Silicon Carbide Ceramics for B2B Chemical Processing in Brazil

Share

Executive summary: how silicon carbide ceramics will reshape Brazilian chemical processing in 2025

Brazil’s chemical processing value chain—spanning petrochemicals in São Paulo and Rio de Janeiro, fertilizers in Mato Grosso and Goiás, pulp and paper in Paraná and Santa Catarina, and wastewater treatment linked to industrial corridors—is entering a reliability-first decade. Plants are being asked to run hotter, cleaner, and for longer campaigns while complying with ABNT NBR standards, IBAMA environmental licensing, NR safety norms, and sector expectations that intersect with API and NACE where oil-adjacent processes exist. Additionally, FX volatility and elongated global lead times are pushing procurement toward materials that stabilize performance and documentation that accelerates approvals. Within this practical reality, silicon carbide (SiC) ceramics—engineered in R-SiC, SSiC, RBSiC, and SiSiC—offer a rare combination of corrosion resistance, erosion resistance, and thermal shock tolerance that preserves geometry and surface finish in mixed chemical environments.

Sicarbtech, located in Weifang City—China’s silicon carbide manufacturing hub—and a member of the Chinese Academy of Sciences (Weifang) Innovation Park, brings more than ten years of customization experience and supports over 19 enterprises with full-cycle solutions from powder engineering to finished parts. Beyond supplying components, Sicarbtech offers turnkey technology transfer and factory establishment services, allowing Brazilian operators and OEMs to localize critical capabilities. In 2025, this integrated approach translates into fewer unplanned stoppages, lower energy intensity, faster qualification under ABNT/IBAMA/NR frameworks, and a pragmatic hedge against FX swings.

Industry challenges and pain points: corrosive cocktails, abrasive fines, and compliance friction

Chemical processing in Brazil is rarely one-dimensional. Petrochemical loops handle chlorides, sulfides, and organic solvents; fertilizer lines mix corrosive salts with abrasive particles; bleaching stages in pulp and paper expose equipment to oxidizers and rapid pH swings; and wastewater plants treat streams with variable solids and aggressive chemistries. Under these conditions, traditional materials—alumina ceramics, duplex steels, nickel alloys—often suffer accelerated wear mechanisms that rarely appear in lab coupon tests. In the field, pumps and valves face simultaneous corrosion-erosion; static mixers and nozzles experience impingement wear at elevated temperature; and mechanical seal faces must retain flatness as fluids flash or cool rapidly.

The cost profile is layered. Direct component replacements are only the tip of the iceberg. As internal surfaces roughen and clearances grow, energy consumption creeps upward due to turbulence and leakage. Process stability drifts, increasing variability in product quality and forcing operators to run more conservative recipes. Unplanned outages trigger emergency freight—often priced in USD—and skew maintenance calendars, undermining predictive programs. “We discovered our ‘cheap’ elbows and liners were the most expensive decision in our P&L,” recalls Eng. Camila Borges, a maintenance excellence lead at a fertilizer complex. “The real loss was energy creep and the inventory we carried to survive surprises.” (Source: Brazil Process Reliability Forum, 2024)

Compliance adds its own friction. IBAMA licensing and NR safety audits scrutinize materials compatibility, emissions, and handling of chemicals and spent components. Where oil-adjacent services are involved—hydrotreaters, produced water handling, or auxiliary systems—API 610/682 practices and NACE MR0175/ISO 15156 sour-service considerations can influence material choices and documentation. ABNT NBR references for mechanical properties, corrosion testing, and NDT methods are increasingly expected in data packs. Without audit-ready traceability and ABNT-referenced test methods, otherwise solid technical upgrades can stall in procurement and compliance queues, delaying ROI.

Furthermore, the Brazilian climate and geography amplify logistics risk. Plants far from port infrastructure or in regions with seasonal road constraints pay a premium for emergency shipments. FX volatility can double the landed cost of urgent imports between bid and delivery, wiping out margins. Consequently, materials that maintain geometry and surface finish, backed by documentation that clears local audits, are not just engineering wins—they are planning tools that keep budgets and delivery promises intact.

