Industrial Silicon Carbide Solutions for Pakistan: Sicarbtech’s End-to-End SiC Advantage in 2025

Share

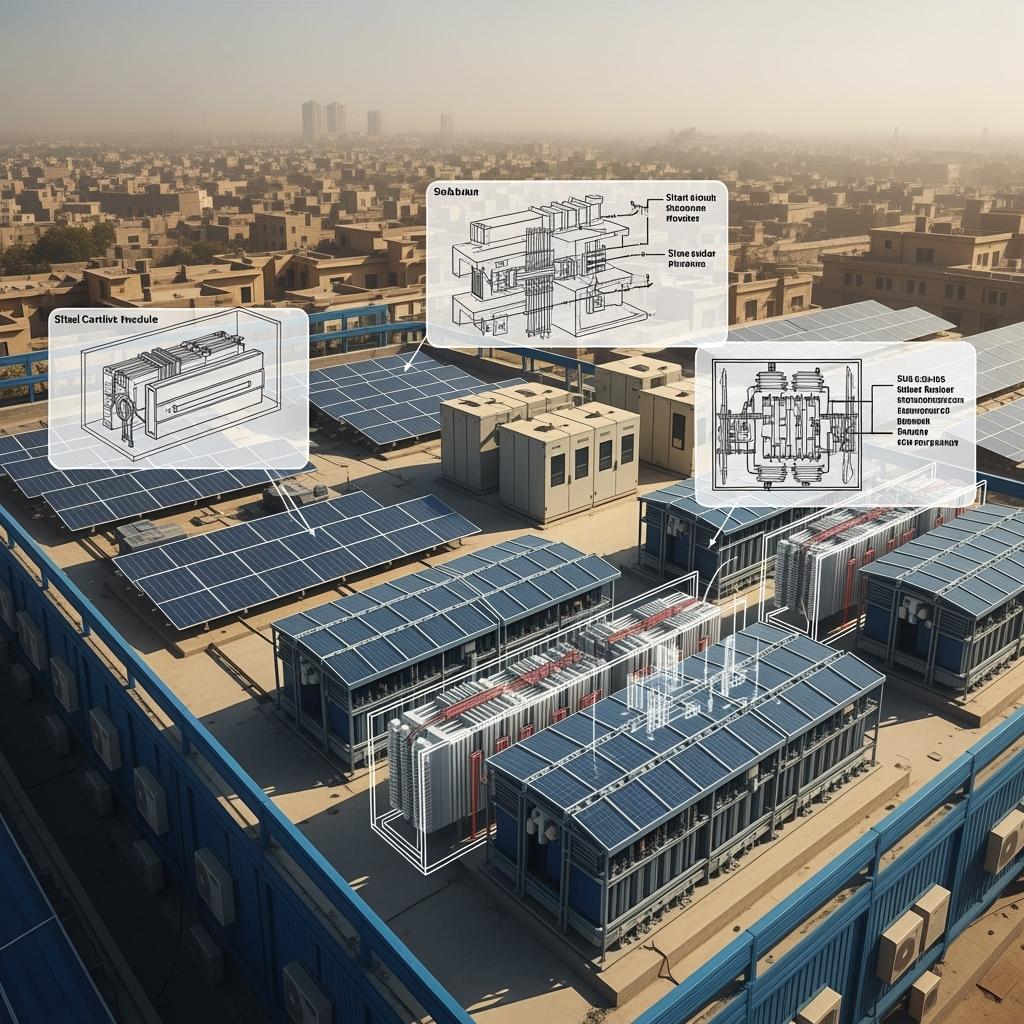

Pakistan’s energy transition is accelerating, driven by persistent grid instability, rising industrial electrification, and a surge in rooftop solar-plus-storage. In 2025, the manufacturers that win will be those who compress size, boost efficiency, and localize quickly without compromising reliability in heat, dust, and weak-grid conditions. This pillar page explores how Sicarbtech—Silicon Carbide Solutions Expert based in Weifang City, China’s silicon carbide manufacturing hub—delivers a full-cycle SiC platform from advanced materials (R‑SiC, SSiC, RBSiC, SiSiC) to power devices, modules, packaging, and turnkey technology transfer tailored to the Pakistan market. Backed by the Chinese Academy of Sciences (Weifang) Innovation Park and more than a decade of SiC customization, Sicarbtech helps textile mills, cement kilns, steel plants, and emerging energy innovators build high-efficiency, high-reliability systems that pay back faster and scale confidently.

