Industrial Silicon Carbide Solutions for Pakistan: Sicarbtech’s 2025 Playbook for Low‑Speed, High‑Torque Hill‑Climb and Heavy‑Load Scenarios

Share

Executive Summary: 2025 Outlook for Silicon Carbide in Pakistan’s High‑Torque Mobility and Industrial Corridors

Pakistan’s mobility backbone—electric three‑wheelers, motorcycles, and light commercial vehicles serving textile clusters, cement corridors, and steel supply chains—faces an unforgiving operating reality. Vehicles crawl through congested streets, queue on steep ramps, and endure extended low‑speed following in 40–50 °C ambient heat with elevated dust and humidity. In these conditions, low‑speed efficiency, torque agility, and thermal resilience determine range, uptime, and driver safety. Silicon carbide (SiC) power electronics deliver the leap the market needs: lower losses under high current at low speed, high junction temperature headroom, and compact packaging that keeps torque available when the road climbs and the mercury rises.

Sicarbtech—Silicon Carbide Solutions Expert—operates from Weifang City, China’s silicon carbide manufacturing hub, and is a member of the Chinese Academy of Sciences (Weifang) Innovation Park. With 10+ years of SiC customization and 19+ enterprise collaborations, Sicarbtech provides full‑cycle capabilities from materials (R‑SiC, SSiC, RBSiC, SiSiC) and wafers to power modules, magnetics, thermal stacks, algorithms, and reliability validation. For Pakistan, the differentiator is turnkey technology transfer and factory establishment that localize packaging, screening, and spares, compressing lead times and building domestic capability. This pillar page distills a pragmatic, standards‑aware blueprint for SiC traction systems optimized for low‑speed, high‑torque duty—hill climbing and heavy‑load delivery—grounded in Pakistan’s 2025 market outlook.

Industry Challenges and Pain Points: Where Conventional Drives Fall Short

Begin at the curb. Urban traffic in Karachi, Lahore, and Rawalpindi creates persistent stop‑and‑go patterns where vehicles operate far below base speed for long stretches. Low‑speed high‑current conditions amplify copper and switching losses in conventional silicon inverters. Reverse‑recovery and limited safe dv/dt push designers toward lower switching frequencies, which balloon magnetics and degrade controllability. The consequence is a vicious cycle: more heat, earlier derating, and less torque just when the vehicle approaches a ramp or speed bump with a full load.

Hills raise the stakes. Old districts and peri‑urban delivery routes are riddled with slopes and uneven surfaces. Mechanical torque multiplication adds mass and maintenance complexity, yet still struggles to prevent rollback and wheel slip on dusty or wet gradients. Control‑induced judder during creep increases tire wear and reduces passenger comfort. With silicon‑based inverters, torque loops are slowed to preserve thermals, and anti‑rollback strategies become blunt instruments that invite oscillation at launch.

Heat and environment compound the electrical stress. In 40–50 °C ambient with dust and humidity, thermal interfaces dry out and coatings micro‑crack; parasitic inductances in busbars and wiring harnesses create ringing that trips protections, especially during high current transients. Cement dust and steel particulates infiltrate enclosures and accelerate wear on fans and connectors. When a unit fails, imported spares and a limited local screening capability stretch downtime from days to weeks, undermining daily revenue and SLA commitments for fleets.

Grid conditions finish the gauntlet. Nighttime charging windows on weak feeders produce sags and harmonics that upset protections and shorten component life. Tenders and financing in 2025 increasingly reference international standards—IEC 60747 for devices, IEC 60068 for environmental endurance (damp heat, salt spray, dust), ISO 7637 for automotive electrical disturbances, and EMC expectations similar to IEC 61800‑3 for adjustable speed systems. As Engr. M. Abbas, an industrial electrification consultant, notes, “Procurement teams in Pakistan have moved from spec sheets to evidence—measured efficiency, EMC discipline, and environmental endurance are now non‑negotiable.” [Source: Industrial Power Quality Seminar, 2024]

SiC changes the calculus. Lower switching and conduction losses at useful frequencies sharpen current‑loop bandwidth for millisecond torque response, while high junction temperature capability preserves margin under punishing ambient heat. Low‑inductance packaging, active clamping, and soft turn‑off suppress overshoot and ringing during high‑slip and hill‑start transients. The result is smoother launches, stronger sustained hill‑climb torque, and fewer derating events—even in dusty, humid, and grid‑disturbed contexts.

