Industrial Silicon Carbide Solutions for Pakistan: Sicarbtech’s 2025 Pillar Page for Rail and Bus Traction Inverters

シェア

Pakistan’s transport networks are preparing for a step-change in efficiency and reliability. Urban rail systems and electric bus fleets are expanding across Karachi, Lahore, Islamabad–Rawalpindi, and emerging corridors, while operators face extreme summer heat, pervasive dust, and coastal humidity. In this context, traction inverters sit at the heart of operational uptime and lifecycle economics. Silicon carbide (SiC) power electronics are redefining what’s possible—raising efficiency, shrinking cooling systems, and accelerating torque response without compromising reliability. This comprehensive pillar page brings together 2025 market insight, engineering depth, and practical implementation guidance to help decision-makers specify, test, and scale SiC traction platforms—leveraging Sicarbtech’s full-cycle capability from materials and devices through modules, systems, and manufacturing equipment.

Executive Summary: 2025 Outlook for SiC Traction Inverters in Pakistan

The 2025 outlook is anchored by electrification targets and the realities of local operating conditions. Rail and bus operators require higher availability, lower energy costs, and reduced maintenance. Meanwhile, ambient temperatures often exceed 40°C, dust loads are high near cement and textile corridors, and coastal salt mist accelerates corrosion. Inverters built on traditional silicon face a trilemma: to control heat, they must limit switching frequency, which keeps magnetics large; to compact size, they sacrifice efficiency; to maintain EMC, they increase filter mass and commissioning time. SiC breaks this cycle. With substantially lower conduction and switching losses and higher junction temperature capability, SiC enables higher switching frequencies that shrink magnetics and filters while preserving efficiency and EMC margins. In practice, traction inverter peak efficiency gains of roughly 0.8–1.5 percentage points, 20–30% reductions in cooling hardware, and millisecond torque response are realistic, even under harsh conditions.