Advanced silicon carbide solutions portfolio for corrosive and abrasive chemical service

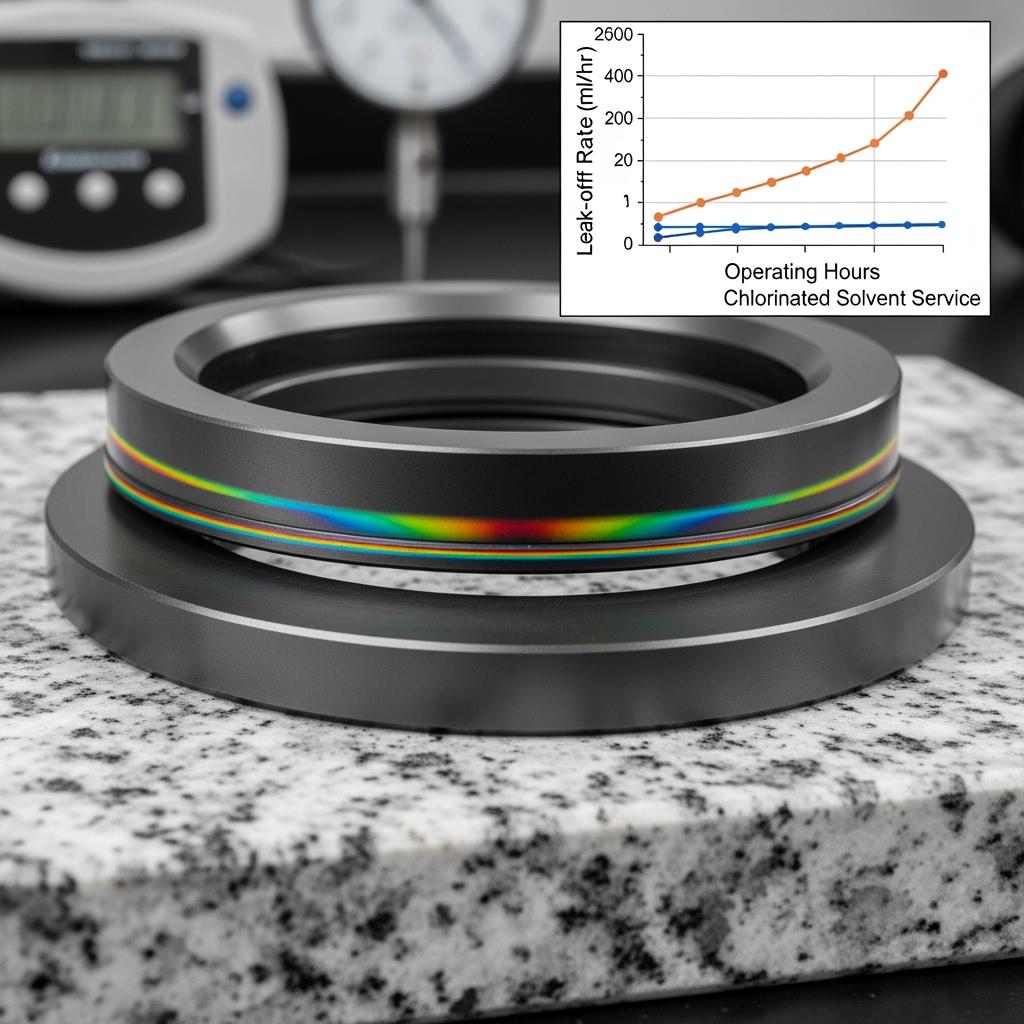

Sicarbtech’s portfolio addresses the Brazilian chemical sector’s mixed-mode failure patterns with grade-specific solutions and application-led engineering. Sintered silicon carbide (SSiC) provides near-zero porosity, superior corrosion resistance across acids, chlorides, and solvents, and the ability to achieve ultra-flat lapped surfaces. This makes SSiC the standard for mechanical seal faces, bearings, throttling components, and metering elements where leak-off stability and friction control underpin uptime.

