Revolutionizing Thermal Management: The Power of Silicon Carbide in Modern Heat Exchangers

Share

In the relentless pursuit of efficiency, durability, and performance, industries are increasingly turning to advanced materials that can withstand extreme operational demands. When it comes to thermal management, particularly in corrosive and high-temperature environments, silicon carbide (SiC) heat exchangers have emerged as a transformative technology. These components are not just incremental improvements; they represent a paradigm shift in how engineers approach heat transfer in some of the most challenging industrial applications. This blog post delves into the world of custom silicon carbide heat exchangers, exploring their unparalleled advantages, diverse applications, and crucial design considerations. We will also shed light on how Sicarb Tech, a pivotal player rooted in Weifang City – the heart of China’s SiC industry – is driving innovation and providing world-class custom SiC solutions.

Introduction: The Imperative for Advanced Heat Exchange – Enter Silicon Carbide

Heat exchangers are fundamental to countless industrial processes, from chemical production and energy generation to pharmaceutical manufacturing and waste heat recovery. Traditional metallic heat exchangers, while widely used, often falter under conditions of extreme heat, aggressive chemical attack, or severe abrasion. This limitation leads to frequent maintenance, costly downtime, and compromised process efficiency. The quest for a superior alternative has led to the adoption of technical ceramics, with silicon carbide standing out as a premier material.

Silicon carbide heat exchangers are specifically designed to operate reliably in environments where other materials quickly degrade. Their intrinsic properties allow for more compact designs, higher process temperatures, and the handling of fluids that would rapidly corrode even high-grade alloys. As industries push the boundaries of process intensification and energy efficiency, the demand for robust and reliable heat exchange solutions is paramount.

Unveiling the Performance Edge: Why Silicon Carbide Excels in Heat Exchanger Applications

The exceptional performance of silicon carbide in heat exchanger applications stems from its unique combination of physical and chemical properties. Unlike traditional materials, SiC offers a compelling suite of characteristics that translate directly into operational benefits and long-term cost savings for industrial heat transfer systems.

Key advantages include:

- Exceptional Thermal Conductivity: Silicon carbide exhibits thermal conductivity significantly higher than many other ceramics and even some metals (e.g., stainless steel). This allows for rapid and efficient heat transfer, leading to more compact heat exchanger designs for a given thermal duty. For instance, SSiC can have thermal conductivity in the range of 100-200 W/mK, depending on purity and temperature.

- High-Temperature Stability: SiC maintains its mechanical strength and structural integrity at extremely high temperatures, often exceeding 1300∘C and, for certain grades, reaching up to 1650∘C or even higher in non-oxidizing atmospheres. This makes it ideal for applications like waste heat recovery from flue gases or high-temperature chemical synthesis.

- Superior Corrosion and Erosion Resistance: This is arguably one of SiC’s most significant advantages. It is virtually inert to a wide range of aggressive chemicals, including strong acids (sulfuric, nitric, hydrochloric, hydrofluoric), bases, and organic solvents, even at elevated temperatures. Its extreme hardness also provides excellent resistance to erosion from particle-laden fluids or high-velocity flows, making corrosion-resistant SiC a game-changer in harsh chemical processing.

- Outstanding Mechanical Strength and Hardness: SiC is an exceptionally hard and strong material, contributing to its erosion resistance and allowing for thinner-walled components, which further enhances heat transfer efficiency. Its high modulus of elasticity ensures components maintain their shape under stress.

- Excellent Thermal Shock Resistance: Due to its high thermal conductivity and relatively low thermal expansion coefficient, SiC can withstand rapid temperature fluctuations without cracking or failing, a critical attribute in processes with cyclic heating and cooling.

- Lower Fouling Tendency: The smooth, hard surface of silicon carbide often results in reduced fouling and scaling compared to metallic surfaces. This translates to longer operational cycles between cleanings and sustained thermal performance.

- Lightweight: Compared to many high-temperature alloys, SiC components are lighter, which can simplify structural support requirements and installation.

