The Unyielding Guardian: Why Silicon Carbide is the Gold Standard for Mechanical Seals

Share

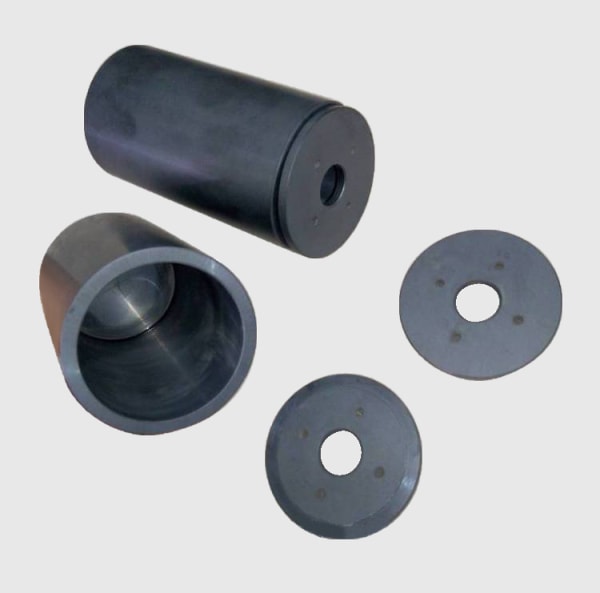

In the relentless world of industrial operations, where machinery runs continuously under demanding conditions, the reliability of every component is paramount. Among the most critical, yet often unsung, heroes are mechanical seals. These precision devices are essential for preventing leakage, containing pressure, and excluding contaminants in rotating equipment such as pumps, mixers, and compressors. When it comes to selecting the material for these crucial components, especially the seal faces, custom silicon carbide (SiC) stands out as an engineering champion. Its exceptional properties make it indispensable in high-performance industrial applications, ensuring longevity and efficiency where other materials falter.

The challenge for engineers and procurement managers is not just finding a robust material, but one that can be tailored to specific, often harsh, operational environments. This is where custom SiC mechanical seals shine. Unlike off-the-shelf solutions, custom-designed SiC seal components can be optimized for unique temperature ranges, chemical exposures, pressure differentials, and abrasive media. This bespoke approach ensures maximum performance, minimizes downtime, and ultimately contributes to a more reliable and cost-effective operation. The demand for such high-quality, technical ceramic seals is consistently growing across various sectors, driven by the need for enhanced operational reliability and reduced maintenance.

Key Industrial Applications for SiC Mechanical Seals

The versatility and superior performance of silicon carbide mechanical seals make them the preferred choice across a multitude of demanding industries. Their ability to withstand extreme conditions ensures the integrity and efficiency of critical rotating equipment. Industrial pump seals and agitator seals made from SiC are fundamental to maintaining operational continuity and safety.

Here’s a breakdown of key sectors where SiC seal faces are making a significant impact:

- Chemical Processing: This industry frequently handles corrosive and aggressive chemicals at varying temperatures and pressures. SiC’s exceptional chemical inertness and resistance to a wide pH range make it ideal for pumps and mixers transferring acids, alkalis, solvents, and other reactive substances. Custom SiC seals prevent hazardous leaks, protect equipment, and ensure process purity.

- Oil and Gas: From upstream extraction to downstream refining, equipment in the oil and gas sector operates under high pressures, elevated temperatures, and often in the presence of abrasive particles (e.g., sand in crude oil). High-performance mechanical seals fabricated from robust SiC grades can withstand these harsh conditions, ensuring reliable sealing in pumps, compressors, and pipelines, thereby preventing costly downtime and environmental incidents.

- Water and Wastewater Treatment: Pumps in water treatment plants handle everything from raw, untreated water containing grit and solids to treated water with various chemical additives. Wear-resistant ceramic seals, particularly those made from SiC, offer extended service life in these abrasive and sometimes mildly corrosive environments, reducing maintenance cycles and operational costs for municipal and industrial water systems.

- Pharmaceuticals and Food Processing: These industries demand the highest levels of hygiene and product purity. SiC seals are favored for their non-contaminating nature, resistance to cleaning chemicals (including steam-in-place, SIP), and smooth, crevice-free surfaces that prevent bacterial growth. Customized SiC components for pumps ensure that processes remain sterile and meet stringent regulatory standards.

