SiCモジュール認定のための生産ラインパワーサイクリングおよび高温/高湿度信頼性試験装置

シェア

On the production floor of a Lahore inverter OEM, the difference between a promising SiC module and a bankable product is proven not in a datasheet but in the stress chambers next door. Production‑Line Power Cycling and High‑Temperature/High‑Humidity Reliability Test Equipment for SiC Module Qualification is where that proof is forged. For Pakistan’s textile, cement, and 鉄鋼 sectors—where 50–250 kW string inverters must endure 50°C inlet air, dust, and weak‑grid events—Sicarbtech’s reliability equipment transforms qualification from an art into a repeatable, auditable process. The mission is straightforward: compress years of field stress into weeks of controlled cycling, then release only the hardware that stays electrically tight, thermally stable, and mechanically sound.

Production‑Line Power Cycling and High‑Temperature/High‑Humidity Reliability Test Equipment for SiC Module Qualification product overview and 2025 market relevance

As Pakistan’s C&I PV market accelerates and 1500 V DC platforms proliferate, the demand for SiC module durability has never been higher. Production‑Line Power Cycling and High‑Temperature/High‑Humidity Reliability Test Equipment for SiC Module Qualification addresses that demand with fixtures and chambers designed to validate die‑attach integrity, interconnect robustness, and insulation coordination under realistic operating profiles. Power cycling rigs emulate inverter current stress with controlled junction temperature swings, while THB (temperature‑humidity‑bias) chambers expose insulation systems and passivation to 85°C/85% RH conditions at relevant DC bias. Together, they create a test tapestry that mirrors Pakistan’s thermal cycles, monsoon humidity surges, and dust‑driven hot spots.

In 2025 tenders, beyond IEC 62109 safety and IEC 61000‑6‑2/‑6‑4 EMC, buyers increasingly probe manufacturers’ reliability evidence—THB hours, cycling counts to specific ΔTj, and failure analysis protocols. Production‑Line Power Cycling and High‑Temperature/High‑Humidity Reliability Test Equipment for SiC Module Qualification, integrated into Sicarbtech’s technology transfer, gives Pakistani OEMs the capability to answer those questions with confidence and local data, shortening certification loops and fortifying PKR‑based business cases.

Production‑Line Power Cycling and High‑Temperature/High‑Humidity Reliability Test Equipment for SiC Module Qualification technical specifications and advanced features