To illustrate these benefits, consider the following comparison:

| Property | Silicon Carbide (SSiC) | Stainless Steel (316L) | Graphite (Impervious) | Alumina (99%) |

|---|---|---|---|---|

| Max. Use Temp. (∘C) | ~1600 | ~870 | ~200 (oxidizing) | ~1700 |

| Thermal Conductivity (W/mK) | 100−200 | 16 | 100−150 | 25−30 |

| Corrosion Resistance | Excellent (acids, bases) | Moderate | Good (non-oxidizing) | Good (some acids) |

| Erosion Resistance | Excellent | Fair | Poor | Good |

| Hardness (Mohs) | 9−9.5 | 5.5−6 | 1−2 | 9 |

| Density (g/cm$^3$) | 3.1−3.2 | 8.0 | 1.8 | 3.9 |

This table clearly demonstrates why advanced ceramic components like those made from SiC are increasingly specified for demanding thermal management solutions.

Diverse Industrial Landscapes: Key Applications of Silicon Carbide Heat Exchangers

The unique properties of silicon carbide make it the material of choice for heat exchangers in a wide array of demanding industrial sectors. Custom SiC tubes, plates, and other components engineered by specialists like Sicarb Tech are enabling advancements and improving reliability across these fields:

- Chemical Processing: This is a primary application area due to SiC’s exceptional resistance to highly corrosive substances.

- Acid Concentration/Dilution: Handling sulfuric acid, nitric acid, hydrochloric acid, and hydrofluoric acid at various concentrations and temperatures.

- Halogenated Compounds: Processes involving chlorine, bromine, or fluorine compounds where metals would rapidly corrode.

- Specialty Chemicals & Fine Chemicals: Manufacturing processes requiring high purity and resistance to aggressive reagents, ensuring no metallic ion contamination. SiC material properties make it ideal for maintaining product integrity.

- Petrochemical Industry:

- High-Temperature Gas Processing: Applications in reformers, crackers, and syngas production where extreme temperatures are common.

- Corrosive Fluid Handling: Managing sour gas or streams containing abrasive catalysts.

- Pharmaceutical & Biotechnology:

- Ultra-Pure Water (UPW) & Water for Injection (WFI) Systems: Heating and cooling where non-contamination is critical.

- Aggressive Solvent Recovery: Handling various organic solvents and reactive intermediates without degradation or leaching.

- Waste Heat Recovery Systems (WHRS):

- Flue Gas Heat Recovery: Recovering heat from hot, often corrosive, exhaust gases from furnaces, incinerators, and power plants to improve overall energy recovery systems efficiency.

- Recuperators and Regenerators: Preheating combustion air or process streams using waste heat.

- Power Generation:

- High-Temperature Gas Turbines: Components in advanced gas turbine systems operating at higher firing temperatures for increased efficiency.

- Fuel Cells (SOFCs): Heat exchangers for managing high-temperature gas flows in solid oxide fuel cells.

- Concentrated Solar Power (CSP): Receivers and heat exchangers handling molten salts or other high-temperature heat transfer fluids.

- Metal Finishing and Mining:

- Pickling Baths: Heating corrosive acid solutions used for cleaning and treating metal surfaces.

- Electrowinning and Plating: Temperature control of aggressive electrolyte solutions.

- Slurry Heating/Cooling: Handling abrasive and corrosive slurries in mineral processing.

- Semiconductor Manufacturing:

- Ultra-Pure Fluid Handling: Temperature control of etching solutions, cleaning agents, and high-purity chemicals where metallic contamination is unacceptable.

- Exhaust Gas Abatement: Cooling corrosive exhaust gases from deposition and etching processes.

The versatility of custom SiC components allows for tailored solutions for each of these applications, ensuring optimal performance and longevity. Sicarb Tech, with its comprehensive understanding of material science and manufacturing processes, supports diverse industries by providing high-quality, customized silicon carbide heat exchanger parts.

Choosing Your Champion: Recommended SiC Grades for Optimal Heat Exchanger Performance

Not all silicon carbide is created equal. Different manufacturing processes result in various SiC grades with distinct properties, influencing their suitability for specific heat exchanger applications. The two most prominent grades used for heat exchangers are Sintered Silicon Carbide (SSiC) and Reaction-Bonded Silicon Carbide (RBSiC), also known as Siliconized Silicon Carbide (SiSiC).

- Sintered Silicon Carbide (SSiC):

- Manufacturing: Produced by sintering fine, high-purity SiC powder at very high temperatures (typically >2000∘C) without the use of sintering aids, or sometimes with non-oxide sintering aids. This results in a single-phase, dense SiC body.

- Key Characteristics:

- Highest operating temperature capability (up to 1650∘C or more in controlled atmospheres).