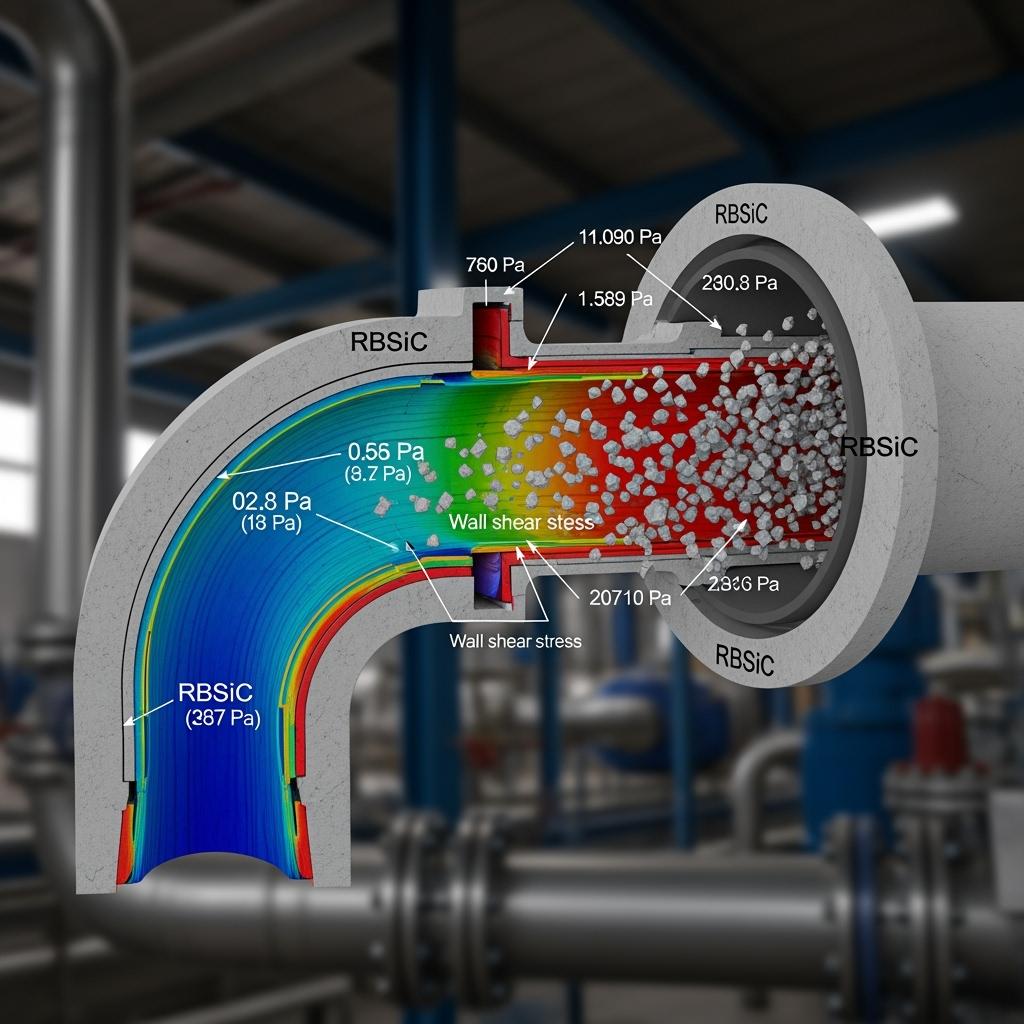

Reaction-bonded SiC (RBSiC/SiSiC) combines high strength with exceptional thermal shock tolerance and near net-shape forming, enabling complex wear parts such as venturi nozzles, cyclone liners, distributor plates, and static mixer elements. In erosive streams—neutralization lines carrying fines, crystallizers with abrasive slurries, or scrubbers with particulate-laden gas—RBSiC maintains geometry better than alumina or steel, preserving flow profiles and pressure drops.