- Power Generation: In power plants, especially thermal and nuclear facilities, pumps and turbines operate at high temperatures and pressures. SiC mechanical seals provide reliable sealing for boiler feedwater pumps, cooling water pumps, and other critical applications, contributing to the overall efficiency and safety of power generation.

- Pulp and Paper: The pulp and paper industry involves abrasive slurries and corrosive chemicals. SiC seals offer the necessary durability to handle these challenging media, extending the life of pumps and reducing maintenance in stock preparation, paper machines, and chemical recovery areas.

- Mining and Mineral Processing: Equipment in this sector is subjected to extreme abrasion from slurries containing hard mineral particles. The exceptional hardness of SiC makes it a prime candidate for seals in slurry pumps and other processing machinery, offering superior wear resistance compared to traditional seal materials.

The widespread adoption of silicon carbide seal rings in these diverse and challenging applications underscores their unmatched combination of properties. For procurement professionals and OEMs looking for reliable, long-lasting sealing solutions, SiC offers a clear advantage.

| Industry Vertical | Common Equipment Using SiC Seals | Key Challenges Addressed by SiC | Typical SiC Grades Used |

|---|---|---|---|

| Chemical Processing | Pumps, Mixers, Agitators | Corrosion, High Temperatures, Aggressive Chemicals | Sintered SiC (SSiC), RBSiC/SiSiC |

| Oil & Gas | Pumps, Compressors | High Pressure, Abrasives, High Temperature | SSiC, Reaction-Bonded SiC (RBSiC) |

| Water Treatment | Pumps (Raw, Process, Sludge) | Abrasion, Mild Corrosion | RBSiC/SiSiC, SSiC |

| Pharmaceuticals | Pumps, Mixers, Homogenizers | Sterility, Chemical Resistance (CIP/SIP) | High-Purity SSiC |

| Power Generation | Boiler Feed Pumps, Cooling Pumps | High Temperature, High Pressure | SSiC, RBSiC |

| Pulp & Paper | Stock Pumps, Liquor Pumps | Abrasion, Corrosive Chemicals | RBSiC/SiSiC, SSiC |

| Mining & Minerals | Slurry Pumps, Process Pumps | Extreme Abrasion, Erosive Wear | SSiC, Specially Formulated RBSiC |

This table illustrates the critical role of technical ceramics for sealing applications, with SiC leading the charge in reliability and performance across demanding industrial landscapes.

Why Choose Custom Silicon Carbide for Your Mechanical Seal Needs?

When standard mechanical seals fall short of meeting the rigorous demands of your specific application, turning to custom silicon carbide seals offers a strategic advantage. The ability to tailor the material properties and design of SiC seal faces and components ensures optimal performance, longevity, and overall cost-effectiveness. This customization is particularly crucial for OEM SiC seal solutions where unique equipment designs necessitate perfectly matched sealing components.

The inherent properties of silicon carbide itself are the primary drivers for its selection in high-stakes sealing applications:

- Exceptional Hardness and Wear Resistance: Silicon carbide is one of the hardest commercially available materials, surpassed only by diamond and boron carbide. This extreme hardness translates directly into superior wear resistance, especially against abrasive particles found in many industrial fluids. Custom SiC seals maintain their integrity and sealing capability for significantly longer periods than seals made from softer materials, drastically reducing maintenance frequency and associated downtime. This is a key factor for wholesale buyers looking for durable and reliable components.

- Excellent Thermal Conductivity: Unlike many other ceramics that act as thermal insulators, SiC exhibits high thermal conductivity. In mechanical seals, this property is vital for dissipating the frictional heat generated at the seal faces. Efficient heat removal prevents overheating, which can lead to seal failure, lubricant degradation, and damage to surrounding components. Custom SiC mechanical seals can be designed to maximize this thermal advantage, ensuring stable operation even at high speeds or in poorly lubricated conditions.

