Hot Pressed Silicon Carbide: The Apex of Performance in Extreme Industrial Environments

Share

In the relentless pursuit of materials that can withstand the harshest industrial conditions, Hot Pressed Silicon Carbide (HPSiC) emerges as a frontrunner. This advanced ceramic material is engineered for exceptional performance where other materials falter, making it indispensable across a spectrum of demanding sectors. For engineers, procurement managers, and technical buyers in fields like semiconductors, high-temperature processing, aerospace, energy, and industrial manufacturing, understanding the capabilities of HPSiC is crucial for driving innovation and operational excellence. This blog post delves into the world of custom Hot Pressed Silicon Carbide products, exploring their applications, advantages, design intricacies, and how to source high-quality components, with a special focus on the expertise available through Sicarb Tech.

Introduction: Unveiling the Power of Hot Pressed Silicon Carbide in Demanding Industries

Hot Pressed Silicon Carbide (HPSiC) represents a superior grade of silicon carbide, a technical ceramic renowned for its remarkable hardness, high-temperature stability, and chemical inertness. What sets HPSiC apart is its manufacturing process. Fine silicon carbide powder, typically sub-micron alpha-SiC, is mixed with non-oxide sintering aids (e.g., boron and carbon, or aluminum-based compounds). This mixture is then simultaneously subjected to high temperatures (often exceeding $2000^\\circ C$) and high mechanical pressure (typically 20−50MPa) in an inert atmosphere or vacuum, usually within graphite dies.

This unique densification process minimizes porosity, resulting in a virtually fully dense material (typically >98-99% of theoretical density). The outcome is a silicon carbide variant with significantly enhanced mechanical properties, including superior strength, hardness, and wear resistance, compared to other forms like reaction-bonded or sintered silicon carbide (without pressure). These characteristics make HPSiC components essential for applications involving extreme wear, high thermal stress, and corrosive environments, pushing the boundaries of performance in high-value industrial applications. For businesses looking into technical ceramics procurement, HPSiC offers a robust solution for their most challenging operational needs.

Key Industrial Applications: Where Hot Pressed Silicon Carbide Excels

The exceptional properties of Hot Pressed Silicon Carbide make it the material of choice for a wide array of critical applications across various industries. Its ability to maintain structural integrity and performance under severe conditions translates into longer service life, reduced downtime, and improved efficiency.

- Aerospace and Defense: HPSiC is utilized for components that demand low weight and high performance at extreme temperatures. Applications include:

- Nozzles for rocket propulsion systems: Withstanding extreme thermal shock and erosive forces.

- Leading edges and control surfaces for hypersonic vehicles: Requiring high thermal conductivity and resistance to oxidation.

- Lightweight armor systems (ballistic protection): Its high hardness and compressive strength make it effective in ceramic armor plates for personnel and vehicles.

- Bearings and wear components in aerospace mechanisms: Offering low friction and high wear resistance in critical moving parts.

- Semiconductor Manufacturing: The purity, stiffness, and thermal stability of HPSiC are vital for producing high-quality semiconductor wafers.

- Wafer chucks and susceptors: Providing uniform temperature distribution and dimensional stability during processing.

- Focus rings, gas distribution plates, and chamber components: Resisting a_gg_ressive plasma environments and maintaining purity.

- Precision alignment pins and guides: Ensuring accuracy in automated handling systems.

- High-Temperature Processing and Furnaces: HPSiC’s excellent thermal shock resistance and strength at elevated temperatures are invaluable.

- Burner nozzles and radiant tubes: For industrial furnaces, offering long life in corrosive and high-heat zones.

- Kiln furniture and supports: Maintaining strength and shape under heavy loads at high temperatures.

