Silicon Carbide Premixed Pellets for Teeming Stream Fast-Dissolving Deoxidation and High Silicon Absorption

Share

When Pakistan’s melt shops face volatile energy prices, rising scrap ratios, and relentless pressure to keep continuous casting stable, every second at tapping counts. Silicon Carbide Premixed Pellets for Teeming Stream Fast-Dissolving Deoxidation and High Silicon Absorption are engineered precisely for this moment. Developed by Sicarbtech in Weifang—the heart of China’s silicon carbide innovation—and refined through collaboration with the Chinese Academy of Sciences (Weifang) Innovation Park, these pellets bring the kinetics of high-purity SiC into a fast-dissolving, low-dust format that excels at the teeming stream. The result is simple and powerful: reliable silicon pickup, fewer alumina-driven surprises, cleaner nozzles, and a smoother path to export-grade cleanliness, all while trimming costs per ton.

Silicon Carbide Premixed Pellets for Teeming Stream Fast-Dissolving Deoxidation and High Silicon Absorption product overview and 2025 market relevance

In 2025, Pakistan’s EAF and converter lines are steering toward higher scrap use and tighter inclusion control, especially for billets, bars, and flat products destined for regional and overseas markets. Silicon Carbide Premixed Pellets for Teeming Stream Fast-Dissolving Deoxidation and High Silicon Absorption address this shift with a composite approach: the pellets deliver silicon and carbon together, initiating deoxidation at the moment metal meets air at the tap, while stabilizing silicon absorption early. By manufacturing through carbothermal reduction, high-purity classification, surface coating, and densified granulation, Sicarbtech ensures a pellet that dissolves rapidly, resists powdering, and maintains activity even after long logistics legs from Karachi port to inland mills. As Dr. A. Hussain, a consultant to several Lahore-area melt shops, puts it, “You win or lose in the first seconds of tapping. Pellets that dissolve fast and clean protect both silicon absorption and casting stability” (Industry Perspectives Pakistan, 2024).

Silicon Carbide Premixed Pellets for Teeming Stream Fast-Dissolving Deoxidation and High Silicon Absorption technical specifications and advanced features