- Superior Chemical Inertness: Silicon carbide demonstrates remarkable resistance to a vast array of chemicals, including strong acids, alkalis, solvents, and oxidizing agents, even at elevated temperatures. This chemical resistant seals characteristic makes it suitable for the most aggressive environments found in chemical processing, petrochemicals, and pharmaceutical manufacturing. Customization allows for the selection of SiC grades that are specifically optimized for the chemical cocktail they will encounter.

- High-Temperature Stability: SiC retains its mechanical strength and structural integrity at very high temperatures, far exceeding the limits of most metals and polymers. This makes high-performance mechanical seals from SiC ideal for applications involving hot fluids or high ambient temperatures, such as in power generation or certain chemical reactions.

- Low Coefficient of Friction (when paired appropriately): When used in combination with suitable mating materials (like carbon-graphite or another SiC face), silicon carbide can achieve a low coefficient of friction. This minimizes frictional heat generation and reduces the power consumption of the rotating equipment. The surface finish of custom SiC seal faces can be precisely controlled to optimize tribological performance.

- Dimensional Stability: SiC has a low coefficient of thermal expansion and high elastic modulus, meaning it maintains its shape and dimensions even under fluctuating temperatures and high mechanical loads. This dimensional stability is critical for maintaining the precise flatness and parallelism required for effective sealing.

- Resistance to Thermal Shock: Certain grades of SiC, particularly Reaction-Bonded Silicon Carbide (RBSiC), offer good resistance to thermal shock, allowing them to withstand rapid temperature changes without cracking or failing. This is important in applications with cyclic temperature profiles.

By opting for custom silicon carbide components for pumps and other rotating equipment, businesses can move beyond the limitations of standard parts. Sicarb Tech, located in Weifang City, the hub of China’s silicon carbide customizable parts manufacturing, leverages its deep expertise and connection with the Chinese Academy of Sciences to provide such tailored solutions. With over 40 SiC production enterprises in the Weifang region accounting for more than 80% of China’s total output, SicSino has been instrumental in advancing production technology since 2015. Our understanding of material science and manufacturing processes allows us to help clients select or develop the ideal SiC grade and design for their unique sealing challenges, ensuring they receive components that deliver unparalleled performance and value.

Key Takeaways for Choosing Custom SiC Seals:

- Tailored Performance: Match material properties to specific operational challenges.

- Extended Service Life: Benefit from superior wear and chemical resistance.

- Improved Reliability: Reduce a_sync_failure_rates and unplanned downtime.

- Enhanced Safety: Ensure secure containment of process fluids.

- Optimized Efficiency: Leverage properties like high thermal conductivity and low friction.

For technical procurement professionals and engineers, the decision to specify custom SiC seals is an investment in operational excellence.

Recommended SiC Grades and Compositions for Optimal Seal Performance

Selecting the appropriate grade of silicon carbide is crucial for maximizing the performance and lifespan of mechanical seals. Different manufacturing processes and additive compositions result in SiC materials with varying properties, making them suitable for specific operational conditions. Understanding these distinctions is key for engineers and technical buyers aiming to procure the most effective SiC seal faces and components.

The primary grades of silicon carbide used in mechanical seals include:

- Reaction-Bonded Silicon Carbide (RBSiC), also known as Siliconized Silicon Carbide (SiSiC):

- Manufacturing: RBSiC is produced by infiltrating a porous compact of SiC grains and carbon with molten silicon. The silicon reacts with the carbon to form additional SiC, which bonds the initial SiC grains. The resulting material typically contains 8-15% free silicon.

- Properties:

- Excellent wear resistance and hardness.

- Good thermal conductivity.

- Good chemical resistance, though the free silicon can be attacked by strong alkalis and certain acids at high temperatures.

- Relatively lower manufacturing cost compared to SSiC.

- Good thermal shock resistance.

- Applications: Widely used for general-purpose applications in pumps handling abrasive fluids, water, wastewater, and some chemical slurries. It’s a common choice for industrial pump seals where a balance of performance and cost is needed. Sicarb Tech has supported numerous local enterprises in Weifang to achieve large-scale production and technological advancements in RBSiC products, ensuring high-quality and cost-competitive options.

- Considerations: The presence of free silicon makes it less suitable for extremely corrosive environments or very high temperatures where the silicon might melt or react.