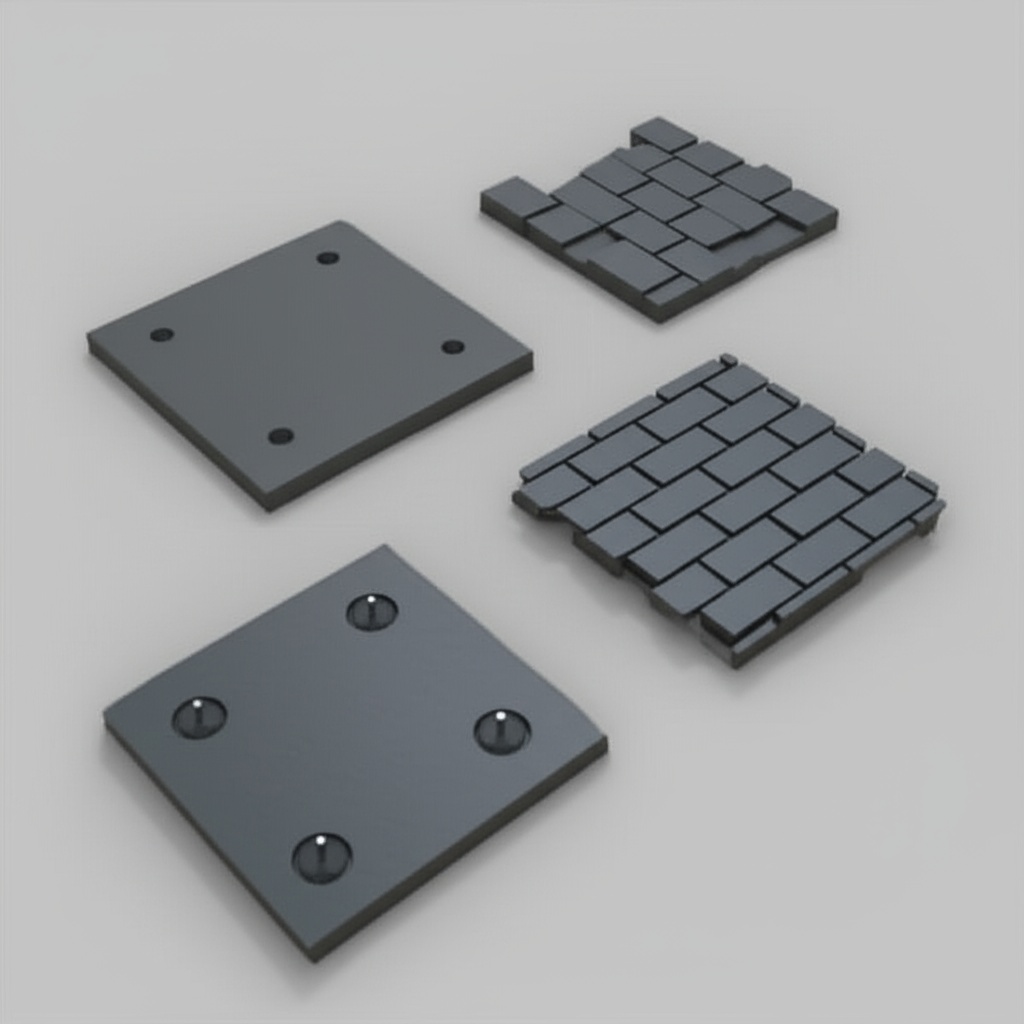

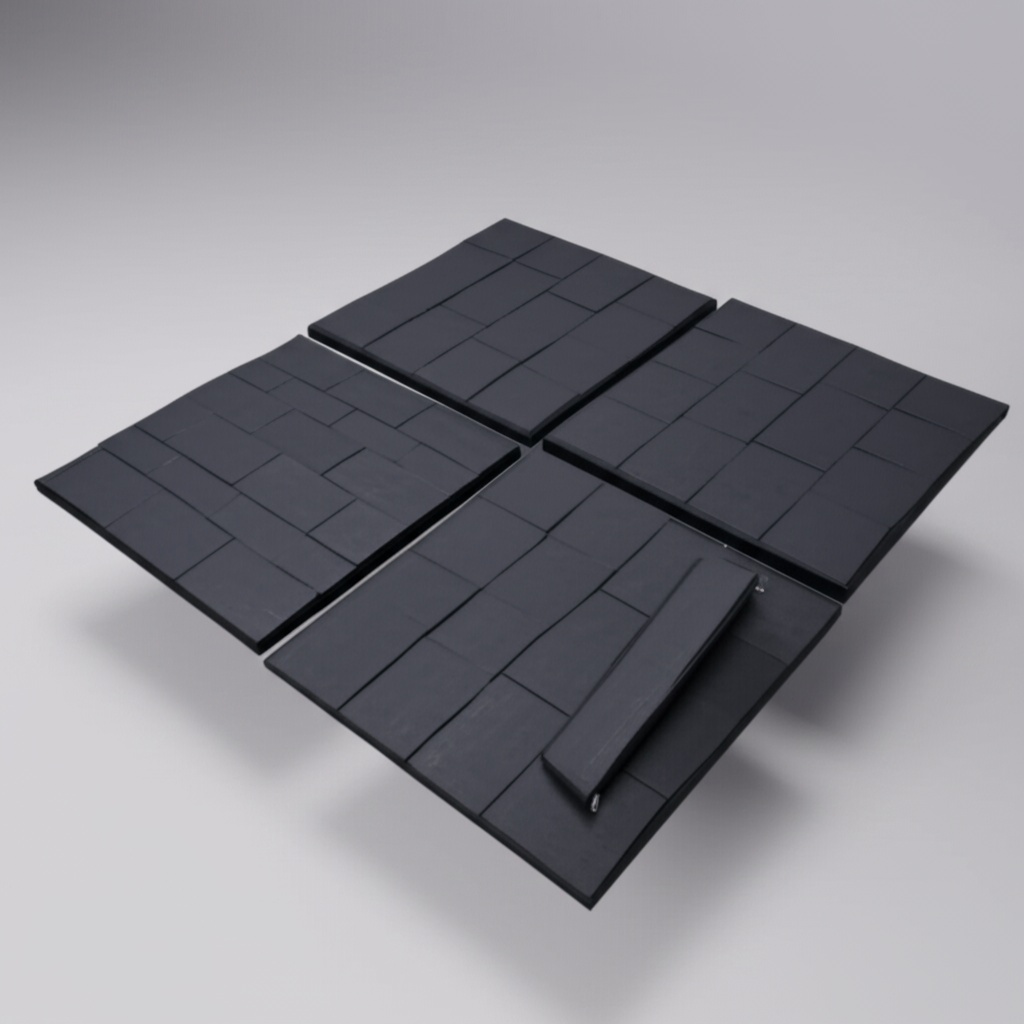

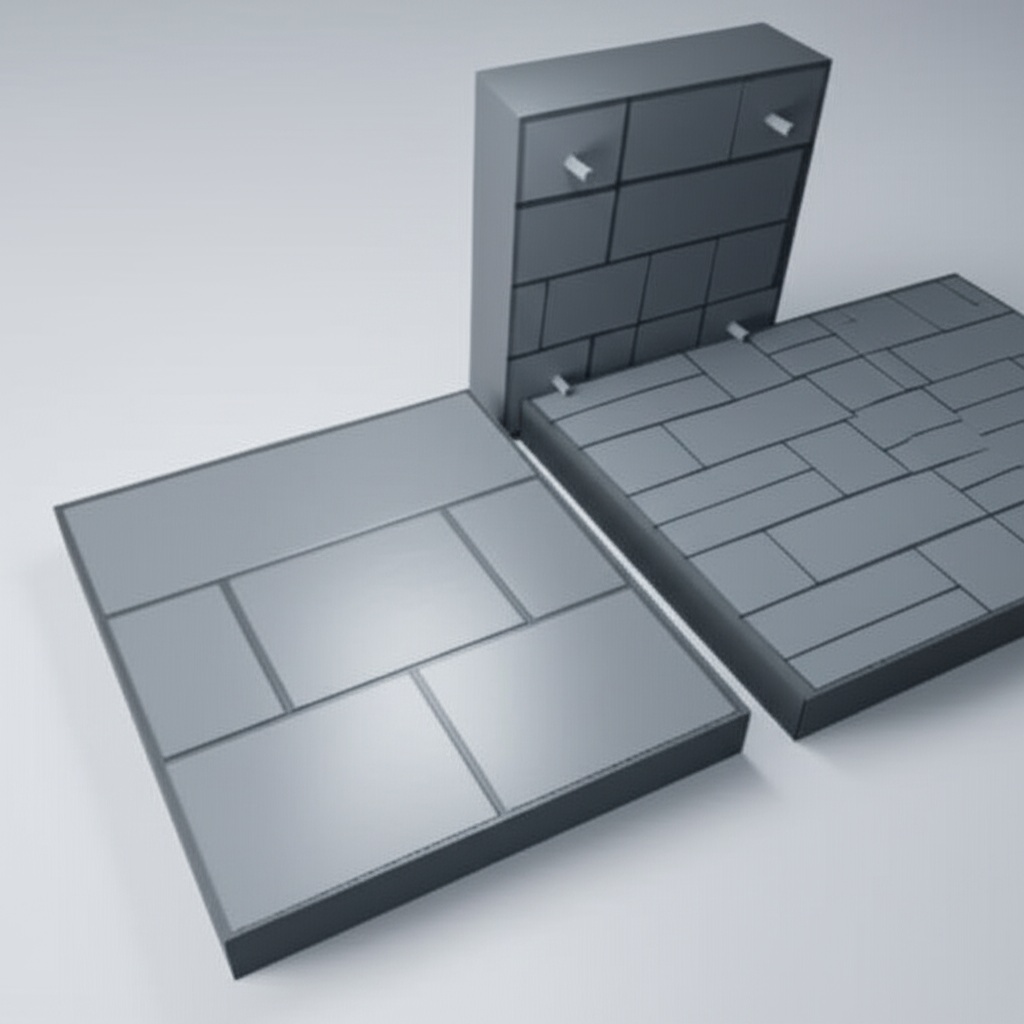

- Crucibles and containers for molten metals (non-ferrous): Resisting chemical attack and thermal cycling. Explore our product examples for a visual understanding.