- Exceptional corrosion resistance, even to the most aggressive acids and bases, due to its monolithic SiC structure.

- Very high thermal conductivity.

- Excellent wear and erosion resistance.

- High purity, making it suitable for applications sensitive to contamination.

- Typical Heat Exchanger Uses: Extreme chemical environments, pharmaceutical applications requiring high purity, very high-temperature gas heat exchange. Ideal for industrial ceramic heat exchanger components facing the harshest conditions.

- Reaction-Bonded Silicon Carbide (RBSiC or SiSiC):

- Manufacturing: Made by infiltrating a porous preform, typically composed of SiC grains and carbon, with molten silicon. The silicon reacts with the carbon to form new SiC, which bonds the original SiC grains. The resulting material contains a network of interpenetrating SiC and some residual free silicon (typically 8-15%).

- Key Characteristics:

- Good high-temperature strength (up to ~1350−1380∘C, limited by the melting point of silicon).

- Excellent thermal conductivity.

- Very good wear and abrasion resistance.

- Good corrosion resistance to many acids and alkalis, though generally not as comprehensive as SSiC, especially against strong oxidizing agents or hydrofluoric acid at high temperatures.

- Allows for the manufacture of complex, near-net-shape components with relatively lower manufacturing costs compared to SSiC.

- Typical Heat Exchanger Uses: General chemical processing, waste heat recovery, applications where complex shapes (like large tubes or intricate plates) are needed, and where the ultimate corrosion resistance of SSiC is not strictly necessary. Often used for SiC tubes for heat exchangers in various industries.

Here’s a comparative overview:

| Feature | Sintered Silicon Carbide (SSiC) | Reaction-Bonded Silicon Carbide (RBSiC/SiSiC) |

|---|---|---|

| Composition | Primarily α-SiC or β-SiC (high purity) | SiC grains bonded by silicon-infiltrated SiC matrix, residual free Silicon |

| Max. Operating Temp. | ~1650∘C (or higher in non-oxidizing) | ~1350−1380∘C |

| Thermal Conductivity | Very High | High to Very High |

| Corrosion Resistance | Exceptional (broadest range) | Very Good (some limitations with strong oxidizers/HF at high temps) |

| Mechanical Strength | Very High | High |

| Ability to Form Complex Shapes | Good, but can be more costly | Excellent, often more cost-effective for intricate designs |

| Relative Cost | Higher | Moderate |

| Primary Application Focus | Extreme corrosion, ultra-high temps, high purity | General purpose, complex shapes, good cost/performance |

Sicarb Tech, drawing upon its deep technological roots within the Chinese Academy of Sciences ecosystem and its experience in assisting numerous local Weifang SiC enterprises, possesses the expertise to guide clients in selecting the optimal SiC grade. They can also develop custom SiC compositions tailored to specific operational challenges, ensuring that the chosen material perfectly aligns with the application’s demands for thermal performance, chemical compatibility, and mechanical integrity. Their ability to offer both SSiC and RBSiC, along with other specialized grades, makes them a versatile Weifang SiC supplier for global markets.

From Concept to Reality: Design and Engineering Considerations for Custom SiC Heat Exchangers

Designing a silicon carbide heat exchanger requires a nuanced understanding of the material’s unique properties and manufacturing capabilities. It’s not simply a matter of substituting SiC for metal in an existing design. Effective custom SiC heat exchanger design involves careful consideration of thermal, mechanical, and fluid dynamic aspects to maximize performance and ensure long-term reliability.

Key design and engineering considerations include:

- Heat Exchanger Type and Configuration:

- Tube-and-Shell: A common configuration where SiC tubes are often preferred for their robustness and ease of sealing. Design must accommodate thermal expansion differences if metallic shells are used.

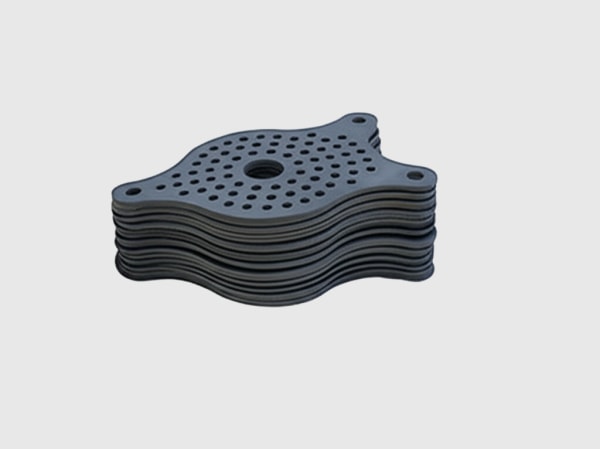

- Plate-Type: SiC plates can offer very high surface area to volume ratios, leading to compact and highly efficient units. The challenge lies in sealing between plates and managing pressure differentials.

