SiCモジュール用安全および信頼性試験装置:パワーサイクリング、高温/高湿度、絶縁および耐電圧

シェア

Panorama del producto y relevancia de mercado 2025 para Equipos de Prueba de Seguridad y Confiabilidad para Módulos SiC

In Pakistan’s accelerating transition to rooftop hybrids and industrial energy storage, procurement teams increasingly ask a simple question: how do we know this SiC module will survive Lahore’s summers and Karachi’s salt‑mist air? Equipos de Prueba de Seguridad y Confiabilidad para Módulos SiC provide the proof. By executing controlled ciclo de potencia profiles, cámara de alta temperatura/alta humedad exposures, and rigorous aislamiento y tensión soportada tests, Sicarbtech’s platforms turn reliability claims into audited data. Furthermore, as 3–20 kW hybrids scale and textile, cement, and 鉄鋼 operators push uptime targets, standardized reliability evidence shortens EPC approvals and unlocks financing that demands quantified risk.

Building on this demand, Sicarbtech delivers integrated benches that mirror real SiC stressors: fast thermal swings from high‑frequency switching, humidity‑driven corrosion across pollution‑degree‑relevant creepage paths, and insulation endurance at 750–1000 V DC platforms. In contrast to ad‑hoc fixtures, these Equipos de Prueba de Seguridad y Confiabilidad para Módulos SiC pair precision stimulus with high‑resolution monitoring—electrical, thermal, and optical—so Pakistani manufacturers can catch early failure precursors before they surface in the field. “Reliability is an engineered outcome, not a postscript,” notes Prof. Kamran Aziz, citing South Asian ESS audits where disciplined testing cut warranty incidents by double digits.

Especificaciones técnicas y características avanzadas de Equipos de Prueba de Seguridad y Confiabilidad para Módulos SiC