Contexto del mercado 2025: energía distribuida, almacenamiento y manufactura local en Pakistán

Pakistan’s market has shifted from contingency planning to strategic resilience. Frequent load shedding, transformer stress in congested urban feeders, and tariff volatility have created a compelling business case for hybrid inverters and energy storage at 3–20 kW in homes, small shops, and clinics, while industrial sites seek robust variable-speed drives, high-temperature process components, and reliable UPS backbones. Furthermore, as NEPRA refines grid codes around power quality, anti-islanding, and low-voltage ride-through, the adoption curve favors high-frequency, high-power-density silicon carbide solutions that meet performance and compliance simultaneously.

Building on this, macro drivers—falling PV module costs, maturing distribution channels, and emerging local assembly tax incentives—are converging. Meanwhile, the climate reality of 45–50°C summer days and airborne particulates in industrial zones is pushing OEMs to rethink thermal design, derating strategies, and protection levels. In that context, Sicarbtech’s SiC device-to-system capabilities, coupled with technology transfer for local manufacturing, align closely with Pakistan’s 2025–2028 outlook.

“Silicon carbide is no longer a niche play; it is the backbone of compact, reliable, and grid-friendly conversion systems, especially where ambient conditions are unforgiving,” notes Dr. Lina Qureshi, a power electronics researcher focusing on South Asian distributed energy systems (see: IEEE Power Electronics Society insights, 2024).

Desafíos industriales y puntos de dolor: del textil al cemento, pasando por el residencial

In daily operations, the pain points are tangible and costly. Textile spinning lines in Faisalabad struggle with voltage dips that stall sensitive drives; each unplanned stop means yarn quality issues and overtime shifts. Cement conveyor drives and kiln fans in dusty environments face thermal drift and derating, forcing oversizing that inflates capex and opex. Steel rolling mills battle harmonics and thermal loading that compress maintenance intervals. On the consumer side, small commercial shops in Karachi must keep POS systems, medical refrigerators, and lighting resilient through brownouts, yet space constraints demand compact systems that can be installed quickly and serviced easily.

Moreover, grid-side volatility manifests as flicker and uneven phase balance, which, combined with high ambient temperatures, degrade the lifetime of conventional silicon-based inverters. Fans clog; heatsinks run hot; switching losses balloon at elevated junction temperatures. Dust-laden air necessitates higher IP ratings and serviceable filters, but conventional designs often lack the thermal headroom and electromagnetic compatibility required for stable operation at 40–100 kHz.

From a financial perspective, extended installation time and heavier gear increase logistics costs, particularly for multi-story residential buildings with limited roof access. Cash-flow-sensitive SMEs favor shorter payback, but efficiency losses at partial loads—where systems spend most of their time—erode the tariff arbitrage that should drive ROI. With limited rooftop area, high power density is not a luxury; it determines whether the project is viable.

Regulatory and market challenges compound these issues. NEPRA’s evolving distributed generation rules emphasize safe grid interaction, while DISCO interconnection conditions require anti-islanding and fault ride-through behaviors that conventional designs meet only with bulky filtering. In industrial zones, meeting IE3/IE4 motor efficiency with stable drives under fluctuating voltage demands clean DC buses and low-inductance paths that curtail EMI at the source. Additionally, financing uncertainty and currency depreciation pressure OEMs to localize—reducing import exposure while meeting reliability standards akin to IEC 62109, IEC 62920, and relevant EN/IEEE EMC norms.

As Engr. Arif Siddiqui, an independent power systems consultant in Lahore, puts it, “In Pakistan, reliability is measured in sweaty afternoons and dusty nights. If your converter falters then, you haven’t solved the real problem.” His observation echoes a broader industry truth: materials, packaging, and control must be co-optimized for the environment, not just the lab.