- Microchannel Heat Exchangers: For applications requiring extremely rapid heat transfer and compact footprints, SiC microchannel designs are emerging, leveraging SiC’s thermal conductivity and precision manufacturing.

- Flow Path Optimization:

- Design for optimal fluid distribution to ensure uniform heat transfer across all surfaces and prevent hot spots.

- Minimize pressure drop while achieving the desired heat transfer coefficient. Computational Fluid Dynamics (CFD) modeling is often employed.

- Sealing and Manifold Design: This is one of the most critical aspects.

- SiC is a rigid material, so sealing mechanisms must accommodate this. Elastomeric O-rings (for lower temperatures), graphite gaskets, or specialized high-temperature sealing systems are used.

- Compression sealing is common, requiring precise control of clamping forces to avoid overstressing the ceramic components.

- Manifold design must ensure leak-tight connections to the SiC core and to external piping, often involving transitions from SiC to metallic materials.

- Managing Thermal Expansion and Stress:

- While SiC has a low coefficient of thermal expansion, differences in expansion between SiC components and any metallic housing or piping must be carefully managed to prevent mechanical stress and failure, especially during thermal cycling. Flexible elements or expansion joints may be incorporated.

- Finite Element Analysis (FEA) is crucial for predicting thermal stresses and optimizing the design to stay within the material’s limits.

- Manufacturability of Complex Geometries:

- Consider the limitations and possibilities of SiC forming techniques (e.g., extrusion for tubes, slip casting or pressing for plates and more complex shapes).

- Design features like wall thickness, corner radii, and aspect ratios must be compatible with the chosen manufacturing process to ensure component integrity and cost-effectiveness.

- Joining and Assembly:

- Joining SiC parts to each other or to other materials (like metals) requires specialized techniques such as brazing, shrink-fitting, or mechanical clamping with appropriate interface materials.

- Handling and Installation:

- Although strong, SiC is a ceramic and can be brittle under impact loads. Designs should facilitate safe handling and installation, and robust mounting systems are essential.

Sicarb Tech excels in this domain. Their team of experts, backed by the extensive research capabilities of the Chinese Academy of Sciences and practical experience gained from supporting Weifang’s SiC industry, collaborates closely with clients from the initial concept stage. They provide crucial input on design for manufacturability (DfM), material selection, and performance optimization, ensuring that the final custom SiC heat exchanger delivers on its promise. Their integrated approach, from material science to final product, allows them to tackle complex design challenges and produce highly efficient and reliable thermal management solutions.

Precision and Quality: Manufacturing Custom SiC Heat Exchanger Components

The manufacture of high-quality custom SiC heat exchanger components is a multi-stage process that demands precision, expertise, and stringent quality control. From the raw SiC powder to the final, meticulously finished part, each step is critical to achieving the desired performance and durability. Sicarb Tech, leveraging the advanced manufacturing ecosystem in Weifang and its own technological prowess, ensures that every component meets the highest standards.

The typical manufacturing journey includes:

- Powder Preparation:

- Starting with high-purity SiC powders (and potentially additives or binders depending on the grade and forming method).

- Milling and mixing to achieve the desired particle size distribution and homogeneity, which are crucial for consistent final properties.

- Forming Techniques: The choice of forming technique depends on the SiC grade, component geometry, size, and production volume.

