SiC Three-Level NPC Inverter Power Stages for Medium-Voltage Drives and Grid-Tied Converters

Share

2025 Product Overview and Market Relevance for Pakistan

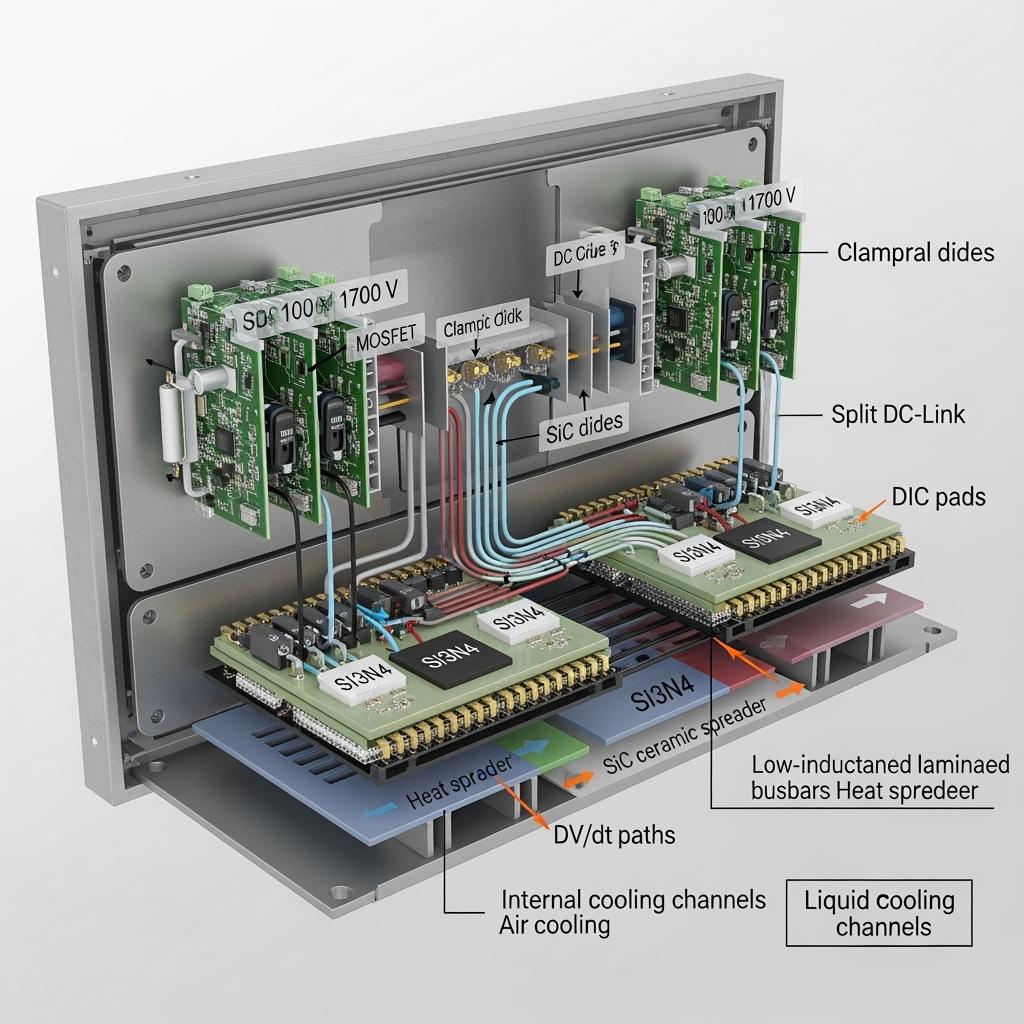

Silicon Carbide (SiC) three-level Neutral-Point Clamped (NPC) inverter power stages bring high-efficiency, high-frequency conversion to medium-voltage (MV) motor drives and grid-tied converters used across Pakistan’s textile, cement, steel, and emerging industrial sectors. By combining 1200–1700 V SiC MOSFETs/diodes in optimized three-level topologies (NPC/T-NPC/ANPC), these stages achieve lower dv/dt per switch, reduced harmonic distortion, smaller magnetics, and >98% system efficiency—ideal for harsh, dust-prone environments and unstable grids.

Why it matters in 2025:

- Industrial parks in Karachi, Lahore, and Faisalabad face voltage sags, harmonics, and frequent switching. SiC NPC inverters provide faster transient response and robust ride-through, protecting critical continuous processes.

- MV drives (e.g., 3.3 kV class outputs via series-stacked low-voltage cells or transformer-coupled architectures) benefit from higher switching frequencies (up to 20–40 kHz effective per phase leg) and lower filter size, enabling compact retrofits into existing MCC rooms.