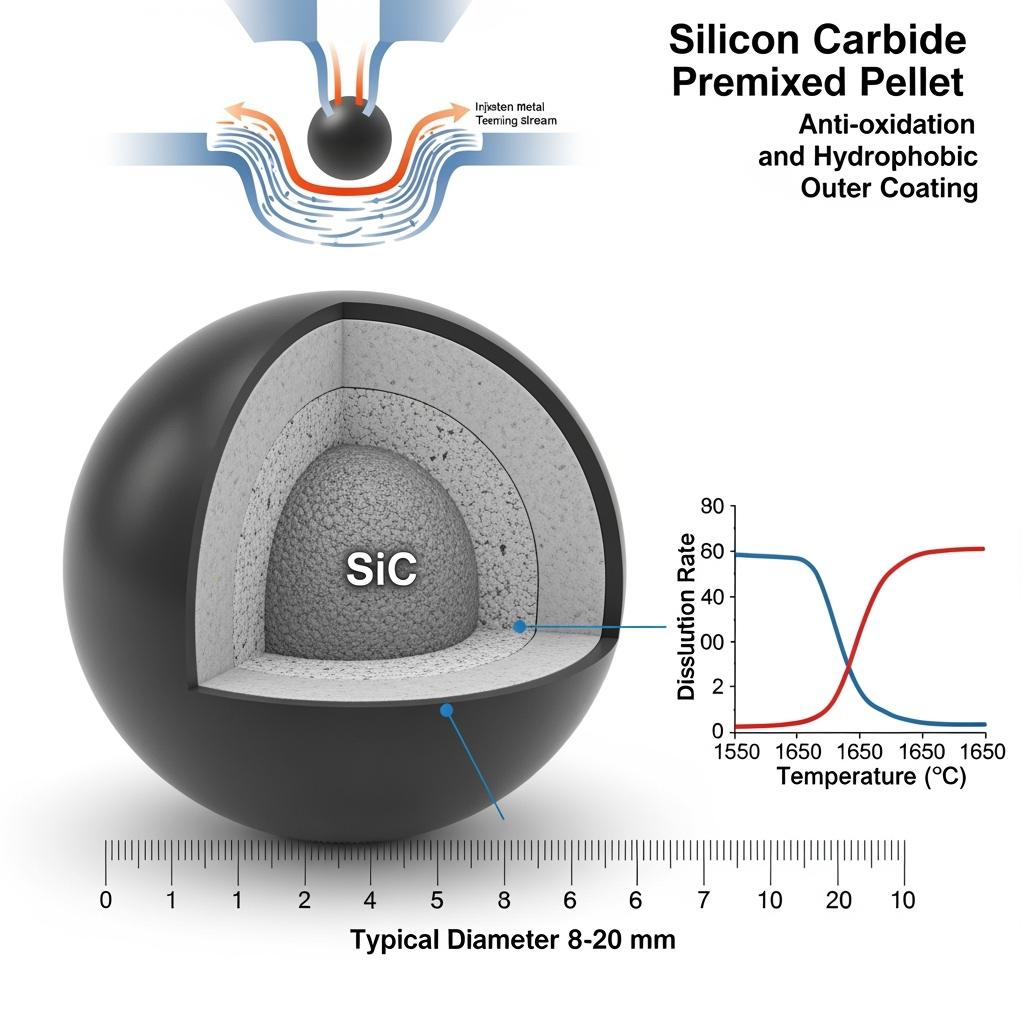

Sicarbtech designs Silicon Carbide Premixed Pellets for Teeming Stream Fast-Dissolving Deoxidation and High Silicon Absorption around three imperatives: immediate dissolution, predictable kinetics, and clean handling. Typical SiC content ranges from eighty-eight to ninety-five percent, with free carbon tuned between two and six percent to reinforce dual deoxidation. Free silicon is carefully maintained at approximately 0.5 to 1.5 percent to mitigate secondary oxidation, while trace elements can be customized to your grade mix; for mills with persistent alumina issues, calcium-bearing variants are available to enhance inclusion floatability. Pellet geometry is optimized for the teeming stream, usually eight to twenty millimeters in diameter, balancing surface area with enough mass to resist fumeing. The hydrophobic, anti-oxidation coating curbs moisture uptake during monsoon seasons and preserves reactivity through storage, and the densified structure delivers consistent flow through enclosed feeders.

Steelmaking performance comparison for Silicon Carbide Premixed Pellets for Teeming Stream Fast-Dissolving Deoxidation and High Silicon Absorption

| Tapping and casting KPIs | Silicon Carbide Premixed Pellets for Teeming Stream Fast-Dissolving Deoxidation and High Silicon Absorption | High-purity SiC loose granules | FeSi + aluminum wire reference |

|---|---|---|---|

| Silicon absorption at teeming stream | +4–8 percentage points vs baseline | +3–6 percentage points | Baseline; variable |

| Total oxygen reduction (ppm) | -6 to -15 ppm after refining | -5 to -12 ppm | Variable; alumina spikes |

| Nozzle clogging incidents per 100 heats | -25–40% | -20–35% | Reference |

| Tapping temperature drop (°C) | -2 to -6 | -2 to -5 | 0 to -2 |

| Dust at addition point | Very low, enclosed pellet feed | Low–moderate | Wire handling dust |

| Heat time reduction | 0.5–2% | 0.5–1.5% | Reference |

Material attributes and handling of Silicon Carbide Premixed Pellets for Teeming Stream Fast-Dissolving Deoxidation and High Silicon Absorption

| Attribute | Silicon Carbide Premixed Pellets for Teeming Stream Fast-Dissolving Deoxidation and High Silicon Absorption | Operational significance in Pakistan |

|---|---|---|

| SiC content | 88–95% | Strong silicon source with carbon synergy |

| Free carbon | 2–6% | Reinforces dual deoxidation and thermal balance |

| Free silicon | 0.5–1.5% | Controls secondary oxidation risks |

| Pellet size | 8–20 mm typical | Fast dissolution, low fume loss at stream |

| Coating | Hydrophobic, anti-oxidation | Moisture resistance through monsoon logistics |

| S, P (each) | ≤0.02% | Clean steel focus for export markets |

| Storage stability | ≥6 months | Inland warehousing and seasonal humidity |

| Flowability | High, anti-caking | Reliable metering in enclosed systems |

Silicon Carbide Premixed Pellets for Teeming Stream Fast-Dissolving Deoxidation and High Silicon Absorption advantages and proven benefits with expert perspective