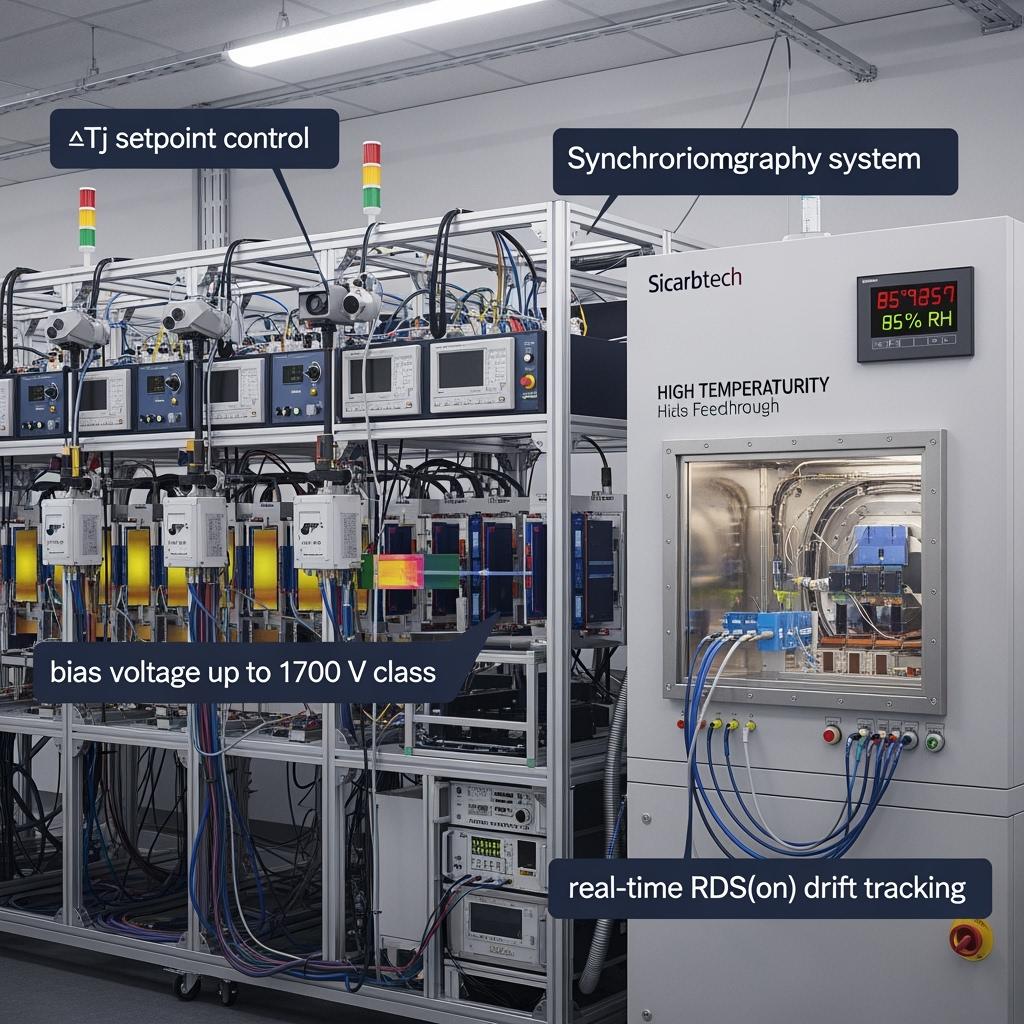

At the heart of Production‑Line Power Cycling and High‑Temperature/High‑Humidity Reliability Test Equipment for SiC Module Qualification are two families of tools. The power cycling systems deliver programmable current pulses to SiC half‑bridge and full‑bridge modules, holding junction temperature swings at defined ΔTj—often 40–80°C—with cycle counts that map to expected field life. Closed‑loop control uses IR thermography or embedded NTCs to pin ΔTj even as device characteristics evolve, while on‑the‑fly RDS(on) sampling and VCE(sat)/VF proxies catch early drift that signals die‑attach or bond fatigue. High‑bandwidth logging captures transient behavior so failure precursors are not missed.

Complementing these are THB and environmental chambers tailored for SiC insulation stacks. With bias up to the 1700 V class and carefully managed dew points, Production‑Line Power Cycling and High‑Temperature/High‑Humidity Reliability Test Equipment for SiC Module Qualification stresses passivation layers, substrate metallization, and seals that must survive coastal Karachi’s salt‑laden air or monsoon humidity in Punjab. Fixtures respect creepage and clearance and include guard rings to detect leakage paths early. All systems feed a central database, enabling Weibull analyses and lot‑to‑lot traceability that certification bodies and bankability studies increasingly expect.

Pakistan‑focused capability comparison for Production‑Line Power Cycling and High‑Temperature/High‑Humidity Reliability Test Equipment for SiC Module Qualification

| Reliability validation dimension | SiCモジュール認定のための生産ラインパワーサイクリングおよび高温/高湿度信頼性試験装置 | Generic thermal chamber and bench setup |

|---|---|---|

| ΔTj control and accuracy | Closed‑loop ±2°C with IR/NTC feedback | Open‑loop; variable ΔTj |

| Current/bias capability | High‑current pulsing; 1200/1700 V bias | Limited current; low bias |

| Inline parameter tracking | RDS(on), VF, leakage, partial discharge | Manual spot checks |

| Test throughput in production | Multi‑bay, parallel cycling | Single‑DUT, slow |

| データの整合性とトレーサビリティ | Centralized, lot‑linked analytics | Scattered logs, limited QA value |

Key advantages and proven benefits of Production‑Line Power Cycling and High‑Temperature/High‑Humidity Reliability Test Equipment for SiC Module Qualification with expert quote

The decisive advantage is predictive confidence. Production‑Line Power Cycling and High‑Temperature/High‑Humidity Reliability Test Equipment for SiC Module Qualification reveals how modules age under Pakistani duty cycles before they leave the factory. With controlled ΔTj and 85/85 bias, weak interfaces show themselves as trendable drifts rather than field failures. Furthermore, faster test throughput shortens R&D loops and allows OEMs to iterate packaging stacks—silver sinter, vacuum braze, and busbar geometry—without losing tender windows.

“Bankability is shifting from spec sheets to statistically defensible reliability,” notes Dr. Mariam Qureshi, an IEEE senior member advising regional lenders on PV asset risk (source: IEEE Reliability & Bankability Forum, 2025). “If you can show ΔTj‑controlled cycling data and 85/85 bias leakage trends with traceable lots, your SiC inverter moves from ‘interesting’ to ‘investable’.”