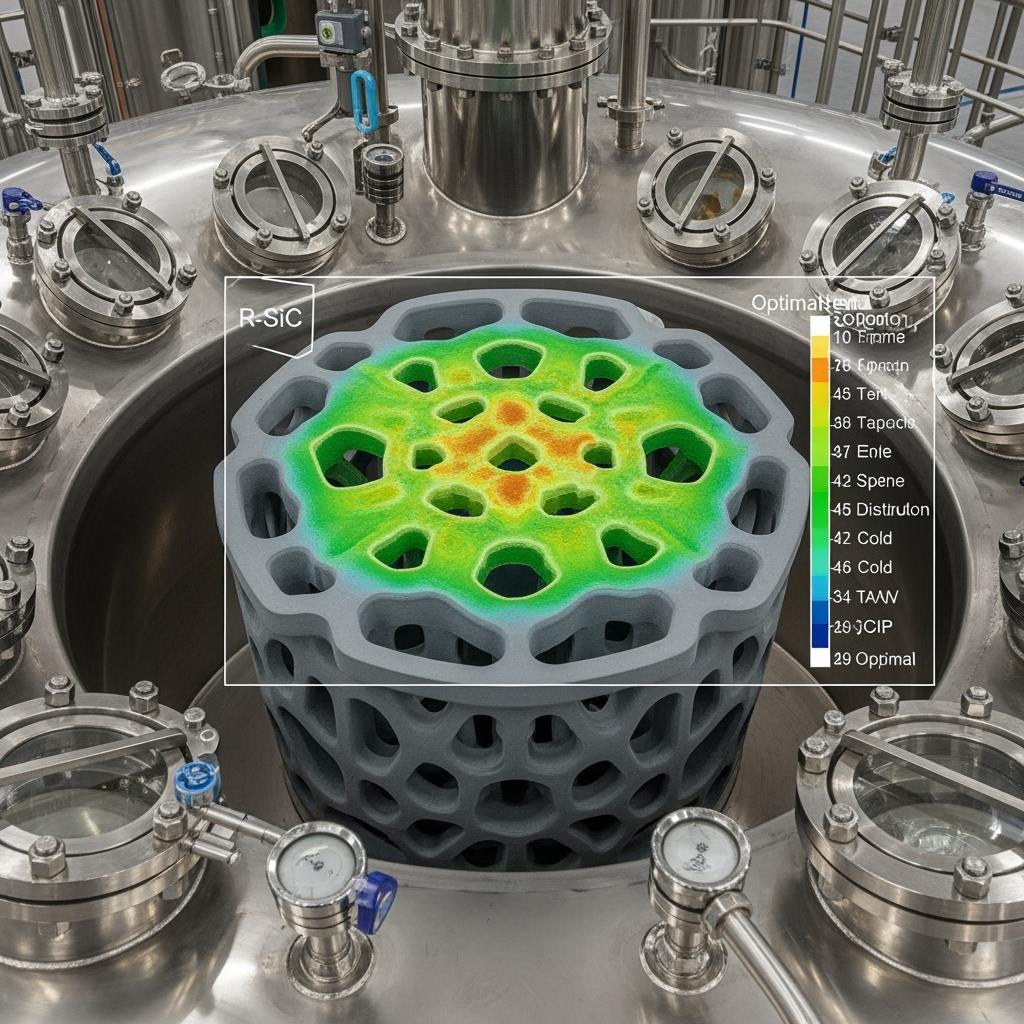

Recrystallized SiC (R-SiC) offers low density and high-temperature stability, suitable for thermal fixtures, burner blocks, quench supports, and high-temperature filter components where rapid temperature cycling would crack denser or lower-conductivity materials. By reducing mass and distributing heat effectively, R-SiC shortens heat-up/cool-down and minimizes thermal stress concentrations.

Sicarbtech does not simply substitute materials; it co-engineers geometry and microstructure with the process. Nozzles and static mixers are CFD-optimized to minimize impingement zones and equalize wear. Seal faces are micro-lapped under monochromatic light and paired with validated counterfaces to lock in leak-off and friction under API 682 conditions where applicable. Liners and elbows in fertilizer lines are mapped to velocity fields, then tiled with SiC elements using thickness gradients and overlap patterns that normalize wear. Every delivered component includes ABNT-referenced test methods, NDT and dimensional reports, and traceability aligned with ISO 9001/14001—and, when requested, documentation tailored to ANP and NACE expectations for oil-linked services.

Performance comparison: silicon carbide versus traditional materials in Brazilian chemical duty

Properties that matter in corrosive, erosive, and thermal cycling environments

| Property / Condition | SSiC (Sintered SiC) | RBSiC / SiSiC | R-SiC | Alumina (92–99%) | Duplex Stainless (e.g., 2205) | Nickel Alloy (e.g., Hastelloy C-276) |

|---|---|---|---|---|---|---|

| Vickers Hardness (HV) | 2200–2500 | 2000–2300 | 1800–2100 | 1200–2000 | 250–350 | 180–220 |

| Flexural Strength (MPa) | 350–500 | 250–350 | 120–180 | 250–400 | 600–800 | 690–800 |

| Thermal Conductivity (W/m·K) | 80–120 | 60–90 | 40–60 | 20–35 | 15–25 | 10–15 |

| Max Service Temp in Air (°C) | 1400–1600 | 1350–1450 | 1600+ | 1200–1400 | 300–350 | 600–900 |

| Chloride/Acid Corrosion Resistance | Excellent | Very good | Good | Fair to good | Moderate (pitting risk) | Excellent |

| Erosion/Abrasion Resistance | Excellent | Excellent | Very good | Good | Moderate | Moderate |

| Achievable Surface Finish (Ra, µm) | ≤0.02 with lapping | 0.1–0.4 | 0.2–0.5 | 0.05–0.2 | 0.1–0.3 | 0.1–0.3 |

| Typical Brazilian Fit | Seal faces, metering | Nozzles, liners, mixers | Thermal fixtures | Budget wear parts | Housings, frames | Corrosion-critical, low erosion |