- Sintered Silicon Carbide (SSiC):

- Manufacturing: SSiC is produced by sintering fine SiC powder at very high temperatures (typically > 2000 ∘C) with the aid of sintering additives (e.g., boron and carbon). This process results in a dense, single-phase SiC material with minimal or no free silicon.

- Properties:

- Highest hardness and wear resistance among SiC grades.

- Excellent corrosion resistance across a wide pH range, even at elevated temperatures, due to the absence of free silicon.

- Very high thermal conductivity.

- Superior high-temperature strength and creep resistance.

- Can be produced in high purity forms.

- Applications: The preferred choice for highly demanding applications involving aggressive chemicals, high temperatures, high pressures, and severe abrasion. Commonly used in chemical processing, pharmaceuticals (high-purity grades), oil and gas, and power generation. High-performance mechanical seals often utilize SSiC faces.

- Considerations: Generally more expensive to manufacture than RBSiC. Can be more susceptible to thermal shock than some RBSiC grades if not carefully designed.

- Graphite-Loaded Silicon Carbide:

- Manufacturing: These are typically RBSiC or SSiC materials into which graphite is incorporated. The graphite can be added as particles or flakes.

- Properties:

- Combines the hardness and wear resistance of SiC with the self-lubricating properties of graphite.

- Improved dry-running capability and reduced coefficient of friction, especially during start-up or upset conditions where fluid film lubrication might be compromised.

- Good thermal shock resistance.

- Applications: Ideal for applications where boundary lubrication conditions are expected, or where intermittent dry running might occur. Used in pumps handling non-lubricating fluids or in seals requiring enhanced emergency running properties.

- Considerations: The addition of graphite may slightly reduce the overall chemical resistance or mechanical strength compared to pure SSiC, depending on the concentration and form of graphite.

Comparing Key Properties of Common SiC Grades for Seals:

| Property | Reaction-Bonded SiC (RBSiC/SiSiC) | Sintered SiC (SSiC) | Graphite-Loaded SiC |

|---|---|---|---|

| Hardness (Knoop) | ~ 2500−2800 | ~ 2500−2900 | ~ 2200−2700 (matrix dependent) |

| Free Silicon | 8−15% | Typically <1% (often nil) | Varies (matrix dependent) |

| Chemical Resistance | Good (limited by free Si) | Excellent | Good to Excellent |

| Thermal Conductivity | High | Very High | Good to High |

| Max. Use Temp. | ~1350 ∘C | ~1600 ∘C (or higher) | ~500−1350 ∘C (graphite oxidation can be a limit) |

| Relative Cost | Moderate | Higher | Moderate to Higher |

| Dry Run Capability | Fair | Poor to Fair (unless treated) | Good to Excellent |

When selecting a silicon carbide seal supplier, it’s essential to partner with one that has a deep understanding of these material nuances and can guide you to the optimal grade for your application. Sicarb Tech, with its robust scientific backing from the Chinese Academy of Sciences and its pivotal role in the Weifang SiC industry cluster, possesses a domestic top-tier professional team specializing in customized production. We offer a wide array of technologies, including material formulation and process optimization, enabling us to meet diverse customization needs for technical ceramic seals and ensure you receive higher-quality, cost-competitive components from China.

Design Considerations for Manufacturing High-Performance SiC Seal Faces

Designing effective and reliable silicon carbide mechanical seals goes beyond simply selecting the right SiC grade. The geometric design of the seal faces and associated components is critical for achieving optimal performance, longevity, and manufacturability. Engineers must consider several factors to ensure the custom SiC seals function as intended under demanding operational conditions. These considerations are paramount for both end-users and OEMs integrating SiC seal solutions into their equipment.

Key design considerations for high-performance SiC seal faces include:

- Seal Face Geometry and Profile:

- Flatness: Achieving and maintaining extreme flatness on the mating seal faces is fundamental for creating an effective seal. Deviations from flatness can lead to leakage paths. Typical specifications call for flatness within a few helium light bands (HLBs).

- Parallelism: The mating faces must also be parallel to each other to ensure uniform contact and pressure distribution.

