How to Source SiC Abrasives and Refractories in Bulk

シェア

Sicarbtech — Silicon Carbide Solutions Expert. From Weifang City, China’s silicon carbide manufacturing hub, and as a member of the Chinese Academy of Sciences (Weifang) Innovation Park, we help Pakistani manufacturers, foundries, and kiln operators secure reliable bulk supplies of silicon carbide abrasives and refractories. With more than 10 years of customization experience and 19+ enterprise collaborations, Sicarbtech delivers full‑cycle solutions—from powder processing and grading to shaped refractory products—supported by OEM packaging, custom formulations, factory establishment, and technology transfer.

Executive Summary: 2025 Outlook for SiC Abrasives and Refractories in Pakistan

Pakistan’s industrial economy is recalibrating procurement toward lifecycle value and reliability. Energy price volatility and PKR fluctuations pressure plants to squeeze more productivity from every maintenance cycle, while provincial environmental enforcement is tightening expectations around fuel intensity, particulate control, and refractory waste. In this context, bulk silicon carbide (SiC) abrasives and refractories—covering black and green SiC powders, grains, and engineered bricks or shapes—are moving from opportunistic spot buys to strategic supply programs. High hardness, oxidation resistance, and excellent thermal conductivity make SiC a mainstay for high‑temperature processes in 鉄鋼, cement, glass, non‑ferrous foundries, and advanced ceramics manufacturing.

Furthermore, procurement teams face rising documentation demands. PSQCA‑referenced conformity now appears in tenders; ISO 9001/14001/45001 alignment is becoming routine; and insurers and export buyers increasingly request evidence of reliability engineering and traceable materials. Building on this shift, Sicarbtech’s integrated approach—precise grading, low‑impurity formulations, shaped refractories tailored to duty, and PKR‑based ROI modeling—gives buyers a defensible path to reduce unplanned downtime, stabilize heat flux, and meet audits with confidence.

Industry Challenges and Pain Points in Pakistan’s Abrasive and Refractory Supply

Sourcing SiC in Pakistan has traditionally been a balancing act. On one side sit unit price and short lead times; on the other, consistency in particle size distribution, impurity levels, and brick microstructure. In steel, roll‑grinding and descaling require predictable abrasive performance; variation in grit shape or hardness yields inconsistent material removal and overheating, which cascades into quality defects. Foundries and heat‑treaters rely on refractory bricks and ramming mixes that must resist thermal shock, chemical attack, and mechanical abrasion; inconsistent porosity or binder chemistry shortens campaigns, forces hot repairs, and increases slag pick‑up. Cement kilns and preheaters need abrasion‑resistant linings that also dissipate heat uniformly; microstructural drift causes hot spots and spalling, which inflate fuel consumption and destabilize clinker quality.

Operational realities magnify these technical issues. Many plants operate on start‑stop profiles driven by load shedding or fuel availability, imposing thermal cycling that punishes refractories. Monsoon humidity changes dust behavior, accelerating preheater fouling and altering abrasive cutting mechanics. Currency volatility complicates landed‑cost planning, while ocean freight fluctuations stretch lead times and force uncomfortable trade‑offs between safety stock and working capital. “Every unplanned outage writes a larger bill than the invoice you see,” observes Engr. Faraz Khan, a reliability auditor active across Punjab’s industrial corridor (South Asia Reliability Insights, 2024). He stresses that mean time between failures must align with planned shutdowns or indirect costs—overtime, emergency freight, off‑spec product—quickly overwhelm any headline savings.

Compliance adds weight. Provincial Environmental Protection Agencies are stricter about dust, spent refractory disposal, and kiln or furnace efficiency. PSQCA‑referenced conformity and ISO documentation appear more frequently in procurements, and insurers ask for evidence of maintenance discipline. “Materials that reduce dust, extend service intervals, and stabilize heat flow produce a compliance dividend,” notes Dr. Nadia Rahman, EHS advisor to multiple estates (EHS & Industry Review, 2024). In contrast, mixing low‑grade abrasives with inconsistent refractories often creates hidden loss: slower grinding rates, premature brick failure, higher fuel intensity, and more frequent patch repairs that never align with outage calendars.

Finally, fragmented supply chains create risk. Buying abrasives and refractories from different vendors without integrated engineering support leads to finger‑pointing when performance drifts. Without batch‑to‑batch traceability, root‑cause analysis stalls. And when packaging and logistics are not engineered—moisture barriers, palletization for Pakistani warehousing, HS code clarity for customs—quality can degrade before materials reach the floor.

