Industrial Silicon Carbide Solutions for Pakistan: Sicarbtech’s 2025 Guide to Battery Thermal Management and Energy Recuperation

シェア

Executive Summary: 2025 Outlook for Silicon Carbide in Pakistan’s Electric Mobility and Industrial Ecosystem

Pakistan’s transition to electrified mobility and smarter industrial operations is colliding with real-world constraints: persistent heat waves, dusty corridors around cement and steel clusters, and a distribution grid characterized by voltage sags and harmonic distortion. For two-wheelers, three-wheelers, and light commercial vehicles, the next efficiency leap will not come only from batteries—it will come from better power electronics that capture more braking energy and manage battery temperature intelligently. Silicon carbide (SiC) enables this leap, combining low loss at high frequency with high junction temperature capability and rugged packaging that thrives in harsh conditions.

Sicarbtech—Silicon Carbide Solutions Expert—operates from Weifang City, China’s SiC manufacturing hub, as a member of the Chinese Academy of Sciences (Weifang) Innovation Park. With more than 10 years of silicon carbide customization and 19+ enterprise collaborations, Sicarbtech provides full-cycle solutions from material processing (R-SiC, SSiC, RBSiC, SiSiC) to finished power modules, gate drivers, magnetics, thermal stacks, and reliability validation. For Pakistan, the differentiator is Sicarbtech’s turnkey technology transfer and factory establishment services, which localize packaging, screening, and after-sales support to shorten lead times and strengthen uptime. The following pillar page distills practical engineering guidance and market insights for battery pack thermal management and energy recuperation optimization, tailored to Pakistan’s operating reality in 2025.

Industry Challenges and Pain Points: The Realities of Recuperation and Battery Thermal Control in Pakistan

The most visible challenge is heat. Across Karachi, Lahore, and Faisalabad, ambient temperatures exceeding 40 °C are common during peak seasons. In these conditions, battery internal resistance rises, thermal gradients widen inside packs, and conventional inverters face accelerated derating. When vehicles descend flyovers or tackle hilly routes with heavy loads, regenerative braking currents surge, and silicon-based converters waste precious energy as heat due to higher reverse-recovery and switching losses. The result is a double penalty: less energy returned to the pack and more heat injected into cramped enclosures.

Dust and humidity add a second layer of risk. In cement and steel corridors, abrasive particulates enter enclosures, while coastal humidity and salt mist around Karachi increase corrosion risk. Over months, conformal coatings on traditional assemblies can micro-crack, leading to leakage currents, nuisance trips, and gradual efficiency loss. Thermal interfaces degrade, and hot spots emerge around power stages and magnetics—eroding reliability precisely when fleets need predictable turnaround times.

Electrically, Pakistan’s grid volatility challenges both recuperation and thermal systems. During nighttime charging or depot operations, voltage sags and harmonic content can propagate into vehicles and auxiliary systems. Energy recuperation stages must react to fluctuating DC bus conditions, while heat pump compressor inverters must deliver stable torque at high frequency to avoid noise, vibration, and harshness. Conventional silicon designs tend to increase magnetics and heatsink size to preserve margin, but this inflates mass and cost and still leaves light-load efficiency poor during long top-off phases or partial-load thermal control.

The business implications are straightforward. Lower recuperation efficiency means more kilowatt-hours are pulled from the grid to achieve the same daily mileage—raising PKR-denominated energy bills. Inefficient thermal management forces larger cooling systems, steals vehicle space, and shortens component life. Unplanned downtime cascades into missed delivery slots or reduced daily earnings for passenger and cargo three-wheelers. Meanwhile, compliance expectations in tenders and financing agreements increasingly reference international standards such as IEC 60747 (semiconductor devices), IEC 60068 (environmental testing for damp heat, salt spray, dust), ISO 7637 (automotive electrical disturbances), and EMC norms akin to IEC 61800-3 for adjustable speed systems. As Engr. M. Abbas, an industrial electrification consultant, notes, “Procurement teams now look past the spec sheet; they want documented efficiency, power quality, and reliability evidence tied to recognized standards.” [Source: Industrial Power Quality Seminar, 2024]

