Silicon Carbide Substrates: The Foundation for Next-Generation Industrial Excellence

Share

In the relentless pursuit of technological advancement, materials science plays a pivotal role. Among the champions of this field is Silicon Carbide (SiC), a remarkable ceramic material renowned for its exceptional properties. Specifically, silicon carbide substrates are becoming indispensable in a multitude of high-performance industrial applications, acting as the foundational layer upon which cutting-edge technologies are built. From powering the semiconductor revolution to enabling operations in the harshest industrial environments, custom SiC substrates offer a unique combination of thermal, mechanical, and electrical characteristics that outperform traditional materials. This blog post delves into the world of SiC substrates, exploring their applications, advantages, design considerations, and how to choose the right supplier for your critical needs, with a special focus on the expertise offered by Sicarb Tech.

The importance of custom silicon carbide products cannot be overstated, especially when standard off-the-shelf components fall short of demanding operational requirements. Industries are increasingly turning to technical ceramic substrates like SiC due to their ability to withstand extreme temperatures, resist wear and corrosion, and maintain stability in chemically aggressive environments. As we explore the multifaceted nature of SiC substrates, it becomes clear why they are essential for engineers, procurement managers, and technical buyers aiming for unparalleled performance and reliability.

Introduction to Silicon Carbide Substrates: The Bedrock of High-Performance Applications

Silicon Carbide (SiC) is a synthetically produced crystalline compound of silicon and carbon. Its inherent properties, including high hardness, excellent thermal conductivity, low thermal expansion, and superior chemical inertness, make it an ideal candidate for demanding applications. A silicon carbide substrate is essentially a wafer or plate made from SiC that serves as a base layer for the fabrication of electronic devices or as a structural component in high-temperature and high-wear environments.

The journey of silicon carbide from a laboratory curiosity in the late 19th century to a cornerstone of modern industry is a testament to its versatile and robust nature. Initially used primarily as an abrasive, its unique semiconductor properties were later recognized, paving the way for its use in electronics. Today, industrial SiC components are vital in sectors where performance and durability are non-negotiable.

Why are SiC substrates, particularly custom-designed ones, so essential?

- Extreme Environment Tolerance: They can operate reliably at temperatures exceeding 1000∘C, where many metals and other ceramics would fail.

- Superior Electrical Properties: For electronic applications, SiC offers a wider bandgap, higher breakdown electric field, and higher saturated electron drift velocity compared to silicon, leading to more efficient and powerful devices.

- Mechanical Robustness: With a Mohs hardness second only to diamond, SiC substrates resist abrasion and wear, extending the lifespan of components.

- Thermal Management: The high thermal conductivity of SiC allows for efficient heat dissipation, a critical factor in power electronics and high-density integrated circuits.

The demand for high-quality, reliable SiC substrates for power electronics and SiC for semiconductor manufacturing is rapidly growing. This is where specialized manufacturers and technology partners like Sicarb Tech become crucial. Located in Weifang City, the heart of China’s silicon carbide customizable parts manufacturing hub (accounting for over 80% of the nation’s total SiC output), SicSino has been instrumental in advancing SiC production technology since 2015. Leveraging the robust scientific and technological capabilities of the Chinese Academy of Sciences , SicSino, as part of the Chinese Academy of Sciences (Weifang) Innovation Park, offers unparalleled expertise in custom SiC solutions.

Diverse Applications of Silicon Carbide Substrates Across Industries

The versatility of silicon carbide substrates allows them to be employed in a wide array of industrial sectors. Their unique combination of properties makes them suitable for applications where conventional materials like silicon, sapphire, or various metals reach their performance limits. Procurement professionals and engineers in technical buying roles are increasingly specifying SiC for critical components to enhance efficiency, durability, and overall system performance.

Here’s a look at some key industries and their applications for SiC substrates:

- Semiconductor Manufacturing:

- Power Electronics: SiC substrates are fundamental for producing high-voltage power devices such as MOSFETs, Schottky diodes, and power modules. These devices are crucial for electric vehicles (EVs), renewable energy inverters (solar and wind), industrial motor drives, and power supplies. The ability of SiC wafer suppliers to provide high-purity, low-defect substrates is critical here.

- LED Manufacturing: While GaN-on-SiC is common, SiC substrates themselves offer excellent thermal management for high-power LEDs, improving their lifespan and brightness. The lattice matching and thermal expansion compatibility are key advantages.

- RF Devices: SiC’s high thermal conductivity and electron saturation velocity make it an ideal substrate for high-frequency, high-power RF devices used in radar, telecommunications (5G base stations), and satellite communications.