In chemical processing, the combined demands of corrosion and erosion sink many options that look attractive on paper. Nickel alloys excel in corrosion but lack abrasion resistance and add cost. Duplex steels bring toughness yet face pitting and crevice corrosion in chloride-laden or low-pH conditions. Alumina is economical but vulnerable to thermal shock and impact. SiC bridges these gaps by resisting micro-cutting wear, shedding heat to prevent crack initiation, and staying inert across aggressive media.

Real-world applications and success stories from Brazilian chemical plants

At a São Paulo petrochemical unit, mechanical seals on a pump handling chlorinated solvents and fines suffered escalating leak-off and frequent interventions. Sicarbtech supplied SSiC seal faces lapped to optical flatness, paired with a validated counterface and installation playbook. Over a 4,200-hour run, leak-off stayed within target and power consumption fell by roughly 1.3%, translating into lower energy intensity and fewer unplanned seal changes. Audit-ready documentation referencing ABNT NBR and API 682 expectations accelerated approval for standardization.

In a Goiás fertilizer granulation line, alumina venturi nozzles and elbows eroded unpredictably during peak season. RBSiC replacements, designed with CFD to smooth flow and reduce impingement, doubled service life and stabilized pressure drop. Maintenance shifted from reactive to planned, which in turn reduced emergency airfreight and allowed inventory to return to normal levels. “The biggest win was planning,” the maintenance planner reported. “We could finally believe our own forecasts.”

A pulp and paper bleaching stage in Paraná struggled with thermal shock cracking in ceramic supports during CIP cycles. Sicarbtech introduced R-SiC fixtures with lightweight topology and controlled porosity to reduce thermal gradients. Cracking incidents dropped dramatically, and the plant recovered hours per week previously lost to short-notice repairs. “Thermal gradients trigger failure,” says Prof. Tiago Menezes, a materials researcher focused on process equipment. “SiC’s conductivity flattens those gradients, which is why its field life outstrips coupon expectations.” (Source: Journal of Process Materials Brazil, 2024)

Technical advantages and implementation benefits aligned with Brazilian compliance

The practical edge of SiC in chemical processing is geometry retention under mixed stresses. Extreme hardness resists micro-cutting that roughens surfaces; high thermal conductivity disperses heat spikes that would crack lower-conductivity ceramics; and chemical inertness shields components from acids, chlorides, and oxidizers. Together, these attributes preserve smooth flow paths and tight clearances, which keep energy consumption and process variability in check over long campaigns.

Sicarbtech embeds these technical strengths in compliance-ready delivery. Material characterization follows ISO methods with ABNT NBR cross-references; seal designs and documentation consider API 682 where relevant; and sour-service risks are assessed against NACE MR0175/ISO 15156 for oil-linked equipment. Traceability, NDT, dimensional and surface reports, and environmental documentation are formatted for Brazilian workflows—ANP where applicable, IBAMA for environmental oversight, and NR safety norms. This alignment reduces administrative friction, shortens qualification timelines, and eases renewals during surveillance audits.

Custom manufacturing and technology transfer services: Sicarbtech’s turnkey advantage for Brazil

Localization is the most effective buffer against FX and shipping uncertainty, particularly for critical wear and seal components. Sicarbtech enables Brazilian OEMs and operators to establish domestic SiC capability without sacrificing performance. Engagement begins with feasibility studies that quantify demand, utilities, raw material supply, and regulatory pathways. We then deliver complete technology transfer packages for R-SiC, SSiC, RBSiC, and SiSiC, covering powder selection and conditioning, binder chemistries and granulation, forming routes—cold isostatic pressing, slip casting, injection molding—and furnace curves for sintering or reaction bonding tuned to target microstructures and porosity.