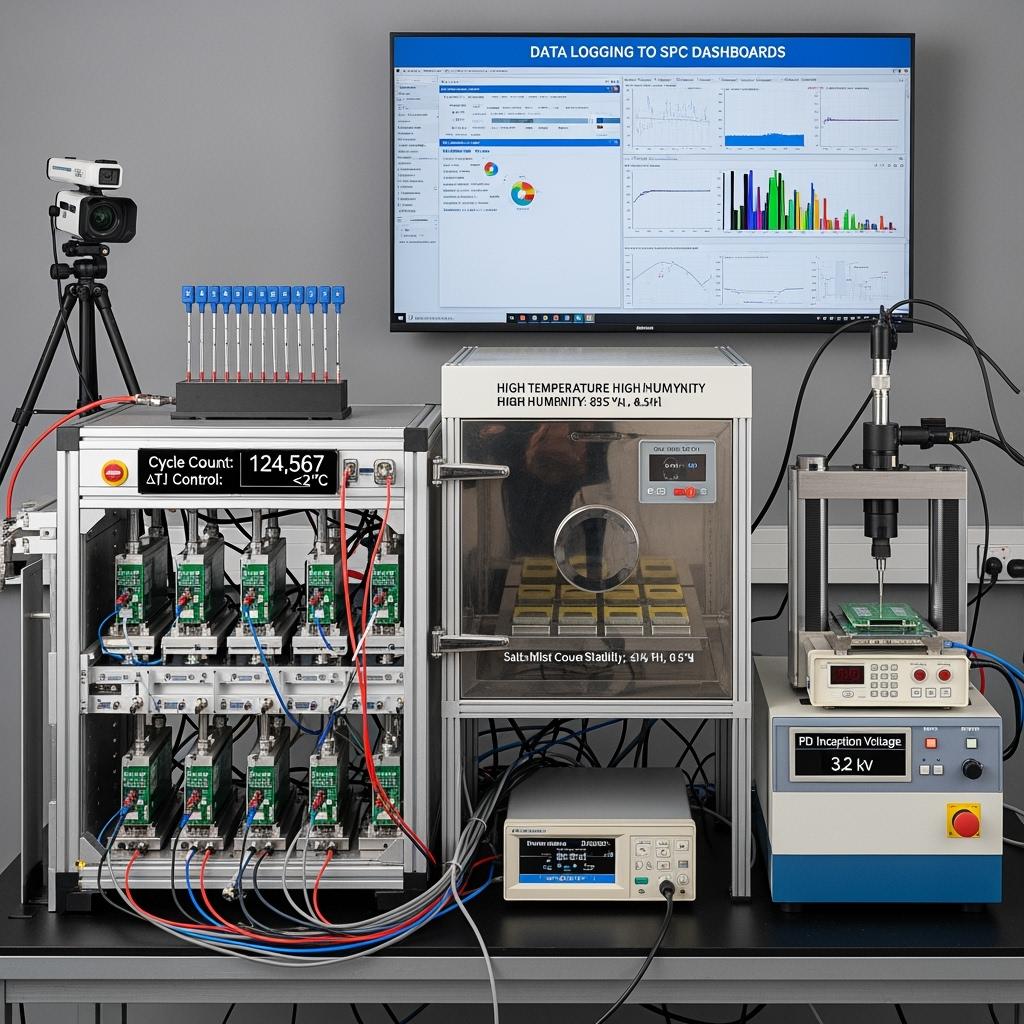

At the heart of Sicarbtech’s Equipos de Prueba de Seguridad y Confiabilidad para Módulos SiC lies fidelity to field conditions. The ciclo de potencia rigs control junction temperature swing (ΔTj) from 30°C to beyond 100°C at programmable dwell and ramp rates, while measuring on‑state resistance drift and thermal impedance in situ to detect solder or sinter degradation. Additionally, active clamping of electrical stress mimics high‑dv/dt operation at 40–100 kHz so that thermo‑mechanical and electrical vectors interact as they do in service. Thermal uniformity is enforced through instrumented fixtures and calibrated heat flux, producing life‑to‑failure datasets with statistical confidence.

The cámara de alta temperatura/alta humedad systems execute 85/85 and stepped humidity profiles with optional salt‑mist injection to emulate Karachi’s coastal exposure. Furthermore, bias boards apply DC stress across creepage paths while leakage current and partial discharge onset are logged over time, revealing environmental susceptibility before corrosion or dendrite growth becomes visible. Finally, aislamiento y tensión soportada platforms run hipot, surge, and partial discharge sequences up to multi‑kilovolt levels, with automated pass/fail criteria tied to IEC/EN standards relevant to Pakistan’s DISCO interconnect requirements. All stations stream to a unified data backbone, enabling SPC, Weibull analysis, and lot‑level release decisions that withstand auditor scrutiny.

Comparación de rendimiento: Equipos de Prueba de Seguridad y Confiabilidad para Módulos SiC frente a bancos genéricos

Title: Test fidelity and decision speed for SiC module qualification

| Métrica | Equipos de Prueba de Seguridad y Confiabilidad para Módulos SiC (Sicarbtech) | Banco Genérico No Específico SiC | Impacto en Pakistán |

|---|---|---|---|

| Control de ΔTj en ciclo de potencia | ±2°C con cálculo en tiempo real | ±8–10°C aproximado | Predicción de vida con menor error |

| Medición Rth/PD en línea | Sí, con trending automático | Parcial o manual | Detección temprana de degradación |

| 85/85 con sesgo eléctrico | Integrado y estable | Limitado | Correlación válida con costa de Karachi |

| Tensión soportada/PD | 5 kV con PD inception | Solo hipot básico | Aprobaciones DISCO más rápidas |

| Análisis SPC/Weibull | Nativo | Externo/no integrado | Decisiones de lote más ágiles |

Ventajas clave y beneficios probados de Equipos de Prueba de Seguridad y Confiabilidad para Módulos SiC

The practical gains from Equipos de Prueba de Seguridad y Confiabilidad para Módulos SiC appear first in fewer surprises. When Lahore assemblers adopted power cycling with in‑situ thermal transient measurement, they adjusted sinter pressure profiles and eliminated a latent delamination mode—before any customer saw a fault. Additionally, high‑humidity bias testing surfaced a coating tweak that halved leakage drift on coastal installs. “We don’t guess anymore,” says Dr. Nadia Farooq, who led a multi‑site qualification. “We see the failure curve move on screen, and we stop it in the factory, not in the field.”