Sicarbtech’s Silicon Carbide Portfolio for Bulk Buyers and OEMs

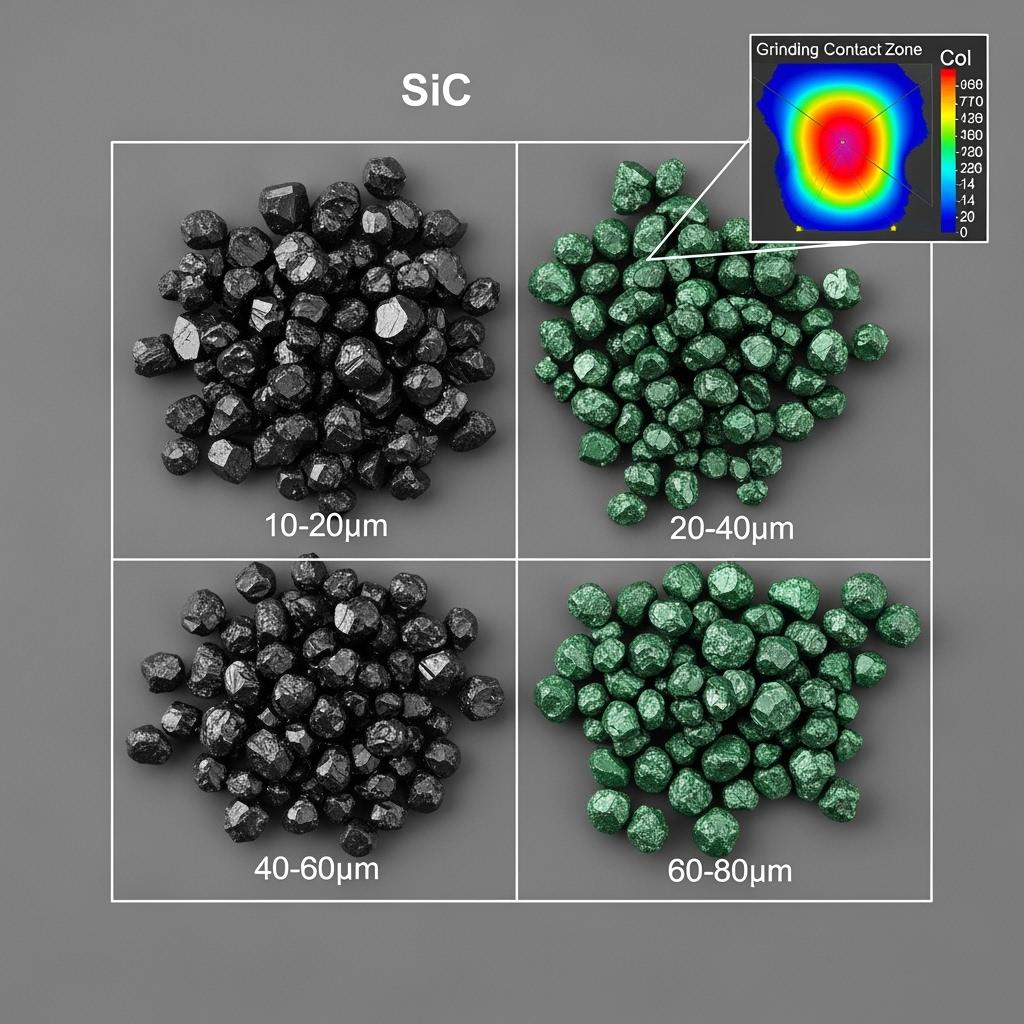

Sicarbtech builds SiC supply programs that combine powder and shaped products with engineering and documentation. For abrasives, we supply black SiC and green SiC from microgrits to macrograins, with tight particle size distributions, controlled blockiness/roundness profiles, and guaranteed impurity limits suited to grinding, lapping, and blasting. For refractories, we produce SiC‑rich bricks, tiles, and monolithics engineered for thermal shock resistance, oxidation behavior, and wear performance. Specialty mixes for ramming, gunning, and castables are tuned to local cement chemistries and service atmospheres.