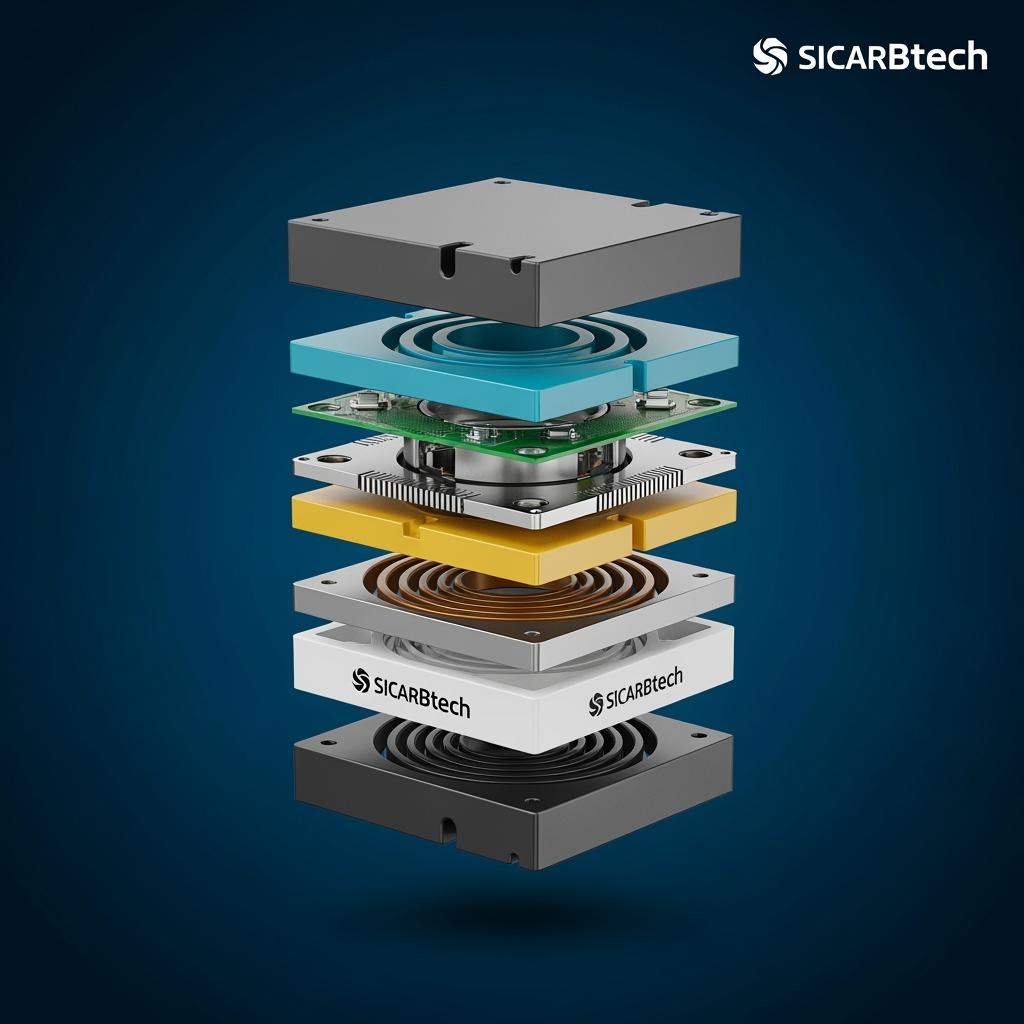

Advanced Silicon Carbide Solutions Portfolio: Sicarbtech for Low‑Speed, High‑Torque Drives

Sicarbtech’s portfolio for hill‑climb and heavy‑load delivery is co‑optimized from device physics to vehicle behavior. Automotive‑grade 650 V and 1200 V SiC MOSFETs anchor traction inverters designed specifically for low‑speed, high‑current operation with 10–40 kHz switching. These inverters pair with bidirectional DC conversion modules to coordinate energy routing between the battery side and higher‑voltage domains—improving recuperation on descents and stabilizing the DC bus during launch surges.