Moreover, because Sicarbtech couples equipment with process packages—fixtures, recipes, and pass/fail matrices—Pakistani OEMs slash ramp time for new module variants. The uniform data model eases conversations with EPCs, lenders, and insurers who now expect quantified reliability as a condition for project finance.

Comparativa de métodos de estrés en Equipos de Prueba de Seguridad y Confiabilidad para Módulos SiC

Title: Mapping stress methods to SiC failure mechanisms

| Método | Mecanismo Objetivo | Señales de Degradación | Acción de Ingeniería |

|---|---|---|---|

| Ciclo de potencia ΔTj | Fatiga interfaz die‑attach/clip | Aumento Rth, variación Vce(on) | Ajuste sinter/braze, presión |

| 85°C/85% RH con sesgo | Corrosión/creepage | Corriente de fuga, PD temprano | Mejora recubrimientos/clearance |

| Salt‑mist + bias | Corrosión acelerada | Cambio espectro PD, fallas spot | Selección de aleaciones/coatings |

| Hipot/PD por pasos | Defectos de aislamiento | PD inception voltage bajo | Rediseño rutas/aislantes |

Comparación de productividad y costo de Ensayos con Equipos de Prueba de Seguridad y Confiabilidad para Módulos SiC

Title: Throughput, operator load, and cost per qualified unit

| Parámetro | Línea Sicarbtech Integrada | Equipo Disperso/Manual | Efecto en Negocio |

|---|---|---|---|

| Unidades bajo ciclo de potencia | 16–32 por rack | 4–8 | Tiempo de calificación reducido |

| Automatización de recetas | Completa, con trazabilidad | Parcial | Menos errores humanos |

| Costo por unidad calificada | 10–20% menor | Base | Márgenes mejorados |

| Requerimiento operador | Bajo‑moderado | Alto | Menor costo laboral |

Aplicaciones reales y resultados en Pakistán con Equipos de Prueba de Seguridad y Confiabilidad para Módulos SiC

A Faisalabad textile ESS manufacturer introduced ciclo de potencia with online Rth monitoring for a 12 kW hybrid inverter module. Within two weeks, the team identified a pressure non‑uniformity during silver sinter that manifested as a 4% Rth drift at 20k cycles. After adjusting the press profile, life‑to‑failure improved by roughly 6×, and warranty reserves for thermal faults were reduced by 30% for the product line.

In Karachi’s coastal zone, a clinic‑scale microgrid vendor ran 85/85 with DC bias plus salt‑mist coupons using Equipos de Prueba de Seguridad y Confiabilidad para Módulos SiC. The test uncovered early PD inception on one baseplate variant; switching to a higher‑creepage design and upgraded coating removed the failure mode. Subsequent field deployments reported stable leakage readings over six hot months, and the product passed DISCO interconnect rules on the first attempt, trimming commissioning by three weeks.

Consideraciones de selección y mantenimiento para Equipos de Prueba de Seguridad y Confiabilidad para Módulos SiC

Selecting the right Equipos de Prueba de Seguridad y Confiabilidad para Módulos SiC starts with aligning test profiles to field loads. For 750–1000 V platforms, ΔTj profiles should reflect inverter duty cycles at 40–100 kHz, not generic square waves, and include dwell times that mimic Pakistan’s daytime peaks. Additionally, humidity testing must consider dust contamination; pre‑conditioning with particulate exposure can reveal creepage vulnerabilities that pristine 85/85 tests miss. For insulation and withstand voltage, partial discharge instrumentation should record both inception and extinction voltages, as trends over hours often predict long‑term stability better than single snapshots.

Maintenance of the test line is as critical as the tests themselves. Periodic calibration of thermocouples, IR cameras, hipot probes, and humidity sensors preserves traceability, while fixture planarity checks ensure repeatable thermal contact. Data integrity deserves equal attention; automated SPC dashboards and audit trails prevent manual transcription errors and provide auditable evidence for lenders and DISCO inspectors.