- Energy Sector: From power generation to oil and gas, HPSiC components contribute to reliability and efficiency.

- Seals and bearings in pumps for a_gg_ressive media: Handling corrosive fluids and high pressures.

- Components for heat exchangers and recuperators: Optimizing energy recovery in high-temperature processes.

- Wear parts in drilling and exploration equipment: Resisting abrasive wear in harsh downhole conditions.

- Industrial Manufacturing and Wear Parts: The extreme hardness and wear resistance of HPSiC significantly extend the life of components in demanding manufacturing processes.

- Mechanical seals and pump components: For chemical processing, offering superior resistance to wear and corrosion.

- Blasting nozzles and shot blast components: Maintaining orifice geometry for consistent performance.

- Grinding media and wear liners: In material processing and mining applications.

- Precision metrology components: Such as gauge blocks and anvils, due to their dimensional stability and wear resistance.

Below is a table highlighting some key applications and the HPSiC properties that make it suitable:

| Industry Sector | Typical HPSiC Components | Key HPSiC Properties Utilized |

|---|---|---|

| Aerospace & Defense | Nozzles, Armor, Bearings | High Hardness, High-Temperature Strength, Thermal Shock Resistance |

| Semiconductor Processing | Wafer Chucks, Focus Rings, Chamber Parts | High Purity, Stiffness, Thermal Stability, Plasma Resistance |

| High-Temp Furnaces | Burner Nozzles, Kiln Furniture, Crucibles | High-Temperature Strength, Thermal Shock Resistance, Creep Resistance |

| Energy | Seals, Bearings, Heat Exchanger Components | Wear Resistance, Corrosion Resistance, Thermal Conductivity |

| Industrial Manufacturing | Mechanical Seals, Blasting Nozzles, Wear Liners | Extreme Hardness, Wear Resistance, Chemical Inertness |

The demand for custom HPSiC manufacturing is driven by the need for components tailored to these specific, often unique, operational challenges.

The Unmatched Advantages of Custom Hot Pressed Silicon Carbide

Choosing Hot Pressed Silicon Carbide for demanding applications offers a multitude of advantages, particularly when components are customized to precise specifications. The hot pressing process itself imbues the material with superior characteristics, and tailoring these to specific operational needs further enhances their value.

- Exceptional Density and Low Porosity: Hot pressing achieves near-theoretical density (typically >99%), significantly reducing porosity. This leads to:

- Enhanced Mechanical Strength: Higher flexural strength and fracture toughness compared to other SiC types.

- Improved Wear Resistance: A dense surface is more resistant to abrasion, erosion, and friction.

- Greater Chemical Resistance: Reduced pathways for corrosive agents to penetrate and degrade the material.

- Superior Hardness and Wear Resistance: HPSiC is one of the hardest commercially available materials, second only to diamond and boron carbide. This results in:

- Extended Component Lifespan: Particularly in applications involving abrasive particles or sliding contact.

- Reduced Maintenance and Downtime: Fewer replacements and repairs needed for critical parts.

- Consistent Performance: Components maintain their critical dimensions and surface finish for longer periods.

- Excellent High-Temperature Performance: HPSiC retains its strength and structural integrity at very high temperatures (up to $1650^\\circ C$ or higher in non-oxidizing atmospheres).

- High Thermal Conductivity: Allows for efficient heat dissipation, crucial in applications like heat sinks or semiconductor processing equipment.

- Good Thermal Shock Resistance: Can withstand rapid temperature changes without cracking, essential for furnace components and aerospace applications.

- Low Thermal Expansion: Ensures dimensional stability across a wide temperature range.

- Outstanding Chemical Inertness: HPSiC exhibits excellent resistance to a wide range of acids, alkalis, and molten metals.

- Suitability for Corrosive Environments: Ideal for chemical processing, oil and gas, and handling a_gg_ressive fluids.

- High Purity Applications: Its inertness prevents contamination in sensitive processes like semiconductor manufacturing.

- Benefits of Customization: Opting for custom HPSiC components allows for designs optimized for specific functional requirements.

- Tailored Geometries: Complex shapes and intricate features can be produced to meet exact application needs.

- Optimized Performance: Dimensions, tolerances, and surface finishes can be specified to maximize efficiency and lifespan.

- Integration with Existing Systems: Custom parts can be designed for seamless integration into larger assemblies.

The combination of these intrinsic material properties and the ability to customize designs makes HPSiC a go-to solution for engineers tackling extreme environment challenges. For organizations seeking high-performance ceramics, HPSiC offers a compelling value proposition.

