High Purity Silicon Carbide: The Ultimate Material for Extreme Industrial Challenges

Share

In the relentless pursuit of materials that can withstand the harshest industrial environments, high purity silicon carbide (SiC) emerges as a frontrunner. Its exceptional combination of physical, chemical, and electrical properties makes it indispensable for applications where performance, reliability, and longevity are paramount. For engineers, procurement managers, and technical buyers in sectors like semiconductors, aerospace, and high-temperature processing, understanding the nuances of high purity SiC is crucial for driving innovation and maintaining a competitive edge. This blog post delves into the world of custom high purity silicon carbide products, exploring their applications, advantages, and the critical considerations for sourcing these advanced technical ceramics.

At Sicarb Tech, we are at the forefront of custom silicon carbide manufacturing. Situated in Weifang City, the heart of China’s SiC industry which accounts for over 80% of the nation’s output, we leverage the robust scientific capabilities of the Chinese Academy of Sciences . Since 2015, SicSino has been instrumental in advancing SiC production technology, assisting local enterprises in achieving large-scale production and technological breakthroughs. As part of the Chinese Academy of Sciences (Weifang) Innovation Park, a national-level innovation and entrepreneurship service platform, we offer unparalleled expertise in advanced ceramics manufacturing, ensuring our clients receive components that meet the most stringent purity and performance standards.

High Purity Silicon Carbide: The Gold Standard for Demanding Applications

What exactly is high purity silicon carbide? Standard industrial-grade SiC is already a remarkable material, but “high purity” takes its capabilities to another level. This designation typically refers to SiC with minimal impurities, often exceeding 99.9% or even 99.999% (5N) purity for specialized applications like semiconductor processing. These impurities, even in trace amounts, can significantly affect the material’s thermal conductivity, electrical resistivity, optical properties, and chemical resistance at elevated temperatures or in corrosive environments.

The essential nature of high purity SiC lies in its ability to perform reliably under conditions that would cause most other materials to degrade or fail. Its importance is particularly pronounced in:

- Preventing contamination: In semiconductor manufacturing or pharmaceutical processing, any leaching of impurities from equipment components can compromise product quality and yield.

- Ensuring consistent properties: Variations caused by impurities are minimized, leading to predictable and repeatable performance in critical applications.

- Maximizing intrinsic material benefits: The inherent strengths of SiC, such as its high thermal conductivity and hardness, are fully realized when impurities are removed.