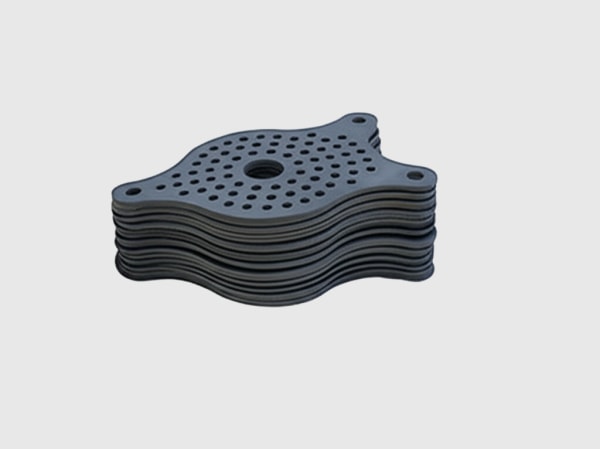

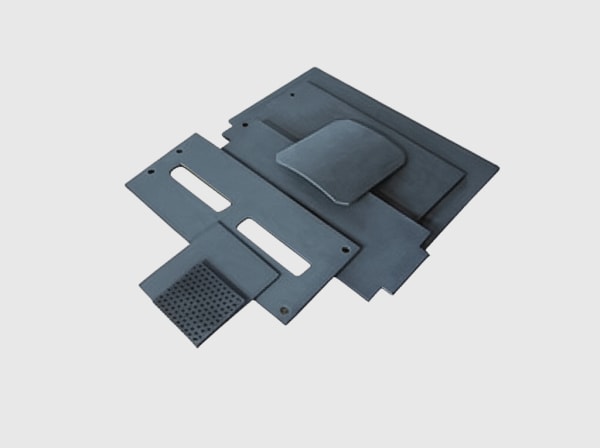

- Wafer Chucks and Susceptors: In semiconductor processing equipment, SiC is used for electrostatic chucks (E-chucks) and susceptors due to its high-temperature stability, chemical inertness, and ability to be precisely machined.

- High-Temperature Processing & Furnaces:

- Furnace Components: SiC beams, rollers, tubes, and plates are standard in industrial furnaces operating at extreme temperatures (e.g., in ceramics firing, metal heat treatment, and glass manufacturing). High-temperature SiC substrates and structural parts offer longevity and prevent contamination.

- Kiln Furniture: Setter plates, support beams, and other kiln furniture made from SiC provide excellent strength at high temperatures, allowing for denser packing of products and energy savings.

- Aerospace and Defense:

- Mirror Substrates: The low thermal expansion, high thermal conductivity, and high stiffness of SiC make it an excellent material for lightweight, stable mirror substrates in telescopes and satellite optics. SiC in aerospace applications often involves highly customized shapes and surface finishes.

- Heat Exchangers and Combustors: In advanced propulsion systems and gas turbines, SiC components can withstand higher operating temperatures, leading to improved efficiency and reduced emissions.

- Armor: Certain grades of SiC are used in lightweight ceramic armor systems due to their extreme hardness and ability to defeat projectiles.

- Energy Sector:

- Nuclear Applications: SiC’s radiation resistance and stability at high temperatures make it a candidate for fuel cladding and structural components in next-generation nuclear reactors.

- Concentrated Solar Power (CSP): Components in CSP systems, such as receivers, benefit from SiC’s thermal shock resistance and high-temperature endurance.

- Industrial Manufacturing & Wear Parts:

- Mechanical Seals and Bearings: The exceptional wear resistance and chemical inertness of SiC make it ideal for mechanical seals, bearings, and pump components handling abrasive or corrosive fluids.

- Nozzles and Liners: For applications involving abrasive material flow, such as sandblasting nozzles or cyclone liners, SiC offers significantly longer service life than metals or other ceramics.

- Precision Metrology Components: The dimensional stability of SiC is valuable for manufacturing ultra-precise components like CMM (Coordinate Measuring Machine) stages and air bearings.

The table below summarizes some key applications and the relevant SiC properties:

| Industry Sector | Application Examples | Key SiC Properties Utilized |

|---|---|---|

| Semiconductor | Power MOSFETs, LEDs, RF Transistors, Wafer Chucks | Wide Bandgap, High Thermal Conductivity, High Breakdown Field |

| High-Temp. Processing | Furnace Beams, Kiln Furniture, Thermocouple Protection Tubes | High-Temperature Strength, Thermal Shock Resistance, Inertness |

| Aerospace & Defense | Optical Mirrors, Turbine Components, Armor | High Stiffness, Low Thermal Expansion, Hardness |

| Energy | Nuclear Fuel Cladding, CSP Receivers | Radiation Resistance, High-Temperature Stability |

| Industrial | Mechanical Seals, Bearings, Nozzles, Wear Liners | Extreme Hardness, Wear Resistance, Chemical Inertness |

Sicarb Tech has witnessed and contributed to the growth of these applications by supporting local Weifang enterprises with advanced SiC production technologies. Their expertise spans the entire process from material science to finished custom SiC components, enabling them to cater to the diverse needs of these demanding industries.

The Unmatched Advantages of Custom Silicon Carbide Substrates

While standard SiC components serve many purposes, the ability to customize silicon carbide substrates and parts unlocks a new level of performance and integration for specific, often mission-critical, industrial applications. Opting for custom solutions provides engineers and procurement managers with components that are precisely tailored to their unique operational parameters, leading to enhanced efficiency, longevity, and often, reduced overall system costs. The benefits of customization in technical ceramics like SiC are manifold, revolving around its core material advantages.

Key advantages of choosing custom SiC substrates include:

- Exceptional Thermal Resistance and Management:

- High Operating Temperatures: SiC can maintain its structural integrity and mechanical properties at temperatures where many other materials degrade or melt (typically up to 1650∘C or even higher for certain grades). Custom designs can optimize heat dissipation paths for specific thermal loads.

- High Thermal Conductivity: With thermal conductivity often exceeding that of metals like copper (depending on purity and grade, ranging from 120-270 W/mK for sintered SiC), SiC substrates excel at spreading and removing heat from critical areas. Customization allows for integrated cooling channels or specific surface features to enhance heat transfer.

- Low Thermal Expansion: SiC has a low coefficient of thermal expansion, meaning it changes size minimally with temperature fluctuations. This provides dimensional stability, crucial for precision optical systems and in applications where components are bonded to materials with different expansion rates. Custom substrates can be designed to match the CTE of adjoining materials more closely.