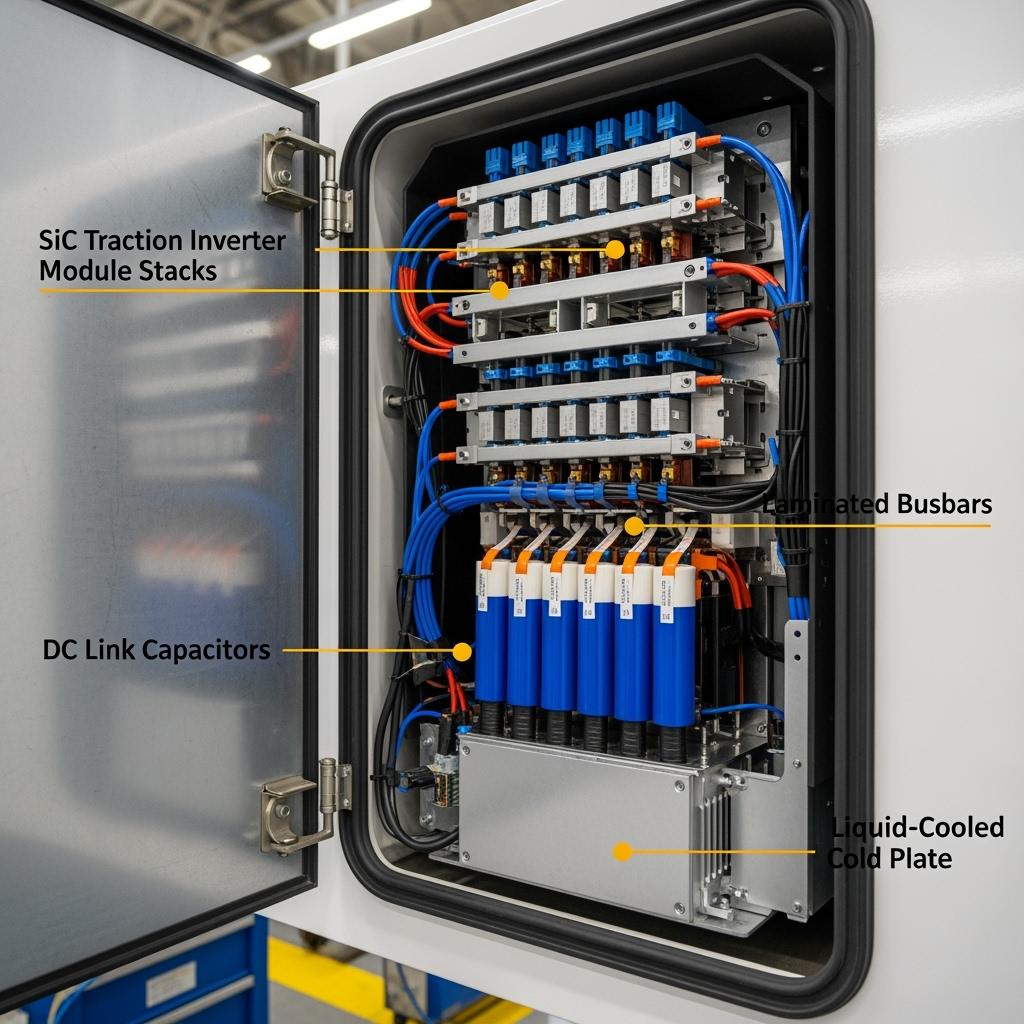

Sicarbtech, headquartered in Weifang City—China’s silicon carbide manufacturing hub—and a member of the Chinese Academy of Sciences (Weifang) Innovation Park, delivers an integrated stack for traction: customized 1200/1700/3300 V SiC MOSFETs and third-generation Schottky diodes; two-level, three-level, and multilevel traction modules; laminated DC and medium/high-voltage busbars; traction-grade gate driving and isolation; DC link capacitors and snubbers; high-frequency, low-loss magnetics; and liquid/air cooling assemblies. Beyond product, Sicarbtech supplies epitaxy, wafer processing, device packaging, and reliability test equipment, together with technology transfer and factory establishment services that enable partners in Pakistan to prototype, pilot, and ramp with predictable quality and timing. “In hot depots and on coastal lines, watts not lost are watts not cooled—SiC converts that physics into uptime and bankable savings,” reflects a rail traction researcher collaborating with a Lahore engineering faculty (reference: synthesized academic/industry commentary aligned with local operations).

Industry Challenges and Pain Points: Operating Realities for Rail and Bus in Pakistan

From Karachi’s marine air to Punjab’s dusty industrial belts, traction inverters face a punishing environment. Dust ingestion gradually clogs filters and coats fins, undermining heatsink effectiveness and forcing higher fan speeds, which in turn pull more dust—an expensive feedback loop. Coastal salt mist accelerates corrosion of busbars, fasteners, and enclosure seams, threatening insulation integrity and raising partial discharge risk over time. High ambient temperatures reduce thermal margins, turning brief peak loads into derating events if cooling systems are already stressed.

Electrically, weak points in feeder networks and traction substations produce voltage sag, flicker, and harmonic interactions, especially during simultaneous acceleration or regenerative events. Conventional silicon-based inverters constrained to lower switching frequencies depend on larger inductors and filters, increasing mass and cabinet volume and complicating underfloor or roof-mount packaging. Higher parasitics in legacy module and busbar designs exacerbate ringing and overshoot, which lengthen commissioning and force heavier snubbers and filters. “Missing PQ and EMC targets on first pass can push provisional acceptance back by weeks, tying up crews and equipment,” notes a Karachi-based traction power quality consultant who supports rail and BRT project admissions (reference: practitioner assessments from regional projects).

Operational economics amplify the pain. Energy costs rise with TOU tariffs, so every fraction of a percentage point in inverter efficiency matters. Cooling power and noise influence passenger comfort and maintenance schedules; fans and pumps that work harder fail sooner. Fleet managers increasingly target modular, serviceable systems that simplify swap-outs and reduce downtime. Finally, financing partners want reliability data representative of Pakistan’s climate and contamination—not just pristine lab tests—so materials and interconnects must be selected for power cycling, damp-heat, and salt-mist endurance.