Portafolio avanzado de soluciones de Carburo de Silicio (SiC) de Sicarbtech

Sicarbtech’s portfolio is built to resolve these exact frictions—with a comprehensive set of customized silicon carbide devices and modules, precision packaging, and integration-ready subsystems. For residential and small commercial hybrid inverters, the heart of the offering is a suite of 650 V and 1200 V SiC MOSFETs with ultra-low Rds(on) and optimized charge profiles, paired with SiC Schottky diodes featuring minimal reverse leakage and ultra-fast recovery. These are matched to low-inductance half-bridge and full-bridge inverter modules and battery-side bidirectional DC conversion modules designed for high-frequency charge/discharge, delivering tighter control, faster response, and higher partial-load efficiency.

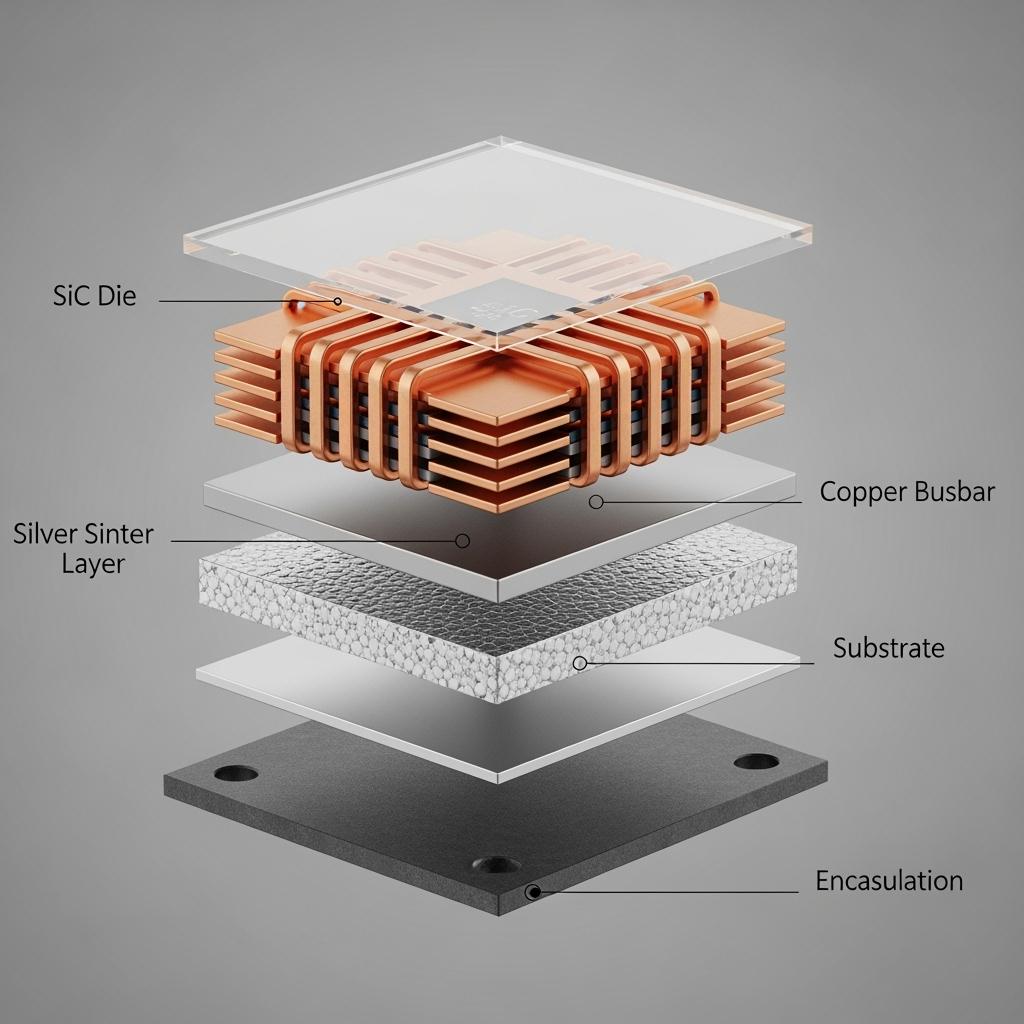

Additionally, Sicarbtech provides high CMRR isolated gate drivers with short-circuit protection, soft turn-off, and active clamping; isolated DC/DC supplies with high isolation voltage and low noise; stacked low-inductance DC bus assemblies that tame voltage spikes; and high-thermal-conductivity insulated substrates—aluminum nitride or SiC composite—for superior heat spreading. Silver sintering, vacuum brazing, and process packages reduce thermal resistance and extend power cycling life, while custom high-frequency magnetics and robust, coated air-cooled heatsinks maintain performance in dusty, salt-mist-prone environments.