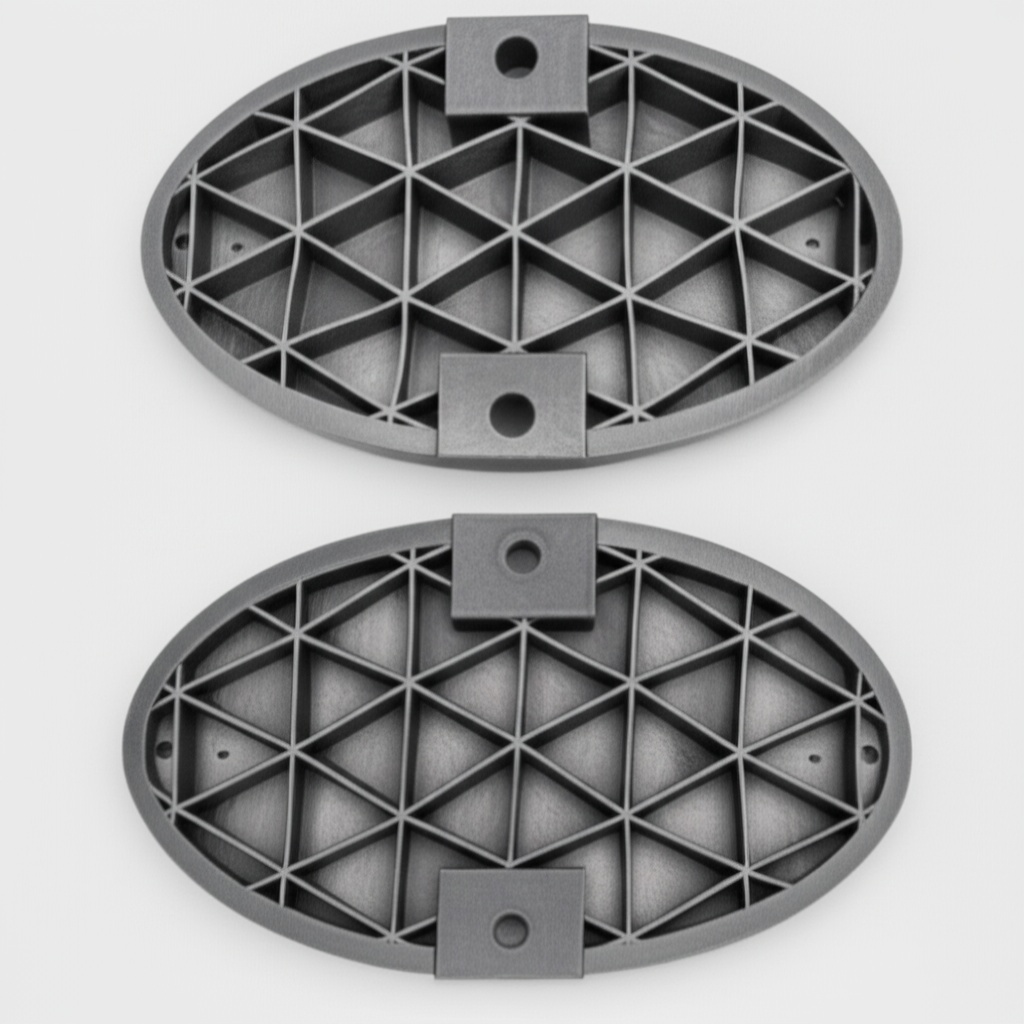

Customization is key when dealing with high purity SiC components. Off-the-shelf solutions rarely suffice for cutting-edge applications. Engineers require precisely tailored geometries, specific surface finishes, and guaranteed purity levels to meet their unique operational demands. This is where specialized suppliers like Sicarb Tech play a vital role. Our deep understanding of SiC material science, combined with advanced manufacturing processes, allows us to produce custom SiC parts that deliver optimal performance. We work closely with our clients, from initial design to final product, ensuring that every component aligns perfectly with its intended application, making us a preferred partner for OEM SiC parts and industrial SiC solutions.

Diverse Frontiers: Key Industrial Applications of High Purity SiC

The exceptional properties of high purity silicon carbide have paved its way into a multitude of demanding industrial applications. Its ability to maintain structural integrity, chemical inertness, and desired electrical characteristics under extreme conditions makes it a material of choice for innovation and reliability.

Semiconductor Manufacturing: This is perhaps the most significant and demanding sector for high purity SiC.

- Wafer Handling and Processing: Components like wafer chucks, dummy wafers, showerheads for CVD/PVD systems, and edge rings require ultra-high purity to prevent contamination of silicon wafers. The material’s high thermal conductivity also ensures uniform temperature distribution during processing.

- Rapid Thermal Processing (RTP): SiC’s excellent thermal shock resistance and high emissivity make it ideal for RTP chamber components, including susceptors and liners.

- Plasma Etch Chambers: Liners, focus rings, and other chamber parts made from high purity SiC offer superior resistance to aggressive plasma chemistries, minimizing particle generation and extending component lifetime. For semiconductor grade SiC, purity levels are often in the 5N (99.999%) to 6N (99.9999%) range.

Aerospace and Defense:

- Optical Systems: High purity SiC, particularly Chemical Vapor Deposited (CVD) SiC, is used for lightweight, high-stiffness mirrors and optical benches in satellites and telescopes due to its excellent thermal stability and polishability.

- High-Temperature Components: Nozzles, combustion chamber liners, and leading edges for hypersonic vehicles benefit from SiC’s ability to withstand extreme temperatures and oxidative environments.

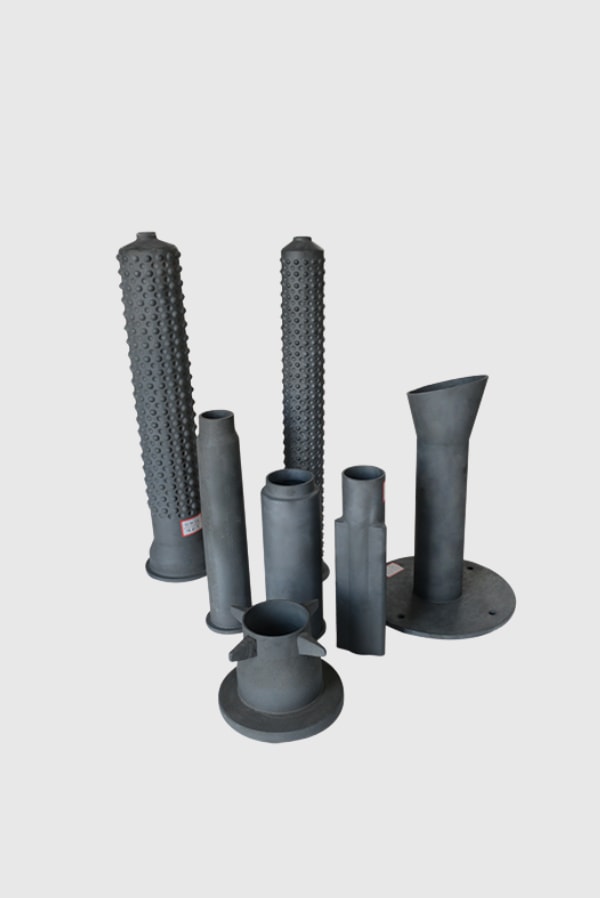

High-Temperature Furnaces and Heat Treatment:

- Kiln Furniture: Beams, rollers, plates, and setters made from high purity SiC (often recrystallized SiC or dense sintered SiC) offer long service life and minimal contamination in firing ceramics, powder metallurgy, and other high-temperature processes up to 1600∘C or higher.