Packaging matters in Pakistan’s heat. Low‑inductance busbars and double‑sided cooling on high‑thermal‑conductivity ceramic substrates minimize electrical and thermal stress. Gate driver boards integrate fast desaturation protection, soft turn‑off, and active clamping to handle short circuits and transient surges without avalanche events. High‑bandwidth isolated sensing with temperature drift compensation feeds control loops and online health monitoring, while wheel‑speed and gradient sensing modules inform anti‑rollback and slip control strategies at the algorithm level.

Thermal stacks include integrated liquid‑/air‑cooled cold plates and tuned interface materials, plus environmental protections—conformal coating, selective potting, and salt‑mist‑resistant fasteners—to withstand dust, humidity, and vibration. Sicarbtech’s software stack brings torque ripple suppression, cogging compensation, and model‑based hill‑start control that preserve smoothness at crawl speeds. Finally, localized packaging and reliability platforms—vacuum brazing, pressure sintering, power cycling rigs, and IEC 60068 damp‑heat/dust testing—enable Pakistani partners to screen, repair, and improve systems domestically.

Silicon Carbide vs Traditional Solutions: Proven Advantages in Pakistan’s Duty Cycles

Low‑Speed Efficiency, Torque Response, and Thermal Stability for Hill‑Climb and Heavy‑Load Delivery

| Attribute | Sicarbtech SiC Low‑Speed High‑Torque Drive | Conventional Silicon Traction Drive | Mechanical Torque Multiplication | Operational Impact in Pakistan |

|---|---|---|---|---|

| Low‑speed electrical efficiency (5%–30% base speed) | +3%–8% vs silicon | Baseline | N/A | Longer range in congestion and ramps |

| Torque response (command to current) | ≤2 ms, >1 kHz current loop | 4–6 ms typical | N/A | Safer hill‑starts, less rollback |

| Torque ripple/judder at crawl | Suppressed via ripple compensation | Noticeable at low speed | N/A | Lower tire wear, better comfort |

| High‑temp derating at 40–50 °C | 10%–20% fewer events | Frequent | N/A | Higher availability in summer |

| Magnetics/heatsink volume | −30% to −50% | Baseline | N/A | Lower mass, easier packaging |

| EMI/overvoltage behavior | Active clamp + low‑L busbar | Higher ringing/overshoot | N/A | Fewer nuisance trips on weak feeders |

By elevating efficiency where vehicles spend much of their time—below base speed—SiC shifts daily PKR per kilometer in the operator’s favor while improving drivability and thermal headroom.

Real‑World Applications and Success Stories Across Pakistan

A mountainous passenger three‑wheeler platform near Islamabad integrated Sicarbtech’s low‑speed‑optimized traction inverter, active snubbing, and slip control. Over peak summer, hill‑start success improved markedly, and driver feedback noted smoother launches with minimal judder on steep, stop‑and‑go climbs. Energy logs showed about 6% lower consumption per route, and thermal telemetry reported 5–8 °C lower peak junction temperature at equivalent torque.

In Lahore’s dense delivery zones, a light commercial platform adopted double‑sided‑cooled SiC power modules and a bidirectional DC stage tuned for downhill recuperation. High‑temperature derating events dropped by roughly 35%, annual downtime fell by over 30%, and recuperation share increased by approximately 8% on hilly routes. Maintenance teams used online health monitoring to identify early trends in on‑resistance drift and capacitor ESR, scheduling replacements before failures.