- Superior Wear and Abrasion Resistance:

- Extreme Hardness: SiC is one of the hardest commercially available materials (Mohs hardness of 9-9.5, Knoop hardness ~25 GPa). This makes custom SiC wear parts exceptionally resistant to abrasive wear, erosion, and sliding wear, significantly outlasting hardened steels and other ceramics in demanding environments like slurry pumps, nozzles, and grinding media.

- Extended Component Life: Custom-designed SiC components for wear applications mean fewer replacements, reduced downtime, and lower maintenance costs over the product lifecycle.

- Outstanding Chemical Inertness and Corrosion Resistance:

- Resistance to Acids and Alkalis: SiC is highly resistant to attack by most strong acids (e.g., HF,HNO3,H2SO4) and alkalis, even at elevated temperatures. This makes it ideal for chemical processing equipment, seals, and valves handling corrosive media.

- Oxidation Resistance: While SiC can oxidize at very high temperatures (typically above 800∘C) to form a protective silica (SiO2) layer, this layer itself passivates the surface and slows further oxidation. Custom material grades can be selected to optimize this behavior for specific atmospheric conditions.

- Excellent Mechanical Properties:

- High Strength and Stiffness: SiC exhibits high compressive and flexural strength, coupled with a high Young’s modulus (stiffness). This allows for the design of lightweight yet rigid structures that can withstand significant mechanical loads without deformation. Custom geometries can optimize strength-to-weight ratios.

- Good Thermal Shock Resistance: The combination of high thermal conductivity and relatively low thermal expansion gives SiC good resistance to thermal shock (sudden temperature changes), a critical property for components in furnaces and rapid heating/cooling cycles.

- Tailored Electrical Properties for Advanced Electronics:

- Wide Bandgap Semiconductor: For electronic applications, SiC’s wide bandgap ($ \approx 3.26 eV$ for 4H-SiC) enables devices to operate at higher temperatures, higher voltages, and higher frequencies than silicon-based devices.

- High Breakdown Electric Field: This allows for thinner drift layers in power devices, reducing on-state resistance and switching losses.

- Custom Doping and Resistivity: SiC substrates can be produced with specific doping levels (n-type or p-type) and electrical resistivity, tailored to the requirements of semiconductor device fabrication. Semi-insulating SiC substrates are crucial for high-frequency RF devices to minimize parasitic losses.

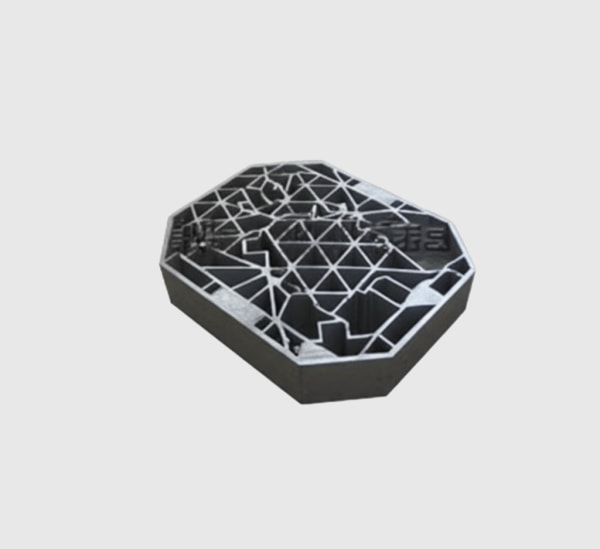

The ability to customize dimensions, shapes, surface finishes, and even material composition (e.g., by selecting specific sintering aids or controlling porosity) allows for the creation of SiC substrates and components that are perfectly aligned with the application’s demands. This level of tailoring is something that Sicarb Tech excels at, thanks to their deep understanding of SiC material science and their comprehensive range of processing technologies. They can work with clients from initial concept through to full-scale production, ensuring that the custom SiC solution delivers optimal performance.

Navigating SiC Grades and Design for Optimal Substrate Performance

Choosing the correct grade of Silicon Carbide and adhering to sound design principles are crucial for manufacturing effective and reliable SiC substrates and components. Different manufacturing processes yield SiC materials with varying microstructures and, consequently, distinct properties. Understanding these nuances allows engineers and technical buyers to select or specify the most suitable material for their application, while proper design ensures manufacturability and performance.

Recommended SiC Grades and Compositions:

Several primary types of Silicon Carbide are commercially available, each with its own set of characteristics, advantages, and typical applications.

- Reaction-Bonded Silicon Carbide (RBSiC or SiSiC – Silicon Infiltrated SiC):

- Manufacturing: Produced by infiltrating a porous preform of SiC grains and carbon with molten silicon. The silicon reacts with the carbon to form new SiC, which bonds the original grains. The remaining pores are typically filled with residual metallic silicon (usually 8-20%).

- Properties: High strength, excellent wear and oxidation resistance, good thermal shock resistance, high thermal conductivity. The presence of free silicon limits its maximum service temperature to around 1350−1380∘C (the melting point of silicon). It cannot be used in applications involving strong alkalis or hydrofluoric acid that attack free silicon.

- Applications: Kiln furniture (beams, rollers, plates), nozzles, mechanical seals, wear liners, heat exchangers. RBSiC components are often cost-effective for complex shapes.

- SicSino offers robust RBSiC formulations ideal for structural components requiring high strength and wear resistance.