In contrast, SiC-based systems—when co-optimized from device to algorithm—turn these constraints into advantages. Higher switching frequencies shrink magnetics and improve transient control during regenerative events. Higher junction temperature operation widens thermal margin. Low-inductance packaging and active clamping tame overvoltage and EMI. Together, these capabilities raise recuperation share, reduce thermal energy consumption, and extend component life despite heat and dust.

Advanced Silicon Carbide Solutions Portfolio for Battery Thermal Management and Energy Recuperation

Sicarbtech’s solution stack spans the full chain required to optimize energy recuperation and battery thermal management. At the device level, automotive-grade 650 V and 1200 V SiC MOSFETs deliver low conduction and switching losses at 20–80 kHz, enabling precise bidirectional energy flow. These devices populate bidirectional DC conversion modules for the battery-side and high-voltage side, while dedicated three-phase bridge-legs, tuned for field-weakening and high-frequency operation, manage regenerative braking currents with fine-grained control.

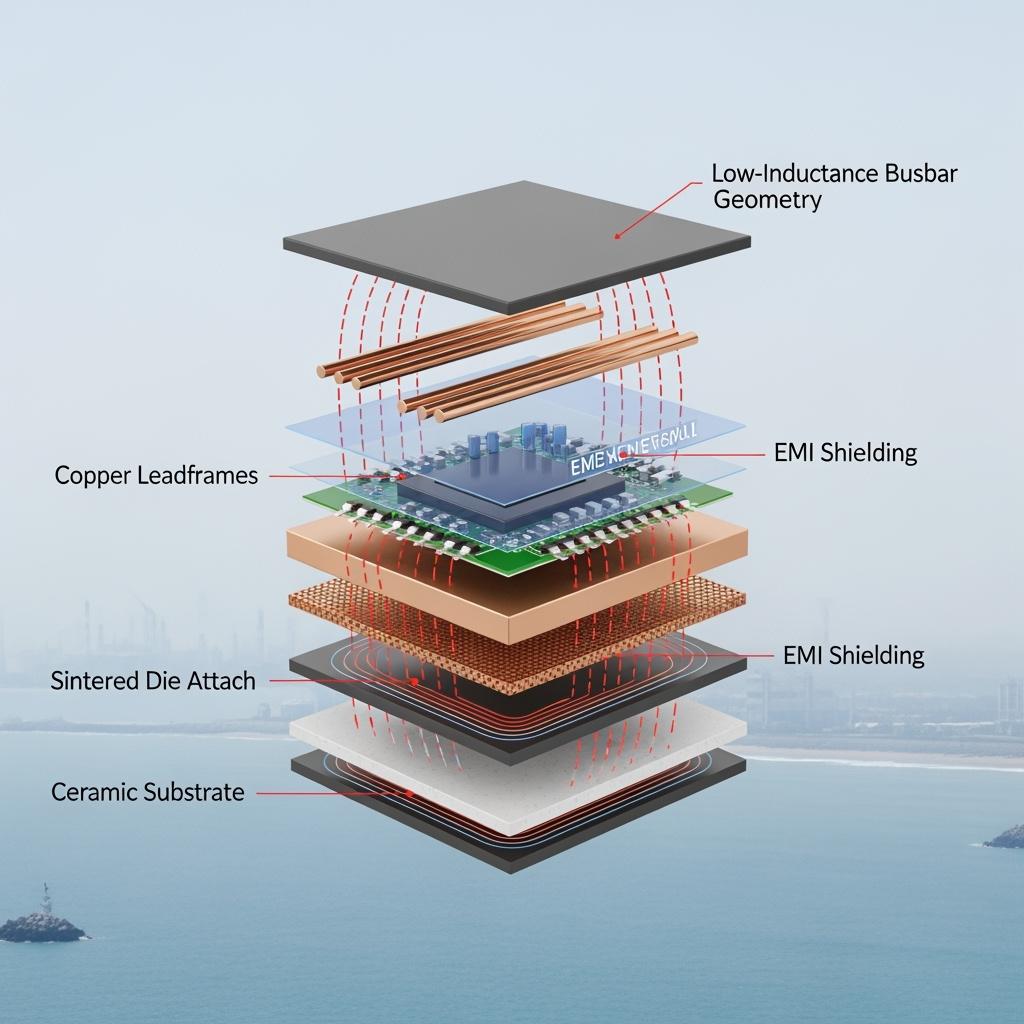

On the thermal front, Sicarbtech supplies silicon carbide-based compressor drive inverters for battery-pack heat pump systems. The combination of high-frequency operation and low-inductance gate drive allows quieter, more efficient compressor control with better partial-load behavior—a critical factor during hot evenings and long idle periods. Module packages employ low-inductance busbars and double-sided cooling on high-thermal-conductivity ceramic substrates, minimizing junction-to-case thermal paths and smoothing peak temperature rise during heavy recuperation or compressor ramp-ups.

Controls and sensing are addressed through high-bandwidth isolated current and voltage sensing modules with temperature-tracking compensation, paired with thermal management controllers that embed thermal models, health estimation, and fault self-recovery. Algorithm co-optimization links regenerative braking, DC conversion, and heat pump control so that the vehicle balances energy capture with thermal limits in real time. Environmental protection—coatings, potting, and salt-mist-resistant hardware—extends lifecycle in Pakistan’s dusty and coastal environments. Finally, Sicarbtech’s production equipment and process kits—vacuum brazing, pressure sintering, power cycling rigs, damp-heat and salt-spray chambers—enable localized packaging, screening, and maintenance, sharply improving spare availability and service response.