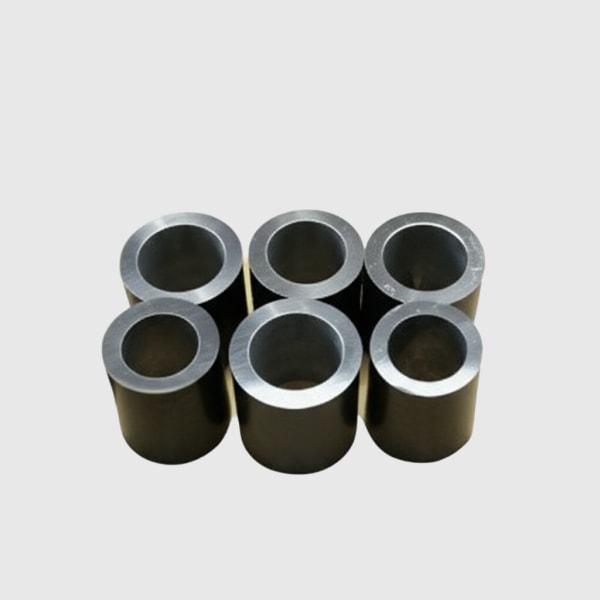

- Pressing (Isostatic or Uniaxial): Suitable for simpler shapes like plates, blocks, or short cylinders. Powder is compacted in a die under high pressure.

- Extrusion: Ideal for producing long, uniform cross-section components like SiC tubes for heat exchangers. A SiC paste is forced through a die.

- Slip Casting: Used for more complex shapes. A SiC slurry is poured into a porous mold, which absorbs the liquid, leaving a solid layer.

- Injection Molding: For intricate, smaller parts in higher volumes, though less common for large heat exchanger components.

- (Emerging) Additive Manufacturing (3D Printing): Offers potential for highly complex geometries and rapid prototyping, though still evolving for widespread SiC production.

- Green Machining (Optional):

- Some basic shaping or feature creation can be done on the “green” (unfired) component, which is softer and easier to machine.

- Sintering / Reaction Bonding: This is the critical high-temperature step that transforms the formed powder into a dense, strong ceramic.

- Sintering (for SSiC): Green parts are heated to very high temperatures (e.g., 2100−2200∘C) in a controlled atmosphere, causing the SiC particles to bond and densify.

- Reaction Bonding (for RBSiC/SiSiC): A porous SiC/carbon preform is infiltrated with molten silicon (around 1500−1700∘C). The silicon reacts with the carbon to form new SiC, bonding the structure.

- Diamond Grinding and Finishing: After firing, SiC becomes extremely hard, so any subsequent machining requires diamond tooling.

- Grinding: To achieve tight dimensional tolerances, precise geometries (e.g., flat surfaces for plates, roundness for tubes), and required surface finishes.

- Lapping and Polishing: For applications requiring exceptionally smooth surfaces to minimize fouling, improve sealing, or for specific optical/fluidic properties. Surface roughness (Ra) values can be brought down to sub-micron levels.

- Quality Control and Inspection:

- Dimensional Checks: Using precision measuring tools (CMMs, micrometers, profilometers).

- Non-Destructive Testing (NDT):

- Visual Inspection: For surface defects.

- Dye Penetrant Testing: To detect surface-breaking cracks.

- Ultrasonic Testing: To identify internal flaws or variations in density.

- X-ray Inspection: For detecting internal voids or inclusions.

- Material Property Verification: Density, hardness, and sometimes microstructural analysis on sample pieces.

Sicarb Tech emphasizes a rigorous quality assurance program throughout its manufacturing processes and those of its partner enterprises in Weifang. Their access to domestic top-tier professional teams specializing in customized SiC production, combined with their own material, process, design, measurement, and evaluation technologies, ensures that custom silicon carbide products are delivered with consistent quality and dimensional accuracy. This commitment allows them to meet diverse customization needs and provide higher-quality, cost-competitive advanced ceramic components from China.

The following table outlines typical achievable tolerances for SiC components, though these can vary based on size, complexity, and grade:

| Feature | Typical Achievable Tolerance | Notes |

|---|---|---|

| Diameter (Tubes/Rods) | ±0.1 mm to ±0.5 mm | Tighter tolerances possible with extensive grinding |

| Length (Tubes/Rods) | ±0.5 mm to ±1.0 mm | Depends on overall length |

| Flatness (Plates) | 0.01 mm/100mm to 0.1 mm/100mm | Lapping can significantly improve flatness |

| Thickness (Plates) | ±0.05 mm to ±0.2 mm | |

| Surface Roughness (Ra) | 0.4 µm to 1.6 µm (as-ground) | <0.1 µm possible with polishing |

Achieving such precision is vital for the assembly and performance of SiC heat exchangers, particularly for ensuring effective sealing and optimal flow characteristics.