- Sintered Silicon Carbide (SSiC or S-SiC):

- Manufacturing: Made from fine, high-purity SiC powder, typically with non-oxide sintering aids (like boron and carbon). It is sintered at very high temperatures (over 2000∘C) in an inert atmosphere, resulting in a dense, single-phase SiC material (typically >98% SiC).

- Properties: Highest strength at elevated temperatures, excellent corrosion and wear resistance (superior to RBSiC in highly corrosive environments), very high thermal conductivity, and high purity. Can be used up to 1650∘C or higher.

- Applications: Chemical pump components, mechanical seals for aggressive media, bearings, semiconductor processing equipment (susceptors, E-chucks), armor, high-end kiln furniture. Sintered SiC substrates are often preferred for demanding semiconductor and chemical applications due to their purity and resilience.

- Sicarb Tech specializes in high-purity SSiC, providing superior performance for critical applications in the semiconductor and chemical processing industries.

- Nitride-Bonded Silicon Carbide (NBSiC):

- Manufacturing: SiC grains are bonded by a silicon nitride (Si3N4) phase.

- Properties: Good thermal shock resistance, good mechanical strength, resistant to molten non-ferrous metals (like aluminum). Generally lower cost than SSiC or RBSiC.

- Applications: Kiln furniture, components for aluminum smelting (e.g., thermocouple sheaths, riser stalks), furnace linings.

- Recrystallized Silicon Carbide (R-SiC or RSIC):

- Manufacturing: Produced by firing compacted high-purity SiC grains at very high temperatures (around 2500∘C), causing the grains to bond directly to each other through sublimation and condensation. No binders or sintering aids are typically used.

- Properties: Excellent thermal shock resistance due to controlled porosity, high hot strength, good stability. Can be used at very high temperatures (up to 1650∘C or more).

- Applications: High-temperature kiln furniture (plates, setters, posts), radiant tubes, burner nozzles. Often used where extreme thermal cycling is a concern.

- Chemical Vapor Deposited Silicon Carbide (CVD-SiC):

- Manufacturing: SiC is deposited from precursor gases onto a substrate.

- Properties: Extremely high purity (can be >99.9995%), theoretical density, excellent corrosion and erosion resistance, and can form conformal coatings or bulk shapes.

- Applications: Semiconductor processing components (etch rings, showerheads, susceptors), optical components (mirrors), coatings for graphite or other ceramics to enhance their properties. CVD SiC coating is a premium option for ultra-high purity environments.

The following table compares key properties of common SiC grades:

| Property | RBSiC (SiSiC) | SSiC | NBSiC | R-SiC |

|---|---|---|---|---|

| Max. Service Temp. | ≈1350−1380∘C | ≈1650∘C+ | ≈1400∘C | ≈1650∘C+ |

| Density | 3.02−3.10 g/cm3 | 3.10−3.18 g/cm3 | 2.5−2.7 g/cm3 | 2.5−2.7 g/cm3 |

| Thermal Conductivity | 80−150 W/mK | 120−270 W/mK | 15−20 W/mK | 20−25 W/mK |

| Flexural Strength (RT) | 250−400 MPa | 400−550 MPa | 50−100 MPa | 30−60 MPa |

| Corrosion Resistance | Good (except to strong alkalis) | Excellent | Good | Good |

| Relative Cost | Medium | High | Low-Medium | Medium |

| Key Feature | Complex shapes, good value | High purity, best performance | Good thermal shock, cost-effective | Excellent thermal shock |

Design Considerations for SiC Products:

Designing parts for manufacturability is critical when working with hard, brittle materials like Silicon Carbide. Poor design can lead to manufacturing difficulties, increased costs, or premature failure.

- Geometry Limits & Complexity:

- While RBSiC allows for relatively complex shapes due to the green machining and infiltration process, SSiC often requires simpler geometries or more extensive (and expensive) diamond grinding post-sintering.

- Avoid sharp internal corners; use radii instead to reduce stress concentrations.

- Consider draft angles for pressed parts to facilitate removal from molds.

- Wall Thickness:

- Maintain uniform wall thickness where possible to ensure even shrinkage during sintering and reduce internal stresses.

- Specify minimum and maximum wall thicknesses appropriate for the chosen SiC grade and manufacturing process. Thin walls can be fragile, while overly thick sections can be difficult to sinter uniformly.

- Stress Points:

- Identify areas of high mechanical or thermal stress in the application and design accordingly. This might involve adding fillets, ribs, or selecting a higher strength SiC grade.

- Consider how the component will be mounted or integrated into the larger assembly to avoid inducing stress.

- Tolerances:

- Understand the achievable tolerances for different SiC manufacturing routes. As-sintered tolerances are generally wider than those achievable with diamond grinding. Specify tight tolerances only where absolutely necessary, as this significantly impacts cost.

- Joining and Assembly:

- Consider how SiC components will be joined to other parts (SiC-SiC or SiC-metal). Brazing, shrink-fitting, or mechanical fastening are common methods, each requiring specific design features.

Sicarb Tech, with its team of domestic top-tier professionals specializing in customized production of silicon carbide products, provides invaluable design support. Their expertise in material, process, design, measurement, and evaluation technologies allows them to guide clients through these complex considerations, ensuring that the final custom SiC substrates and components meet both performance and manufacturability requirements. They understand the nuances of each SiC grade and can recommend the optimal choice for your specific application, from high-purity SiC wafers to robust industrial SiC structural elements.

Precision Engineering: Tolerances, Surface Finish, and Post-Processing of SiC Substrates

Achieving the desired performance from silicon carbide substrates and components often hinges on precise dimensional control, appropriate surface finish, and necessary post-processing treatments. Silicon Carbide is an extremely hard material, which makes its machining and finishing challenging and often costly. Therefore, understanding the capabilities and limitations is crucial for both design engineers and procurement specialists.