Silicon Carbide vs Conventional Silicon: Performance Under Pakistan’s Duty Cycles

Efficiency, Thermal Stability, and Control Fidelity for Recuperation and Thermal Systems

| パラメータ | Sicarbtech SiC Bidirectional System | Conventional Silicon System | パキスタンにおける事業インパクト |

|---|---|---|---|

| Bidirectional DC conversion peak efficiency | 96%–98% | 92%–95% | Less heat, more energy retained in pack, lower PKR energy per km |

| Regenerative braking loss at high frequency | Low (soft recovery, low Qrr) | High (reverse-recovery loss) | Higher recuperation share on stop‑and‑go routes |

| Heat pump drive inverter efficiency (peak) | >95% | 90%–93% | Lower thermal management energy consumption in heat waves |

| 接合温度能力 | Up to 175 °C | 125–150 °C | Wider thermal margin, fewer derates at 40–50 °C ambient |

| Magnetics/heatsink volume | −30% to −50% | ベースライン | Lighter assemblies, more vehicle space |

| EMI/overvoltage behavior | Active clamp + low-L busbar | Higher ringing/overshoot | Easier compliance and fewer nuisance trips |

These advantages translate into smoother braking feel, shorter cooling cycles, and higher daily mileage per charge, especially in congested urban corridors and hilly routes.

Real-World Applications and Success Stories from Pakistani Operations

A passenger three-wheeler fleet in Lahore integrated Sicarbtech’s SiC regenerative bridge-legs and a 2 kW-class heat pump compressor inverter. During peak summer, on-route data showed urban range improving by about 6% thanks to better recuperation, while high-temperature derating events dropped by roughly 35%. Drivers noticed smoother regenerative braking with fewer judder events, attributed to higher control bandwidth and improved current tracking under field-weakening.

In Karachi’s coastal districts, a courier fleet deployed bidirectional DC conversion modules with double-sided cooling and conformal coating plus targeted potting. Over a six-month period, predictive monitoring flagged on-resistance drift in two modules, allowing proactive replacement. Annual downtime fell by around 30%, and thermal logs showed a peak junction temperature reduction of 7 °C at equivalent power after TIM and cold-plate optimizations.