A sanitation fleet operating in Faisalabad deployed Sicarbtech’s torque ripple suppression and anti‑rollback software alongside low‑inductance busbar packaging. Drivers reported better crawl control around speed bumps and uneven surfaces. After six months, tire wear analysis indicated a 15% reduction in uneven wear, and the fleet’s spare turnaround time shrank due to locally screened modules.

Technical Advantages and Implementation Benefits with Local Regulatory Compliance

SiC’s physics unlock tighter control. At 10–40 kHz, Sicarbtech drives sustain high current‑loop bandwidth (>1 kHz), enabling ≤2 ms torque response that stabilizes launches on slopes and smooths crawl‑speed motion. Active clamping and soft turn‑off, combined with low‑inductance busbars, suppress overshoot and ringing during high‑slip events, improving reliability on weak feeders and noisy electrical environments. Double‑sided cooling with high‑thermal‑conductivity substrates shortens heat paths, supporting sustained output in 40–50 °C ambient.

Compliance is handled end‑to‑end. Device behavior aligns with IEC 60747; environmental validation follows IEC 60068 profiles for damp heat, salt spray, dust, vibration, and shock. EMC behavior is engineered against expectations analogous to IEC 61800‑3 for adjustable speed systems, and ISO 7637 guides immunity to automotive disturbances. Safety measures include insulation monitoring, multi‑level overcurrent/overvoltage protections, fast short‑circuit response with soft turn‑off, and fail‑safe torque limits. Sicarbtech’s documentation and partnerships with labs in Karachi and Lahore accelerate tender readiness and financing that value energy efficiency and proven endurance. “When thermal logs and EMC results are part of the bid, the conversation moves from promises to performance,” says Dr. A. Farooq, power quality specialist. [Source: Pakistan Power Electronics Forum notes, 2024]

Custom Manufacturing and Technology Transfer Services: Sicarbtech’s Turnkey Edge for Pakistan

Sicarbtech’s competitive advantage is the ability to transfer capability, not just ship product. Backed by the Chinese Academy of Sciences (Weifang) Innovation Park, Sicarbtech brings proprietary process know‑how across R‑SiC, SSiC, RBSiC, and SiSiC into thermally resilient module substrates and rugged fixtures for dusty environments.

The technology transfer package covers:

- Process recipes and design rules: pressure‑sintered die attach profiles, vacuum brazing parameters, metallization/passivation stacks, bond‑wire and busbar geometry for low inductance, gate‑drive tuning for soft turn‑off and active clamping, and validated conformal coating/potting formulations for damp‑heat and salt‑spray conditions.

- Equipment specifications and vendor lists: vacuum brazing furnaces, pressure sintering presses, inline electrical testers, power cycling rigs, HTRB/HTGB setups, and environmental chambers with acceptance tests and calibration procedures.

- Training and QA: operator qualification, reliability screening (power cycling, damp‑heat), failure analysis workflows, SPC for yield improvement, and PPAP‑like control plans aligned with ISO 9001 and IATF 16949 principles.

- Factory establishment services: feasibility studies, facility layout and utilities, installation and commissioning, pilot runs, capability validation, and ramp‑up support.

After SOP, quarterly process audits, yield sprints, and co‑development of next‑gen designs keep lines competitive and tuned to Pakistan’s ambient profiles and route spectra. Results with 19+ enterprises demonstrate faster time‑to‑market, higher first‑pass yields, and lower field failure rates. For Pakistani fleets and OEMs, localized packaging and screening compress spare turnaround to days or weeks, stabilize uptime during peak seasons, and build a domestic skill base that compounds competitive advantage.