- Surface Finish: A highly polished surface finish (typically Ra<0.2μm) is required to minimize friction, wear, and the potential for fluid leakage between the dynamic and static faces.

- Edge Treatment: Sharp edges on SiC components can be prone to chipping due to the material’s inherent brittleness. Incorporating small chamfers or radii on edges can significantly improve handling robustness and reduce the risk of damage during assembly or operation.

- Hydrodynamic Features: For certain high-speed or high-pressure applications, specialized features like waves, grooves, or scallops can be designed into the seal faces to promote the formation of a stable fluid film. This hydrodynamic lubrication reduces friction, wear, and heat generation. The design of such features requires careful engineering and precise manufacturing.

- Seal Balance:

- Mechanical seals can be “unbalanced” or “balanced.” Balanced seals are designed to reduce the hydraulic closing forces acting on the seal faces. This results in lower face loading, reduced friction and heat generation, and longer seal life, especially in high-pressure applications.

- The degree of balance is a critical design parameter that influences the pressure limits and overall performance of the industrial pump seal. Achieving the desired balance often involves careful design of the seal ring’s shoulders and diameters.

- Minimizing Stress Concentrations:

- Silicon carbide is a strong but brittle material. Therefore, designs must avoid sharp internal corners, notches, or abrupt changes in cross-section that can act as stress concentrators, potentially leading to fracture under mechanical or thermal loads.

- Generous radii and smooth transitions are essential in customized SiC components for pumps and other equipment to distribute stress more evenly. Finite Element Analysis (FEA) is often employed during the design phase to identify and mitigate high-stress areas.

- Material Compatibility and Mating Faces:

- While SiC vs. SiC is a common pairing for its excellent wear resistance, it can be susceptible to issues in poor lubrication conditions. Often, SiC is run against a softer, self-lubricating material like carbon-graphite.

- The choice of mating face material combination depends on the fluid being sealed, operating temperature, speed, and pressure. Custom designs must consider the tribological system as a whole.

- Thermal Management:

- While SiC has excellent thermal conductivity, the overall seal design should facilitate heat dissipation from the seal faces. This might involve optimizing the cross-sectional area of the seal rings or ensuring adequate coolant flow near the seal chamber.

- Manufacturability:

- Complex geometries can be challenging and costly to produce in SiC due to its hardness. Designers should work closely with experienced silicon carbide seal manufacturers like Sicarb Tech to ensure that the proposed design is manufacturable within acceptable tolerances and cost constraints. Our expertise in Weifang, China’s SiC hub, allows us to advise on design for manufacturability (DFM) from the outset.

- Assembly and Installation:

- The design should also consider ease of assembly and installation. Features that aid in alignment or prevent incorrect installation can improve the overall reliability of the sealed joint.

By carefully considering these design aspects, engineers can harness the full potential of silicon carbide, leading to high-performance mechanical seals that deliver exceptional reliability and service life in the most challenging industrial environments. Sicarb Tech not only supplies custom SiC components but also offers design support, leveraging our material and process expertise to help clients optimize their seal designs.

Achievable Tolerances, Surface Finish, and Precision in SiC Seal Components

The performance of a silicon carbide mechanical seal is intrinsically linked to the precision with which its components, particularly the seal faces, are manufactured. Achieving tight dimensional tolerances, exceptional surface finishes, and overall geometric accuracy is critical for ensuring a reliable, low-leakage seal that can withstand demanding operational conditions. For technical procurement professionals and engineers specifying custom SiC seals, understanding the achievable precision is key to setting realistic expectations and designing effective sealing systems.

Dimensional Tolerances: Silicon carbide, due to its extreme hardness, requires specialized grinding and machining processes. While it is more challenging to machine than metals, advanced manufacturing techniques allow for impressive dimensional accuracy.

- Diameter and Thickness: Tolerances for diameters and thicknesses of SiC seal rings can typically be held within ±0.01 mm to ±0.05 mm (±0.0004 inches to ±0.002 inches), depending on the size and complexity of the part. For critical dimensions, even tighter tolerances may be achievable with specialized processes, albeit potentially at a higher cost.

- Parallelism: The parallelism between the two primary faces of a seal ring is crucial for even contact. This can often be maintained within 2 μm to 5 μm (0.00008 inches to 0.0002 inches).