Navigating Design and Engineering for Hot Pressed SiC Components

While Hot Pressed Silicon Carbide offers exceptional properties, its inherent characteristics – particularly its hardness and brittleness – necessitate careful consideration during the design and engineering phases. Designing for manufacturability is key to achieving cost-effective and reliable HPSiC components.

- Complexity and Geometric Limitations:

- The hot pressing process often involves rigid graphite molds, which can limit the complexity of “as-pressed” shapes. Highly intricate features may require extensive and costly post-press machining (diamond grinding).

- Design Tip: Simplify geometries where possible. Aim for shapes that can be readily formed in a die or easily machined from simpler blanks. Avoid sharp internal corners and sudden changes in cross-section, which can act as stress concentrators.

- Wall Thickness and Aspect Ratios:

- Uniform wall thickness is preferred to ensure even densification and minimize internal stresses during hot pressing and cooling.

- Extremely thin walls or very high aspect ratios can be challenging to manufacture and may be prone to warping or fracture.

- Design Tip: Maintain a minimum practical wall thickness (e.g., 2−3mm for many components, but this is highly dependent on size and geometry). Consult with your HPSiC supplier, like Sicarb Tech, early in the design phase for guidance.

- Stress Concentration:

- As a brittle ceramic, HPSiC is sensitive to stress concentrations. Sharp corners, notches, and small holes can significantly reduce the effective strength of a component.

- Design Tip: Incorporate generous radii on all internal and external corners. Blend intersecting features smoothly. If holes are necessary, consider their placement carefully to avoid high-stress regions.

- Joining with Other Materials:

- Differences in thermal expansion coefficients between HPSiC and other materials (e.g., metals) can induce significant stress at joints, especially during thermal cycling.

- Design Tip: Consider brazing, shrink-fitting, or mechanical clamping methods. Intermediate layers or compliant materials can sometimes be used to accommodate CTE mismatch. Design for minimal stress at the interface.

- Features for Manufacturability and Machining:

- While HPSiC can be machined to tight tolerances, it requires diamond tooling and is a slow, expensive process.

- Design Tip: Design components with machining allowances in mind. Provide flat, stable surfaces for clamping if extensive machining is required. Specify tolerances and surface finishes only as tight as absolutely necessary for functionality. See our customizing support page for more details on how we assist in this process.

Early collaboration with an experienced HPSiC manufacturer is crucial. Sicarb Tech offers extensive customizing support, leveraging our deep understanding of material behavior and manufacturing processes to help optimize your designs for performance and cost-effectiveness.

Achieving Precision: Tolerance, Surface Finish, and Post-Processing of Hot Pressed SiC

The utility of Hot Pressed Silicon Carbide components in high-technology applications often hinges on achieving precise dimensions, specific surface characteristics, and sometimes, additional post-processing treatments. Given the material’s extreme hardness, these steps require specialized expertise and equipment.

Tolerances: Achievable tolerances for HPSiC parts depend on the manufacturing stage:

- As-Pressed Tolerances: Components directly from the hot press will have looser tolerances, typically in the range of pm0.5 to pm1 of the dimension, or a minimum of pm0.1mm to pm0.5mm, depending on size and complexity. This is often sufficient for applications like kiln furniture.

- Ground/Machined Tolerances: For high-precision applications, diamond grinding is employed. With this method, very tight tolerances can be achieved:

- Dimensional tolerances: Down to pm0.005mm (5 microns) or even tighter for critical features on smaller parts.

- Parallelism, flatness, and perpendicularity: Can often be controlled to within a few microns.

Surface Finish: The surface finish of HPSiC can be tailored to the application’s requirements:

- As-Pressed Surface: The surface finish will replicate that of the graphite die, typically in the range of 1.6−6.3mumRa. This might be acceptable for certain wear parts or furnace components.

- Ground Surface: Standard grinding can achieve surface finishes of 0.4−0.8mumRa.

- Lapped Surface: Lapping can improve the surface finish significantly, often to 0.1−0.2mumRa, resulting in a very smooth, reflective surface suitable for seals or bearings.

- Polished Surface: For applications requiring exceptionally smooth surfaces, such as optical components (though less common for HPSiC) or some semiconductor parts, polishing can achieve finishes better than 0.05mumRa.

Post-Processing Needs: Beyond basic shaping and surface finishing, some HPSiC components may require additional post-processing steps to enhance performance or meet specific design criteria:

- Edge Chamfering/Radiusing: To remove sharp edges, reduce chipping susceptibility, and improve handling safety.

- Cleaning: Specialized cleaning processes may be required, especially for high-purity applications like semiconductor components, to remove any residues from machining or handling.