Our application engineering bridges materials to duty. In steel roll shops, we map grit size and morphology to removal rates and temperature rise; in cement preheater lines, we tune SiC content, bond type, and porosity to resist alkali attack while dissipating heat; in glass forehearth and feeder areas, we balance thermal conductivity with glaze compatibility; and in foundry linings, we manage slag‑refractory interaction to extend campaign length. We pair these with OEM packaging—moisture‑barrier sacks, ton‑bags with liners, labeled pallets—and provide PSQCA‑referenced conformity, ISO 9001/14001/45001 documentation, and where needed, third‑party test reports. For OEM programs, we align with IATF 16949 expectations, providing control plans and PPAP evidence.

Technical Comparison: SiC Abrasives and Refractories vs Conventional Options

Material properties and performance in Pakistani duty cycles

| Property and operating relevance | Black SiC Abrasive | Green SiC Abrasive | SiC‑Rich Refractory Brick | High‑Alumina Brick | Fused Alumina Abrasive |

|---|---|---|---|---|---|

| 硬度(モース) | ~9.2 | ~9.4 | - | - | ~9.0 |

| Typical grit shape | Angular, sharp | Sharper, more friable | - | - | Blocky/angular (grade dependent) |

| Thermal conductivity (W/m·K) | - | - | 15–30 (formulation dependent) | 2–6 | - |

| Oxidation resistance at high T | グッド | Good–very good | 素晴らしい | グッド | - |

| Abrasion on ferrous alloys | Strong cutting rate | Very aggressive, fine finishing | - | - | Moderate–strong |

| Thermal shock resistance (refractory) | - | - | 高い | 中程度 | - |

| Alkali/slag resistance (refractory) | - | - | 高い | 中程度 | - |

SiC abrasives cut cooler and sharper than many fused aluminas, improving throughput and finish. SiC‑rich refractories conduct heat better and resist thermal shock, a decisive advantage for cement preheaters, steel reheat, and foundry linings under cyclic loads common in Pakistan.

Black vs Green Silicon Carbide for bulk abrasive buyers

| Consideration | Black SiC | Green SiC |

|---|---|---|

| Composition and purity | Slightly higher free C and impurities; robust general purpose | Higher purity; sharper edges; lower metallic impurities |

| Cutting behavior | Excellent stock removal on ferrous and non‑ferrous | Superior for hard, brittle materials and precision finishing |

| Typical applications in Pakistan | Foundry grinding, descaling, general blasting | Fine grinding, lapping, ceramic and glass finishing |

| Cost and availability | More economical, widely available | Higher cost; favored for premium finishes |

| Heat generation during cut | Low–moderate | Low; efficient chip formation in brittle materials |

For Pakistani roll shops and foundries aiming at throughput, black SiC provides strong economics. Where finish and dimensional control matter—e.g., precision ceramics, glass, or carbide tooling—green SiC earns its premium.

SiC refractories versus traditional high‑alumina in high‑temperature service

| 基準 | SiC‑Rich Refractory | High‑Alumina Refractory |

|---|---|---|

| Thermal conductivity and heat flux | Higher; stabilizes temperature fields, reduces hot spots | Lower; can insulate but risks local hot spots under high flux |

| 耐熱衝撃性 | High; low CTE minimizes spalling | Moderate; higher CTE increases crack risk under cycling |

| Abrasion/erosion resistance | Very high; resists clinker and solid particle streams | Moderate; grain pull‑out accelerates wear |

| Oxidation and alkali resistance | Excellent with protective layers | Good; may suffer under alkali and CO/CO₂ cycling |

| Campaign life in Pakistani duty | 1.5–3× vs alumina in erosive zones | Baseline; frequent patching in abrasive areas |

When energy stability, campaign life, and lower maintenance are priorities, SiC refractories outperform alumina in many Pakistani hot‑zone and erosive applications.