- Heating Elements: While not always “high purity” in the semiconductor sense, specialized SiC heating elements provide efficient and reliable heat sources.

- Process Tubes and Crucibles: For applications requiring controlled atmospheres and resistance to chemical attack at high temperatures, high purity SiC tubes and crucibles are indispensable.

Chemical Processing Industry (CPI):

- Pump Components: Seals, bearings, and shafts in pumps handling highly corrosive or abrasive chemicals benefit from SiC’s wear and chemical resistance.

- Heat Exchangers: For aggressive media where metallic contamination is a concern, SiC heat exchangers (often SiSiC or SSiC) offer excellent thermal conductivity and corrosion resistance. While extreme purity might not be the primary driver here, the base material’s inertness is crucial.

Energy Sector:

- Nuclear Applications: High purity SiC is explored for fuel cladding and structural components in advanced nuclear reactors due to its radiation resistance and stability at high temperatures.

- Concentrated Solar Power (CSP): Components in CSP systems, such as receivers, can leverage SiC’s high thermal conductivity and resistance to thermal shock.

The following table highlights some key applications and the specific benefits high purity SiC brings:

| Industry Sector | Application Example | Key Benefits of High Purity SiC | Typical SiC Grades Used (Purity Focus) |

|---|---|---|---|

| Semiconductor | Wafer Chucks, CVD/Etch Chamber Parts | Ultra-high purity (no contamination), thermal conductivity, plasma resistance | CVD-SiC, High Purity Sintered SiC |

| Aerospace | Satellite Mirrors, Optical Benches | High stiffness-to-weight ratio, thermal stability, polishability | CVD-SiC |

| High-Temp. Furnaces | Kiln Furniture, Process Tubes | High-temperature strength, thermal shock resistance, chemical inertness | Recrystallized SiC (RSiC), Dense SSiC |

| Chemical Processing | Pump Seals, Bearings | Extreme wear resistance, corrosion resistance to acids/alkalis | Sintered SiC (SSiC) |

| Energy (Nuclear) | Fuel Cladding, Structural Components | Radiation resistance, high-temperature stability | High Purity CVD-SiC, SSiC |

Sicarb Tech specializes in providing custom SiC solutions for these demanding sectors. Our expertise in material selection and precision manufacturing ensures that components meet the exacting purity and performance requirements of each unique application, making us a reliable China SiC supplier for global industries.

The Purity Advantage: Unpacking the Benefits of Custom High Purity SiC

Opting for custom high purity silicon carbide is not merely a preference; it’s often a necessity for applications pushing the boundaries of technology. Standard SiC grades, while robust, may contain binders, sintering aids, or inherent impurities from raw materials that can compromise performance in critical scenarios. The “purity advantage” translates into tangible benefits that directly impact efficiency, yield, and component lifespan.

Superior Thermal Management:

- High Thermal Conductivity: Pure SiC exhibits excellent thermal conductivity (often >200W/mK, with some grades like CVD-SiC reaching >300W/mK at room temperature). This allows for rapid and uniform heat dissipation, crucial in semiconductor processing equipment, high-power electronics, and heat exchangers. Impurities can scatter phonons, reducing thermal conductivity.

- Low Thermal Expansion: SiC has a low coefficient of thermal expansion (CTE), which, combined with high thermal conductivity, results in outstanding thermal shock resistance. This means components can withstand rapid temperature changes without cracking or failing. Custom designs can further optimize for thermal stresses.

- High-Temperature Stability: High purity SiC maintains its mechanical strength and structural integrity at very high temperatures (up to 1600−1800∘C in non-oxidizing atmospheres, and even higher for short durations or specific grades). It exhibits minimal creep and deformation.

Exceptional Wear and Corrosion Resistance:

- Extreme Hardness: Silicon carbide is one of the hardest synthetic materials available (Mohs hardness of 9-9.5, Knoop hardness typically 2500-3000 kg/mm²). This translates to superior resistance to abrasive wear, making it ideal for components like mechanical seals, nozzles, and bearings.

- Outstanding Chemical Inertness: High purity SiC is highly resistant to a wide range of corrosive chemicals, including strong acids (HF, H2SO4, HNO3) and bases, even at elevated temperatures. This makes it suitable for handling aggressive media in chemical processing and semiconductor wet etch processes. The absence of metallic or oxide impurities, which could act as reactive sites, enhances this inertness.

Tailored Electrical Properties:

- Semiconducting Nature (tunable): While often used for its insulating properties in its high-purity, undoped state (especially CVD-SiC), silicon carbide is inherently a wide-bandgap semiconductor. Its electrical resistivity can be controlled through doping (e.g., with nitrogen for n-type or aluminum for p-type) or by selecting specific polytypes and purity levels. This allows for applications ranging from high-temperature sensors and power electronics to highly resistive components for electrostatic chucks.