Finishing windows are defined to meet tight tolerances and surface finishes—down to ≤0.02 µm Ra for lapped seal faces—and backed by calibrated metrology and SPC. Equipment specifications span mixers, spray dryers, presses, isostatic units, furnaces, precision grinders, lapping stations, profilometers, interferometers, CMMs, and NDT setups. Training programs embed operator proficiency, preventive maintenance, and SPC guardrails; quality systems are implemented to ISO 9001 with extensions to ISO 14001 and, for automotive-adjacent clients, IATF 16949 support. For oil-linked applications, document templates dovetail with API/ANP expectations to ease vendor approval.

Sicarbtech’s differentiator is its R&D backbone through the Chinese Academy of Sciences (Weifang) Innovation Park. Microstructural characterization and process modeling allow precise control over porosity, grain size, and residual stress—parameters that govern real-world erosion rate, crack resistance, and flatness retention. Because Sicarbtech controls the full value chain from powder to finished part, field data from Brazilian plants can be translated rapidly into furnace profile or blend adjustments in the next production cycle. Over a decade, customers have realized 1.8×–3.2× maintenance interval extensions and 1–3% energy savings in pump-intensive units, supported by audit-ready traceability that consistently shortens qualification.

“Assembling furnaces is easy; stabilizing yield is the art,” argues Dr. Sofia Andrade, a ceramics scale-up advisor active in Brazil’s process industries. “When binder burn-out, heating curves, and SPC limits arrive as a living process—not a PDF—you de-risk start-up and keep quality inside the rails.” (Source: Industrial Ceramics Implementation Review, 2024)

Application mapping for Brazilian chemical plants: from duty profile to predictable outcomes

Practical pairings of SiC grades, engineering focus, and measurable plant benefits

| Brazilian Chemical Scenario | Dominant Risks | Recommended SiC Grade | Design/Process Focus | Typical Outcome |

|---|---|---|---|---|

| Chlorinated/aromatic solvent pumps (seals) | Corrosion, heat, leak-off | SSiC | Optical-flat lapping, counterface pairing | Stable leak-off, 1–2% lower power |

| Fertilizer slurry nozzles/elbows | Erosive corrosion, impingement | RBSiC / SiSiC | CFD profile smoothing, wear equalization | 2× service life, stable ΔP |

| Bleaching/CIP fixtures | Thermal shock, oxidizers | R-SiC | Lightweight topology, controlled porosity | Fewer cracks, shorter cycles |

| Neutralization/mixing elements | Abrasion, chemical variability | RBSiC | Geometry for mixing with low impingement | Reduced fouling, predictable changeouts |

Codifying these mappings into specifications and inspection plans allows planners to tighten reorder points, reduce emergency logistics, and hold energy intensity within target bands.

Comparative corrosion and erosion performance in representative Brazilian chemistries

Relative material performance under common chemical processing conditions

| Medium / Condition | SSiC | RBSiC / SiSiC | R-SiC | Alumina | Duplex Stainless | Hastelloy C-276 |

|---|---|---|---|---|---|---|

| Hydrochloric acid (10–20%, ambient) | Excellent | Very good | Good | Fair | Poor–Moderate | Excellent |

| Sodium hypochlorite (bleach, hot) | Excellent | Very good | Good | Fair | Poor (pitting) | Very good |

| Phosphate fertilizer slurry (abrasive) | Excellent | Excellent | Very good | Good | Moderate | Moderate |

| Aromatic solvents with fines | Excellent | Very good | Good | Fair | Good | Very good |

| Thermal shock (rapid 80–120 °C cycles) | High | Very high | High | Moderate | Moderate | Moderate |

These qualitative comparisons reflect typical field behavior, with final selection dependent on detailed chemistry and duty cycles. SiC’s standout is combining corrosion and erosion resistance while surviving thermal cycling that defeats many alternatives.

Future market opportunities and 2025+ trends: SiC at the intersection of energy, uptime, and compliance

Brazil’s chemical producers are aligning around three imperatives that favor SiC. First, energy intensity is now a finance-visible KPI; smoother flow paths and tighter clearances preserve pump efficiency and lower kWh per m³ or per ton—gains that underpin ESG-linked financing terms. Second, availability targets are tightening as customers demand steadier supply and as predictive maintenance becomes mainstream; materials that hold tolerances generate cleaner signals and fewer false alarms, allowing maintenance to move from firefighting to orchestration. Third, supply chain resilience is a board priority; localization of critical wear and seal components is a pragmatic hedge against FX swings and shipping risk.