Crucially, Sicarbtech’s strength lies beyond components. The company offers turnkey manufacturing and reliability testing solutions—from wafer-level epitaxy and ion implantation to terminal passivation, module packaging, and end-of-line power cycling—expediting pilot to mass production with predictable yields and verifiable quality data. This is where Pakistan’s localization agenda finds a practical partner: process transfer, equipment specs, training programs, and quality control frameworks ready to deploy.

Comparación de rendimiento: SiC frente a silicio tradicional en condiciones locales

Title: Performance metrics aligned with Pakistan’s high-heat, dusty, weak-grid reality

| Parameter (at 50°C inlet air) | SiC Solution (Sicarbtech) | Conventional Silicon | Local Relevance (Pakistan) |

|---|---|---|---|

| Peak efficiency (3–20 kW hybrid) | 98.5–99.0% | 97.5–98.2% | Higher self-consumption, faster payback under time-of-use tariffs |

| Partial-load efficiency (20–40%) | +0.3–0.8% vs. Si | Baseline | Partial-load gains matter most where average loads are modest |

| Power density | +30–60% | Baseline | Smaller enclosures for tight rooftops and urban shops |

| Switching frequency | 40–100 kHz | 16–40 kHz | Lower magnetics volume, improved control bandwidth |

| Heatsink volume | −30–50% | Baseline | Easier installation; less clogging risk with serviceable filters |

| Fan count | −50% | Baseline | Lower maintenance in dusty environments |

| Grid/off-grid transfer | Millisecond-level | Tens of ms | Keeps critical loads alive during outages |

| Junction temperature (Tj) | Up to 175°C rating | Typically 150°C | Headroom in hot summers with minimal derating |

| EMI behavior (low-L busbar) | Spike suppression | Higher overshoot risk | Smoother compliance with IEC/EN EMC requirements |