- High Breakdown Electric Field: SiC can withstand much higher electric fields before breakdown compared to silicon, making it crucial for high-voltage power devices.

Why Customization is Crucial for High Purity Applications: The benefits of high purity SiC are maximized when components are tailored to the specific application. Custom SiC component design allows for:

- Optimized Geometry: Parts can be designed to manage thermal stresses, improve fluid dynamics, or integrate seamlessly with existing equipment.

- Specific Surface Characteristics: Applications may require ultra-smooth polished surfaces (e.g., for optics or wafer handling) or specific textured surfaces.

- Controlled Purity Levels: Not all “high purity” applications need 6N purity. Customization allows selection of the appropriate purity grade to balance performance and cost.

Sicarb Tech excels in this arena. Our customizing support encompasses material selection, design assistance, and manufacturing processes tailored to achieve the desired purity and performance. We leverage our deep understanding of various SiC grades and their properties to guide our clients. For instance, our Reaction-Bonded Silicon Carbide (RBSiC or SiSiC) offers excellent wear resistance and thermal shock resistance for many industrial applications, while our Sintered Silicon Carbide (SSiC) provides superior chemical resistance and high-temperature strength without the presence of free silicon, making it suitable for more demanding chemical and thermal environments where extreme purity is critical. For the utmost purity, we can facilitate access to specialized grades like CVD-SiC through our network. Our commitment as a technical ceramics wholesale supplier extends to ensuring that the purity advantage is fully realized in your end-product.

Understanding the Material: Grades, Compositions, and Manufacturing of High Purity SiC

Achieving “high purity” in silicon carbide is a result of carefully controlled raw materials and sophisticated manufacturing processes. While various types of SiC exist, their suitability for high-purity applications differs significantly. The key is minimizing or eliminating secondary phases, binders, and metallic impurities that can compromise performance.

Common SiC Grades and Their Relation to Purity:

- Reaction-Bonded Silicon Carbide (RBSiC or SiSiC):

- Manufacturing: Produced by infiltrating a porous SiC and carbon preform with molten silicon. The silicon reacts with the carbon to form new SiC, which bonds the original SiC grains.

- Purity: Typically contains 8-15% free silicon. While excellent for many wear and thermal applications, the free silicon makes it unsuitable for ultra-high purity or very high-temperature applications where silicon might melt or react. Purity is generally lower than SSiC or CVD-SiC.

- Sicarb Tech offerings: We provide high-quality RBSiC components with optimized microstructures for various industrial uses.

- Sintered Silicon Carbide (SSiC):

- Manufacturing: Made from fine SiC powder, often with non-oxide sintering aids (like boron and carbon), and sintered at high temperatures (typically >2000∘C) in an inert atmosphere. Pressureless Sintered SiC (SSiC) and Hot-Pressed SiC (HPSiC) are common types.

- Purity: Can achieve very high SiC content (typically >98-99%). The sintering aids are present in very small amounts. SSiC is generally considered a high-purity material suitable for many semiconductor and chemical applications due to its excellent corrosion resistance and high-temperature strength without free silicon.

- Sicarb Tech offerings: We specialize in dense SSiC components, ensuring minimal porosity and high chemical resistance, ideal for demanding applications including those requiring semiconductor grade SiC characteristics.

- Nitride-Bonded Silicon Carbide (NBSiC):

- Manufacturing: SiC grains are bonded by a silicon nitride (Si3N4) phase.

- Purity: The presence of the nitride phase means it’s not typically used for “high purity” SiC applications in the semiconductor sense, but it offers good thermal shock resistance and strength for kiln furniture.

- Recrystallized Silicon Carbide (RSiC):

- Manufacturing: Made by firing high-purity SiC powders at very high temperatures (>2300∘C), causing the grains to bond directly without binders or sintering aids through a process of evaporation and condensation.

- Purity: Can be very high (often >99.5% SiC). It has an open porous structure, which is beneficial for some applications like filters or kiln furniture requiring excellent thermal shock resistance but may not be suitable where gas tightness is needed.

- Sicarb Tech offerings: We can produce RSiC components known for exceptional thermal shock resistance and stability at extreme temperatures.

- Chemical Vapor Deposited Silicon Carbide (CVD-SiC):

- Manufacturing: Produced by a chemical reaction of gaseous silicon-containing (e.g., methyltrichlorosilane – MTS, or silane + propane) and carbon-containing precursors at high temperatures on a substrate (often graphite). This process results in a theoretically dense, ultra-pure SiC layer or bulk material.

- Purity: This is the gold standard for ultra-high purity SiC, capable of achieving 5N (99.999%) to 6N (99.9999%) purity or even higher. It has virtually no porosity and extremely low levels of metallic impurities.

- Applications: Dominant in semiconductor wafer processing equipment (chamber components, chucks, rings) and high-end optics. While Sicarb Tech primarily focuses on SSiC and RBSiC, our expertise and network within Weifang’s SiC hub allow us to facilitate and advise on CVD-SiC solutions for specialized requirements.