Tolerance, Surface Finish & Dimensional Accuracy:

- Achievable Tolerances:

- As-Sintered Tolerances: For components used in their as-sintered state (without grinding), typical dimensional tolerances for RBSiC might be around ±0.5% to ±1.5% of the dimension. SSiC as-sintered tolerances can be similar or slightly tighter, but depend heavily on the complexity and size of the part. These are general guidelines and can vary significantly.

- Ground Tolerances: For applications requiring high precision, diamond grinding is employed. With precision grinding, very tight tolerances can be achieved, often in the range of ±0.005 mm to ±0.025 mm (±5 to 25 micrometers), or even tighter for specialized applications like semiconductor wafer chucks or optical components. However, extensive grinding significantly increases the cost.

- It’s essential to specify tolerances that are genuinely required by the application to avoid unnecessary expense.

- Surface Finish Options:

- As-Sintered Surface: The surface finish of an as-sintered SiC part depends on the manufacturing method and tooling. It is generally rougher than a ground surface. Typical Ra (average roughness) values might be 1−5 µm for RBSiC and 0.4−1.5 µm for SSiC.

- Ground Surface: Diamond grinding can produce much smoother surfaces. Ra values can range from 0.2 µm down to 0.02 µm or even lower with lapping and polishing.

- Lapped and Polished Surfaces: For applications like SiC mirror substrates, semiconductor wafers, or high-performance mechanical seals, lapping and polishing are used to achieve ultra-smooth, low-scatter surfaces. Ra values can be in the nanometer range (e.g., <1 nm for optical polishing).

- The required surface finish is highly application-dependent. A rougher surface might be acceptable or even desirable for kiln furniture (to prevent sticking), while a mirror-smooth finish is critical for optical or semiconductor applications.

- Dimensional Accuracy & Stability:

- SiC exhibits excellent dimensional stability over time and temperature due to its low thermal expansion and high stiffness. This makes it suitable for precision instrumentation and metrology components.

- Achieving high initial dimensional accuracy requires careful control of the manufacturing process, from powder preparation to sintering and final machining.

Post-Processing Needs for SiC Substrates and Components:

Beyond basic shaping and sintering, many SiC applications require additional post-processing steps to enhance performance, meet specific tolerances, or improve durability.

- Grinding:

- As mentioned, diamond grinding is the most common method for achieving tight dimensional tolerances and improved surface finishes on SiC. This includes surface grinding, cylindrical grinding, and complex profile grinding.

- Due to SiC’s hardness, grinding can be time-consuming and requires specialized diamond tooling and machinery.

- Lapping and Polishing:

- Lapping uses abrasive slurries to achieve very flat surfaces and fine finishes.

- Polishing, often using progressively finer diamond abrasives, is employed to create highly reflective, ultra-smooth surfaces for optical applications or to minimize friction in mechanical seals. This is particularly important for SiC wafer suppliers producing epi-ready substrates.

- Sealing (for porous grades):

- Some grades of SiC, like certain types of R-SiC or partially sintered materials, may have residual porosity. For applications requiring gas or liquid tightness, these pores may need to be sealed.

- Sealing can be achieved through glass infiltration or by applying specialized coatings (e.g., CVD SiC or polymeric sealants for lower temperature applications).

- Coating:

- CVD SiC Coating: Applying a thin layer of ultra-pure CVD SiC can enhance the corrosion resistance, wear resistance, or purity of a substrate made from another SiC grade (e.g., coating an RBSiC part) or even a different material like graphite.

- Other Coatings: Depending on the application, other coatings (e.g., anti-reflective coatings for optics, metallic coatings for brazing) might be applied.

- Edge Profiling and Chamfering:

- For applications like semiconductor wafers, precise edge profiles (e.g., TTV – Total Thickness Variation, bow, warp control) and chamfering are critical to prevent chipping and ensure compatibility with processing equipment.

- Cleaning:

- For high-purity applications, especially in the semiconductor industry, SiC substrates undergo rigorous cleaning processes to remove any contaminants from manufacturing and handling.

The choice and extent of post-processing significantly influence the final cost and lead time of custom SiC products. Sicarb Tech has the integrated process capabilities from materials to finished products, including advanced machining and finishing technologies. This allows them to offer a comprehensive solution, meeting diverse customization needs for precision SiC components and ensuring that post-processing steps are optimized for both performance and cost-effectiveness. Their expertise in measurement and evaluation also guarantees that the final product meets all specified tolerances and surface characteristics.

Overcoming Challenges in SiC Substrate Manufacturing and Implementation

While silicon carbide substrates offer a wealth of advantages, their unique material properties also present certain challenges in manufacturing and application. Understanding these potential hurdles and knowing how to mitigate them is crucial for successful implementation, ensuring that engineers and procurement professionals can confidently specify SiC for their demanding projects.

Common Challenges:

- Brittleness and Fracture Toughness:

- Challenge: Like most advanced ceramics, SiC is inherently brittle. This means it has low fracture toughness compared to metals, making it susceptible to catastrophic failure from impact, stress concentrations, or pre-existing flaws (like microcracks).

- Mitigation:

- Design Optimization: Avoid sharp corners and stress raisers; use generous radii and fillets. Design for compressive loads where possible, as ceramics are much stronger in compression than in tension.

- Material Selection: Some SiC grades (e.g., those with specific microstructures or reinforcing phases, though less common in pure SiC substrates) might offer slightly improved toughness. However, the primary approach is through design.