- Concentricity/Runout: For rotating components, concentricity and runout are important. These can be controlled to tight specifications, ensuring smooth operation and minimizing vibration.

Surface Finish (Roughness, Waviness, and Flatness): The quality of the seal face surface is perhaps the most critical aspect for achieving a high-integrity seal.

- Surface Roughness (Ra): SiC seal faces are typically lapped and polished to achieve a mirror-like finish. Surface roughness values of Ra<0.2 μm (8 μin) are standard, with values as low as Ra<0.05 μm (2 μin) achievable for ultra-critical applications. This ultra-smooth surface minimizes friction and wear and provides a very tight interface for the fluid film.

- Flatness: As mentioned previously, extreme flatness is paramount. For high-performance mechanical seals, flatness is often specified in terms of Helium Light Bands (HLBs), where 1 HLB is approximately 0.29 μm (11.6 μin). Common specifications for SiC seal faces are 1 to 3 HLBs, meaning the deviation from a perfectly flat plane is less than 0.29 μm to 0.87 μm over the entire sealing surface. Achieving and verifying such flatness requires specialized lapping equipment and optical measurement techniques like interferometry.

- Waviness: Waviness refers to longer-wavelength variations on the surface. Low waviness is also important for ensuring consistent contact across the seal face.

Precision Capabilities of Leading Suppliers: Achieving these exacting standards requires significant expertise in ceramic processing, precision grinding, lapping, and polishing, along with advanced metrology. This is where a supplier like Sicarb Tech excels. Situated in Weifang, the heart of China’s SiC manufacturing, and backed by the technological prowess of the Chinese Academy of Sciences , SicSino and its partner enterprises have access to state-of-the-art manufacturing and measurement technologies.

Our commitment to quality ensures that customized SiC components for pumps and other demanding applications meet the most stringent specifications. We leverage an integrated process from raw materials to finished products, incorporating meticulous measurement and evaluation at each stage. This allows us to consistently deliver SiC seal components with:

- Highly controlled dimensions

- Superior surface finishes

- Exceptional flatness and parallelism

This precision is not just about meeting a specification on a drawing; it’s about delivering wear-resistant ceramic seals that perform reliably day in and day out, minimizing leakage, extending maintenance intervals, and enhancing the safety and efficiency of your operations. When sourcing SiC seal rings or other technical ceramics for sealing applications, the ability of the supplier to consistently meet these high precision standards is a critical factor in the decision-making process.

Table: Typical Achievable Precision for Custom SiC Seal Faces

| Parameter | Typical Specification Range | Importance for Seal Performance |

|---|---|---|

| Flatness | 1−3 HLBs (0.29−0.87 μm) | Critical for minimizing leakage and ensuring uniform contact |

| Surface Roughness (Ra) | <0.2 μm (often <0.1 μm) | Reduces friction, wear, and leak paths |

| Parallelism | 2−5 μm | Ensures even pressure distribution across the seal face |

| Thickness Tolerance | ±0.01 mm to ±0.05 mm | Affects assembly fit-up and axial positioning |

| Diameter Tolerance | ±0.01 mm to ±0.05 mm | Critical for proper housing fit and dynamic sealing interface |

Post-Processing and Enhancement of SiC Mechanical Seals

Once the basic shape of a silicon carbide mechanical seal component is formed (e.g., through pressing and sintering or reaction bonding), several post-processing steps are often necessary to achieve the final, exacting specifications required for optimal performance. These steps are crucial for refining the geometry, surface characteristics, and overall quality of the SiC seal faces and rings, ensuring they function reliably in demanding industrial pump seals and other applications. For OEM SiC seal solutions, these finishing touches are integral to the component’s success.

Common post-processing and enhancement techniques include:

- Grinding: Due to its extreme hardness, silicon carbide cannot be machined using conventional cutting tools. Diamond grinding is the primary method for shaping SiC components to near-net dimensions and achieving precise geometric features after the initial forming and sintering/bonding stages. Specialized diamond grinding wheels and carefully controlled machining parameters are used to remove material accurately.