- Coatings (Less Common for HPSiC): While HPSiC is inherently very resistant, in some ultra-specific environments, thin coatings (e.g., CVD diamond or other ceramics) might be applied to modify surface properties further. However, the base HPSiC properties are usually sufficient.

- Annealing: In some cases, a post-machining annealing step might be used to relieve any residual stresses induced during grinding, although this is less common for HPSiC than for some other ceramics.

- Joining/Assembly: If the HPSiC part is a component of a larger assembly, specialized brazing or bonding processes might be considered part of the post-processing phase.

It’s important for technical buyers and engineers to clearly specify their tolerance and surface finish requirements, understanding that tighter specifications usually translate to higher costs due to the intensive machining involved. Sicarb Tech works closely with clients to define the optimal balance between precision and cost for their custom HPSiC components. Our capabilities include advanced grinding and finishing techniques to meet even the most stringent specifications. Refer to our main equipment to understand the technology we leverage.

Overcoming Material and Manufacturing Hurdles with Hot Pressed SiC

While Hot Pressed Silicon Carbide offers a superior property profile, its inherent nature and demanding manufacturing process present certain challenges. Understanding these hurdles and the strategies to overcome them is crucial for successful implementation.

- Brittleness and Low Fracture Toughness:

- Challenge: Like most advanced ceramics, HPSiC is brittle, meaning it has low resistance to crack propagation. This makes it susceptible to fracture from impact or high tensile stresses, especially if flaws are present.

- Mitigation:

- Design: Employ ceramic-friendly design principles (e.g., generous radii, avoiding stress concentrators, compressive loading where possible).

- Material Quality: Ensure high-purity raw materials and meticulous process control during hot pressing to minimize internal flaws and achieve fine, uniform grain structures.

- Handling: Implement careful handling protocols throughout manufacturing and assembly to prevent accidental damage.

- Proof Testing: For critical applications, components can be proof-tested to screen out parts with sub-critical flaws.

- Machining Complexity and Cost:

- Challenge: The extreme hardness of HPSiC makes it very difficult and time-consuming to machine. Only diamond tooling can effectively cut it, leading to high tooling costs and slower material removal rates compared to metals.

- Mitigation:

- Near-Net Shaping: Optimize the hot pressing stage to produce parts as close to the final dimensions as possible, minimizing the amount of material that needs to be removed by grinding.

- Advanced Machining Techniques: Utilize specialized grinding machines, optimized diamond wheels, and techniques like ultrasonic-assisted machining to improve efficiency and precision.

- Supplier Expertise: Partner with a supplier like Sicarb Tech with extensive experience in machining HPSiC. Our team has honed techniques to efficiently achieve tight tolerances. View some of our successful cases.

- Design for Manufacturability (DFM): As discussed earlier, design components to reduce machining complexity wherever feasible.

- Cost of Raw Materials and Processing:

- Challenge: High-purity, fine silicon carbide powders and the specialized sintering aids required for HPSiC are relatively expensive. The hot pressing process itself involves high temperatures, high pressures, and often long cycle times, contributing to higher energy consumption and equipment costs.

- Mitigation:

- Volume Optimization: For larger production runs, economies of scale can help reduce per-unit costs.

- Process Efficiency: Continuous improvement in hot pressing cycles and energy management by experienced manufacturers can help control costs.

- Value Engineering: Focus on using HPSiC where its unique properties provide a clear performance or lifespan advantage that justifies the cost. In many cases, the extended service life and reduced downtime offered by HPSiC far outweigh its initial procurement cost.

- Strategic Sourcing: Working with a supplier with strong supply chain relationships and production expertise, such as Sicarb Tech situated in Weifang, the hub of China’s silicon carbide industry, can offer cost advantages.

- Thermal Shock Sensitivity (Relative to some metals):

- Challenge: While HPSiC has good thermal shock resistance for a ceramic, very rapid and extreme temperature fluctuations can still induce fracture, especially in complex shapes with uneven heating or cooling.

- Mitigation:

- Material Selection: Ensure the grade of HPSiC selected has optimal thermal conductivity and a microstructure designed for thermal shock resistance.

- Component Design: Design for uniform heating/cooling where possible. Avoid sharp thermal gradients across the component.

- Operational Parameters: Control heating and cooling rates in the application where feasible.

By acknowledging these challenges and proactively implementing mitigation strategies through careful design, material selection, and collaboration with expert manufacturers, the full potential of Hot Pressed Silicon Carbide components can be realized.

Selecting Your Ideal Partner for Custom Hot Pressed Silicon Carbide: Why Sicarb Tech Leads the Way

Choosing the right supplier for your custom Hot Pressed Silicon Carbide (HPSiC) components is a critical decision that directly impacts the quality, performance, and cost-effectiveness of your final product. The specialized nature of HPSiC manufacturing demands a partner with deep technical expertise, robust quality systems, and a commitment to customer collaboration.

