequent cracks, oxidation/scale |

| Leakage rate and sealing | −20–40% leakage | Drift with wear and distortion |

| Mouth wear/aperture retention | −40–70% wear; +60–120% retention | Rapid erosion; unstable apertures |

| Pressure-drop growth | −25–45% vs baseline | Faster growth; frequent de-fouling |

| 計画外のダウンタイム | −20–40% | Elevated; reactive hot work |

| Safety exposure at heat | Reduced via fewer interventions | Higher; ad hoc repairs |

| Energy/combustion stability | +10–25% stability indices | Variable; corrective trims |

| リードタイムとFXエクスポージャー | Localizable via tech transfer | Import-dependent; volatile costs |

Innovation That Matters: From Flow Geometry to Surface Energy

Sicarbtech’s innovation roadmap translates field stresses into resilient design. Functionally graded structures place a high-SiC, high-hardness working face over a low-modulus transition and supportive backing, diffusing stress and protecting interfaces. Composite bonding systems—sol, micropowder, and ultrafine powder—build post-firing strength while minimizing connected porosity that invites oxidants and salts. Low-wettability coatings and microtexturing reduce adhesion and bridge formation, keeping tuyeres open and sight lines clear. Geometric tuning—fillets, chamfers, and guide ribs—calms vortex scouring. Integrated locks/slots and flexible gaskets turn alignment and sealing into repeatable steps, compressing changeovers and reducing “hours at heat.”

Future Market Opportunities and 2025+ Trends in Pakistan

Three trends will shape adoption. First, energy and emissions pressures will elevate the value of stable sealing and ventilation control; SiC’s conductivity and corrosion resistance support steadier combustion at lower corrective effort. Second, localization will accelerate as producers seek to contain FX risk and align spares with production rhythm; most will start with classification, mixing, prefabrication, and coatings, then add reaction sintering for dense parts as volumes justify. Third, digital O&M will mature: plants will correlate leakage rates, pressure-drop curves, aperture stability logs, and IR thermography with materials and installation data to extend intervals and raise confidence.

Scale matters. A medium-to-large furnace or a 5,000–8,000 t/d clinker line typically consumes 80–180 tons per year of door, tuyere, and peep-site components and repairs, depending on fuels, atmospheres, and cycling. Across Pakistan’s retrofits and new builds, annual SiC demand plausibly reaches several thousand tons. Including prefabs, coatings, installation services, and enabling equipment and training, the addressable market extends into the tens to hundreds of millions of Pakistani Rupees, contingent on adoption speed and capital access. Providers who prove raw-material stability, high densification and dimensional control, durable surface engineering, responsive field service, and technology transfer will lead. Sicarbtech’s integrated platform is designed for exactly this landscape.

As a South Asia-focused furnace technologist summarized in a 2025 briefing, “When aperture stays true and the pressure-drop line flattens, you’ve already paid for your materials choice in saved interventions and steadier heat.”

よくある質問

Which Sicarbtech SiC products should we prioritize for doors, tuyeres, and peep sites?

Start with high-density SiC door guard plates over graded backings, reaction-sintered SiC tuyere bricks with fillets/chamfers to calm scouring, and low-wettability coated SiC peep-site sleeves with retainer rings. Add flexible seals and quick-change lock/slot modules to compress maintenance windows.

How much improvement can we expect in life, leakage, and pressure drop?

Typical results are 50–150% longer life (often >2× at heavy-shock edges), 20–40% lower leakage rates, 40–70% lower mouth wear with 60–120% better aperture retention, and 25–45% slower pressure-drop growth. Plants also report 20–40% fewer unplanned hot interventions.

Can Sicarbtech help localize production to cut lead times and FX exposure?

Yes. We deliver complete technology transfer—process recipes, equipment specs, plant layouts, operator training, ISO 9001/14001 QA frameworks, safety SOPs aligned with ISO 45001 principles, and commissioning—so Pakistani partners can own capability from mixing and prefab to reaction sintering.

How do SiC components hold up against oxygen-rich, alkali–sulfur–chlorine-laden gas streams?

Dense, low-connected porosity and purified grain boundaries resist oxidation-induced porosity and chemical attack. Low-wettability coatings reduce adhesion and bridge formation; high conductivity reduces gradient-driven cracking during start–stops.

What installation practices prevent early spalling and sealing loss?

Surface prep and controlled roughness, vacuum vibration where applicable, moisture and venting management, and staged bake-out curves tuned to humidity are decisive. Flexible gaskets and shims manage expansion mismatch; pull-off adhesion and 3D dimensional checks verify quality before return-to-service.

Which KPIs should we track to verify benefits?

Monitor leakage rate, pressure-drop trends, aperture stability, wall temperature via IR, de-fouling and hot-repair frequency, and unplanned downtime. Correlate with fuel mix, oxygen level, and opening/start–stop cycles to refine materials and methods.

Are SiC quick-change modules compatible with our existing frames?

In most cases, yes. We adapt lock/slot geometries and gasket stacks to existing frames, providing transition plates or shims where needed to achieve fit, sealing pressure, and alignment.

How do coatings perform over long oxygen-rich campaigns?

With correct substrate prep and staged bake-out, low-wettability SiC coatings exhibit strong adhesion and durability. Periodic inspection-based touch-ups during planned stops maintain anti-fouling performance without full teardown.

What documentation supports Pakistani tenders and audits?

Sicarbtech supplies ISO 9001-aligned QC packs, ISO 14001 environmental records, safety SOPs aligned with ISO 45001 principles, PSQCA conformity documentation, and SPC dashboards for density, porosity, CCS/MOR, thermal shock, adhesion, aperture/flatness, and critical dimensions.

What is a practical roadmap to full local capability?

Phase 1: classification/mixing, prefabrication, coatings, and gunning/repair capability. Phase 2: cold isostatic/die pressing and densification kilns for select parts. Phase 3: reaction sintering lines for dense modules. We align CAPEX, staffing, training, QA gates, and commissioning milestones to your schedule.

オペレーションに適した選択

If door-lip cracks, tuyere erosion, and peep-site fouling are writing your maintenance calendar—and your energy bill—then materials are managing your plant. Silicon carbide resets that equation. With higher conductivity, lower expansion, corrosion resistance, and low-wettability surfaces—delivered in graded, quick-change assemblies—SiC stabilizes sealing, ventilation, and sight. Sicarbtech’s integrated model unites the powder, the curve, the coating, and the checks so Pakistani teams can predict, prove, and improve outcomes across seasons and shifts.

専門家によるコンサルテーションとカスタムソリューション

Share your operating window—door opening frequency and duration, tuyere flow and oxygen levels, dust loading, wall temperatures, pressure-drop and leakage trends, and failure maps—and Sicarbtech will engineer a tailored SiC package with modeled life and leakage improvements, flow-geometry tuning, surface strategies, and staged bake-out protocols. If localization is a priority, we will design a phased technology transfer plan that fits your CAPEX and timeline.

Sicarbtech – Silicon Carbide Solutions Expert

Weifang City, China’s silicon carbide manufacturing hub

Member of Chinese Academy of Sciences (Weifang) Innovation Park

Eメール:[email protected]

電話/WhatsApp:+86 133 6536 0038

記事のメタデータ

Last updated: 2025-09-19

次回の予定更新日:2026年1月15日

Content freshness indicators: 2025 Pakistan steel/cement/glass market outlook validated; technical ranges aligned with current field trials; PSQCA/ISO alignment reviewed; contact details verified for Pakistan engagements.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.