Key Factors Defining “High Purity”:

- Low Metallic Impurity Levels: Elements like Fe, Al, Ca, Na, K, etc., must be minimized, often to parts per million (ppm) or parts per billion (ppb) levels for semiconductor applications.

- Absence of Secondary Phases: For the highest purity, materials like free silicon (in RBSiC) or binders are undesirable.

- Stoichiometry: A precise silicon-to-carbon ratio is important for consistent properties.

The selection of an appropriate grade depends on the specific purity requirements, operating conditions, and cost considerations of the application.

| SiC Grade | Typical SiC Content | Key Impurities/Secondary Phases | Max. Service Temp. (approx.) | Primary Strengths for Purity-Sensitive Apps |

|---|---|---|---|---|

| RBSiC (SiSiC) | 85-92% SiC | 8-15% Free Silicon | 1350−1380∘C | Good for many industrial uses, cost-effective |

| SSiC | >98-99% | Sintering aids (e.g., B, C) | 1600−1800∘C | High purity, no free Si, excellent corrosion & temp. resistance |

| RSiC | >99.5% | (Porous, no binders) | 1650−1700∘C | Very high purity, excellent thermal shock (but porous) |

| CVD-SiC | >99.999% | Trace elements (ppb levels) | >2000∘C (in theory) | Ultra-high purity, theoretical density, superior for semiconductor |

Sicarb Tech is dedicated to assisting customers in navigating these material choices. Our team in Weifang, the hub of China’s silicon carbide customizable parts factories, possesses deep knowledge of material science and process technologies to deliver high-quality, cost-competitive customized silicon carbide components.

Engineering Excellence: Design, Tolerances, and Finishing for High Purity SiC Components

Manufacturing components from high purity silicon carbide is a complex process that demands careful attention to design, achievable tolerances, and surface finishing. These factors are intrinsically linked and play a crucial role in the final performance and reliability of the SiC part, especially in precision-driven industries like semiconductors and optics.

Design Considerations for Manufacturability: Silicon carbide is a hard and brittle ceramic, which imposes certain limitations on design complexity compared to metals or plastics.

- Simplicity is Key: While complex shapes are possible, simpler geometries generally lead to lower manufacturing costs and reduced risk of stress concentrations. Avoid sharp internal corners and rapid changes in cross-section, which can become stress points. Generous radii are recommended.

- Wall Thickness: Minimum wall thickness depends on the overall size and manufacturing process (e.g., SSiC parts can achieve thinner walls than some larger RBSiC structures). It’s crucial to discuss limitations with your supplier.

- Draft Angles: For net-shape forming processes like slip casting or injection molding (used for green bodies before sintering), draft angles may be necessary for demolding.

- Avoiding Stress Concentrators: Features like small holes or slots in highly stressed areas should be carefully evaluated. The inherent brittleness means SiC is notch-sensitive.

- Joining and Assembly: If the SiC component needs to be joined to other parts (SiC or different materials), the design must account for differences in thermal expansion and appropriate joining techniques (e.g., brazing, diffusion bonding, mechanical clamping).

Achievable Tolerances and Dimensional Accuracy: The achievable tolerances for SiC components depend on the manufacturing method (forming, sintering, and post-sintering machining).

- As-Sintered Tolerances: For net-shaped parts without extensive machining, typical tolerances might be in the range of ±0.5% to ±1% of the dimension.

- Machined Tolerances: Due to its extreme hardness, machining SiC (grinding, lapping, polishing) is a time-consuming and expensive process, typically done with diamond tooling. However, it allows for much tighter tolerances.

- Grinding: Can achieve tolerances of ±0.005 mm to ±0.025 mm ( ±0.0002 to ±0.001 inches).

- Lapping and Polishing: Can achieve even tighter dimensional control and superior surface finishes, with flatness and parallelism in the micrometer or sub-micrometer range.

- Impact of Purity: High purity grades, especially CVD-SiC, are often machined to extremely tight tolerances for semiconductor applications. The consistency of high purity material aids in achieving repeatable machining results.

Surface Finish (Roughness – Ra): The required surface finish is highly application-dependent.

- Industrial Applications: For kiln furniture or general wear parts, a standard as-sintered or ground finish (Ra 0.4 – 1.6 μm) may be sufficient.

- Precision Applications:

- Mechanical Seals: Often require lapped surfaces with Ra < 0.2 μm for effective sealing.

- Semiconductor Components (e.g., wafer chucks, rings): May demand polished surfaces with Ra < 0.1 μm or even down to angstrom levels for certain optical-grade SiC parts to minimize particle generation and ensure planarity.

- High Purity Considerations: A smooth, non-porous surface is critical in high purity applications to prevent trapping of contaminants and to facilitate cleaning.