Feature and outcome comparison for Production‑Line Power Cycling and High‑Temperature/High‑Humidity Reliability Test Equipment for SiC Module Qualification

| 属性 | SiCモジュール認定のための生産ラインパワーサイクリングおよび高温/高湿度信頼性試験装置 | Minimal compliance setup |

|---|---|---|

| Cycle‑to‑failure modeling | Weibull with censoring and FA hooks | Basic pass/fail |

| Failure analysis integration | Pre‑planned decap/SAM/X‑ray triggers | Ad‑hoc FA |

| Throughput per shift | Dozens of modules, parallel bays | Few modules, sequential |

| Impact on certification timeline | Shorter, with stronger evidence | Longer, iterative |

| OPEX and warranty risk | Lower via early detection | Higher due to field surprises |

Real‑world applications and measurable success stories using Production‑Line Power Cycling and High‑Temperature/High‑Humidity Reliability Test Equipment for SiC Module Qualification

A Lahore OEM migrating to 1500 V SiC string inverters implemented Production‑Line Power Cycling and High‑Temperature/High‑Humidity Reliability Test Equipment for SiC Module Qualification alongside a silver‑sinter packaging change. Over eight weeks, the team executed 300k cycle tests at ΔTj = 60°C on pilot lots and ran 1000‑hour 85°C/85% RH bias tests on insulation stacks. The data showed a 2–3× improvement in cycling life versus soldered die‑attach, while leakage during THB held below threshold. With that evidence, the project cleared third‑party reliability audits and shaved a month off certification, enabling earlier shipments before summer tariffs peaked.

In southern Punjab, a distributed plant’s inverter supplier traced sporadic field trips to a specific lot through the centralized database in Production‑Line Power Cycling and High‑Temperature/High‑Humidity Reliability Test Equipment for SiC Module Qualification. Correlating RDS(on) drift patterns with FA confirmed a localized die‑attach void issue. Rapid containment limited replacements to a handful of cabinets, protecting PKR margins and customer confidence.

Deployment outcomes enabled by Production‑Line Power Cycling and High‑Temperature/High‑Humidity Reliability Test Equipment for SiC Module Qualification

| Business/technical goal | With Production‑Line Power Cycling and High‑Temperature/High‑Humidity Reliability Test Equipment for SiC Module Qualification | Without dedicated equipment |

|---|---|---|

| Time‑to‑market on 1500 V platform | Accelerated by 3–5 weeks | Extended; multiple re‑tests |

| Warranty reserve sizing | Lower due to quantified risk | Higher to hedge uncertainty |

| Field failure containment | Fast root‑cause and lot isolation | Broad recalls; reputational hit |

| Rooftop project logistics | Lighter sinks validated; fewer fans | Over‑engineered thermal stack |

Selection and maintenance considerations for Production‑Line Power Cycling and High‑Temperature/High‑Humidity Reliability Test Equipment for SiC Module Qualification

Choosing the right configuration for Production‑Line Power Cycling and High‑Temperature/High‑Humidity Reliability Test Equipment for SiC Module Qualification starts with your module portfolio and voltage class. Half‑bridge and full‑bridge footprints benefit from modular cycling bays with adaptable clamp forces and Kelvin sensing to maintain accurate ΔTj control as devices age. For THB, ensure bias feedthroughs and guard structures maintain creepage per 1500 V requirements and that humidity control is stable in Pakistan’s monsoon season. Sicarbtech typically pairs these with non‑destructive evaluation stations—SAM and X‑ray—so any drift in electrical parameters quickly routes to imaging before destructive FA.

Operationally, chamber calibration is the quiet backbone of credibility. Regular verification of temperature uniformity, humidity accuracy, and current waveform fidelity keeps data defensible. In dusty urban environments, cleanroom‑adjacent procedures for fixture prep and filter maintenance preserve the integrity of Production‑Line Power Cycling and High‑Temperature/High‑Humidity Reliability Test Equipment for SiC Module Qualification, ensuring that contamination does not masquerade as device fatigue.

Industry success factors and customer testimonials for Production‑Line Power Cycling and High‑Temperature/High‑Humidity Reliability Test Equipment for SiC Module Qualification

Pakistan’s 2025 tenders reward OEMs who combine efficiency with reliability proof. Production‑Line Power Cycling and High‑Temperature/High‑Humidity Reliability Test Equipment for SiC Module Qualification underpins both agendas. A Karachi program manager summarized the shift after installing Sicarbtech’s line: “Our reliability meetings stopped being debates and became reviews. With cycling and 85/85 data on screen, investors stopped asking ‘if’ and started asking ‘when can you ship?’”