Navigating the Nuances: Overcoming Common Challenges in SiC Heat Exchanger Implementation

While silicon carbide offers remarkable advantages for heat exchangers, like any advanced material, its implementation comes with specific considerations and potential challenges. Understanding these nuances and employing appropriate mitigation strategies is key to successfully harnessing the full potential of silicon carbide heat transfer technology. Sicarb Tech, with its extensive experience supporting numerous SiC enterprises in China, provides valuable insights and solutions.

Common challenges and how to address them:

- Initial Investment Cost:

- Challenge: SiC components can have a higher upfront cost compared to traditional metallic parts. This is due to the energy-intensive manufacturing processes and the hardness of the material requiring specialized machining.

- Mitigation: Focus on the Total Cost of Ownership (TCO). The extended lifespan, reduced maintenance, minimized downtime, and improved process efficiency of SiC heat exchangers often result in significantly lower TCO over the equipment’s lifecycle. SicSino’s position in Weifang, the SiC manufacturing hub, allows them to offer cost-competitive solutions without compromising quality.

- Perceived Brittleness:

- Challenge: Like other ceramics, SiC is inherently more brittle than ductile metals and can fracture under high impact loads or excessive tensile stress.

- Mitigation:

- Robust Design: Engineering designs that primarily subject SiC components to compressive loads, where they excel. Avoid stress concentrations through careful geometric design (e.g., filleted corners).

- Material Grade Selection: Certain SiC grades offer higher fracture toughness.

- System Design: Incorporate protective measures in the overall system to prevent mechanical shock or overpressure situations.

- Proper Handling and Installation: Educating users on best practices for handling and installing ceramic components is crucial.

- Joining SiC to Metallic Components:

- Challenge: Effectively sealing and joining SiC parts (like tubes or plates) to metallic headers, shells, or piping systems can be complex due to differences in thermal expansion coefficients and mechanical properties.

- Mitigation:

- Specialized Sealing Systems: Utilizing compressed O-rings (graphite, PTFE, FKM, FFKM depending on temperature and chemical environment), advanced gaskets, or mechanical seals designed for ceramic applications.

- Intermediate Flanges/Collars: Using materials with intermediate thermal expansion or designing floating/flexible joints.

- Brazing or Active Metal Brazing: For permanent, high-strength joints, though this is a specialized process.

- SicSino’s design expertise includes developing reliable joining solutions tailored to specific application conditions.

- Handling, Installation, and Maintenance Practices:

- Challenge: Lack of familiarity with ceramic materials can lead to improper handling, installation errors, or unsuitable maintenance procedures.

- Mitigation:

- Supplier Guidance: Reputable suppliers like SicSino provide detailed guidelines for handling, installation, and maintenance.

- Training: Offering training to an end-user’s engineering and maintenance teams.

- Design for Maintenance: Designing the heat exchanger assembly to allow for easier inspection and replacement of components if necessary.

- Scaling and Fouling (though reduced):

- Challenge: While SiC has a lower fouling tendency, some degree of scaling or deposition can still occur in certain aggressive process fluids or with high particulate loads over extended periods.

- Mitigation:

- Surface Finish: Smoother, polished SiC surfaces can further reduce adhesion points for foulants.

- Flow Velocity Optimization: Maintaining adequate flow velocities can help keep surfaces clean.

- Appropriate Cleaning Regimens: Although less frequent cleaning is typically needed, compatible chemical or mechanical cleaning methods should be established (e.g., CIP systems). SiC’s chemical resistance allows for more aggressive cleaning agents if required.

By proactively addressing these challenges through careful design, material selection, and collaboration with experienced suppliers like Sicarb Tech, industries can confidently implement SiC heat exchangers and reap their substantial benefits. SicSino’s commitment extends to providing comprehensive technical support, drawing from their vast knowledge base and the collective experience of the Weifang SiC cluster, to help clients navigate these nuances effectively.

Frequently Asked Questions (FAQ) about Silicon Carbide Heat Exchangers

To further clarify the capabilities and considerations of using silicon carbide in heat exchangers, here are answers to some commonly asked questions:

- What is the maximum operating temperature for a silicon carbide heat exchanger?

- The maximum operating temperature depends on the specific grade of silicon carbide used. Sintered Silicon Carbide (SSiC) can typically operate up to 1600∘C (2912∘F) or even higher in non-oxidizing or controlled atmospheres. Reaction-Bonded Silicon Carbide (RBSiC/SiSiC) is generally limited to around 1350−1380∘C (2462−2516∘F) due to the presence of free silicon. It’s crucial to select the grade based on the specific thermal demands of your application.