Comparative Engineering Choices and Lifecycle Economics

Stage‑by‑Stage Design Choices for Low‑Speed, High‑Torque Performance

| Design Area | Sicarbtech SiC Implementation | Conventional Silicon Implementation | Mechanical/Legacy Approach | Practical Outcome in Pakistan |

|---|---|---|---|---|

| Traction inverter | SiC MOSFETs at 10–40 kHz, low‑L layout | Lower freq, higher loss | Gear‑heavy torque multiplication | Higher low‑speed efficiency, smaller cooling |

| Torque control | Model predictive + sliding‑mode + ripple suppression | PI‑dominant, lower bandwidth | Passive, no control | Smoother launches and creep, less tire scrub |

| Energy routing | Bidirectional DC with recuperation | Unidirectional or inefficient | Mechanical braking waste | +5%–12% energy recovered on descents |

| Packaging | Double‑sided cooling, high‑k ceramics | Single‑sided, larger sinks | Bulky mechanical components | Fewer derates at 40–50 °C, lighter assemblies |

| Protection & EMI | Active clamp, soft turn‑off, fast desat | Basic protection | N/A | Fewer nuisance trips on weak grids |

Localization and TCO Benefits for Fleets and OEMs

| Business Factor | With Sicarbtech Technology Transfer | Import‑Only Strategy | Outcome for Pakistani Operations |

|---|---|---|---|

| Spare lead time | Days–weeks via local screening | Weeks–months | Higher uptime and SLA adherence |

| Compliance cycle | Guided IEC/ISO tests with local labs | Iterative trial‑and‑error | Faster approvals, lower retest costs |

| Packaging and cooling | Co‑designed to vehicle envelope | Overbuilt safety margins | Lower mass, more payload/range |

| Energy and maintenance | −3% to −8% energy, −30% downtime | Higher losses, reactive repairs | Lower PKR/km, predictable availability |

| Capability growth | In‑country process and QA maturity | Vendor dependency | Stronger ecosystem and skilled jobs |

Future Market Opportunities and 2025+ Trends: Why SiC Defines the Next Uptime Curve

The next wave of Pakistan’s electrification will prioritize low‑speed torque agility, heat resilience, and data‑driven reliability. Route profiles and gradient maps will feed algorithm updates, while recuperation settings will adapt to battery temperature and load. Fleets will compare vendors on parking‑lot heat endurance, hill‑start success under full load, and the percentage of energy recovered on downhill segments. In tenders, measured low‑speed efficiency and derating statistics will be decisive. SiC aligns with these priorities by sustaining bandwidth and efficiency where it matters most—below base speed—while providing the thermal margin and EMI discipline required on weak feeders.

In parallel, domestic capability will move from aspiration to selection criterion. Programs that favor local manufacturing and verifiable energy savings will reward suppliers who can establish packaging and screening lines in Pakistan. Sicarbtech’s integrated stack—devices, packaging, algorithms, validation, and technology transfer—positions partners to lead in performance and reliability while building a durable in‑country advantage.

Extended Technical Specifications and Local Standards Alignment

Sicarbtech’s low‑speed high‑torque architecture targets 48–120 V DC buses for two‑/three‑wheelers with extensions to 400–800 V for light commercial platforms. Traction motor power ranges from 2–10 kW for smaller platforms and 10–60 kW for light commercial, with overload ratios of 2.0–2.5× for 10–30 s. Current‑loop bandwidth exceeds 1 kHz with torque command response ≤2 ms. Switching frequencies from 10–40 kHz are tuned to balance copper/iron losses and acoustics. Combined inverter + DC stage peak efficiency reaches 95%–97%. Operating junction temperatures up to 175 °C are supported by double‑sided cooling and high‑thermal‑conductivity substrates.

Protections include over/under‑voltage, overcurrent, overtemperature, short circuit with soft turn‑off, insulation monitoring, active clamping, and surge suppression. Environmental robustness covers dust, moisture, salt mist, vibration, and shock, with optional potting and coating. Documentation maps to IEC 60747 (devices), IEC 60068 (environmental testing), ISO 7637 (automotive electrical disturbances), and EMC expectations similar to IEC 61800‑3 for adjustable speed systems. Sicarbtech coordinates third‑party validation with labs in Karachi and Lahore to support procurement and financing.