- Careful Handling: Implement proper handling procedures throughout manufacturing, assembly, and maintenance to prevent chipping or impact damage.

- Proof Testing: For critical applications, components can be proof-tested to screen out parts with critical flaws.

- Finite Element Analysis (FEA): Use FEA during the design phase to identify high-stress regions and optimize the geometry.

- Machining Complexity and Cost:

- Challenge: The extreme hardness of SiC makes it very difficult and time-consuming to machine. Only diamond tooling can effectively cut or grind SiC, leading to higher machining costs and longer lead times compared to metals or softer ceramics.

- Mitigation:

- Near-Net Shape Manufacturing: Utilize manufacturing processes that produce parts as close to the final desired shape as possible (e.g., precision casting for RBSiC, powder compaction for SSiC) to minimize the amount of material that needs to be removed by grinding.

- Optimize Tolerances: Specify tight tolerances and fine surface finishes only where absolutely necessary for functionality.

- Advanced Machining Techniques: Explore options like ultrasonic-assisted machining or laser machining for specific features, though these also have their own cost and complexity implications.

- Supplier Expertise: Partner with suppliers like Sicarb Tech who have extensive experience and advanced equipment for machining technical ceramics. Their expertise can lead to more efficient and cost-effective machining solutions.

- Thermal Shock Sensitivity (Relative to Metals):

- Challenge: While SiC generally has good thermal shock resistance for a ceramic (especially R-SiC and some SSiC grades due to high thermal conductivity and moderate strength), it can still fracture if subjected to extremely rapid and severe temperature changes that induce high thermal stresses.

- Mitigation:

- Grade Selection: R-SiC is often chosen for applications with severe thermal cycling due to its porous microstructure which can arrest microcracks. High-purity, dense SSiC with high thermal conductivity also performs well.

- Design for Thermal Management: Ensure designs allow for uniform heating and cooling where possible. Avoid features that create large thermal gradients.

- Controlled Operating Procedures: Implement controlled ramp-up and cool-down rates in high-temperature equipment.

- Joining SiC to Other Materials (Especially Metals):

- Challenge: The significant difference in Coefficient of Thermal Expansion (CTE) between SiC and most metals can create high stresses at the joint during temperature changes, potentially leading to joint failure or fracture of the SiC.

- Mitigation:

- Brazing: Use active braze alloys and design joints (e.g., with compliant interlayers or specific joint geometries) to accommodate CTE mismatch.

- Mechanical Fastening: Design mechanical joints that allow for some differential movement or use compliant gaskets.

- Diffusion Bonding: For certain applications, diffusion bonding can create strong joints, but it requires careful surface preparation and processing.

- Graded Interlayers: In some advanced applications, functionally graded materials can be used as interlayers to transition CTE.

- Cost of Raw Materials and Processing:

- Challenge: High-purity SiC powders and the energy-intensive processes required for sintering or chemical vapor deposition make SiC substrates and components generally more expensive than those made from conventional materials like alumina or metals.

- Mitigation:

- Application-Specific Grade Selection: Don’t over-specify. Choose the most cost-effective SiC grade that meets all performance requirements. For example, RBSiC might be suitable where the ultra-high purity or corrosion resistance of SSiC is not needed.

- Volume Production: Costs tend to decrease with higher production volumes due to economies of scale.

- Long-Term Value Proposition: Focus on the total cost of ownership. The extended lifespan, reduced downtime, and improved performance of SiC components often justify the higher initial investment.

- Strategic Sourcing: Partnering with a knowledgeable and vertically integrated supplier can help manage costs. SicSino, located in the Weifang SiC hub, benefits from the region’s established supply chain and production efficiencies.

By understanding these challenges, manufacturers and end-users can work together to develop robust solutions. Sicarb Tech, with its foundation in the scientific prowess of the Chinese Academy of Sciences and its practical experience supporting over 10 local enterprises, is well-equipped to help clients navigate these complexities. They offer not just custom SiC part manufacturing but also technology transfer for clients wishing to establish their own specialized SiC production facilities, providing a full turnkey project service. This deep understanding of the entire lifecycle, from material to final application, is invaluable in overcoming potential hurdles.

Choosing Your Partner for Custom SiC Substrates: Key Considerations for Success

Selecting the right supplier for custom silicon carbide substrates and components is a critical decision that can significantly impact the quality, performance, cost, and timely delivery of your products. For procurement managers, engineers, and OEMs, this choice goes beyond just price; it involves evaluating a vendor’s technical capabilities, material expertise, quality systems, and overall reliability.

How to Choose the Right SiC Supplier:

- Technical Expertise and Material Knowledge:

- Range of SiC Grades: Does the supplier offer a comprehensive range of SiC grades (RBSiC, SSiC, etc.) or specialize in the specific grade you need? Can they clearly articulate the pros and cons of each for your application?

- Customization Capabilities: Assess their ability to produce custom shapes, sizes, and features. Do they have in-house design support or engineering services to help optimize your component for manufacturability and performance?

- Understanding of Applications: A good supplier should understand the demands of your industry (e.g., semiconductor, aerospace, chemical processing) and how SiC properties translate to performance in that context.

- Manufacturing Capabilities and Quality Control:

- In-House Processes: To what extent are manufacturing processes (powder preparation, forming, sintering, machining, finishing) performed in-house? Vertical integration can offer better control over quality and lead times.

- Machining and Finishing Prowess: Given the difficulty of machining SiC, inquire about their diamond grinding, lapping, and polishing capabilities. Can they achieve the tolerances and surface finishes you require?