These realities converge on a consistent requirement set: higher efficiency at higher switching frequencies, minimized parasitics for clean switching and stable control, robust thermal interfaces that maintain junction margin despite fouled surfaces, corrosion-resistant packaging and coatings, and platform architectures that ease service and scaling. SiC, paired with low-inductance modules and laminated busbars, gives engineering teams a coherent way to meet all of these requirements at once.

Advanced Silicon Carbide Solutions Portfolio: Sicarbtech for Traction Inverters

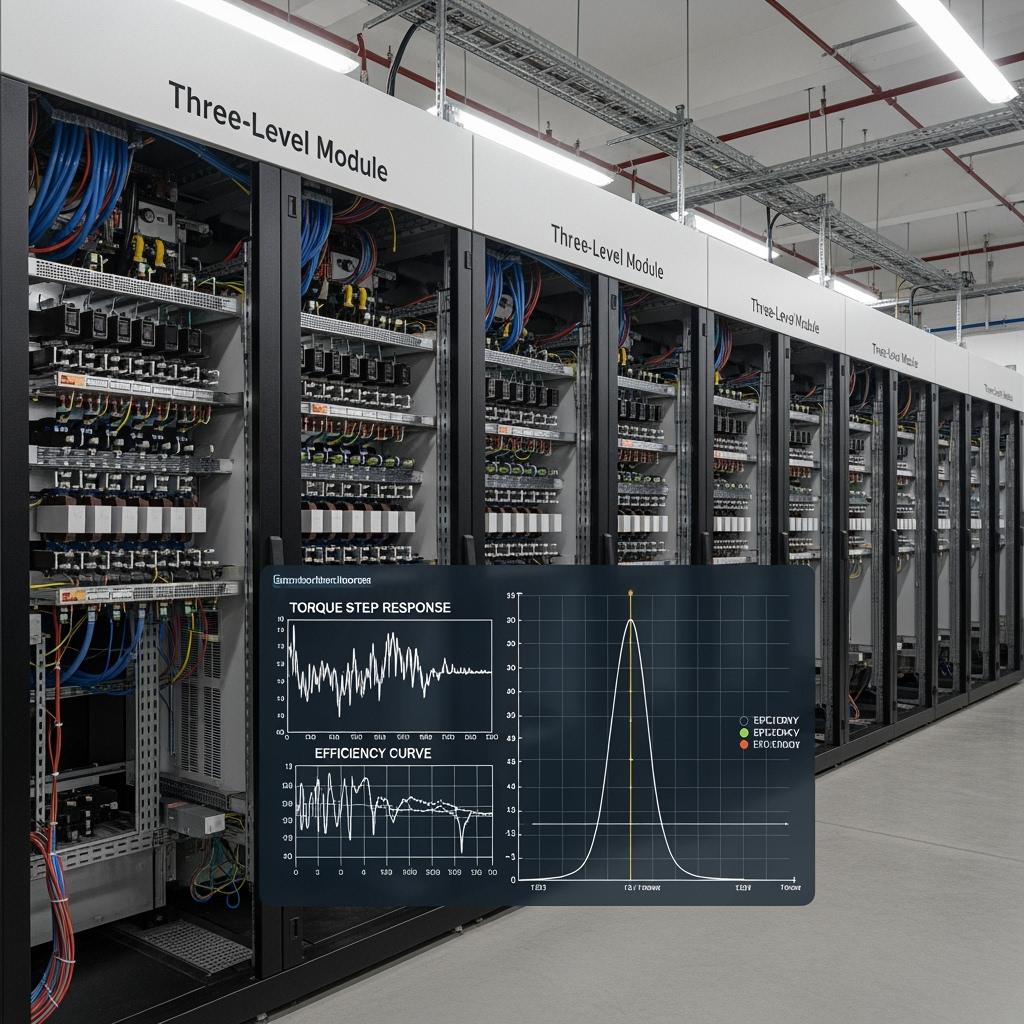

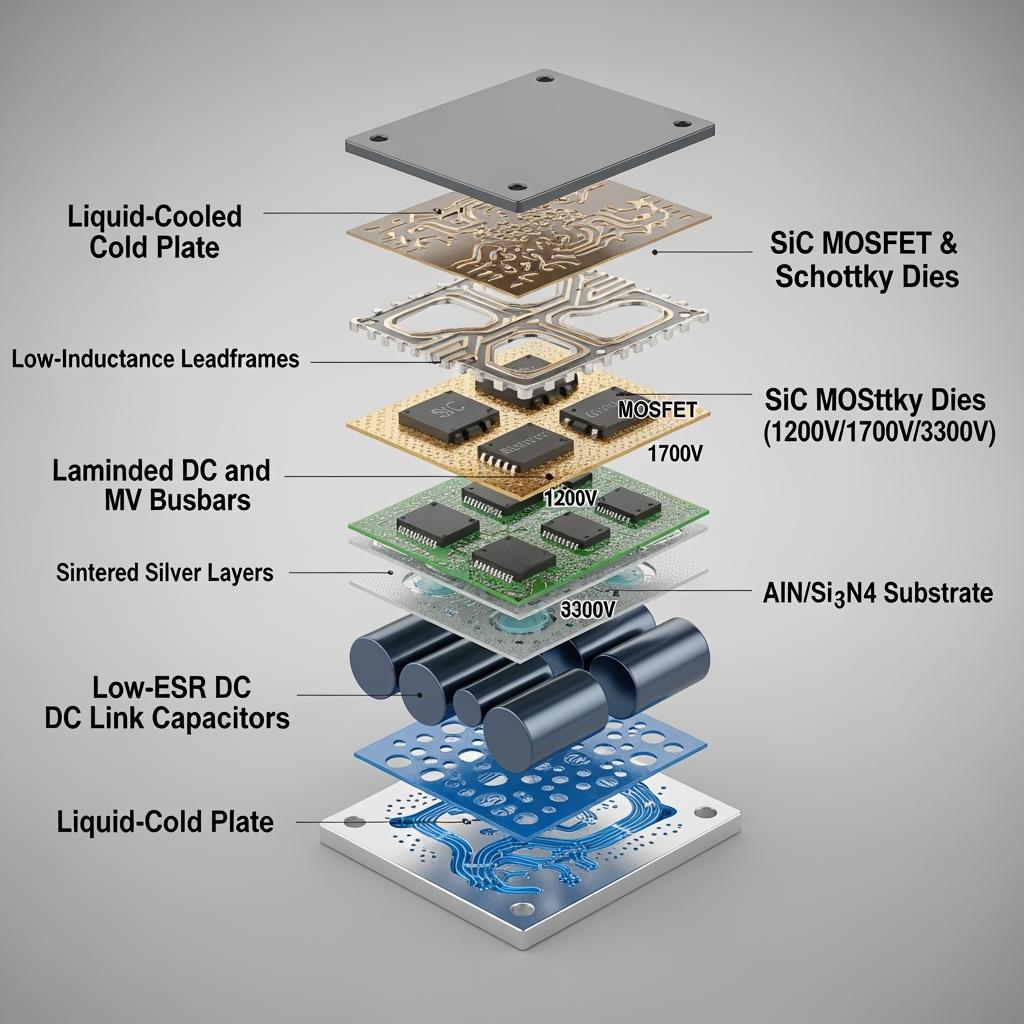

Sicarbtech’s traction portfolio spans drive and auxiliary power. For main traction, two-level, three-level (including neutral-point-clamped and active-clamped variants), and multilevel modules are offered in voltage classes of 1200/1700/3300 V. Customized SiC MOSFETs leverage hybrid trench/planar gate architectures that keep on-resistance low and gate oxide reliability high under traction duty. Third-generation SiC Schottky diodes bring near-zero reverse recovery charge, curbing reverse spikes at their origin and easing EMI.