Sicarb Tech understands the critical interplay between design, tolerance, and surface finish. Our domestic top-tier professional team specializes in the customized production of silicon carbide products. We employ advanced machining and finishing techniques to meet the exacting specifications of our clients. Our integrated process, from materials to finished products, includes precise measurement and evaluation technologies to ensure every custom SiC part adheres to the agreed-upon dimensional and surface quality standards. This precision capability is a cornerstone of our service to OEMs and technical procurement professionals.

Beyond Fabrication: Essential Post-Processing for Optimal High Purity SiC Performance

The journey of a high purity silicon carbide component doesn’t end once it’s formed and sintered. To achieve the exacting standards required by many advanced industrial applications, particularly in the semiconductor and optical fields, meticulous post-processing steps are essential. These processes refine the component’s dimensions, improve its surface characteristics, and ensure the ultimate purity and performance in its intended environment.

Key Post-Processing Techniques for High Purity SiC:

- Precision Grinding:

- Purpose: To achieve tight dimensional tolerances, flatness, parallelism, and specific profiles on sintered SiC parts. Due to SiC’s extreme hardness, diamond grinding wheels are exclusively used.

- Process: Involves various grinding operations such as surface grinding, cylindrical grinding, and centerless grinding. Coolants are used to manage heat and remove swarf.

- Importance for Purity: While grinding shapes the component, care must be taken to use high-purity coolants and to clean parts thoroughly afterward to remove any residues from the grinding process itself, which could compromise the “high purity” status.

- Lapping:

- Purpose: To achieve very high degrees of flatness, parallelism, and an improved surface finish (smoother than grinding).

- Process: Components are rubbed against a flat lapping plate with an abrasive slurry (typically diamond or boron carbide) in between.

- Applications: Critical for mechanical seal faces, valve components, and substrates requiring extreme flatness.

- Polishing:

- Purpose: To produce an even smoother, often mirror-like surface finish with minimal subsurface damage. This is crucial for optical applications and for semiconductor components where particle generation must be minimized.

- Process: Utilizes finer abrasive slurries (e.g., fine diamond, colloidal silica) and specialized polishing pads. Techniques can include mechanical polishing and chemo-mechanical polishing (CMP) for the finest finishes.

- High Purity Focus: For semiconductor grade SiC, polishing is a critical step. The choice of polishing media and cleaning procedures are paramount to maintain purity.

- Cleaning and Purity Verification:

- Purpose: To remove any contaminants, machining residues, organic films, or particles from the SiC surface. This is arguably the most critical step for ensuring the “high purity” integrity of the final component.

- Process: Multi-stage cleaning processes are often employed, which may include:

- Ultrasonic cleaning in deionized (DI) water or specialized solvents.

- Acid etching (e.g., with HF/HNO3 mixtures, carefully controlled) to remove surface oxides or metallic contaminants.

- Rinsing with ultra-high purity DI water.

- Drying in a cleanroom environment (e.g., nitrogen-purged ovens).

- Verification: Surface analysis techniques like X-ray Photoelectron Spectroscopy (XPS), Auger Electron Spectroscopy (AES), or Total Reflection X-ray Fluorescence (TXRF) may be used to verify surface purity for the most demanding applications.

- Edge Treatment and Chamfering:

- Purpose: To remove sharp edges, which can be sources of chipping, particle generation, or stress concentration.

- Process: Precise grinding or lapping techniques are used to create defined chamfers or radii on component edges.

- Annealing (Stress Relief):

- Purpose: In some cases, particularly after extensive machining, an annealing step at elevated temperatures might be performed to relieve internal stresses induced during grinding, though this is less common for SiC than for some other ceramics.

Sicarb Tech and its partner enterprises in Weifang are equipped with advanced post-processing facilities. We understand that the value of high purity SiC is intrinsically linked to the quality of its finish and its ultimate cleanliness. Our quality control procedures incorporate rigorous inspection and cleaning protocols to ensure that the custom SiC components we deliver meet the stringent requirements of our B2B clients, including wholesale buyers and OEMs in high-technology sectors. Our commitment to quality ensures that the advanced ceramics manufacturing processes yield products ready for immediate integration into critical systems.

Strategic Sourcing: Selecting Your High Purity SiC Partner & Navigating Costs

Choosing the right supplier for high purity silicon carbide components is a critical decision that can significantly impact your project’s success, timeline, and budget. The specialized nature of these materials and the precision required in their manufacturing demand a partner with proven technical expertise, robust quality systems, and a transparent approach to cost. For technical procurement professionals and OEMs, this selection process goes beyond just price.

Key Criteria for Evaluating a High Purity SiC Supplier:

- Technical Expertise & Material Knowledge:

- Does the supplier have a deep understanding of different SiC grades (RBSiC, SSiC, capabilities regarding CVD-SiC if needed) and their specific properties?

- Can they provide expert advice on material selection for your application?

- Do they have experience with your industry (e.g., semiconductor, aerospace)?

- Sicarb Tech Advantage: Backed by the Chinese Academy of Sciences National Technology Transfer Center, we possess a domestic top-tier professional team specializing in customized SiC production. Our expertise spans material science, process technology, design, and evaluation.