Real‑World Applications and Success Stories from Pakistani Plants

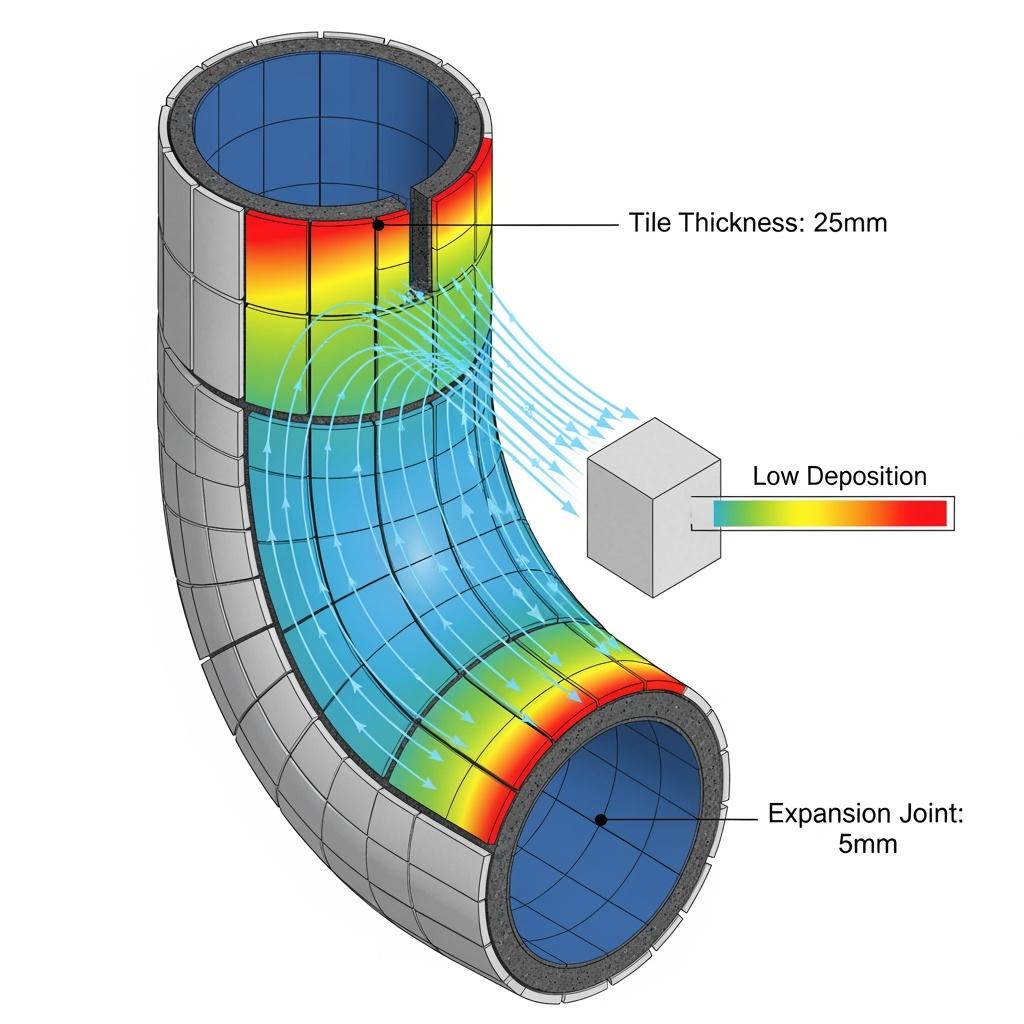

A North Punjab cement producer experiencing rapid wear in preheater elbows and riser ducts switched from mixed alumina bricks to SiC‑rich segmented tiles engineered by Sicarbtech. CFD‑informed tile geometry reduced impingement, while higher thermal conductivity eliminated local hot spots that had been driving spalls. Over the subsequent kiln campaign, the site reported smoother pressure profiles, fewer fouling events during monsoon season, and a payback within nine months after accounting for reduced fuel and emergency maintenance.

In a Karachi steel mini‑mill roll shop, inconsistent grinding rates and overheating forced frequent wheel changes and rework. Sicarbtech standardized black SiC grains with narrower PSD and controlled shape factors, paired with a tailored bond recipe for the local wheel maker. Removal rates rose 12–18% on typical grades, burn marks disappeared on critical passes, and scrap regrinds decreased meaningfully. The wheel maker appreciated OEM packaging and batch‑level COAs that simplified their audits.

A glass manufacturer in Sindh migrated from general fused alumina blasting to green SiC for mold surface preparation. The sharper cut reduced dwell time, producing more consistent textures and extending mold life. “Quality follows stability,” remarks Engr. S. Aftab, a reliability consultant to multiple OEMs and processors (Pakistan Maintenance & Reliability Exchange, 2024). “When your consumables act predictably, you spend less time firefighting and more time producing.”

Technical Advantages and Implementation Benefits with Local Regulatory Compliance

SiC’s covalent lattice yields extreme hardness and chemical durability while its thermal conductivity and low thermal expansion stabilize heat transfer. In abrasive use, this means cooler cutting, faster stock removal, and better surface finish. In refractories, it means fewer hot spots, lower thermal gradients, and resistance to erosive particle streams. The downstream results are familiar to Pakistani operations: reduced energy intensity, longer campaign life, fewer patch repairs, and cleaner stack profiles.