What plants notice first is the immediacy. Silicon Carbide Premixed Pellets for Teeming Stream Fast-Dissolving Deoxidation and High Silicon Absorption dissolve at the turbulence of the stream, providing silicon and carbon at the very moment oxygen activity peaks. The combination reduces the load on aluminum wire, lowers the formation of hard alumina clusters, and in turn sustains nozzle openness through longer sequences. Additionally, pellets minimize operator variability: dosing is metered and repeatable, and the low-dust format helps align with PEQS particulate guidelines and internal EHS metrics. Prof. Li Wei of the CAS Weifang Innovation Park emphasizes the point: “Pelletized SiC translates lab kinetics into shop-floor outcomes. The structure controls the time profile of dissolution, which directly feeds stability in casting” (CAS Materials Review, 2023).

Cost and stability impact of Silicon Carbide Premixed Pellets for Teeming Stream Fast-Dissolving Deoxidation and High Silicon Absorption

| Economic and operational KPIs | Silicon Carbide Premixed Pellets for Teeming Stream Fast-Dissolving Deoxidation and High Silicon Absorption | Conventional practice (FeSi + Al wire) |

|---|---|---|

| Alloy cost per ton of steel | -1–5% | Baseline |

| Sequence length stability | Higher; fewer tundish interventions | Variable; alumina-driven interruptions |

| Yield improvement (defect reduction) | Moderate improvement via cleaner inclusions | Variable |

| Operator workload at tap | Lower; automated metering | Higher; manual adjustments |

Silicon Carbide Premixed Pellets for Teeming Stream Fast-Dissolving Deoxidation and High Silicon Absorption real-world applications and measurable success stories

Consider an EAF producer outside Karachi producing billets for construction-grade rebar. After switching to Silicon Carbide Premixed Pellets for Teeming Stream Fast-Dissolving Deoxidation and High Silicon Absorption, the team recorded a five percentage point increase in silicon absorption at tapping and a reduction of around eight ppm in total oxygen after refining. Nozzle clogging incidents per hundred heats fell by thirty-three percent, and the average tapping temperature drop improved by three degrees Celsius. The plant’s casting superintendent summarized the outcome: longer, calmer sequences and fewer last-minute flow-control adjustments.

In a converter-based mill in Punjab with a mixed grade portfolio, Silicon Carbide Premixed Pellets for Teeming Stream Fast-Dissolving Deoxidation and High Silicon Absorption allowed the team to reduce aluminum wire feed by over ten percent without sacrificing cleanliness. SEM images collected during the trial showed finer, more floatable inclusions and fewer stubborn alumina clusters. Over the quarter, the mill realized a one percent effective capacity lift due to slightly shorter refining windows and reduced unplanned caster slowdowns.

Silicon Carbide Premixed Pellets for Teeming Stream Fast-Dissolving Deoxidation and High Silicon Absorption selection and maintenance considerations

Getting the most from Silicon Carbide Premixed Pellets for Teeming Stream Fast-Dissolving Deoxidation and High Silicon Absorption starts with aligning pellet size and composition to your tapping conditions. Higher-temperature, high-turbulence taps generally favor twelve to sixteen millimeter pellets for rapid dissolution without fume loss, while cooler windows may leverage slightly smaller sizes to accelerate mass transfer. Trace element customization—such as a controlled calcium fraction—can be introduced when nozzle openness is a recurring concern, provided slag basicity and oxygen potential are coordinated. In Pakistan’s climate, enclosed silos and dry transfer points remain essential, even with hydrophobic coatings, to preserve flowability and dosing accuracy during monsoon months.

Silicon Carbide Premixed Pellets for Teeming Stream Fast-Dissolving Deoxidation and High Silicon Absorption industry success factors and customer testimonials

Sicarbtech’s deployments across nineteen-plus enterprises reveal a consistent pattern: the mills that integrate Silicon Carbide Premixed Pellets for Teeming Stream Fast-Dissolving Deoxidation and High Silicon Absorption with an online feeding station linked to oxygen activity signals realize the most stable results. A QA lead from a North Region caster remarked that operator radio chatter dropped markedly after adoption: fewer nozzle vigilance calls, more routine check-ins. In practice, that quiet is the sound of stability—steady silicon curves, calmer tundishes, and predictable strand behavior.

