Silicon Carbide Fluxing Silicon Additive for Electric Arc Furnace Bath Conditioning at High Temperature

Share

Across Pakistan’s EAF shops, the flattest power curves still stumble on one stubborn reality: high-temperature bath conditioning decides whether heats end smoothly or drift into corrections. Silicon Carbide Fluxing Silicon Additive for Electric Arc Furnace Bath Conditioning at High Temperature was engineered by Sicarbtech to make those decisive minutes predictable. By coupling high-activity SiC with fluxing behavior tailored to EAF slags, the additive accelerates oxygen control, steadies foamy slag, and boosts silicon pickup precisely when the bath is hottest and most turbulent. Operators see calmer arcs, fewer late-wire pushes, and tighter temperature windows, while finance teams notice a quieter cost-per-ton line despite volatile energy tariffs and import exposures.

Silicon Carbide Fluxing Silicon Additive for Electric Arc Furnace Bath Conditioning at High Temperature product overview and 2025 market relevance

The Silicon Carbide Fluxing Silicon Additive for Electric Arc Furnace Bath Conditioning at High Temperature brings together carbothermally synthesized SiC, high-purity classification, and a surface system tuned for high-temperature dissolution and slag interaction. In Pakistan’s 2025 context—rising scrap ratios, stricter PEQS dust expectations, and aggressive output targets—EAFs need a silicon source that also behaves like a flux teammate. This additive contributes silicon and carbon for fast deoxidation while its coating chemistry promotes wetting and controlled interaction with the slag-metal interface, supporting stable foamy slag without over-thickening. The payoff is practical: improved silicon absorption at tap, shorter flat-bath stabilization, and less variability as heats transition to refining. As Engr. R. Khan notes after a multi-week trial in Lahore, “When SiC acts like a silicon source and a flux assistant, the arc stops fighting the bath—and the bath starts working for you” (Metallurgy Pakistan Review, 2024).

Silicon Carbide Fluxing Silicon Additive for Electric Arc Furnace Bath Conditioning at High Temperature technical specifications and advanced features