- Lapping: This is a critical step for achieving the ultra-flat and smooth surfaces required for SiC seal faces. Lapping involves abrading the SiC surface against a flat plate (the lap) using a slurry containing fine abrasive particles (often diamond). This process progressively removes microscopic high spots, resulting in exceptional flatness (typically within 1-3 HLBs) and a fine matte or semi-polished finish.

- Polishing: Following lapping, polishing may be employed to further improve the surface finish to a mirror-like state (Ra<0.1 μm or better). This uses even finer abrasive slurries and softer lap materials. A highly polished surface minimizes friction and the potential for micro-leakage paths.

- Edge Chamfering/Radiusing: As SiC is brittle, sharp edges can be prone to chipping during handling, assembly, or operation. Controlled edge chamfering or radiusing (also known as edge breaking) is performed to improve the component’s robustness and reduce the risk of stress concentrations that could lead to fractures. This is often done using fine diamond tools or specialized brushing techniques.

- Cleaning: Thorough cleaning is essential after all machining and finishing operations to remove any residual abrasive particles, machining fluids, or contaminants. Multi-stage ultrasonic cleaning processes with appropriate solvents and deionized water are commonly used to ensure the technical ceramic seals are pristine before inspection and packaging.

- Surface Treatments or Coatings (Less Common for SiC-SiC/Carbon pairings, but possible):

- While the inherent properties of SiC are often sufficient, in some niche applications, surface treatments or thin coatings (e.g., Diamond-Like Carbon – DLC) might be considered to further enhance specific properties like lubricity or resistance to very specific chemical attack. However, for most standard mechanical seal applications involving SiC, the intrinsic material properties achieved through careful grade selection and meticulous lapping/polishing are paramount.

- Dimensional and Surface Inspection: Throughout and after post-processing, rigorous quality control is applied. This includes:

- Dimensional checks using precision metrology equipment (CMMs, micrometers, gauges).

- Flatness testing using optical flats and monochromatic light sources (interferometry).

- Surface roughness measurement using profilometers.

- Visual inspection for any defects like cracks, chips, or porosity.

The expertise in these post-processing techniques is a hallmark of a quality silicon carbide seal supplier. Sicarb Tech, leveraging the advanced manufacturing capabilities within the Weifang SiC cluster and its own deep technological know-how, ensures that every custom SiC seal component undergoes the necessary finishing operations to meet the highest standards. Our integrated approach, from material science to final product inspection, guarantees that the customized SiC components for pumps and other equipment provide superior performance and durability. We understand that the final finish is not just cosmetic; it’s fundamental to the sealing function.

The ability to precisely control these post-processing steps allows Sicarb Tech to deliver wear-resistant ceramic seals that are not only dimensionally accurate but also possess the critical surface characteristics needed for long-lasting, leak-free operation in the most challenging industrial environments.

Frequently Asked Questions (FAQ) about Silicon Carbide Mechanical Seals

Engineers, procurement managers, and technical buyers often have specific questions when considering silicon carbide mechanical seals for their applications. Here are some common queries with concise, practical answers to help guide your decision-making process for custom SiC seals and technical ceramic seals.

- What are the main advantages of using silicon carbide (SiC) for mechanical seal faces compared to other materials like tungsten carbide or alumina? Silicon carbide offers a superior combination of properties for many demanding seal applications. Key advantages include:

- Higher Hardness and Wear Resistance: SiC is generally harder than most tungsten carbide grades and significantly harder than alumina, leading to better performance in abrasive environments and longer seal life.

- Excellent Chemical Resistance: Sintered SiC (SSiC), in particular, exhibits broader chemical inertness than tungsten carbide (which can be attacked by certain corrosives due to its metallic binder, typically cobalt or nickel) and alumina (which is susceptible to strong acids and alkalis).

- High Thermal Conductivity: SiC dissipates frictional heat more effectively than alumina and many tungsten carbide grades. This helps prevent overheating at the seal faces, crucial for high-speed or poorly lubricated conditions.

- Lower Density: SiC is lighter than tungsten carbide, which can be beneficial in high-speed applications by reducing rotational mass and dynamic stresses.

- Good Thermal Shock Resistance (especially RBSiC): Certain SiC grades can handle rapid temperature changes better than some ceramics.