- Customization Capabilities:

- Can they manufacture complex geometries to your specific designs?

- What are their capabilities regarding tolerances, surface finishes, and dimensional accuracy?

- Do they offer design assistance or DFM (Design for Manufacturability) feedback?

- Sicarb Tech Advantage: We excel in diverse customization needs, leveraging a wide array of technologies from materials to finished products.

- Quality Control & Assurance:

- What quality management systems are in place (e.g., ISO 9001)?

- What are their inspection and testing procedures for raw materials, in-process components, and final products?

- Can they provide material certifications and traceability for high purity claims?

- Sicarb Tech Advantage: We ensure more reliable quality and supply assurance within China. Our support has benefited 10+ local enterprises through our technologies, emphasizing quality and process control.

- Manufacturing Facilities & Location:

- Do they have the necessary forming, sintering, and precision machining equipment?

- What are their capabilities for post-processing, cleaning, and packaging for high purity applications?

- Sicarb Tech Advantage: Located in Weifang City, the hub of China’s silicon carbide customizable parts factories (over 80% of national output). This ecosystem provides access to a comprehensive supply chain and specialized services.

- Cost Structure & Lead Times:

- Is their pricing transparent and competitive for the specified purity and complexity?

- What are their typical lead times for custom orders?

- Are they flexible in accommodating different order volumes?

Navigating Cost Drivers for High Purity SiC:

The cost of custom high purity SiC components can vary significantly based on several factors:

- Purity Level: The higher the purity (e.g., semiconductor grade 5N or 6N CVD-SiC vs. standard SSiC), the more complex and expensive the raw materials and processing become.

- Material Grade: Different SiC grades (RBSiC, SSiC, RSiC, CVD-SiC) have different raw material and processing costs.

- Complexity of Design: Intricate geometries, thin walls, and complex features require more sophisticated tooling and machining, increasing costs.

- Tolerances and Surface Finish: Tighter tolerances and finer surface finishes (especially polishing) require more extensive and precise machining, which is a major cost driver for hard ceramics like SiC.

- Order Volume: Larger production runs typically benefit from economies of scale, reducing the per-unit cost. Small, highly custom orders will generally have a higher per-unit price.

- Post-Processing & Cleaning: Specialized cleaning and verification steps for high purity add to the cost.

Typical Cost Factor Comparison (Illustrative):

| Cost Factor | Impact on Price (Low to High) | Notes |

|---|---|---|

| Raw Material Purity | Significant | 99.999% SiC is much costlier than 98% SiC |

| Design Complexity | Moderate to Significant | Intricate shapes, small features increase tooling & machining time |

| Dimensional Tolerance | Moderate to Significant | Tighter tolerances (e.g., < ±0.01mm) require extensive grinding/lapping |

| Surface Finish | Moderate to High | Polishing to Ra < 0.1µm is a major cost addition |

| Order Quantity | Significant (per unit) | Economies of scale apply; setup costs are amortized over more units |

Lead Time Considerations: Lead times for custom SiC parts can range from a few weeks to several months, depending on:

- Complexity of the part

- Availability of raw materials

- Current production backlog

- Extent of machining and post-processing required

- Testing and certification requirements

It is crucial to discuss lead times upfront with your supplier. Sicarb Tech is committed to providing higher-quality, cost-competitive customized silicon carbide components in China. We strive for transparent communication regarding costs and realistic lead times, ensuring our clients can plan effectively. For businesses looking to establish their own SiC production, we also offer technology transfer for professional silicon carbide production, including turnkey project services. This unique offering underscores our deep expertise and commitment to fostering the SiC industry.

Frequently Asked Questions (FAQ) about High Purity Silicon Carbide

Q1: What is the typical purity level defined as “high purity” for silicon carbide, and how does it compare to standard grades? A1: “High purity” for silicon carbide can vary by application. For general industrial uses requiring good chemical and thermal resistance, Sintered SiC (SSiC) with >98-99% SiC content might be considered high purity compared to Reaction Bonded SiC (RBSiC), which contains 8-15% free silicon. However, in the semiconductor industry, high purity SiC often refers to materials like Chemical Vapor Deposited SiC (CVD-SiC) with purity levels exceeding 99.999% (5N) or even 99.9999% (6N). These ultra-pure grades have minimized metallic impurities (often in the ppb range) and no secondary phases, which is critical to prevent wafer contamination. Standard industrial SiC powders used for abrasives might be 90-98% pure.

Q2: What are the primary advantages of using custom high purity SiC components in semiconductor manufacturing equipment? A2: In semiconductor manufacturing, the advantages are critical: * Reduced Contamination: Ultra-low levels of metallic and particulate impurities in high purity SiC prevent contamination of silicon wafers, improving device yield and performance. * Superior Plasma Resistance: Components like etch chamber liners and showerheads made from high purity SiC (especially CVD-SiC or high-purity SSiC) exhibit excellent resistance to aggressive plasma chemistries, leading to longer component life and reduced particle generation. * Excellent Thermal Management: High thermal conductivity ensures uniform temperature distribution across wafers (e.g., in chucks and susceptors), critical for precise process control. * High Stiffness and Dimensional Stability: Ensures precision and repeatability in wafer handling and positioning. * Chemical Inertness: Resistance to cleaning chemicals and process gases. Sicarb Tech can assist in sourcing or developing custom SiC solutions tailored for the rigorous demands of semiconductor applications.