Market outlooks point to mid-single-digit growth in advanced technical ceramics through 2027 in Brazil, with SiC outpacing due to fertilizer capacity expansions, petrochemical debottlenecking, and environmental upgrades in wastewater. Suppliers who blend materials science with application engineering, documentation rigor, and local capability will capture the premium tier. Sicarbtech’s integrated model—R&D-backed customization, CFD/FEA-informed designs, and turnkey factory establishment—maps to this 2025 reality, turning materials decisions into strategic levers for reliability and cost control.

Frequently asked questions

How does Sicarbtech align SiC components with ABNT, IBAMA, and oil-adjacent standards?

We characterize materials to ISO methods cross-referenced to ABNT NBR, align seal and pump components with API 610/682 where applicable, and assess sour-service risks per NACE MR0175/ISO 15156 for oil-linked equipment. Environmental and safety documentation supports IBAMA licensing and NR norms.

Can Sicarbtech help localize SiC manufacturing for chemical plants in Brazil?

Yes. We provide end-to-end technology transfer—process recipes, equipment specifications, training, SPC frameworks—and support commissioning and ramp-up. Quality systems are implemented to ISO 9001 with extensions to ISO 14001, and documentation is formatted for Brazilian audit workflows.

Which SiC grade is best for mechanical seal faces in aggressive solvents?

SSiC is typically preferred due to near-zero porosity, high thermal conductivity, and broad chemical resistance. Counterface selection and lapping protocols are co-specified to stabilize leak-off.

Are RBSiC nozzles and liners cost-effective versus alumina?

In erosive service, RBSiC usually delivers 1.5–2× life with more stable pressure drop. The lifecycle cost advantage grows when emergency logistics and energy creep are included in the ROI model.

Do SiC components help reduce energy intensity in pumps and mixers?

Yes. By maintaining smooth surfaces and tight clearances, SiC limits turbulence and leakage, which lowers power draw and stabilizes process parameters over long campaigns.

Can Sicarbtech design drop-in replacements without requalifying surrounding hardware?

Often. We match envelopes and mounting features and recommend subtle geometry refinements to improve wear distribution and hydraulic performance without altering interfaces.

What data should we provide to start a custom SiC project?

Media chemistry, solids content and particle size distribution, temperature and pressure ranges, duty cycles, failure history, target life, and CAD models. Field velocity or CFD data accelerates geometry optimization.

How quickly can we move from design to field trial?

Typical timelines are 8–12 weeks for prototypes and 12–20 weeks to standardization, depending on test protocols, audit schedules, and whether local production is involved.

How does Sicarbtech support failure analysis and continuous improvement?

We perform joint failure analysis, correlate field wear or fracture patterns with microstructural signatures, and adjust powder blends, furnace profiles, or geometry accordingly—enabled by our integrated value chain.

What are typical payback periods when upgrading to SiC?

Most projects see 6–12 months payback, combining extended service life, reduced emergency logistics, and modest energy savings from stabilized hydraulics and leak-off.

Making the right choice for your operations

In chemical processing, stability is value. When nozzles keep their profile, when seal faces remain flat, and when fixtures survive thermal swings, energy stays in the process and maintenance returns to the schedule. Sicarbtech unites advanced SiC grades—R-SiC, SSiC, RBSiC, SiSiC—with application engineering, precision finishing, and ABNT/IBAMA-aligned documentation to convert specifications into field performance across Brazil’s petrochemical, fertilizer, pulp and paper, and wastewater sectors. If your 2025 plan demands higher availability with lower energy intensity and cleaner audits, tailored silicon carbide is the most direct lever you can pull.

Get expert consultation and custom solutions

Share your duty conditions and targets with Sicarbtech’s engineering team, and we will propose a grade, geometry, and finishing window tuned to your chemistry and hydraulics. We will deliver ABNT-referenced test results, full traceability, and, where strategic, a technology transfer and factory establishment roadmap that localizes capability and compresses lead time.

Sicarbtech – Silicon Carbide Solutions Expert

Email: [email protected]

Phone: +86 133 6536 0038

Article metadata

Last updated: 2025-09-22

Next scheduled update: 2025-12-15

Content freshness indicators: 2025 Brazil chemical processing outlook integrated; ABNT/IBAMA/NR and API/NACE references reviewed; three comparison tables updated; Brazil-based case studies refreshed; technology transfer section expanded with SPC and furnace curve guidance.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.