- Quality Management Systems: Are they ISO 9001 certified or compliant with other relevant industry quality standards? What are their inspection and testing procedures (e.g., dimensional checks, material property verification, defect detection)?

- Traceability: Can they provide material traceability throughout the manufacturing process?

- Reputation and Experience:

- Track Record: How long have they been producing SiC components? Can they provide case studies or references for similar applications or clients?

- Industry Presence: Are they recognized within the technical ceramics community? Do they participate in industry conferences or research initiatives?

- Cost Drivers and Lead Time Considerations:

- Transparent Pricing: A reliable supplier should provide a clear breakdown of cost drivers. Key factors influencing the price of custom SiC substrates include:

- Material Grade: High-purity SSiC or CVD-SiC will be more expensive than RBSiC or NBSiC.

- Complexity of Design: Intricate shapes, thin walls, or complex features increase tooling and processing costs.

- Size of the Component: Larger parts consume more material and may require larger, more specialized processing equipment.

- Tolerances and Surface Finish: Tighter tolerances and finer surface finishes require more extensive (and expensive) diamond grinding and polishing.

- Order Volume: Larger production runs typically have lower per-unit costs due to economies of scale in tooling and setup.

- Post-Processing: Any additional steps like coating, sealing, or specialized cleaning will add to the cost.

- Lead Time: Lead times for custom SiC components can be significant due to the complex manufacturing processes.

- Prototyping: Can they offer rapid prototyping services?

- Production Lead Times: Get realistic estimates for production runs and factor these into your project timelines.

- Factors Affecting Lead Time: Raw material availability, current production backlog, complexity of the part, and finishing requirements all influence lead times.

- Transparent Pricing: A reliable supplier should provide a clear breakdown of cost drivers. Key factors influencing the price of custom SiC substrates include:

- Communication and Support:

- Responsiveness: How quickly do they respond to inquiries and provide technical support?

- Project Management: Do they assign a dedicated contact person for your project?

- Collaboration: Are they willing to work collaboratively to solve design challenges or optimize your component?

Why Sicarb Tech Stands Out:

Sicarb Tech presents a compelling option for businesses seeking high-quality, cost-competitive customized silicon carbide components in China.

- Deep Technical Roots: Backed by the Chinese Academy of Sciences and situated in Weifang, the epicenter of China’s SiC industry, SicSino possesses a top-tier professional team. Their expertise spans material science, process engineering, design, and metrology.

- Comprehensive Capabilities: They offer an integrated process from materials to finished products, covering diverse customization needs. This includes assistance with design, selection of appropriate SiC grades (like their specialized RBSiC and SSiC), and advanced manufacturing and finishing.

- Quality and Supply Assurance: Having supported over 10 local enterprises with their technologies, SicSino has a proven track record of delivering reliable quality. Their position within the Chinese Academy of Sciences (Weifang) Innovation Park ensures access to cutting-edge research and a robust ecosystem for technology transfer and commercialization.

- Cost-Effectiveness: Leveraging the industrial efficiencies of the Weifang SiC cluster and their advanced technological know-how, SicSino aims to provide higher-quality, cost-competitive solutions.

- Technology Transfer Services: Uniquely, SicSino is also committed to assisting clients in establishing their own specialized SiC factories. They offer turnkey project services including factory design, equipment procurement, installation, commissioning, and trial production. This empowers clients with reliable technology transformation and a guaranteed input-output ratio.

The following table outlines key factors for supplier evaluation and how SicSino addresses them:

| Evaluation Factor | Key Questions for Supplier | SicSino’s Approach |

|---|---|---|

| Technical Expertise | What SiC grades do you offer? Can you assist with design? | Wide array of technologies (material, process, design), expert team from Chinese Academy of Sciences, support for RBSiC, SSiC, and others. |

| Manufacturing Capability | What are your in-house processes? Machining capabilities? | Integrated process from materials to products, advanced machining and finishing. |

| Quality Control | What are your quality certifications and testing procedures? | Focus on high-quality, reliable supply assurance, measurement & evaluation technologies. |

| Cost & Lead Time | Can you provide transparent pricing? Realistic lead times? | Aims for cost-competitive components, efficiency through technology and location in SiC hub. |

| Support & Partnership | How do you handle technical support and collaboration? | Domestic top-tier professional team, technology transfer, full turnkey project support for factory setup. |

Choosing a supplier is about building a partnership. For wholesale buyers, technical procurement professionals, OEMs, and distributors looking for a reliable source of custom SiC substrates and components, especially those seeking to leverage the strengths of China’s advanced ceramics industry, Sicarb Tech offers a compelling blend of technical excellence, comprehensive service, and strategic partnership potential.

Frequently Asked Questions (FAQ) about Silicon Carbide Substrates

To further assist engineers, procurement managers, and technical buyers, here are answers to some frequently asked questions regarding silicon carbide substrates and custom SiC components.

1. What are the primary differences between Reaction-Bonded Silicon Carbide (RBSiC/SiSiC) and Sintered Silicon Carbide (SSiC) substrates?

The primary differences lie in their manufacturing, composition, and resulting properties:

- RBSiC (SiSiC):

- Manufacturing: A porous SiC + Carbon preform is infiltrated with molten silicon. The silicon reacts with carbon to form more SiC, bonding the structure. Typically contains 8-20% free silicon.

- Properties: Good strength, good thermal conductivity, excellent wear resistance, and relatively lower cost, especially for complex shapes. Maximum service temperature is limited by the melting point of silicon (≈1380∘C). Not suitable for strong alkalis or HF.