Sicarbtech ensures these physics translate into field performance through disciplined implementation. We align grit grading and morphology with grinding kinematics; define refractory microstructure targets for porosity, bonding, and oxidation behavior; and provide installation SOPs that specify substrate preparation, joint design, anchoring, and dry‑out curves. Documentation supports ISO 9001 and 14001; EHS procedures align with ISO 45001; and PSQCA‑referenced conformity packs streamline tenders. For OEMs and distributors, we can prepare IATF 16949‑aligned control plans and PPAP submissions, ensuring batch traceability that satisfies insurer and export‑buyer audits. Designing for documentation shortens acceptance cycles and lowers deployment risk.

Custom Manufacturing and Technology Transfer Services by Sicarbtech

Sicarbtech’s competitive edge for Pakistan’s bulk SiC buyers is a turnkey capability that spans powder science, refractory engineering, and knowledge transfer.

Our advanced R&D, strengthened by the Chinese Academy of Sciences (Weifang) Innovation Park, underpins proprietary processes for black and green SiC grading and for SiC‑rich refractory manufacturing. We engineer powder size distributions, shape factors, and impurity ceilings to fit grinding and blasting targets. For refractories, we apply advanced forming—including pressing, slip casting, and extrusion—followed by carefully profiled firing to lock microstructure. Reaction‑bonded and sintered pathways are selected based on duty, balancing cost, density, and oxidation behavior. The outcome is batch‑to‑batch repeatability that plants can trust.

For buyers pursuing localization, we offer complete technology transfer. Packages include process know‑how from raw material conditioning through mixing, forming, firing, and finishing; equipment specifications for crushers, classifiers, mixers, presses, kilns, and inspection stations; and training programs for operators, QC analysts, and maintenance personnel. Our factory establishment services cover feasibility studies, utilities and HVAC design, plant layout, EHS alignment with Pakistani regulations, and line commissioning. Hybrid models keep critical high‑temperature steps in Weifang while grinding, blending, packaging, or final machining occur in Pakistan, reducing lead times, mitigating FX risk, and building domestic capability.

Quality control systems and certification support are embedded end‑to‑end. Statistical process control tracks PSD, shape, and impurity metrics for abrasives; density, porosity, and strength for refractories; and moisture control for packaging. Mechanical and thermal testing—flexural strength, abrasion index, thermal conductivity—validate performance against specifications. For OEM and EPC programs, we align with IATF 16949, preparing control plans, capability studies, and PPAP documentation. After launch, our engineers continuously optimize firing curves, binder chemistries, and yields based on field feedback, protecting margins while sustaining performance. Over 10+ years and partnerships with more than 19 enterprises, this comprehensive, transferable model has delivered faster qualifications, fewer first‑run issues, and clear PKR‑denominated ROI.

Future Market Opportunities and 2025+ Trends for SiC Abrasives and Refractories

Multiple vectors point to broader adoption. Energy economics and ESG reporting will continue to reward refractories that reduce hot‑spotting and extend campaign life. As cement lines scale alternative fuels, erosive and chemically variable atmospheres will intensify, favoring SiC’s oxidation resistance and thermal stability. Steel mini‑mills pursuing tighter uniformity will migrate toward SiC‑rich hot‑zone components. Foundries and glass plants will standardize higher‑purity abrasives as surface finish and yield targets tighten for export.

Supply chains will professionalize as well. Engineering‑led distributors will differentiate by holding critical grades, supervising first‑fit refractory installations, and collaborating on data‑driven design refreshes. With technology transfer, local finishing and packaging will shorten response times and reduce FX exposure. As tenders emphasize total cost of ownership and OEE, SiC will shift from tactical consumables to strategic levers of reliability and energy performance.

よくある質問

Which SiC grade should I choose for grinding and blasting in Pakistan?

Black SiC offers excellent stock removal and economics for ferrous and non‑ferrous grinding and general blasting. Green SiC, with higher purity and sharper edges, excels in fine grinding, lapping, and finishing of hard, brittle materials such as ceramics, glass, and carbides. We finalize grade, PSD, and shape factors after reviewing removal rate targets, finish requirements, and wheel/bond systems.

How do SiC‑rich refractories improve kiln and furnace performance versus high‑alumina?

Higher thermal conductivity and lower thermal expansion reduce hot spots and thermal stresses, improving heat‑transfer stability and resisting spalling. In erosive zones, SiC’s hardness extends wear life. Plants often see longer campaigns, fewer patch repairs, and lower fuel intensity when switching from alumina to SiC in high‑flux, abrasive areas.