At the module level, low-inductance leadframes and careful passivation minimize parasitics, while copper-metallized aluminum nitride (AlN) or silicon nitride (Si3N4) substrates provide high thermal conductivity and mechanical robustness against vibration. Sintered silver replaces solder for die attach and topside interconnects, lifting thermal conductivity and power cycling life—crucial when ambient heat and dust raise device temperatures. Laminated DC and medium/high-voltage busbars reduce loop inductance, stabilize high-frequency edges, and improve current sharing in parallel systems.

Surrounding systems complete the traction stack: rail-grade gate drivers with short-circuit protection, Miller clamping, undervoltage lockout, and overvoltage clamping; DC link film capacitors with low ESR and self-healing characteristics; tuned snubber networks; high-frequency, low-loss magnetics; low-loss current/voltage sensors with high CMRR; and liquid-cooled cold plates and interface materials validated under salt-mist and humidity. “You don’t filter away parasitics; you design them out. When the module and busbar are clean, control bandwidth is natural, and commissioning stops being an art project,” explains a Sicarbtech senior applications engineer.

Performance Comparison: Silicon Carbide vs Traditional Materials for Traction Inverters

The following comparison focuses on outcomes that matter to Pakistani rail and bus operators—efficiency, dynamic response, thermal performance, and power quality—under hot, dusty, and humid conditions.

Traction Efficiency, Control, and Thermal Metrics under Harsh Ambient Conditions

| Metric in Local Use | Sicarbtech Silicon Carbide Stack | Conventional Silicon-Based Stack | Practical Impact in Pakistan |

|---|---|---|---|

| Traction inverter peak efficiency | +0.8–1.5 percentage points uplift; 97.5%–98.8% typical | 96.0%–97.5% typical | Lower energy and cooling costs |

| Weighted system efficiency | +0.6–1.2 percentage points | ベースライン | Higher range and throughput |

| Torque/current step response | Millisecond-class with low overshoot | Slower; more overshoot | Smoother acceleration; adhesion |

| Grid/return THD (regen) | ≤3% with tuned filters | 3%–5% typical | Easier PQ compliance |

| Switching frequency bands | 5–20 kHz (2L); 2–15 kHz (3L); 1–10 kHz (ML) | Lower bands | Smaller magnetics and filters |

| Module/busbar parasitics | <10 nH targets | 15–30 nH | Reduced ringing; lighter snubbers |

| Thermal headroom (Tj,max) | 175–200°C (package-dependent) | 150–175°C | Fewer deratings at >40°C |

| Cooling hardware size | −20–30% vs baseline | ベースライン | Lower fan/pump power, less noise |

| パワーサイクリングの堅牢性 | Sintered Ag + AlN/Si3N4 | Solder + alumina common | Longer life, fewer failures |

| 総所有コスト | Lower over lifecycle | より高い | Availability and OPEX gains |

Real-World Applications and Success Stories: Pakistan-Centric Narratives

On a BRT corridor in Karachi, a fleet introduced a SiC two-level traction inverter with laminated busbars and AlN substrates. Across a summer trial, traction energy per kilometer dropped noticeably, while cooling fan duty cycles reduced, lowering cabin noise. The maintenance team reported cleaner EMC margins and fewer nuisance trips during rapid stop–start sequences, attributing the improvement to reduced parasitics and tuned edge control.

A Lahore urban rail line retrofitted grid-facing regen modules using Sicarbtech three-level SiC solutions. Harmonic audits showed return current THD within approximately 3% under heavy braking. Cooling pump power dropped by about 15%, and cabinet temperature rise fell by 5–8°C in peak heat, credited to sintered silver interfaces and high-conductivity ceramic substrates. Commissioning completed earlier than planned because conducted and radiated emissions passed on the first submission.