- Common Uses: Kiln furniture, wear parts, mechanical seals, structural components where extreme purity or corrosion resistance isn’t the primary driver.

- SSiC (Sintered SiC):

- Manufacturing: Fine, high-purity SiC powder is mixed with sintering aids (like boron and carbon) and sintered at very high temperatures (>2000∘C) to achieve a dense, single-phase SiC material (typically >98% SiC).

- Properties: Higher strength (especially at elevated temperatures), superior corrosion resistance (even to strong acids and alkalis), higher thermal conductivity, and higher purity. Can operate at higher temperatures (>1650∘C). Generally more expensive.

- Common Uses: Semiconductor processing equipment (chucks, rings), chemical pump components, high-performance mechanical seals, bearings, and applications requiring extreme purity and chemical/thermal stability, such as SiC substrates for power electronics.

Sicarb Tech can help you select the most appropriate grade, whether it’s a cost-effective RBSiC solution or a high-performance SSiC substrate, based on your specific application requirements.

2. How does the cost of Silicon Carbide substrates compare to other materials like Alumina or Silicon?

Generally, silicon carbide substrates are more expensive than alumina (Al2O3) substrates and standard silicon (Si) wafers. The reasons for this include:

- Raw Material Cost: High-purity SiC powder is more expensive to produce than alumina powder.

- Processing Difficulty: SiC requires much higher temperatures for sintering (>2000∘C for SSiC compared to ≈1600−1800∘C for alumina). The extreme hardness of SiC also makes machining (grinding, polishing) significantly more challenging and costly. Diamond tooling and specialized equipment are necessary.

- Energy Consumption: The high-temperature processes involved in SiC manufacturing are energy-intensive.

However, the higher initial cost of SiC is often justified by its superior performance in demanding applications:

- Longer Lifespan: Due to its exceptional wear resistance, corrosion resistance, and high-temperature stability.

- Improved Efficiency: E.g., in power electronics, SiC devices have lower losses. In furnaces, SiC heating elements are more efficient.

- Enabling Technology: In some cases, SiC is the only viable material that can meet the operational demands (e.g., very high temperatures, aggressive chemical environments).

When considering industrial SiC components, a total cost of ownership (TCO) analysis often demonstrates the long-term economic benefits despite a higher upfront investment. SicSino strives to offer cost-competitive customized SiC components by leveraging its technological expertise and its strategic location within China’s SiC manufacturing hub.

3. What information do I need to provide to get an accurate quote for custom Silicon Carbide substrates or components?

To receive the most accurate quotation and appropriate technical recommendations from a supplier like Sicarb Tech, you should provide as much detailed information as possible, including:

- Detailed Drawings and Specifications:

- Clear engineering drawings with all dimensions, critical tolerances, and geometric features (e.g., flatness, parallelism, perpendicularity).

- Required surface finish (e.g., Ra value, polished, as-sintered).

- Any specific edge treatment or chamfering requirements.

- Material Grade:

- Specify the desired SiC grade (e.g., RBSiC, SSiC, specific purity level) if known.

- If unsure, describe the application environment in detail so the supplier can recommend a suitable grade.

- Application Details:

- Operating temperature (maximum, typical, and cycling conditions).

- Chemical environment (e.g., exposure to acids, alkalis, molten metals, specific gases).

- Mechanical loads (e.g., pressure, stress, wear conditions).

- Electrical requirements (e.g., resistivity, dielectric properties for substrates in electronic applications).

- Quantity:

- Number of pieces required for prototypes and for production runs.

- Target Price (if applicable) and Required Delivery Date:

- This helps the supplier understand your budget constraints and timeline.

- Any Special Testing or Certification Requirements:

- E.g., material certifications, dimensional inspection reports, non-destructive testing.

The more comprehensive the information you provide, the better a custom SiC products specialist can understand your needs and offer an optimized solution. Sicarb Techhas a dedicated team to assist with inquiries, ensuring that all necessary details are gathered to provide accurate quotations and high-quality, tailored SiC solutions.

Conclusion: The Enduring Value of Custom Silicon Carbide in Demanding Environments

The journey through the intricacies of silicon carbide substrates reveals a material of exceptional capability, uniquely suited to meet the ever-increasing demands of modern industry. From the heart of semiconductor devices driving our digital world to the fiery core of industrial furnaces, and the precision components in aerospace systems, SiC delivers performance where other materials falter. The ability to customize these substrates and components further amplifies their value, allowing engineers and designers to tailor solutions that precisely match their application’s specific challenges.

Choosing custom SiC solutions from a knowledgeable and capable supplier like Sicarb Tech is an investment in reliability, efficiency, and longevity. Their deep-rooted expertise, stemming from the scientific powerhouse of the Chinese Academy of Sciences and nurtured within the thriving SiC industrial hub of Weifang, positions them as a trusted partner for businesses worldwide. Whether you require intricately designed technical ceramic substrates, robust industrial SiC components, or even assistance in establishing your own specialized SiC production line, SicSino offers a comprehensive suite of services and high-quality products.

As industries continue to push the boundaries of temperature, pressure, power, and chemical exposure, the role of advanced materials like Silicon Carbide will only grow in significance. For procurement managers, technical buyers, and OEMs, understanding the benefits and navigating the considerations of custom silicon carbide products is key to unlocking new levels of performance and innovation in their respective fields. The path to superior industrial outcomes is often paved with superior materials, and SiC is undoubtedly leading the charge.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.