- How does the corrosion resistance of SiC compare to exotic alloys like Hastelloy® or Titanium?

- Silicon carbide, particularly SSiC, often exhibits superior corrosion resistance across a broader range of chemicals and temperatures compared to many exotic alloys. While alloys like Hastelloy® or Titanium offer excellent resistance in specific corrosive environments, SiC is virtually inert to most strong acids (including HF, which attacks Titanium and many other metals), bases, and organic compounds. This makes corrosion-resistant SiC uniquely suited for the most aggressive chemical processing tasks where even high-performance alloys may fail or have limited service life.

- What is the typical lifespan of a SiC heat exchanger?

- The lifespan of a SiC heat exchanger can be significantly longer than traditional material units, especially in highly corrosive or erosive conditions. In well-designed and properly operated systems, SiC components can last for many years, often 5 to 10 years or more, whereas metallic counterparts might require replacement annually or even more frequently. The exact lifespan will depend on the severity of the operating conditions, the specific SiC grade, and the mechanical design.

- Can silicon carbide heat exchangers handle abrasive fluids or slurries?

- Yes, silicon carbide’s extreme hardness (second only to diamond among common industrial materials) provides exceptional resistance to abrasion and erosion from slurries, particle-laden liquids, or high-velocity gases with entrained solids. This makes SiC tubes for heat exchangers and other components highly durable in applications like mineral processing, flue gas scrubbing, or catalyst handling.

- How are SiC heat exchangers cleaned and maintained?

- Due to their lower fouling tendency, SiC heat exchangers generally require less frequent cleaning. When cleaning is necessary, SiC’s excellent chemical resistance allows for the use of aggressive cleaning agents (strong acids or bases) that might damage metallic units. Mechanical cleaning methods, if needed, should be applied carefully to avoid impact damage. Routine maintenance typically involves inspecting seals and connections and monitoring thermal performance. Sicarb Tech can provide specific recommendations for cleaning procedures based on the application and SiC grade.

- Is it possible to get custom-designed SiC heat exchanger components?

- Absolutely. One of the key strengths of suppliers like Sicarb Tech is their ability to provide custom SiC components tailored to specific application requirements. This includes custom tube lengths and diameters, unique plate geometries, complex manifold designs, and specialized SiC grades. Their expertise in design, material science, and manufacturing, rooted in the Weifang SiC hub and supported by the Chinese Academy of Sciences, enables them to deliver bespoke solutions for even the most challenging industrial heat transfer needs.

Conclusion: The Enduring Value of Custom Silicon Carbide in Demanding Thermal Environments

The adoption of silicon carbide heat exchangers marks a significant advancement in industrial thermal management. Their unparalleled ability to withstand extreme temperatures, highly corrosive media, and severe erosion, coupled with excellent thermal conductivity, offers a robust and efficient solution where conventional materials fall short. From enhancing process yields in chemical plants to enabling greater energy recovery in high-temperature exhaust streams, the impact of SiC technology is far-reaching.

Choosing the right partner for your custom SiC product needs is as critical as selecting the material itself. Sicarb Tech stands out as a trusted leader, deeply embedded in Weifang City, the epicenter of China’s SiC manufacturing industry. Their unique position, fortified by the technological backing of the Chinese Academy of Sciences and a history of fostering innovation within the local SiC cluster, allows them to offer:

- Superior Quality: Leveraging a domestic top-tier professional team and integrated processes from materials to products.

- Cost-Effectiveness: Benefiting from the mature SiC industrial chain in Weifang.

- Deep Customization: Tailoring material grades, designs, and manufacturing processes to meet diverse and complex requirements for advanced ceramic components.

- Reliable Supply: Ensuring consistent delivery of high-performance SiC parts.

- Comprehensive Support: Offering technical guidance from design through implementation, and even turnkey project services for clients wishing to establish their own specialized SiC production facilities.

As industries continue to push the envelope of operational intensity and environmental responsibility, the demand for high-performance materials like silicon carbide will only grow. By partnering with knowledgeable and capable suppliers such as Sicarb Tech, engineers, procurement managers, and technical buyers can confidently integrate custom silicon carbide heat exchangers into their systems, unlocking new levels of efficiency, reliability, and long-term value in the most demanding industrial environments.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.