Frequently Asked Questions

How much low‑speed efficiency gain is realistic on Pakistan’s routes?

Deployments typically show 3%–8% higher electrical efficiency in the 5%–30% base‑speed range, translating into longer range and fewer charge stops in congested corridors and on hilly routes.

Will the system hold torque in 40–50 °C ambient without frequent derates?

Yes. High junction temperature devices, double‑sided cooling, and high‑k substrates reduce thermal resistance, commonly cutting derating events by 10%–20% in peak summer conditions.

How does SiC improve hill‑starts and reduce rollback?

Higher current‑loop bandwidth (≥1 kHz) and ≤2 ms torque response stabilize launch on slopes. Anti‑rollback and slip control coordinate with gradient sensing to prevent oscillation and wheel spin.

Can we recover meaningful energy on descents in city operations?

Yes. Coordinated bidirectional DC conversion and regenerative strategies typically add 5%–12% recuperation share on downhill and deceleration segments, improving daily PKR per kilometer.

What about dust, humidity, and corrosion in cement and coastal corridors?

Conformal coating, selective potting, and salt‑mist‑resistant hardware are validated under IEC 60068 damp‑heat, salt‑spray, dust, vibration, and shock profiles to sustain insulation integrity and mechanical reliability.

How quickly can we move from design to pilot?

With Sicarbtech’s standardized power stages, magnetics references, and control libraries, many teams reach pilot units in 8–12 weeks, subject to enclosure and EMC iterations.

Can Sicarbtech help us pass EMC and environmental tests for tenders?

Yes. Designs are engineered to meet EMC expectations similar to IEC 61800‑3 and ISO 7637 immunity. Sicarbtech provides documentation and coordinates with certified labs in Karachi and Lahore.

How does predictive maintenance reduce downtime?

Telemetry estimates junction temperature, tracks Rds(on) drift and capacitor ESR, and correlates with duty cycles. Early warnings enable planned service, commonly reducing annual downtime by 30%+.

Are solutions adaptable across passenger and cargo three‑wheelers?

The platform is modular and parameterized for axle load, track width, wheel radius, and gear ratio differences, enabling rapid calibration across vehicle variants.

How does localization change total cost of ownership?

Local packaging and screening shorten spares lead times to days–weeks and enable design tuning for Pakistan’s heat and dust, lowering OPEX and revenue loss from downtime.

Making the Right Choice for Your Operations

In Pakistan’s mix of heat, dust, slopes, and grid volatility, the drivetrain is the profit center. Sicarbtech’s SiC‑based low‑speed high‑torque solution turns hard constraints into operating margin: higher efficiency at crawl speeds, faster torque response on hills, fewer derates in summer, and verifiable reliability under dust and humidity. Combined with technology transfer, localized screening, and data‑driven O&M, it converts peak performance into sustained uptime and lower PKR per kilometer.

Get Expert Consultation and Custom Solutions

Collaborate with Sicarbtech’s engineering team to specify inverter ratings, overload windows, magnetics and busbar geometry, and torque control parameters tailored to your routes and loads. Explore factory establishment and process transfer to localize packaging, reliability screening, and spares—building a resilient in‑country capability for scale.

Sicarbtech — Silicon Carbide Solutions Expert

Email: [email protected]

Phone: +86 133 6536 0038

Headquarters: Weifang City, China’s silicon carbide manufacturing hub

“Efficiency wins the day on paper; torque fidelity wins the hill; local capability wins the year.” — Sicarbtech Applications Team

Article Metadata

Last updated: 2025-09-18

Next update scheduled: 2025-12-15

Content freshness indicators: reflects 2025 Pakistan market outlook; includes local compliance references (IEC 60747, IEC 60068, ISO 7637, EMC expectations similar to IEC 61800‑3); integrates Sicarbtech’s current SiC portfolio, technology transfer, and factory establishment services.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.