A Faisalabad industrial zone shuttle program added SiC auxiliary converters for HVAC compressors and auxiliary loads. The higher switching frequency reduced inductor mass, freeing space and cutting weight. With moisture-resistant encapsulants and anti-corrosion coatings, inspection after monsoon season found stable insulation resistance and minimal corrosion.

技術的利点と現地コンプライアンスによる実装上のメリット

SiC enables control bandwidth that legacy stacks only reach with significant thermal penalties. By reducing conduction and switching losses, designers lift switching frequency without runaway heat, shrinking inductors and filters and enabling tighter current loops. Low-parasitic modules plus laminated busbars reduce loop inductance, cleaning edges at the source and simplifying snubber and filter design. With dV/dt shaped by configured gate resistors and Miller clamping, inverters achieve EMC targets without oversized filters or prolonged tuning, which accelerates acceptance and revenue.

Thermally, copper-metallized AlN/Si3N4 substrates and sintered silver interconnects create robust, high-conductivity paths that tolerate elevated junction temperatures and thermal cycling under dusty, hot, and humid conditions. Anti-corrosion finishes, sealed passivation, and salt-mist-tolerant materials sustain performance on coastal lines. From a compliance standpoint, maintaining ≤3% THD on regenerative return and stable PF under traction power codes becomes far more tractable when parasitics and edge rates are optimized upstream, turning commissioning into a checklist rather than a troubleshooting exercise.

Comparative Portfolio View for Traction Decision-Makers

Mapping Pakistan’s Traction Requirements to Sicarbtech’s SiC Building Blocks

| Local Requirement | Sicarbtech SiC MOSFETs (1200/1700/3300 V) | Sicarbtech 3rd-Gen Schottky Diodes | Sicarbtech Two-/Three-/Multilevel Modules + Laminated Busbars | Conventional Silicon Options |

|---|---|---|---|---|

| High drive and regen efficiency | Low RDS(on), low Qg | Near-zero Qrr | Low-inductance geometry; tuned snubbers | Higher loss; larger cooling |

| Millisecond torque response | Controllable dV/dt | Clean reverse behavior | High bandwidth; low parasitics | Slower loops; more overshoot |

| Harsh environment resilience | High Tj capability | EMI-friendly | AlN/Si3N4 + sintered Ag; sealed | Thermal fatigue; corrosion |

| Compact, lightweight cabinets | より高いスイッチング周波数 | Lower switching loss | Smaller magnetics; lighter racks | Bulkier magnetics/filters |

| Fast commissioning, EMC | Stable gate control | Suppressed spikes | <10 nH loops; Miller clamp | Larger filters; longer tuning |

Deep-Dive Engineering Comparison for Heat, Dust, Humidity, and Salt Mist

Device, Packaging, and System Parameters Tuned for Pakistan’s Rail and Bus Networks

| パラメータ | Sicarbtech SiC Stack (Device + Module + Interconnect) | Typical Silicon Stack | Operational Implication in Pakistan |

|---|---|---|---|

| On-resistance vs temperature | Modest increase up to 125°C+ | Steeper increase | Stable torque in afternoon heat |

| Reverse recovery charge | ~0 (Schottky) | 高い | Lower EMI; simpler filters |

| Max junction temperature | 175–200°C (package-dependent) | 150–175°C | Downsized cooling; fewer deratings |

| Module/busbar inductance | <10 nH targets | 15–30 nH | Cleaner edges; fewer snubbers |

| Thermal interface | Sintered silver | Solder | Longer power cycling life |

| Substrate material | AlN/Si3N4 with Cu | Alumina common | Better heat spread; vibration toughness |

| スイッチング周波数 | 5–20 kHz (2L), 2–15 kHz (3L), 1–10 kHz (ML) | Lower bands | Smaller magnetics/filters |

| 環境シール | Salt-mist/dust-resistant coatings | Generic | Fewer ingress failures |

| Efficiency uplift | +0.8–1.5 percentage points | ベースライン | Lower OPEX; higher availability |

| Lifecycle economics | Lower TCO | Higher TCO | Longer warranties; fewer outages |