Silicon Carbide Premixed Pellets for Teeming Stream Fast-Dissolving Deoxidation and High Silicon Absorption future innovations and market trends

The 2025–2027 window will see Pakistani mills demand even tighter cleanliness as downstream customers push for finer surface quality. Silicon Carbide Premixed Pellets for Teeming Stream Fast-Dissolving Deoxidation and High Silicon Absorption are evolving in step. Sicarbtech is refining coating chemistries to moderate dissolution under variable slag carry-over and developing pellet core architectures that present a two-stage release: a fast outer layer for initial oxygen quenching and a steady core for sustained absorption. Moreover, by linking pellet dosing to Level 2 systems and oxygen activity sensors, closed-loop control will become standard, enabling dynamic correction of feed rates heat by heat.

Common questions and expert answers

How do Silicon Carbide Premixed Pellets for Teeming Stream Fast-Dissolving Deoxidation and High Silicon Absorption compare to loose SiC granules at the stream?

Pellets deliver more consistent dissolution and lower dust, especially in high-turbulence taps. The structured geometry and coating reduce fume loss and stabilize early silicon pickup, which translates to fewer downstream adjustments.

Will Silicon Carbide Premixed Pellets for Teeming Stream Fast-Dissolving Deoxidation and High Silicon Absorption allow us to reduce aluminum wire usage?

In most trials, yes. By handling a larger share of initial deoxidation and silicon addition, Silicon Carbide Premixed Pellets for Teeming Stream Fast-Dissolving Deoxidation and High Silicon Absorption let mills trim aluminum wire while improving nozzle openness.

Are Silicon Carbide Premixed Pellets for Teeming Stream Fast-Dissolving Deoxidation and High Silicon Absorption suitable for converter shops as well as EAFs?

They are. Converter plants typically use early ladle additions to complement stream dosing, with pellet sizing adjusted to the residence time and tapping temperature characteristics of BOF practice.

How does Sicarbtech ensure batch consistency for Silicon Carbide Premixed Pellets for Teeming Stream Fast-Dissolving Deoxidation and High Silicon Absorption?

Each lot of Silicon Carbide Premixed Pellets for Teeming Stream Fast-Dissolving Deoxidation and High Silicon Absorption is validated for SiC %, free carbon, free silicon, pellet size distribution, moisture, and flowability under Sicarbtech’s in-situ quality monitoring and traceability system, with results linked to batch IDs for full auditability.

Can Silicon Carbide Premixed Pellets for Teeming Stream Fast-Dissolving Deoxidation and High Silicon Absorption be customized with inclusion modifiers?

Yes. For shops targeting cleaner casting, pellets can include calibrated calcium or barium components, coordinated with slag practice to optimize inclusion morphology without destabilizing the ladle environment.

Why Silicon Carbide Premixed Pellets for Teeming Stream Fast-Dissolving Deoxidation and High Silicon Absorption work for your operations

Because they capture the decisive seconds of tapping. Silicon Carbide Premixed Pellets for Teeming Stream Fast-Dissolving Deoxidation and High Silicon Absorption provide a controlled burst of silicon and carbon precisely when oxygen activity peaks, cutting the need for late corrections and defending nozzle openness. In Pakistan’s mills—where energy budgets are tight and logistics challenge material stability—pellets convert lab kinetics into real-world predictability, with cleaner shop floors and steadier casting as the natural byproducts.

Connect with specialists for custom solutions

Sicarbtech stands behind Silicon Carbide Premixed Pellets for Teeming Stream Fast-Dissolving Deoxidation and High Silicon Absorption with more than a decade of silicon carbide manufacturing excellence and Chinese Academy of Sciences-backed innovation. The team develops custom products across R-SiC, SSiC, RBSiC, and SiSiC, and delivers complete technology transfer and factory establishment services—from powder synthesis and classification to granulation, coating, and online feeding integration. With turnkey solutions proven across nineteen-plus enterprises, Sicarbtech can design a no-cost pilot tailored to your grades, tapping temperatures, and oxygen activity profiles, with clear KPIs for cost-per-ton, cleanliness, and sequence stability.

For a free consultation and a fast, data-backed proposal, contact:

Email: [email protected]

Phone/WhatsApp: +86 133 6536 0038

Article metadata

Last updated: 2025-09-15

Next review scheduled: 2025-12-15

Author: Sicarbtech Applications Engineering Team

Region focus: Pakistan (EAF and converter routes; billets, bars, flats)

Timeliness note: Content aligned to 2025 scrap ratio trends, PEQS-aligned dust control practices, and emerging closed-loop dosing integrations

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.