- Which SiC grade – Reaction-Bonded (RBSiC/SiSiC) or Sintered (SSiC) – is better for my mechanical seal application? The choice depends on your specific operating conditions:

- Reaction-Bonded Silicon Carbide (RBSiC/SiSiC): This grade is a good all-around performer and often more cost-effective. It’s well-suited for general industrial applications involving abrasives, water, wastewater, and many chemical slurries. Its good thermal shock resistance is also an advantage. However, the presence of free silicon (typically 8-15%) makes it less suitable for highly corrosive environments (strong alkalis or hydrofluoric acid) or very high temperatures (>1350 ∘C).Sintered Silicon Carbide (SSiC): This grade is virtually pure SiC with no free silicon. It offers the highest chemical resistance across the broadest pH range and at elevated temperatures. It also boasts superior hardness and wear resistance. SSiC is the preferred choice for the most demanding applications in chemical processing, pharmaceuticals, oil and gas, and where extreme corrosion or high temperatures are present. It is generally more expensive than RBSiC.

- How critical is the surface finish and flatness of SiC seal faces, and what can I expect from a quality supplier? Surface finish and flatness are extremely critical for the performance of SiC mechanical seals.

- Flatness: The mating seal faces must be exceptionally flat (typically specified within 1-3 Helium Light Bands, which is less than a micron of deviation) to create a near-perfect interface that prevents leakage. Any significant deviation from flatness will result in an uneven fluid film, increased leakage, and potentially premature failure.Surface Finish (Roughness): A highly polished, smooth surface (typically Ra<0.2 μm, often much lower) is essential to minimize friction, wear, and the hydrodynamic lift generated between the faces. A smoother surface promotes the formation of a stable, thin lubricating film.

Conclusion: The Enduring Value of Custom Silicon Carbide in Demanding Sealing Environments

In the landscape of advanced industrial materials, custom silicon carbide has firmly established itself as the premier choice for mechanical seals operating in the most challenging environments. Its unparalleled combination of hardness, wear resistance, chemical inertness, high thermal conductivity, and stability under extreme temperatures and pressures makes it an indispensable component for ensuring the reliability and efficiency of critical rotating equipment across a vast spectrum of industries. From chemical processing plants handling aggressive media to oil and gas operations facing abrasive conditions, and pharmaceutical facilities requiring utmost purity, SiC mechanical seals deliver where others falter.

The ability to customize SiC components – tailoring the specific grade, design, and precision finish to the unique demands of an application – elevates its value proposition significantly. This bespoke approach, moving beyond generic solutions, allows engineers and technical buyers to specify industrial pump seals and agitator seals that are not just replacements but genuine upgrades, leading to extended mean time between failures (MTBF), reduced maintenance costs, enhanced safety, and improved operational uptime. The investment in high-quality, custom SiC seals translates directly into long-term operational savings and greater productivity.

Choosing the right partner for your custom SiC needs is as critical as choosing the material itself. Sicarb Tech stands as a testament to quality and expertise in this specialized field. Located in Weifang City, the epicenter of China’s silicon carbide customizable parts manufacturing, and leveraging the formidable scientific and technological capabilities of the Chinese Academy of Sciences , SicSino offers more than just components. We provide a comprehensive solution, from material selection and design consultation to precision manufacturing and quality assurance. Our deep involvement in the local SiC industry, assisting numerous enterprises with technological advancements, means we can offer higher-quality, cost-competitive customized SiC components with reliable supply assurance.

Furthermore, for businesses looking to internalize their production, Sicarb Tech extends its expertise to technology transfer for professional silicon carbide production, offering turnkey project services. This commitment to fostering the SiC industry underscores our dedication to innovation and client success.

In conclusion, when your operations demand unwavering seal performance in the face of extreme conditions, custom silicon carbide mechanical seals offer the most robust and reliable solution. By partnering with a knowledgeable and capable supplier like Sicarb Tech, you gain access to superior materials, advanced manufacturing, and the technical expertise necessary to optimize your sealing systems for peak performance and longevity. Embrace the power of custom SiC and fortify your industrial processes with the unyielding guardian of mechanical seals.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.