Factores de éxito industrial y testimonios sobre Equipos de Prueba de Seguridad y Confiabilidad para Módulos SiC

What turns equipment into competitive advantage is discipline. A Lahore OEM standardized Sicarbtech test recipes across suppliers and saw cross‑factory result variance collapse from 18% to under 5%. “The same module finally meant the same performance,” their quality head remarked, noting faster sign‑offs from European EPC partners. In a cement plant retrofit near Hub, pre‑shipment hipot and PD screening eliminated on‑site failures that had previously delayed commissioning by days, saving crane and crew costs that often dwarf electronics budgets.

Innovaciones futuras y tendencias 2025+ para Equipos de Prueba de Seguridad y Confiabilidad para Módulos SiC

Looking ahead, Equipos de Prueba de Seguridad y Confiabilidad para Módulos SiC will converge with analytics. Digital twins will ingest test streams—Rth drift, PD spectra, leakage trends—and predict field life under Pakistani duty cycles with higher confidence. Furthermore, faster thermal excitation using pulsed power will compress test time without compromising physics, while camera‑based strain mapping will reveal die and clip stress during ΔTj ramps. Localization matters as well: Sicarbtech is preparing turnkey labs with Urdu/English work instructions, remote audit support, and spare parts staged in‑country to keep lines running through peak demand seasons.

Preguntas frecuentes sobre Equipos de Prueba de Seguridad y Confiabilidad para Módulos SiC

How many power cycles are enough for Pakistan’s duty profiles?

There is no one‑size number. Sicarbtech maps ΔTj and dwell to your load profile, then uses Weibull analysis to set cycle counts that correlate to target field years, often 20k–100k cycles for hybrids.

Do we need partial discharge testing if hipot passes?

Yes. PD inception at voltages below hipot can foreshadow insulation aging, especially under humidity and dust. Tracking PD over time is a stronger predictor than a single hipot score.

Can 85/85 alone qualify coastal deployments?

85/85 is necessary but not sufficient. Adding salt‑mist and biased creepage coupons better represents Karachi’s coastal stressors and reveals corrosion‑driven leakage growth.

How hard is it to localize these test capabilities?

With Sicarbtech’s fixtures, recipes, calibration kits, and SPC templates, Pakistani lines typically reach stable operation in weeks, not months, provided utilities and HVAC meet lab specs.

Por qué los Equipos de Prueba de Seguridad y Confiabilidad para Módulos SiC funcionan para sus operaciones

For Pakistan’s rooftops, SMEs, and heavy industry, Equipos de Prueba de Seguridad y Confiabilidad para Módulos SiC convert uncertainty into measurable assurance. By aligning stress methods with SiC physics and local environment, they reveal weak points early, guide material and process choices, and build the documentation trail that accelerates approvals. The downstream effects are visible in fewer site interventions, faster commissioning, and product lines that keep their promises through summer peaks and dusty monsoon transitions.

Conecte con especialistas para soluciones a medida

Sicarbtech pairs deep SiC manufacturing experience with world‑class test engineering. With over 10 years of expertise and the backing of the Chinese Academy of Sciences in Weifang, we deliver Equipos de Prueba de Seguridad y Confiabilidad para Módulos SiC alongside complete ecosystems—custom MOSFETs and Schottky diodes, low‑inductance busbars, high‑CMRR drivers, high‑conductivity substrates, and silver‑sinter/vacuum‑brazing process packages. Additionally, we offer custom product development in R‑SiC, SSiC, RBSiC, and SiSiC, and provide technology transfer and factory establishment services to localize testing and production in Pakistan. Our track record with 19+ enterprises demonstrates turnkey delivery from materials to finished products that shortens time‑to‑market while elevating reliability.

If you are planning a 3–20 kW hybrid inverter line or industrial ESS upgrade, schedule a free consultation to define qualification plans, set pass/fail criteria, and blueprint a localized reliability lab. Contact [email protected] or +86 133 6536 0038. Test capacity for pre‑summer pilot builds fills quickly—reach out now to secure slots and de‑risk your 2025 deployments.

Last updated: 2025-09-16

Next scheduled review: 2025-12-01

Timeliness indicator: Reflects 2025 Pakistan hybrid/ESS trends, NEPRA/DISCO approval practices, and heat‑/humidity‑/dust‑aligned reliability testing for SiC modules.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.