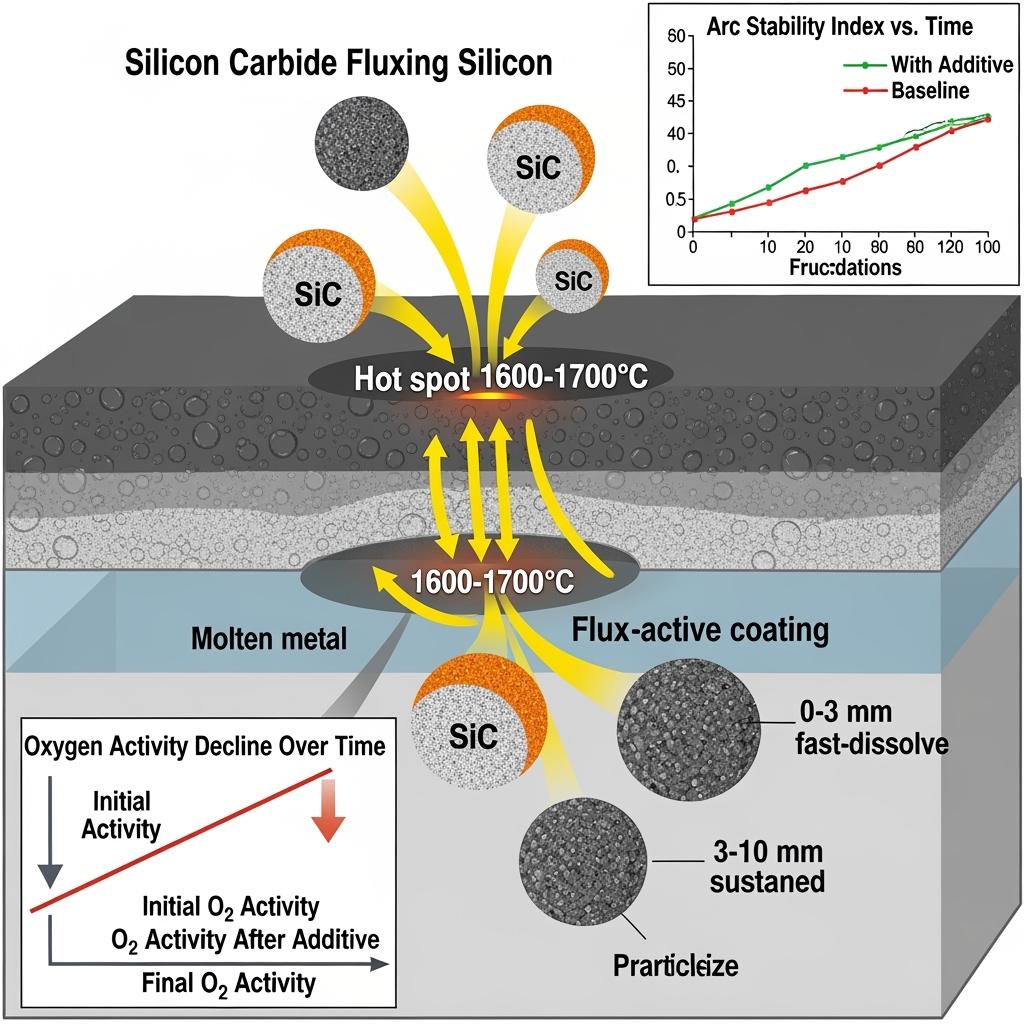

Sicarbtech calibrates the Silicon Carbide Fluxing Silicon Additive for Electric Arc Furnace Bath Conditioning at High Temperature for hot, turbulent EAF windows. Typical SiC content ranges from eighty-nine to ninety-seven percent, with free carbon between one and seven percent to reinforce dual deoxidation and bolster thermal balance as the bath transitions from meltdown to flat. Free silicon is kept within 0.5 to 1.5 percent to curb secondary oxidation and avoid silicon overshoot. Impurities are tightly controlled—sulfur and phosphorus each at or below 0.02 percent—to protect cleanliness goals. The particle size distribution is matched to bath behavior: a 0–3 mm cut supplies immediate dissolution for oxygen knockdown and silicon pickup at flat bath onset, while a 3–10 mm grade sustains release through early refining. The fluxing coating system is hydrophobic for monsoon logistics yet reactive at EAF temperatures, improving wetting and minimizing powdering in enclosed feeders. Reactivity indices are validated against plant thermographs, ensuring dissolution kinetics match your energy and slag practice.

High-temperature bath conditioning outcomes with Silicon Carbide Fluxing Silicon Additive for Electric Arc Furnace Bath Conditioning at High Temperature

| EAF conditioning KPIs | Silicon Carbide Fluxing Silicon Additive for Electric Arc Furnace Bath Conditioning at High Temperature | FeSi + carburizer baseline | High-Al deoxidation route |

|---|---|---|---|

| Time to stable flat bath | Shorter by 0.5–1.5% | Reference | Variable; alumina risk |

| Silicon absorption at tap | +3–8 percentage points | +1–4 percentage points | Variable; late-wire dependent |

| Foamy slag stability | Improved; balanced viscosity | Moderate; separate fluxes needed | Unstable; alumina spikes |

| Oxygen activity decay rate | Faster, smoother profile | Stepwise | Irregular; correction heavy |

| Arc stability index (qualitative) | Calmer; fewer spikes | Baseline | Spiky during wire events |

Material and handling attributes of Silicon Carbide Fluxing Silicon Additive for Electric Arc Furnace Bath Conditioning at High Temperature

| Attribute | Silicon Carbide Fluxing Silicon Additive for Electric Arc Furnace Bath Conditioning at High Temperature | Operational significance in Pakistan |

|---|---|---|

| SiC content | 89–97% | High-activity silicon for hot baths |

| Free carbon | 1–7% | Dual deoxidation, thermal smoothing |

| Free silicon | 0.5–1.5% | Controls reoxidation risk |

| S, P (each) | ≤0.02% | Clean steel/export compliance |

| Particle sizes | 0–3 mm; 3–10 mm | Immediate vs sustained release |

| Coating system | Hydrophobic + flux-active | Monsoon-ready, slag-wetting benefit |

| Storage stability | ≥6 months | Karachi-to-upcountry resilience |

| Injection compatibility | <200 mesh companion grade | Enclosed lances and silos integration |