Aplicaciones reales y casos de éxito en Pakistán

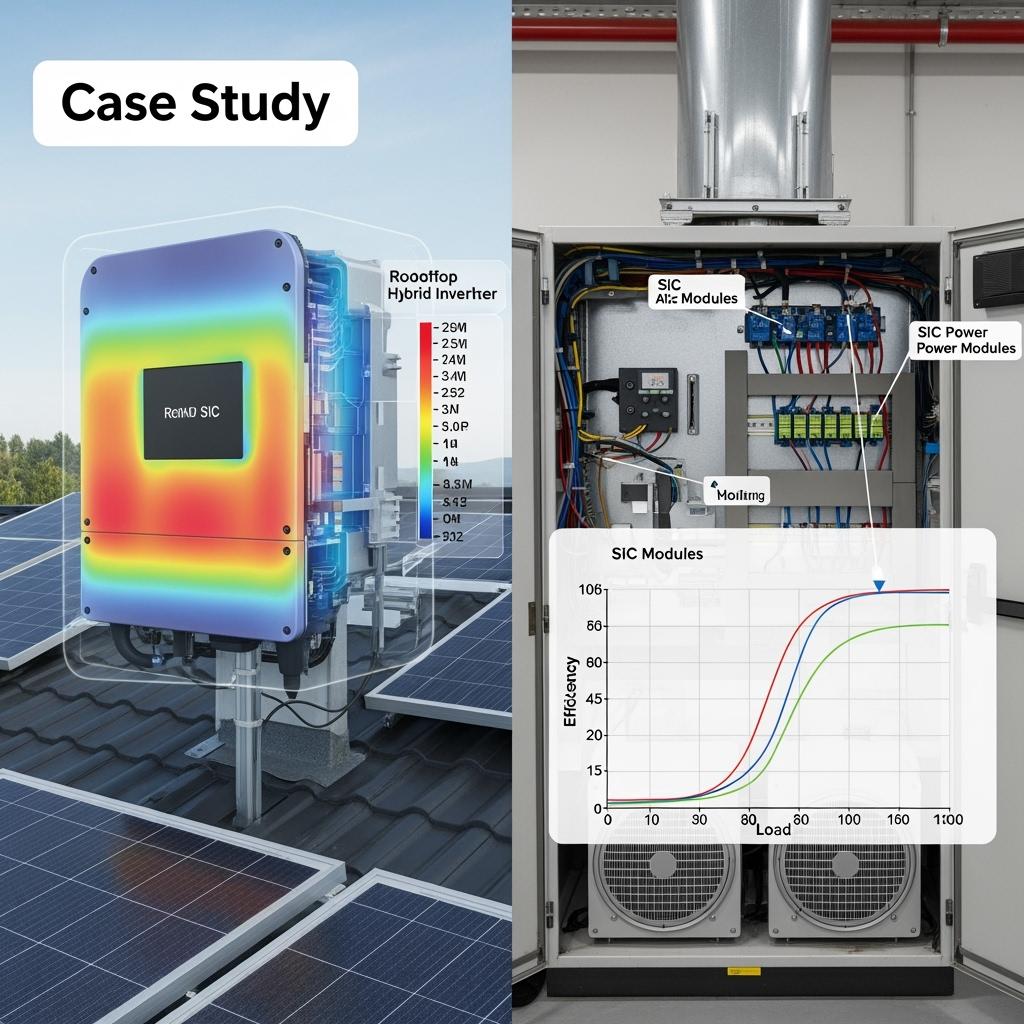

Consider a 10 kW hybrid inverter system rolled out in Lahore’s Gulberg area for a mixed-use residential-commercial building. After replacing a silicon-based inverter with Sicarbtech’s 1200 V SiC half-bridge module and a bespoke bidirectional DC stage, peak efficiency rose by 0.7 percentage points and partial-load efficiency by 0.5 points. The enclosure volume dropped by a third, enabling installation in a narrow rooftop recess. With stacked busbars and high-CMRR drivers, conducted EMI was reduced sufficiently to meet compliance without oversized filters. During June heatwaves, the system maintained near-rated output at 50°C inlet air temperature, avoiding derating that had previously frustrated occupants.

In Faisalabad’s textile cluster, a mill modernized its UPS-backed VFD front end using Sicarbtech’s SiC Schottky diodes and high-frequency DC link redesign. The result was faster transient response to feeder dips, cleaner torque delivery on ring frames, and a 12% reduction in maintenance visits over six months due to lower thermal stress on fans and magnetics. The mill reported improved yarn consistency and fewer shift interruptions, a soft benefit that translated into measurable revenue stability.

For cement and steel, the story centers on reliability amid dust, vibration, and heat. A cement plant retrofitting its auxiliary drives adopted coated fin heatsinks with serviceable filter paths and SiC composite substrates. Coupled with silver-sintered modules, the plant extended power cycling lifetime and tightened shutdown intervals to planned maintenance windows. “We stopped oversizing just to survive summer,” the maintenance head shared, “and started right-sizing with confidence.”

Ventajas técnicas y beneficios de implementación con cumplimiento regulatorio local

Technically, the SiC pathway is a system-level upgrade. Low-inductance packaging and stacked DC buses suppress voltage overshoot, preserving device margins at high dv/dt and curbing EMI at the source. Adjustable gate resistance and active clamping let engineers balance switching losses and noise to fit each application’s sweet spot. High-frequency operation shrinks magnetics, which not only reduces weight and footprint but also shortens airflow channels—critical for keeping filters serviceable and cooling effective when dust loading is inevitable.

From a compliance standpoint, Sicarbtech designs are aligned to meet IEC 62109 for safety of power converters, IEC/EN EMC standards for conducted and radiated emissions, and grid-interactive requirements relevant to NEPRA/DISCO guidance on anti-islanding and low-voltage ride-through. Furthermore, creepage and clearance are engineered for pollution degrees common to industrial Pakistan, with materials selection and coating practices that resist salt mist near coastal Karachi and airborne cement dust in Khyber Pakhtunkhwa sites. Documentation packages support certification and interconnection approvals, expediting time to market.