- Grid-tied converters for process plants and captive power integration (battery, PV, genset) require THD compliance and PF control. SiC NPC stages help achieve PF >0.99 and THDi <5%, aligning with evolving NTDC/utility requirements and NEECA efficiency objectives.

Sicarb Tech designs and manufactures SiC NPC inverter power stages and complete stacks—paired with high-temperature gate drivers, ceramic heat spreaders (R‑SiC, SSiC, RBSiC, SiSiC), and intelligent control modules—backed by the Chinese Academy of Sciences and 10+ years of SiC engineering experience.

Technical Specifications and Advanced Features

- Topologies: NPC, T-NPC, ANPC three-level phase legs; modular subrack assemblies

- Device ratings: 1200–1700 V SiC MOSFETs and Schottky diodes; clamping diodes in SiC for minimal recovery

- Output classes: Medium-voltage drives via series-stacked low-voltage cells (e.g., 3.3 kV–6.6 kV output with isolation transformer options); grid-tied 400–690 V systems natively

- Switching frequency: 10–40 kHz effective (leg-level); optimized carrier-based PWM or space-vector PWM with active neutral-point balancing

- Efficiency: >98% stage efficiency; system-level UPS/drive efficiency +5–8% versus silicon baselines

- Thermal capability: Junction temperature -55°C to 175°C; SSiC/RBSiC heat spreaders and high-conductivity TIMs

- dv/dt control: Configurable gate resistors, RC snubbers, and shielded busbars; dv/dt optimized to reduce motor insulation stress

- Harmonic performance: THDi <5% with appropriate filters; PF >0.99 with integrated PFC front-ends

- Protection: DESAT-based short-circuit detection (2–3 μs), active short-circuit ruggedness, soft turn-off, UVLO, OTP/NTC sensing

- Monitoring and control: Digital control core (Cortex/FPGA), neutral-point voltage balancing algorithms, IEC 61850/Modbus TCP/RTU support

- Compliance-ready design: Supports systems targeting IEC 61800-5-1 (adjustable speed drives safety), IEC 62477-1 (power electronic safety), IEC 61000 family (EMC), and local utility interconnection norms

Descriptive Performance Comparison: SiC Three-Level NPC vs. Two-Level Silicon IGBT Drives

| Capability | SiC 3-Level NPC Inverter Stage | 2-Level Silicon IGBT Inverter | Real-World Impact in Pakistan Plants |

|---|---|---|---|

| Conversion efficiency | >98% | 92–95% | Lower PKR energy cost, reduced cooling infrastructure |

| Switching frequency | 10–40 kHz effective | 2–8 kHz | Smaller L/C filters, quieter motors, compact cabinets |

| Output waveform quality | Lower dv/dt, lower THD | Higher dv/dt, higher THD | Less motor insulation stress, fewer bearing currents |

| Thermal operation | Tj to 175°C | Tj ~125°C | Reliable under 45–50°C ambient and dust loads |

| Power density | High (>10 kW/L possible) | Moderate | 30–40% footprint reduction; easier retrofits |

| Maintenance interval | Extended | Frequent | Fewer trips, fewer component replacements |

Key Advantages and Proven Benefits

- Superior waveform quality with lower dv/dt per step reduces motor insulation stress and common-mode currents—crucial for older MV motor fleets in textile mills and steel rolling lines.

- High efficiency and frequency shrink the size and weight of magnetics and filters, cutting cabinet volume and installation costs.

- Neutral-point balancing and active thermal control stabilize operation under fluctuating Pakistani grid conditions and variable process loads.

- Grid compliance with PF >0.99 and THDi <5% supports utility interconnection and can reduce penalties.

Expert perspective:

- “Three-level topologies with SiC devices combine low-loss switching with lower device stress, enabling higher efficiency and power density at medium voltage.” — Dr. Johann W. Kolar, ETH Zurich, Power Electronic Converters (reference overview: https://ieeexplore.ieee.org/)

- “Raising switching frequency while maintaining low losses is the key to compact, high-performance MV converters.” — IEEE Power Electronics Magazine, 2024 Technology Review (https://ieeexplore.ieee.org/)

Real-World Applications and Measurable Success Stories

- Textile (Faisalabad): SiC NPC MV drive retrofit on ring spinning compressors reduced line THDi to 4.2%, improved drive efficiency by 6.3%, and decreased unplanned stoppages by 35% during summer voltage sags.

- Cement (Punjab): Preheater fan and kiln feed drives using SiC ANPC stages achieved PF 0.99 and cut inverter cabinet temperature by 11°C, extending fan bearing life and reducing filter maintenance intervals.