Q3: How does Sicarb Tech ensure the quality and purity of its custom SiC products, especially for B2B wholesale buyers and OEMs? A3: Sicarb Tech leverages several strategic advantages to ensure quality and purity: * Strong Technical Foundation: Our roots in the Chinese Academy of Sciences provide access to leading material science expertise and advanced process technologies. * Location in Weifang SiC Hub: Being in Weifang, which accounts for over 80% of China’s SiC output, gives us access to a mature supply chain and specialized manufacturing partners whose processes we can influence and enhance with our technology. * Integrated Process Control: We possess a wide array of technologies, including material, process, design, measurement, and evaluation technologies, allowing for an integrated approach from raw materials to finished products. * Support to Local Enterprises: We have provided technological support to over 10 local enterprises, helping them achieve large-scale production and technological advancements. This collaborative approach allows us to ensure high standards. * Customization and Quality Assurance: Our domestic top-tier professional team specializes in customized production. We implement rigorous quality control measures, including material analysis, dimensional checks, and surface inspections, to meet the specific purity and tolerance requirements of our B2B clients. We aim to deliver higher-quality, cost-competitive customized silicon carbide components with reliable supply assurance.

Q4: Can high purity SiC be effectively machined into complex shapes, and what are the limitations? A4: Yes, high purity SiC can be machined into complex shapes, but it presents challenges due to its extreme hardness and brittleness. * Machining Process: Diamond tooling is exclusively used for grinding, lapping, and polishing. Electrical Discharge Machining (EDM) can sometimes be used for conductive SiC grades, and laser machining is also an option for certain features. * Achievable Complexity: While intricate designs are possible, they significantly increase machining time and cost. It’s generally advisable to design for manufacturability, avoiding very sharp internal corners, extremely thin walls without proper support, and features that could lead to high stress concentrations. * Limitations: The primary limitations are cost and lead time associated with machining hard ceramics. Brittleness means that impact resistance is low, and components can chip or fracture if mishandled or subjected to high mechanical shock. Design iterations and close collaboration with a knowledgeable supplier like SicSino are crucial to optimize for both performance and manufacturability.

Q5: What are the typical lead times for custom high purity silicon carbide orders, and what factors influence this? A5: Lead times for custom high purity SiC orders can vary widely, typically ranging from 4 to 16 weeks, or sometimes longer for highly complex or ultra-high purity (e.g., CVD-SiC) parts. Key influencing factors include: * Complexity of Design: More intricate parts require more programming, setup, and machining time. * Purity and Grade of SiC: Specialized raw materials for higher purity grades might have longer procurement times. * Machining Requirements: Extensive grinding, lapping, and especially polishing to very fine finishes significantly extend lead times. * Order Volume: Small, one-off custom orders might take longer on a per-piece basis than larger, repeatable orders once the process is established. * Tooling: Custom tooling or fixtures, if needed, will add to the initial lead time. * Supplier’s Backlog: Current workload at the manufacturing facility. * Testing and Certification: If extensive testing and documentation are required. It is always best to discuss specific lead time requirements with your supplier early in the procurement process. Sicarb Tech works to provide realistic timelines and ensures efficient project management for its industrial SiC solutions.

Conclusion: The Enduring Value of High Purity Silicon Carbide in Advanced Industries

In the landscape of advanced materials, high purity silicon carbide stands out for its unparalleled ability to perform under the most extreme industrial conditions. Its unique combination of thermal stability, chemical inertness, wear resistance, and tailorable electrical properties makes it an indispensable solution for engineers and technical buyers in pioneering sectors such as semiconductors, aerospace, energy, and high-temperature manufacturing. The move towards custom-designed, high purity SiC components is not just a trend but a fundamental requirement for pushing the boundaries of innovation, enhancing product yields, and ensuring operational reliability.

Partnering with a knowledgeable and capable supplier is paramount to harnessing the full potential of this exceptional material. Sicarb Tech, strategically positioned in Weifang, the nucleus of China’s SiC industry, and backed by the formidable R&D power of the Chinese Academy of Sciences, offers a distinct advantage. We provide not only custom silicon carbide components of superior quality and cost-effectiveness but also a wealth of technical expertise, comprehensive customizing support, and even technology transfer for businesses looking to establish their own SiC production capabilities. Our commitment is to empower our clients with advanced ceramic solutions that drive progress and deliver enduring value in their respective fields. For your demanding industrial applications requiring the utmost in material performance, consider the proven excellence of high purity silicon carbide and the dedicated partnership of SicSino.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.