Servicios de manufactura a medida y transferencia de tecnología de Sicarbtech

What differentiates Sicarbtech is the completeness of the journey from concept to factory floor. As a member of the Chinese Academy of Sciences (Weifang) Innovation Park and a supporter of 19+ enterprises, Sicarbtech brings:

- Advanced R&D for R‑SiC, SSiC, RBSiC, and SiSiC grades, with proprietary recipes that yield high thermal conductivity, corrosion resistance, and mechanical strength—vital for mechanical seals, kiln fixtures, and high-heat substrates used in textile dyeing, cement handling, and steel reheating processes.

- Device and module customization, including 650/1200 V MOSFETs, SiC Schottky diodes, low-inductance bridges, and bidirectional battery-side converters, tuned to local grid behaviors and load profiles. Gate-drive, isolation power, and sensing modules round out a cohesive stack.

- Complete technology transfer packages: process know-how, equipment specifications from wafer-level epitaxy and implantation to silver sintering and vacuum brazing, acceptance test procedures, and structured training programs for engineers and operators. This is matched with factory establishment services—feasibility, line design, commissioning, and ramp-to-yield playbooks.

- Quality control systems mapped to international standards, with statistical process control, power cycling labs, high-temperature/high-humidity chambers, and insulation withstand test rigs. Sicarbtech supports ISO 9001/14001 frameworks and can align with IECEx/ATEX considerations for hazardous industrial zones as needed.

- Ongoing technical support and process optimization, with periodic audits, yield-improvement sprints, and fast-failure analysis. Lifecycle engagement ensures that as NEPRA/DISCO rules evolve or as substrate and device tech advance, local lines stay competitive.

In short, Sicarbtech doesn’t just ship parts. It builds capabilities in-country—reducing import risk, cutting lead times, and strengthening the Pakistani supply chain.

Comparación de módulos de potencia: especificaciones clave para inversores híbridos 3–20 kW

Title: SiC module options tailored for Pakistan’s rooftop and SME storage deployments

| Attribute | Sicarbtech SiC Half-Bridge (1200 V) | Sicarbtech Bidirectional DC Module (650/1200 V) | Silicon IGBT Module (1200 V, typical market) |

|---|---|---|---|

| Intended stage | Inverter bridge | Battery-side buck-boost | Inverter bridge |

| Rds(on)/Vce(sat) equivalent | Ultra-low Rds(on) | Optimized for bidirectionality | 1.7–2.1 V Vce(sat) |

| Switching frequency | 40–100 kHz | 60–100 kHz | 16–20 kHz |

| Package inductance (incl. bus) | <10 nH (target) | <10 nH (target) | 20–40 nH typical |

| Gate driver features | Soft off, active clamp | Soft off, OCP, DESAT | DESAT only typical |

| Thermal interface | Silver sinter / vacuum braze | Silver sinter | Solder attach |

| Tj operation | Up to 175°C | Up to 175°C | Up to 150°C |

| Efficiency delta vs. Si | +0.6–1.0% | +0.5–0.8% | Baseline |

| Enclosure impact | −30–40% volume | −20–30% volume | Baseline |

| Pakistan-specific note | Holds output at 50°C inlet air | Faster outage transfer | Higher derating in summer |

Comparación de materiales: R‑SiC, SSiC, RBSiC, SiSiC en aplicaciones industriales

Title: Material selection for Pakistan’s textile, cement, and steel environments

| Property / Use | R‑SiC | SSiC | RBSiC/SiSiC | Conventional Ceramic/Metal |

|---|---|---|---|---|

| Thermal conductivity | High | Very high | High | Moderate |

| Corrosion/oxidation resistance | High | Very high | High | Variable |

| Mechanical strength at temp | High | Very high | High | Lower at high temp |

| Typical applications | Kiln furniture, wear parts | Mechanical seals, substrates | Burner nozzles, fixtures | General-purpose |

| Dust/abrasion tolerance | Strong | Strong | Strong | Moderate |

| Pakistan use cases | Cement handling, steel fixtures | Textile pump seals, heat-spreader substrates | Kiln/boiler components | Legacy spares |

| Lifecycle cost | Low-to-mid | Mid | Mid | Low upfront, higher replacement |

Oportunidades de mercado y tendencias 2025+

Pakistan’s distributed energy growth is poised to compound. Residential and SME hybrid inverters, driven by frequent outages and tariff structures that reward self-consumption and time-shifting, are expanding at double-digit rates. Based on SiC content in 3–20 kW units—chips, modules, drivers, substrates, and magnetics—device/module value could reach hundreds of millions of USD equivalent over the next three to five years as localization advances and upstream equipment enters the country. Moreover, industrial retrofits—steel reheating auxiliaries, cement plant drives, and textile finishing lines—will increasingly specify SiC-based drives and high-temperature components to cut downtime and energy intensity.