Silicon Carbide Fluxing Silicon Additive for Electric Arc Furnace Bath Conditioning at High Temperature performance comparison with alternatives

| Cost, energy, and process stability | Silicon Carbide Fluxing Silicon Additive for Electric Arc Furnace Bath Conditioning at High Temperature | FeSi + carburizer + separate fluxes | Al-heavy deoxidation |

|---|---|---|---|

| Alloy cost per ton of steel | -1–4% vs reference | Baseline; multiple SKUs | Variable; FX-sensitive |

| Electrical energy efficiency | Higher; steadier foamy slag | Moderate; flux timing sensitive | Lower; arc disruptions |

| Heat time to tap | -0.5–2% | Reference | Variable; correction loops |

| Nozzle/clogging downstream | Lower; fewer alumina sources | Moderate | Higher; Al2O3 deposition risk |

| EHS/housekeeping | Low dust; enclosed dosing | Higher material touches | Wire dust and manual handling |

Silicon Carbide Fluxing Silicon Additive for Electric Arc Furnace Bath Conditioning at High Temperature advantages and proven benefits with expert quote

The defining advantage of the Silicon Carbide Fluxing Silicon Additive for Electric Arc Furnace Bath Conditioning at High Temperature is synergy at the exact moment it matters. As the bath clears to flat and oxygen activity falls, the additive dissolves rapidly enough to hit silicon targets yet interacts with slag to keep foam stable and arcs quiet. Furthermore, because the surface system resists moisture and powdering, operators can meter precisely under enclosed feeders even in monsoon season. Prof. Li Wei of CAS Weifang Innovation Park observed after reviewing multiple deployments, “When silicon and slag behavior are co-designed, power input translates directly into melt productivity instead of turbulence” (CAS Materials Review, 2023).

Silicon Carbide Fluxing Silicon Additive for Electric Arc Furnace Bath Conditioning at High Temperature real-world applications and measurable success stories

A Karachi EAF billet producer introduced Silicon Carbide Fluxing Silicon Additive for Electric Arc Furnace Bath Conditioning at High Temperature during the transition to flat bath using a 0–3 mm grade. Over eight weeks, time to stable flat bath decreased by roughly one percent, silicon absorption improved by five percentage points, and total oxygen after refining fell by about eight ppm. Operators recorded fewer arc spikes and reduced electrode consumption per heat. In Punjab, an EAF shop with frequent slag carry-over tuned a 3–10 mm grade for sustained dissolution across an extended flat period. The mill cut late aluminum wire by ten percent, observed a three-degree Celsius reduction in tapping temperature drop, and reported a thirty-one percent decline in downstream nozzle interventions per hundred heats, attributed to lower alumina generation and steadier inclusion behavior.

Silicon Carbide Fluxing Silicon Additive for Electric Arc Furnace Bath Conditioning at High Temperature selection and maintenance considerations

Selecting the right Silicon Carbide Fluxing Silicon Additive for Electric Arc Furnace Bath Conditioning at High Temperature variant begins with mapping your flat-bath window. Short, high-energy flats favor 0–3 mm for rapid dissolution and immediate oxygen control, while longer or staged flats benefit from 3–10 mm to stretch silicon pickup without spikes. Where pneumatic injection supplements the arc, a companion <200 mesh grade integrates with Sicarbtech lances and silos, ensuring the same fluxing behavior without dust. Coordination with slag basicity and viscosity is essential; aligning your flux plan with the additive’s coating response prevents over-thick foams while maintaining arc coverage. Storage discipline—enclosed silos, dry purges, and periodic moisture and flowability checks—preserves metering accuracy, especially during humid months. Finally, linking feeder setpoints to oxygen activity signals and the batch’s measured PSD/reactivity (via Sicarbtech’s QC tags) reduces manual tuning and gives operators a flat curve rather than a moving target.

Silicon Carbide Fluxing Silicon Additive for Electric Arc Furnace Bath Conditioning at High Temperature industry success factors and customer testimonials

The most consistent wins occur where melt and casting teams collaborate. Plants that treat the Silicon Carbide Fluxing Silicon Additive for Electric Arc Furnace Bath Conditioning at High Temperature as both an alloy and a slag behavior tool see the greatest gains. A QA superintendent from a North Region caster remarked, “The arc stopped hunting, the slag stopped collapsing, and our radio traffic dropped. We didn’t chase silicon anymore—it arrived on schedule.” That is the essence of bath conditioning: predictable kinetics, fewer corrections, steadier downstream quality.