Key Criteria for Evaluating an HPSiC Supplier:

- Technical Expertise and Experience:

- Look for proven experience in HPSiC formulation, hot pressing, and precision machining.

- The supplier should have a strong understanding of material science and how different processing parameters affect final properties.

- Inquire about their engineering support for design optimization and problem-solving.

- Material Quality and Consistency:

- The quality of raw SiC powder and sintering aids is paramount.

- The supplier must have stringent quality control over incoming materials and throughout the manufacturing process to ensure consistent density, purity, and mechanical properties.

- Customization Capabilities:

- Assess their ability to produce complex geometries and meet your specific dimensional tolerances and surface finish requirements.

- Flexibility in handling small prototype runs as well as larger volume production is often important.

- Quality Control and Certifications:

- Robust metrology capabilities (CMMs, surface profilometers, etc.) are essential for verifying part accuracy.

- Relevant quality certifications (e.g., ISO 9001) can indicate a commitment to standardized processes.

- Lead Times and Responsiveness:

- Understand their typical lead times for custom orders.

- A responsive supplier who communicates proactively is invaluable, especially for complex projects.

- Cost Competitiveness:

- While cost is a factor, it should be balanced against quality, reliability, and technical support. The cheapest option is not always the best value, especially for critical components.

Why Sicarb Tech is Your Trusted Partner in China:

Located in Weifang City, the undisputed hub of China’s silicon carbide customizable parts manufacturing (accounting for over 80% of the nation’s SiC output), Sicarb Tech stands out as a leader in providing high-quality, cost-competitive custom HPSiC solutions.

- Deep Roots in SiC Technology: Since 2015, we have been instrumental in introducing and implementing advanced silicon carbide production technology, fostering large-scale production and technological advancements within the local industry. We are not just a manufacturer; we are a key enabler of the Weifang SiC ecosystem. Learn more about us.

- Backed by National Scientific Excellence: Sicarb Tech is part of the Chinese Academy of Sciences (Weifang) Innovation Park, collaborating closely with the National Technology Transfer Center of the Chinese Academy of Sciences . This gives us unparalleled access to cutting-edge scientific capabilities, a rich talent pool, and a robust framework for technology transfer and innovation. This ensures more reliable quality and supply assurance within China.

- Unmatched In-House Expertise: We boast a domestic top-tier professional team specializing in the customized production of silicon carbide products, including HPSiC. Our comprehensive expertise spans:

- Material Technology: Advanced formulation and raw material control.

- Process Technology: Optimized hot pressing and sintering cycles.

- Design Technology: Collaborative design for manufacturability and performance.

- Measurement & Evaluation Technology: State-of-the-art metrology for stringent quality assurance.

- An integrated process from raw materials to finished HPSiC components.

- Commitment to Customization and Quality: We have supported over 10 local enterprises with our technologies, demonstrating our capability to meet diverse customization needs. We are dedicated to providing higher-quality, cost-competitive customized silicon carbide components from China.

- Technology Transfer and Turnkey Solutions: Beyond supplying components, Sicarb Tech is committed to advancing SiC technology globally. If you need to establish a professional silicon carbide products manufacturing plant in your country, we offer technology transfer for professional SiC production, along with a full range of turnkey project services including factory design, specialized equipment procurement, installation, commissioning, and trial production. This ensures an effective investment, reliable technology transformation, and a guaranteed input-output ratio.

Choosing SicSino means partnering with a knowledgeable and reliable source that understands the intricacies of Hot Pressed Silicon Carbide and is deeply invested in the success of its clients. We invite procurement professionals, OEMs, and distributors to contact us to discuss their specific technical ceramics procurement needs.

Here’s a comparative look at considerations when selecting a supplier:

| Feature | Generic Supplier Consideration | Sicarb Tech Advantage |

|---|---|---|

| Location & Cost | Varies, may involve complex international logistics | Based in Weifang, China’s SiC hub, offering potential cost efficiencies and streamlined supply for HPSiC supplier China needs. |

| Technical Backing | May rely solely on internal R&D | Backed by the Chinese Academy of Sciences , ensuring access to top-tier research and talent. |

| Experience | Variable; some may be new to complex SiC processing | Extensive experience since 2015 in SiC production technology and supporting numerous enterprises. |

| Customization Scope | May have limitations on complexity or material grades | Wide array of technologies (material, process, design, measurement) to meet diverse custom HPSiC manufacturing needs. |

| Quality Assurance | Standard QC processes | Integrated process control from materials to products, backed by Chinese Academy of Sciences standards. |

| Broader Support | Typically component supply only | Offers technology transfer and turnkey plant setup services, demonstrating deep industry commitment. |

Frequently Asked Questions (FAQ) about Hot Pressed Silicon Carbide

To further assist engineers, procurement managers, and technical buyers, here are answers to some common questions regarding Hot Pressed Silicon Carbide:

- What is the primary difference between Hot Pressed SiC (HPSiC) and Sintered SiC (SSiC) or Reaction Bonded SiC (RBSiC)?