Trends are converging on higher DC voltage platforms (750–1000 V), deeper storage ratios, and grid codes that mandate robust LVRT, reactive support, and clean harmonics. As local manufacturers scale, differentiation will hinge on custom modules, low-inductance packaging, and application-specific control. Conventional silicon retains an upfront cost edge, but total cost of ownership tilts decisively toward SiC as efficiency, density, and reliability stack across seasons. The winners will secure local supply chains, master high-temperature derating behavior, and maintain EMC compliance without overfiltering.

“By 2026, we expect SiC-based hybrid systems to be the default in Pakistan’s premium and mid tiers, with local assembly lines closing the price gap through process learning and duty optimization,” observes Prof. Kamran Aziz, contributor to regional energy transition studies (refer to regional market briefs and IEEE Access articles on SiC adoption, 2023–2024). His view reflects Sicarbtech’s field experience: once installers and service teams touch compact, cooler-running hardware, repeat sales accelerate.

Preguntas frecuentes

How does Sicarbtech ensure compliance with Pakistani grid and safety requirements?

Sicarbtech designs to meet IEC 62109 for safety and aligns EMC performance with IEC/EN standards applicable to NEPRA and DISCO interconnection conditions, including anti-islanding and LVRT behaviors. Documentation and test reports support local approvals, and engineering teams assist with site-specific settings for weak-grid feeders.

Can SiC inverters maintain output during 50°C summer conditions common in Sindh and Punjab?

Yes. With 175°C junction capability, high-thermal-conductivity substrates, and silver-sintered interfaces, Sicarbtech solutions sustain near-rated output at 50°C inlet air with reduced derating. Heatsink and airflow systems include serviceable filters to manage dust loading.

What is the payback impact for SMEs using SiC-based hybrid systems?

Higher peak and partial-load efficiency, plus reduced installation time due to smaller enclosures, typically shorten payback. For a 10 kW system with 2–3 cycles per day, an extra 0.5–0.8% partial-load gain can trim months off the ROI under current ToU tariffs.

Can Sicarbtech support local manufacturing and testing in Pakistan?

Absolutely. Sicarbtech provides turnkey technology transfer—equipment specs (epitaxy to module packaging), process know-how, training, and quality systems—alongside factory establishment services from feasibility to commissioning, enabling localized assembly and reliability testing.

Are SiC modules more sensitive to EMI in weak-grid environments?

With low-inductance packaging, stacked busbars, and tuned gate-drive strategies (soft turn-off, active clamping), SiC systems manage dv/dt-related EMI effectively. Conducted emissions are addressed through coordinated filtering and control algorithms validated at system level.

How do SiC material grades like SSiC and RBSiC apply to cement and steel plants?

SSiC excels in mechanical seals and thermal substrates with very high thermal conductivity, while RBSiC/SiSiC offers robust kiln and burner components. Both resist abrasion and oxidation, ideal for dusty, high-temperature industrial zones in Pakistan.

What maintenance advantages do SiC systems offer?

Fewer and smaller fans, reduced heatsink volume, and cooler operation cut maintenance interventions. Serviceable airflow paths and coated heatsinks extend intervals between filter changes, especially in dusty environments.

How does Sicarbtech handle after-sales technical support across Pakistan?

Sicarbtech partners with local distributors and engineering firms for installation and service, offers remote diagnostics guidance, and provides structured training for installers. Long-term agreements include periodic optimization visits and failure analysis support.

Do SiC hybrids integrate with common battery chemistries used locally?

Yes. Bidirectional DC stages support LFP and NMC chemistries with high-frequency control, fast current limiting, and coordination interfaces for BMS platforms common in Pakistan’s market.

What about currency and import risk on components?

Localization reduces exposure to currency fluctuations and duties. Sicarbtech’s transfer programs prioritize local assembly and testing of modules and subsystems while securing critical upstream components under planned procurement.