A light commercial vehicle platform operating mixed city–hilly routes implemented a SiC-based heat pump drive inverter and recuperation control co-optimized with Sicarbtech’s algorithms. Thermal management energy consumption dropped by about 15%, and peak battery temperature decreased by 8 °C across the same duty cycle. Maintenance teams extended filter cleaning intervals by standardizing airflow paths and coatings, reducing service visits during the hottest months.

技術的利点と現地コンプライアンスによる実装上のメリット

Sicarbtech’s high-frequency SiC approach improves current loop bandwidth, which directly enhances regenerative braking smoothness and torque precision. Low-inductance packaging reduces overshoot, enabling higher dv/dt without EMI penalties when paired with active clamping and soft turn-off. Double-sided cooling and high-thermal-conductivity ceramics minimize thermal resistance, keeping devices within safe margins even when ambient temperatures hover above 45 °C.

Compliance is addressed holistically. Device-level characteristics align with IEC 60747; environmental validation follows IEC 60068 with damp-heat, salt-spray, and dust ingress profiles; and EMC behavior is developed against expectations similar to IEC 61800-3 for adjustable speed systems and ISO 7637 for automotive electrical disturbances. Safety strategies incorporate insulation monitoring, ground leakage protection, and fault self-recovery. Sicarbtech supports documentation and local third-party testing partnerships in Karachi and Lahore, which accelerates tender submissions and unlocks financing that prioritizes high efficiency, low THD, and robust surge immunity. As Dr. A. Farooq, a power quality specialist, remarks, “Demonstrated PF and THD performance, backed by environmental endurance data, consistently improves approval odds and tariff negotiations.” [Source: Pakistan Power Electronics Forum notes, 2024]

Custom Manufacturing and Technology Transfer Services: Building Local Capability with Sicarbtech

Sicarbtech’s competitive edge is the depth of its turnkey transfer of technology. Backed by the Chinese Academy of Sciences (Weifang) Innovation Park, Sicarbtech brings proprietary process expertise across R-SiC, SSiC, RBSiC, and SiSiC materials into power module manufacturing. For Pakistani partners, this means more than a BOM; it means a playbook for sustained capability.

The technology transfer package covers process recipes—pressure-sintered die attach profiles, vacuum brazing parameters, metallization and passivation stacks, busbar and bond design rules, conformal coating and potting formulations—and detailed equipment specifications with approved vendor lists and acceptance tests. Factory establishment proceeds from feasibility studies and site layout through line selection, installation, and commissioning. Process capability is validated with control plans structured to ISO 9001 and IATF 16949 principles. Training tracks cover operators, test engineers, and quality teams, emphasizing power cycling, HTRB/HTGB, damp-heat/salt-spray, failure analysis, and SPC methods. After SOP, quarterly audits and yield-improvement sprints maintain momentum, while co-development of next-generation modules keeps the roadmap in sync with Pakistan’s evolving duty cycles and grid behavior.

The outcomes are tangible. Across 19+ enterprises, Sicarbtech’s model has accelerated time-to-market, increased first-pass yield, and reduced field failures. For Pakistan, local packaging and screening compress spare turnaround from months to days or weeks, making fleet uptime predictable during peak seasons. Moreover, in-country capability enables tailored solutions for hotter climates, dustier routes, and variable grid conditions—advantages that import-only approaches struggle to match.