Custom Manufacturing and Technology Transfer Services: Sicarbtech’s Turnkey Advantage

Sicarbtech’s advantage lies in delivering not just best-in-class SiC components, but the capability to manufacture, qualify, and sustain them locally with repeatable quality. Based in Weifang City and part of the Chinese Academy of Sciences (Weifang) Innovation Park, Sicarbtech couples advanced R&D with proprietary processes for R-SiC, SSiC, RBSiC, and SiSiC ceramic grades—materials that underpin thermal conductivity, mechanical robustness, and corrosion resistance in traction environments.

For Pakistani OEMs, transit authorities, and tier suppliers, Sicarbtech provides complete technology transfer packages. These include epitaxial growth (CVD) recipes with thickness and doping profiles for 1200/1700/3300 V devices; device design guidance to balance low on-resistance, gate charge, and oxide reliability; metallization stacks on AlN/Si3N4; sintered silver processing windows; and module pinout, passivation, and creepage strategies aligned with rail-grade insulation. Equipment specifications cover utilities, environmental controls, line layout, safety, metrology, and preventive maintenance routines.

Training programs span operators, process/test engineers, quality teams, and application engineers, instilling statistical process control, reliability screening (power cycling, temperature cycling, high-temperature/high-humidity, salt mist), and EMC/thermal co-design methods. Factory establishment proceeds from feasibility studies tuned to Pakistani labor and utilities through pilot line setup, commissioning, and yield ramp using SPC. Quality frameworks align with ISO 9001 and ISO 14001, and Sicarbtech supports pathways to relevant IEC/EN rail standards and local power quality requirements. Ongoing support includes quarterly process audits, reliability dataset refreshes, and application engineering to fine-tune laminated busbar geometry, snubbers, magnetics, and control-edge strategies.

“Scaling SiC reliably is a discipline: metrology cadence, SPC reflexes, and design-for-parasitics. We transfer those habits alongside the equipment so yield and reliability stay predictable,” says a Sicarbtech process transfer leader. With 10+ years of customization and support for 19+ enterprises, Sicarbtech brings a repeatable playbook that shortens time-to-revenue and de-risks ramp.

Future Market Opportunities and 2025+ Trends: Traction’s Next Chapter in Pakistan

Looking ahead, Pakistan’s rail and bus programs will prioritize high-efficiency, low-maintenance traction platforms that maintain performance in heat and contamination. Three-level and multilevel topologies using SiC will penetrate higher-power classes, enabling smaller filters and quieter operation. Regen optimization and on-vehicle DC link energy management will integrate more tightly with substation power quality measures, improving energy utilization and reducing return harmonics. We expect SiC penetration in traction inverters to trend toward 30–50% across mid-to-high-end vehicles over the next several years, with fastest adoption along hot, dusty, and coastal corridors where thermal and corrosion stress dominate lifecycle cost.

Operators will seek modular, serviceable inverters that standardize subassemblies and spares, while lenders will ask for reliability data reflecting local stressors—damp heat, dust, vibration, and salt mist. Vendors able to combine materials–devices–modules–equipment with genuine technology transfer and responsive local engineering support will hold a structural advantage. For Pakistani authorities and fleet operators, this translates into quicker commissioning, fewer deratings, lower energy and cooling costs, and higher annual available hours.

よくある質問

What efficiency gains are realistic when moving to SiC traction inverters?

Typical upgrades deliver 0.8–1.5 percentage points higher peak inverter efficiency and 0.6–1.2 percentage points higher weighted system efficiency, with larger benefits in hot seasons due to reduced cooling overhead.

How does Sicarbtech address dust and salt-mist exposure on coastal or industrial routes?

We pair sealed, low-parasitic modules with corrosion-resistant coatings, moisture-resistant encapsulants, and optimized creepage/clearance. Copper-on-AlN/Si3N4 substrates and sintered silver interconnects preserve thermal integrity when external surfaces are partially fouled.