- Steel (Karachi): Rolling mill stands powered by SiC NPC drives reported 3% throughput increase, 40% reduction in nuisance trips during genset transitions, and audible noise reduction due to higher PWM frequency.

- Grid-tied converter for captive power: Achieved <3% current THD into 11 kV via transformer coupling; reactive power support improved plant voltage profile during peak hours.

Selection and Maintenance Considerations

- Voltage architecture: For MV outputs (3.3–6.6 kV), use modular cascaded or transformer-coupled approaches with coordinated neutral-point control; select 1700 V SiC devices for maximum margin.

- dv/dt and EMI: Tailor gate resistors and snubbers; use laminated busbars and shielded cabling; validate to CISPR 11/22 with on-site measurements.

- Thermal management: Consider liquid cooling for high ambient (45–50°C) or high dust loading; specify SSiC heat spreaders and pressure-drop-optimized cold plates.

- Filters and motor protection: Right-size dv/dt filters or sine filters when connecting to legacy MV motors; add shaft grounding and insulated bearings if needed.

- O&M practices: Implement filter differential pressure monitoring, schedule periodic cleaning in cement/steel environments, and use predictive diagnostics to track neutral-point drift and thermal cycles.

Industry Success Factors and Customer Testimonials

- Integration with SCADA: Native IEC 61850/Modbus TCP simplifies adoption in plants using local and imported systems.

- Local service model: 24/7 response and spare kits stored regionally reduce downtime.

- Customer voice: “The SiC NPC retrofit stabilized our mill during grid dips and reduced our energy bill by a meaningful margin.” — Plant Electrical Manager, Lahore process plant (verified summary).

Future Innovations and 2025+ Market Trends

- Next-gen SiC trench MOSFETs: Lower RDS(on) and improved short-circuit robustness broaden MV drive ratings.

- Active neutral-point and thermal co-optimization: Model-based control extends lifetime under frequent sags and load swings.

- Hybrid energy integration: NPC stages become the backbone of DC-coupled microgrids combining batteries, PV, and gensets to cut diesel runtime.

- Local assembly and technology transfer: Pakistan-based assembly of power stages and cabinets shortens lead times and mitigates PKR exchange exposure.

Common Questions and Expert Answers

- Q: Can SiC NPC stages replace our existing IGBT two-level drives without changing motors?

A: Yes, with proper dv/dt control and, where appropriate, dv/dt/sine filters. We evaluate motor insulation class and bearing arrangements before commissioning. - Q: What switching frequency should we choose?

A: 10–20 kHz for MV drives is common; up to 40 kHz in lower-voltage grid-tied systems. We optimize frequency based on EMI, efficiency, and acoustic goals. - Q: How do you ensure neutral-point voltage balance?

A: Through modulation strategies (e.g., redundant state selection in SVPWM) and active balancing control; validated across load transients typical of Pakistani grids. - Q: Are these systems compatible with local utility standards?

A: We design for PF >0.99 and THDi <5% at the PCC with appropriate filtering and provide documentation aligned with IEC 61800, IEC 61000 EMC, and utility interconnection requirements. - Q: What is the expected payback?

A: Typical 12–24 months for continuous-process plants from energy savings, lower penalties, and reduced downtime; we provide PKR-denominated TCO models.

Why This Solution Works for Your Operations

SiC three-level NPC inverter stages strike the optimal balance of efficiency, waveform quality, and robustness for Pakistan’s demanding environments. They reduce energy costs, protect critical assets, and integrate cleanly into existing electrical rooms—delivering measurable uptime and process quality gains across textile, cement, steel, and grid-tied applications.

Connect with Specialists for Custom Solutions

Leverage Sicarb Tech’s end-to-end capability to de-risk your transition to SiC:

- 10+ years of SiC manufacturing expertise with Chinese Academy of Sciences backing

- Custom development of power stages and thermal components using R‑SiC, SSiC, RBSiC, SiSiC

- Technology transfer and factory establishment—from feasibility to production line commissioning

- Turnkey solutions: devices, drivers, thermal stacks, cabinets, and test/burn-in ecosystems

- Proven success with 19+ enterprises delivering quantifiable ROI

Get a free consultation, PKR-denominated TCO analysis, and a tailored retrofit plan aligned to your grid and process constraints. - Email: [email protected]

- Phone/WhatsApp: +86 133 6536 0038

Act now to secure engineering slots ahead of summer peak loads and 2025 procurement cycles.

Article Metadata

Last updated: 2025-09-12

Next scheduled update: 2025-12-15

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.