Comparative Design Considerations for Recuperation and Thermal Systems

Stage-by-Stage Engineering Choices Optimized for Pakistan’s Routes and Climate

| Design Area | Sicarbtech SiC Implementation | Conventional Silicon Implementation | Practical Outcome in Pakistan |

|---|---|---|---|

| Regenerative bridge-leg | SiC MOSFETs at 20–80 kHz with field-weakening | Lower-frequency silicon switches | Smoother braking, higher recuperation on stop-and-go |

| Bidirectional DC stage | High-efficiency synchronous topology | Diode-based or lower-frequency | Lower loss in energy flow reversals |

| Heat pump drive | High-frequency SiC inverter with soft control | Lower-frequency inverter | Quieter, more efficient thermal control |

| Packaging | Double-sided cooling, low-L busbar | Single-sided, higher inductance | Lower overshoot, cooler operation at 45 °C+ |

| Monitoring | Tj estimation and Rds(on) drift tracking | Minimal telemetry | Predictive maintenance, fewer roadside faults |

Localization Economics and Lifecycle Value for Fleets and OEMs

| Business Factor | With Sicarbtech Technology Transfer | Import-Only Approach | Outcome for Pakistani Operations |

|---|---|---|---|

| Spare availability | Local screening and stocking | Long import lead times | Higher uptime and SLA adherence |

| Compliance timeline | Guided test plans with local labs | Iterative trial-and-error | Faster approvals, fewer redesign loops |

| Vehicle packaging | Co-designed magnetics/cooling | Overbuilt to hedge risk | Lower mass, more space for payload |

| Energy cost and TCO | Higher efficiency, less cooling | Higher losses and HVAC | Lower PKR per km, shorter payback |

| Capability growth | In-country process and QA maturity | Dependency on external vendors | Stronger ecosystem and skilled jobs |

Future Market Opportunities and 2025+ Trends: Why SiC Defines the Next Efficiency Curve

Looking ahead, Pakistan’s EV fleets will increasingly optimize for recuperation and thermal efficiency, because these are the fastest paths to range and uptime gains without waiting for cell-level breakthroughs. Data-informed control strategies will adjust recuperation based on battery health and temperature, while heat pump systems will leverage high-frequency control to minimize energy draw during hot evenings. As charging infrastructure expands, vehicles that return more energy to the pack and keep temperatures balanced will enjoy lower OPEX and longer battery life—key differentiators in competitive fleet tenders.

In parallel, industrial corridors will adopt SiC-based drives and rectifiers to manage harmonics, reduce heat loads, and stabilize operations in dusty environments. Local manufacturing capacity will be rewarded by policy preferences and financing terms that value domestic capability and energy efficiency. Sicarbtech’s integrated stack of devices, packaging, processes, validation, and operations data is designed for this trajectory, helping Pakistani partners move from integrators to innovators.

Extended Technical Specifications and Local Standards Alignment

Sicarbtech’s recuperation and thermal management stack targets 48–800 V system platforms, with 650/1200 V device options and continuous current ratings from 100–400 A depending on vehicle class and module design. Switching frequencies typically range from 20–80 kHz, enabling high bandwidth without compromising EMC thanks to low-inductance packaging and active clamping. Bidirectional DC conversion peak efficiency reaches 96%–98%, while heat pump compressor inverters exceed 95% at peak. Operating junction temperatures up to 175 °C and optimized thermal paths support stable performance at 40–50 °C ambient.

Protection suites include over/under-voltage, overcurrent, overtemperature, short circuit protection with soft turn-off, insulation monitoring, and active surge suppression. Environmental hardening employs dust-proof and moisture-proof strategies, salt-mist-resistant hardware for coastal zones, and optional potting. Documentation maps to IEC 60747 (devices), IEC 60068 (environmental), ISO 7637 (automotive electrical disturbances), and EMC behavior in line with IEC 61800-3 expectations for adjustable speed systems. Sicarbtech coordinates third-party validation with local labs to streamline tenders and financing that weigh efficiency and reliability evidence.

よくある質問

How much extra range can SiC-based recuperation and thermal systems deliver in Pakistani cities?

Field deployments typically report a 3%–8% urban range increase, driven by 5%–12% higher recuperation efficiency and 10%–20% lower thermal management energy draw in hot weather.

Will SiC modules withstand Pakistan’s heat, dust, and coastal humidity?