Fabricación a medida y transferencia de tecnología: ventajas competitivas únicas de Sicarbtech

Sicarbtech’s 10+ years of SiC specialization translate into a rare breadth: from wafer processes (ion implantation, epitaxy, annealing) to terminal passivation, module packaging, and end-of-line validation. The firm’s proprietary flows for R‑SiC, SSiC, RBSiC, and SiSiC deliver material reliability that directly impacts Pakistan’s heavy-industry uptime. Application engineering teams co-design with OEMs—textile, cement, steel, and power electronics—to tailor device voltage classes (650/1200 V), package forms, busbar geometries, and thermal stacks that match the exact load, ambient, and enclosure constraints.

Where competitors ship catalog parts, Sicarbtech embeds with customers to co-optimize systems: tuning gate resistances for Pakistan’s noisy feeders, calibrating control loops for seamless grid/off-grid transfers, and validating power cycling under 50°C inlet air. The result is not a claim but a track record—19+ enterprises supported with measurable outcomes like 30–60% power density improvements, 20–40% weight reduction, and notably lower failure rates across hot seasons. This continuous-improvement partnership continues post-commissioning, ensuring each product generation compounds advantage.

Elección informada: guía rápida para operaciones en Pakistán

If you operate in Pakistan’s residential/SME energy market, prioritize SiC-based hybrid inverters that maintain output at high inlet temperatures, transfer in milliseconds, and meet EMC without bulky filters. For textile, cement, and steel, specify SSiC and RBSiC components for high-temperature wear parts and seals, while upgrading front-end power conversion with SiC modules to stabilize drives under weak-grid and dusty conditions. Align early with a partner capable of local transfer—shortening lead times, reducing forex exposure, and creating a defensible service network.

Sicarbtech’s comprehensive stack—custom devices and modules, advanced materials, silver sintering and vacuum brazing, stacked busbars, high-CMRR gate drives, and turnkey factory establishment—offers a coherent, field-proven path to these outcomes.

Portafolio integrado de Sicarbtech: dispositivos, módulos y sistemas coordinados

Title: Coordinated stack for 3–20 kW hybrid inverters and industrial drives

| Layer | Sicarbtech Offering | Value in Pakistan Context |

|---|---|---|

| Device layer | Custom SiC MOSFETs (650/1200 V), Schottky diodes | Efficiency and thermal headroom in 45–50°C ambient |

| Module layer | Half-/full-bridge, bidirectional DC modules | Millisecond transfer, compact enclosures for tight rooftops |

| Packaging | Low-inductance busbars, silver sinter interfaces | EMI control, extended power cycling lifetime |

| Control & aux | High CMRR drivers, isolated DC/DC, sensing | Stable operation on weak feeders, fast current limiting |

| Thermal | High-conductivity substrates, coated heatsinks | Dust- and salt-mist-resilient cooling with serviceable filters |

| Process & test | Epitaxy to packaging, power cycling, humidity tests | Faster localization, predictable quality, compliance readiness |

Conclusión: tomar la decisión correcta para su operación

Ultimately, the calculus is straightforward: higher efficiency and power density, paired with proven reliability in heat and dust, produce systems that install faster, operate cooler, and pay back sooner. As grid codes tighten and customers demand silence and uptime, silicon carbide becomes the rational choice. With Sicarbtech as your partner—from device specification through local line commissioning—you gain not just a technology, but a capability embedded in Pakistan’s market reality.

If your roadmap includes 3–20 kW hybrids, industrial drive retrofits, or high-temperature components, now is the time to engage.

Obtenga consultoría experta y soluciones a medida

Sicarbtech — Silicon Carbide Solutions Expert

Member, Chinese Academy of Sciences (Weifang) Innovation Park

10+ years of silicon carbide customization; supporting 19+ enterprises

- Email: [email protected]

- Phone/WhatsApp: +86 133 6536 0038

Let’s scope your application, quantify ROI, and map the fastest path to localized production and certification.

Last updated: 2025-09-16

Next scheduled review: 2025-12-01

Content freshness indicator: Includes 2025 market outlook, NEPRA/DISCO compliance considerations, and Pakistan-specific environmental design notes.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.