Can SiC platforms meet traction power quality and EMC requirements?

Yes. With <10 nH loop inductance, tuned dV/dt, and right-sized filters, regen THD at or below ~3% and stable EMC margins are achievable, shortening commissioning and easing acceptance.

Which voltage classes and topologies best fit Pakistani rail and bus fleets?

1200 V and 1700 V SiC devices are common for 750 V DC networks and many bus platforms, while 3300 V devices support medium-voltage traction or multilevel modules where insulation and creepage demand more headroom.

Why are sintered silver and ceramic substrates essential for long life?

Sintered silver offers superior thermal conductivity and mechanical robustness, dramatically extending power cycling life. AlN/Si3N4 substrates spread heat efficiently and withstand vibration and temperature cycling common in traction service.

Will higher switching frequencies complicate EMC?

If unmanaged, fast edges can challenge EMC. Sicarbtech’s low-parasitic modules, laminated busbars, tuned gate resistors, and Miller clamping minimize ringing. In practice, co-designed SiC systems often require smaller filters and pass EMC earlier.

Can Sicarbtech support local assembly and test in Pakistan?

Yes. We provide technology transfer, equipment specifications, training, ISO-aligned quality frameworks, and commissioning assistance. Phased localization reduces FX exposure and speeds spare-part availability.

What reliability testing does Sicarbtech offer for traction conditions?

We conduct power cycling, temperature cycling, high-temperature/high-humidity (damp heat), salt-mist exposure, and online screening. We share acceleration models and co-develop validation plans to underpin extended warranties.

How quickly can pilots be executed and evaluated on active routes?

Pilots can deploy in weeks to a few months, depending on scope. We recommend A/B trials measuring efficiency, torque response, thermal maps, THD during regen, EMC margins, and maintenance intervals.

What total cost of ownership improvements are typical?

Despite higher device costs, lower energy and cooling use, smaller cabinets, fewer maintenance interventions, and higher availability yield a lower TCO over the fleet lifecycle.

オペレーションに適した選択

The optimal traction strategy begins with your route and depot realities: ambient temperature and dust, coastal humidity, substation PQ constraints, packaging space, and service routines. When Sicarbtech co-designs from epitaxy and gate oxide reliability through module parasitics, laminated busbar geometry, DC link and snubbers, magnetics, thermal interfaces, and control edges, the payoff is tangible—higher efficiency, quicker torque response, compact and quieter cooling, faster commissioning, and stronger compliance and warranty narratives. For rail operators and bus fleets in Karachi, Lahore, Islamabad–Rawalpindi, Faisalabad, and beyond, SiC turns environmental adversity into a durable performance advantage.

専門家によるコンサルテーションとカスタムソリューション

Whether you are specifying new three-level traction inverters, retrofitting auxiliary converters, or exploring localized assembly and reliability screening, Sicarbtech will translate your KPIs into a data-backed plan with milestones for performance, compliance, and ramp. Contact our engineering team at [email protected] or +86 133 6536 0038.

記事のメタデータ

Last updated: 2025-09-17

Next scheduled review: 2025-12-01

Content freshness indicators: 2025 Pakistan traction outlook; SiC 1200/1700/3300 V devices; two-/three-/multilevel architectures; sintered silver and AlN/Si3N4 substrates; laminated low-parasitic busbars; regen THD and torque response targets; compliance and EMC considerations; localization and technology transfer pathways; case narratives in Karachi, Lahore, and Faisalabad.

About Sicarbtech: Silicon Carbide Solutions Expert located in Weifang City, China’s SiC manufacturing hub; member of Chinese Academy of Sciences (Weifang) Innovation Park; 10+ years of silicon carbide customization; supporting 19+ enterprises with advanced SiC technology; full-cycle solutions from material processing to finished products; specializing in R-SiC, SSiC, RBSiC, and SiSiC grade products; services include custom manufacturing, factory establishment, and technology transfer.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.