Can Sicarbtech provide PSQCA and ISO documentation for tenders and audits?

Yes. We provide PSQCA‑referenced conformity packs, ISO 9001/14001/45001 documentation, and structured third‑party test reports where required. For OEM programs, we support IATF 16949 with control plans, capability studies, and PPAP submissions.

What payback can Pakistani plants expect from SiC upgrades?

Abrasive standardization often pays back within 3–8 months through faster removal rates and fewer rejects. SiC refractory upgrades typically return 6–12 months depending on duty severity, fuel prices, and maintenance discipline. We model ROI in PKR, including duties, installation, and downtime reductions.

How do you ensure moisture control and packaging quality for bulk SiC?

We use moisture‑barrier sacks and lined ton‑bags with humidity indicators where needed, palletize to Pakistani warehousing standards, and label with batch traceability. Packaging specs are part of the QA plan to preserve PSD and flow characteristics.

Can Sicarbtech localize abrasive grading or refractory finishing in Pakistan?

Absolutely. Through technology transfer, we establish grading, blending, and packaging cells for abrasives, and machining or assembly lines for shaped refractories. Critical firing steps can remain in Weifang while downstream operations occur locally to reduce lead time and FX exposure.

What technical data do you need for a custom refractory lining or mix?

We typically request operating temperature and atmosphere, alkali and sulfur chemistry, particle velocities and impact angles, geometry and anchoring details, failure history, target campaign length, and installation constraints. This informs formulation, microstructure targets, and joint design.

How do you control batch‑to‑batch consistency for abrasives and refractories?

For abrasives, SPC on PSD, shape metrics, and impurities; for refractories, density, porosity, strength distributions, and thermal conductivity. We maintain full batch traceability and provide COAs aligned with your acceptance tests.

What lead times and logistics should Pakistani buyers expect?

Custom grades and shaped refractories typically ship in 4–10 weeks, depending on complexity and volume. We align deliveries with outage calendars, can phase shipments, and, under localization, position safety stock locally.

Do you support first‑fit and post‑install audits?

Yes. Our engineers supervise first‑fit refractory installs, validate dry‑out curves, and run wear/heat‑flux audits. For abrasives, we support wheel maker trials, on‑site grinding benchmarks, and process tuning.

オペレーションに適した選択

Sourcing SiC abrasives and refractories in bulk is not just a procurement exercise; it is a strategic decision that dictates uptime, energy intensity, and audit outcomes. By integrating precise grading and formulation with engineered shapes, disciplined installation, and complete documentation, Sicarbtech turns consumables into performance assets. Whether your bottleneck is a slow grinding pass, a spalling preheater lining, or a fouling furnace elbow, the right SiC program will stabilize your process and flatten your cost curve.

専門家によるコンサルテーションとカスタムソリューション

Share your duty profile, removal‑rate targets, kiln or furnace conditions, and pain points with Sicarbtech’s team. We will recommend the optimal SiC grades and refractory formulations, simulate performance where needed, and build an implementation plan synchronized with your shutdown schedule—complete with a PKR‑based ROI model. Contact: [email protected] or +86 133 6536 0038.

Explore Related Cluster Resources

- Why Use Silicon Carbide in Industrial Refractory Applications

- Key Benefits of SiC Abrasives in High-Temperature Processes

- Custom Silicon Carbide Abrasives for Foundries and Kilns

- Tailored SiC Refractory Bricks for Pakistani Manufacturers

- Comparing Black and Green Silicon Carbide for Bulk Buyers

- OEM Packaging and Custom Formulations for SiC Products

- Bulk Supply Options for Silicon Carbide Powder and Bricks

- Industries in Pakistan Using SiC Abrasives and Refractories

- Use Cases of SiC in Steel, Cement, and Glass Manufacturing

- How to Procure SiC Abrasives in Bulk from Trusted Suppliers

記事のメタデータ

Last updated: 2025-09-23

次回のレビュー予定日: 2026年1月15日

Content freshness indicators: 2025 Pakistan SiC abrasives and refractories outlook integrated; PSQCA, ISO 9001/14001/45001, and IATF 16949 considerations reflected; ROI modeled in PKR; case insights from 2023–2025 Sicarbtech deployments with 19+ enterprises; trends calibrated to energy volatility, ESG pressures, monsoon season effects, and localization initiatives.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.