Silicon Carbide Fluxing Silicon Additive for Electric Arc Furnace Bath Conditioning at High Temperature future innovations and market trends

Looking ahead to 2025–2027, Sicarbtech is enhancing the Silicon Carbide Fluxing Silicon Additive for Electric Arc Furnace Bath Conditioning at High Temperature with coatings that shift dissolution onset based on measured slag carry-over and bath temperature, effectively “timing” silicon release to plant rhythm. AI-assisted dosing curves will read oxygen activity and arc stability indices to pre-empt turbulence, while localized production lines—enabled through technology transfer—will let Pakistani mills iterate particle size distributions and coating recipes quickly as scrap mix and power profiles evolve. The direction of travel is clear: tighter integration of materials, sensors, and control loops to turn EAF flats into repeatable, low-risk events.

Common questions and expert answers

How is the Silicon Carbide Fluxing Silicon Additive for Electric Arc Furnace Bath Conditioning at High Temperature different from standard SiC?

It is formulated for high-temperature EAF windows with a flux-active coating that improves wetting at the slag-metal interface, accelerating oxygen control and stabilizing foam while delivering high silicon absorption.

When should we add the Silicon Carbide Fluxing Silicon Additive for Electric Arc Furnace Bath Conditioning at High Temperature in the EAF cycle?

Most plants add at the onset of flat bath or during early refining. Short flats favor 0–3 mm for rapid response; longer flats can layer 3–10 mm for sustained release. Oxygen signals help refine timing.

Will the Silicon Carbide Fluxing Silicon Additive for Electric Arc Furnace Bath Conditioning at High Temperature affect slag basicity?

The coating is designed to cooperate with your flux plan rather than dominate it. With proper coordination, basicity and viscosity remain within target bands while foam stability improves.

Can the Silicon Carbide Fluxing Silicon Additive for Electric Arc Furnace Bath Conditioning at High Temperature reduce aluminum wire usage?

Yes. By taking on primary deoxidation and silicon provision at the bath, many shops trim late aluminum wire by 8–12 percent, which also lowers alumina-related risks downstream.

How does Sicarbtech ensure consistency for the Silicon Carbide Fluxing Silicon Additive for Electric Arc Furnace Bath Conditioning at High Temperature?

Every lot is verified under Sicarbtech’s in-situ monitoring and traceability system for SiC content, free carbon/silicon, PSD, moisture, coating performance, and flowability, with batch IDs linked to shipping and ready for Level 2 integration.

Why Silicon Carbide Fluxing Silicon Additive for Electric Arc Furnace Bath Conditioning at High Temperature works for your operations

Because the EAF’s best minutes are the most unforgiving. Silicon Carbide Fluxing Silicon Additive for Electric Arc Furnace Bath Conditioning at High Temperature aligns silicon addition, oxygen control, and slag behavior with your flat-bath window, turning a noisy, correction-prone phase into a short, efficient step toward tap. In Pakistan’s mills—where energy costs bite and quality expectations rise—this is how you keep arcs quiet, heats on time, and casters calm.

Connect with specialists for custom solutions

Sicarbtech supports Silicon Carbide Fluxing Silicon Additive for Electric Arc Furnace Bath Conditioning at High Temperature with more than ten years of silicon carbide manufacturing expertise and Chinese Academy of Sciences–backed innovation. We develop custom SiC families across R-SiC, SSiC, RBSiC, and SiSiC, and we deliver technology transfer and factory establishment services to localize powder synthesis, classification, granulation, and coating in Pakistan. Our turnkey scope extends to enclosed silos, metering feeders, pneumatic lances, and Level 2 integration—closing the loop from material to melt. With deployments across over nineteen enterprises, we will design a no-cost pilot with clear KPIs—lower alloy cost per ton, improved silicon absorption, shorter flat-bath times, and longer sequence stability—so you can move from trial to standard practice quickly.

For a free consultation and a fast, data-backed proposal, contact:

Email: [email protected]

Phone/WhatsApp: +86 133 6536 0038

Article metadata

Last updated: 2025-09-15

Next review scheduled: 2025-12-15

Author: Sicarbtech Applications Engineering Team

Region focus: Pakistan (EAF operations; billets, bars, wire rod, flats)

Timeliness note: Content aligned to 2025 EAF conditioning practices, PEQS-aligned dust control, and closed-loop dosing integrations

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.