- The main difference lies in the manufacturing process and resulting density/purity.

- HPSiC: Uses external pressure along with high temperature during sintering. This results in the highest density (typically >99%), minimal porosity, and often superior mechanical properties (strength, hardness). Sintering aids are used.

- SSiC (Pressureless Sintered SiC): SiC powder with sintering aids is fired at high temperatures without external pressure. Achieves high density (typically >95-98%), good strength, and excellent corrosion resistance.

- RBSiC (or SiSiC – Silicon Infiltrated Silicon Carbide): A porous SiC preform is infiltrated with molten silicon. The silicon reacts with some carbon to form more SiC, bonding the original grains. Contains free silicon (typically 8-15%), which limits its very high-temperature use (above $1350^\\circ C$) and chemical resistance in certain environments. However, it’s often more cost-effective for complex shapes.

- Key Takeaway: HPSiC generally offers the peak performance in terms of hardness, strength, and density, making it ideal for the most extreme wear and structural applications.

- The main difference lies in the manufacturing process and resulting density/purity.

- What are the typical temperature limitations for Hot Pressed SiC components?

- HPSiC can typically be used at temperatures up to $1650^\\circ C$ ($3000^\\circ F$) in inert or reducing atmospheres. In oxidizing atmospheres (like air), long-term service temperature is generally limited to around $1500^\\circ C$ to $1600^\\circ C$ due to the slow formation of a protective silica (SiO_2) layer. The specific sintering aids used can also influence the maximum use temperature and oxidation resistance. For applications exceeding these, or for specific chemical environments, it’s crucial to consult with material experts like those at Sicarb Tech.

- Is Hot Pressed SiC electrically conductive?

- Silicon Carbide is a semiconductor. The electrical conductivity of HPSiC can vary significantly depending on the purity of the initial SiC powder, the type and amount of sintering aids used, and the overall microstructure. Typically, HPSiC is not as conductive as metals but is more conductive than most insulating ceramics. Its resistivity can be tailored to some extent. For applications where specific electrical properties are critical (e.g., electrostatic chucks or heating elements), these requirements must be clearly communicated to the manufacturer. Some HPSiC grades can be quite resistive, while others can be moderately conductive.

- Can HPSiC be used for food or medical applications?

- While HPSiC is chemically inert and wear-resistant, its use in direct food contact or medical implant applications would require specific certifications and biocompatibility testing for the particular grade and manufacturing process. The sintering aids used in HPSiC (often containing elements like boron or aluminum) would need to be evaluated for leachability and biocompatibility according to relevant standards (e.g., FDA, USP Class VI). Generally, other ceramics like high-purity alumina or zirconia are more commonly used for medical implants, though SiC coatings or components are explored for specific biomedical wear applications. Always verify compliance with industry-specific regulations.

Conclusion: The Enduring Value of Custom Hot Pressed Silicon Carbide

In the landscape of advanced materials, Hot Pressed Silicon Carbide stands as a testament to engineering ingenuity, offering an unparalleled combination of hardness, strength, thermal stability, and wear resistance. Its ability to perform reliably in environments that would cause conventional materials to degrade rapidly makes it a cornerstone for innovation in critical industries. From the demanding precision of semiconductor manufacturing to the extreme conditions of aerospace and high-temperature industrial processes, custom HPSiC components provide solutions that enhance efficiency, prolong service life, and enable new technological frontiers.

Partnering with a knowledgeable and experienced supplier is paramount to unlocking the full potential of this exceptional material. Sicarb Tech, with its deep expertise rooted in the heart of China’s SiC manufacturing hub and backed by the scientific prowess of the Chinese Academy of Sciences, is uniquely positioned to deliver superior custom Hot Pressed Silicon Carbide products. We offer not just components, but comprehensive solutions, from design consultation and bespoke manufacturing to technology transfer for establishing your own SiC production capabilities. We encourage you to explore our diverse product examples and learn about our rigorous customizing support.

For engineers, procurement managers, and technical buyers seeking the ultimate in material performance for their most challenging applications, Hot Pressed Silicon Carbide, especially when tailored through expert customization, represents a sound investment in durability, reliability, and long-term value. We invite you to contact Sicarb Tech to discuss how HPSiC can elevate your next project.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.