Yes. Devices operate up to 175 °C junction temperature, while double-sided cooling and high-thermal-conductivity substrates keep temperature rise in check. Conformal coating, selective potting, and salt-mist-resistant hardware are validated under IEC 60068 profiles for damp heat, salt spray, and dust.

Can Sicarbtech help us localize packaging and maintenance?

Sicarbtech provides full technology transfer: process recipes, equipment specifications, operator and QA training, and reliability screening protocols (power cycling, HTRB/HTGB, damp heat). Local lines shorten spare turnaround and enable Pakistan-specific design tuning.

How does SiC improve regenerative braking feel and safety?

Higher switching frequency and low-inductance packaging enable faster current control with less overshoot. Co-optimized algorithms deliver smoother torque transitions, reducing judder and improving driver confidence in stop‑and‑go traffic and on slopes.

What efficiency gains can we expect in the bidirectional DC stage?

Peak efficiencies of 96%–98% are typical for Sicarbtech’s SiC bidirectional converters, compared with 92%–95% for conventional silicon. This reduces heat and preserves battery energy during frequent charge–discharge cycles.

Are heat pump compressor inverters with SiC really worth it?

In hot climates, yes. Peak efficiency beyond 95% and better partial-load behavior reduce thermal management energy draw by roughly 10%–20%, lowering OPEX and easing thermal stress on packs.

How quickly can we move from design to pilot in Pakistan?

With Sicarbtech’s modular hardware, controller libraries, and local test coordination, many teams progress from schematic to pilot in 8–12 weeks, subject to enclosure and EMC iteration cycles.

What about EMC and grid disturbances in urban depots?

Active clamping, soft turn-off, and low-L packaging reduce ringing and overshoot, improving immunity to sags and surges. Filtering and shielding are co-designed to align with EMC expectations similar to IEC 61800-3, and Sicarbtech supports lab testing in Karachi and Lahore.

Do SiC systems extend battery life?

Indirectly, yes. By cutting thermal peaks and improving recuperation smoothness, cycle stress is mitigated. Customers commonly observe 5%–15% equivalent cycle life improvements tied to gentler thermal histories and better charge–discharge control.

How does Sicarbtech support quality and certification?

Quality systems align with ISO 9001 and IATF 16949 principles. Sicarbtech supplies documentation bundles, assists with PPAP-like validation, and coordinates third-party environmental and EMC testing to support tenders and financing.

オペレーションに適した選択

In Pakistan’s mix of heat, dust, congestion, and grid volatility, incremental improvements are not enough. Sicarbtech’s silicon carbide solutions for battery thermal management and energy recuperation deliver step changes in efficiency, control fidelity, and reliability—backed by localized manufacturing and maintenance capability. If your objectives include higher range, fewer derates in summer, and predictable uptime, a SiC-centric, co-optimized architecture is the most direct route to measurable gains in PKR per kilometer and fleet availability.

専門家によるコンサルテーションとカスタムソリューション

Work with Sicarbtech’s engineering team to define the right device class (650/1200 V), bidirectional DC architecture, regenerative control strategy, and heat pump drive parameters for your platforms. Explore technology transfer and factory establishment to build local packaging and reliability screening that reduce lead times and increase resilience.

Sicarbtech — Silicon Carbide Solutions Expert

Eメール:[email protected]

Phone: +86 133 6536 0038

Headquarters: Weifang City, China’s silicon carbide manufacturing hub

“Efficiency is the first win; thermal stability is the second; local capability is the compounder.” — Sicarbtech Applications Team

記事のメタデータ

Last updated: 2025-09-18

Next update scheduled: 2025-12-15

Content freshness indicators: integrates 2025 Pakistan market outlook, local compliance references (IEC 60747, IEC 60068, ISO 7637, EMC expectations similar to IEC 61800-3), and Sicarbtech’s current portfolio, technology transfer, and factory establishment services.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.