Future innovations and market trends around Production‑Line Power Cycling and High‑Temperature/High‑Humidity Reliability Test Equipment for SiC Module Qualification

Looking forward, Production‑Line Power Cycling and High‑Temperature/High‑Humidity Reliability Test Equipment for SiC Module Qualification will evolve toward faster ΔTj ramp control, live partial‑discharge monitoring during humidity bias, and AI‑assisted drift detection that flags subtle precursors before classical thresholds. Sicarbtech’s roadmap includes combined electro‑thermal stress profiles that mirror Pakistan’s diurnal load and dust‑induced cooling degradation, plus cloud‑linked databases that let lenders audit reliability evidence across fleets. Localization will also deepen, with Pakistani partners adopting on‑site FA capability integrated into the test line to accelerate close‑the‑loop learning.

Common questions and expert answers on Production‑Line Power Cycling and High‑Temperature/High‑Humidity Reliability Test Equipment for SiC Module Qualification

How does Production‑Line Power Cycling and High‑Temperature/High‑Humidity Reliability Test Equipment for SiC Module Qualification map to field life?

By controlling ΔTj and cycle profiles to mirror daily load swings, then correlating cycle‑to‑failure with field telemetry through Weibull models. This provides a credible translation from accelerated tests to expected service years.

Is Production‑Line Power Cycling and High‑Temperature/High‑Humidity Reliability Test Equipment for SiC Module Qualification necessary if we already pass IEC safety and EMC?

Safety and EMC are entry tickets; bankable reliability needs cycling and 85/85 evidence. The equipment uncovers latent weaknesses—die‑attach voiding, bond fatigue, insulation leakage—that compliance alone won’t reveal.

Can Production‑Line Power Cycling and High‑Temperature/High‑Humidity Reliability Test Equipment for SiC Module Qualification support 1700 V SiC platforms?

Yes. Bias feedthroughs and fixtures are designed for 1200/1700 V classes with appropriate creepage, clearance, and guard structures, making it suitable for 1500 V DC string inverters.

How quickly can we integrate Production‑Line Power Cycling and High‑Temperature/High‑Humidity Reliability Test Equipment for SiC Module Qualification into an existing line?

Sicarbtech delivers turnkey setups with fixtures, profiles, and QA templates. Most partners reach stable operation within weeks, not months, thanks to on‑site training and remote analytics support.

What KPIs should we log with Production‑Line Power Cycling and High‑Temperature/High‑Humidity Reliability Test Equipment for SiC Module Qualification?

ΔTj, cycle count, RDS(on)/VF drift, leakage current under bias, partial discharge events where applicable, and post‑test imaging results (SAM/X‑ray). Lot and operator traceability closes the loop.

Why Production‑Line Power Cycling and High‑Temperature/High‑Humidity Reliability Test Equipment for SiC Module Qualification works for your operations

Pakistan’s climate and grid do not forgive weak joints or marginal insulation. Production‑Line Power Cycling and High‑Temperature/High‑Humidity Reliability Test Equipment for SiC Module Qualification exposes those flaws early, letting you ship only what will survive dust, heat, and voltage swings. With better data, designs iterate faster, heat sinks shrink, fan counts fall, and commissioning timelines compress. The result is a tighter, lighter, more reliable inverter portfolio that holds its rating exactly when tariffs make it count.

カスタムソリューションのスペシャリストと連携

Sicarbtech stands behind Production‑Line Power Cycling and High‑Temperature/High‑Humidity Reliability Test Equipment for SiC Module Qualification with more than 10 years of SiC manufacturing expertise and the innovation backing of the Chinese Academy of Sciences in Weifang. We deliver not just equipment, but full technology transfer—cycling and THB profiles, fixturing, calibration routines, and QA analytics—so Pakistani partners stand up robust, auditable reliability programs. Because Sicarbtech also develops R‑SiC, SSiC, RBSiC, and SiSiC materials, assembles power modules, and supplies test stations, we provide turnkey solutions from material processing to finished product qualification, validated with 19+ enterprise collaborations.

Engage our engineers for a free consultation to design your reliability lab around 1000/1500 V platforms, compress certification timelines, and de‑risk warranty exposure. Email [email protected] or call/WhatsApp +86 133 6536 0038. With 2025 tenders tightening, early deployment of production‑line reliability testing is your fastest path to bankable SiC shipments.

記事のメタデータ

最終更新日2025-09-16

次回レビュー予定2025-12-01

Timeliness indicators: Reflects Pakistan’s shift to 1500 V DC strings, NEPRA/IEC/PEC expectations, and 2024–2025 trends in power cycling and THB testing for SiC module qualification, including investor and certification requirements.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.