Optimized Gate-Drive Solutions for SiC Inverters with Active Miller Clamp and Common-Mode EMI Suppression

Share

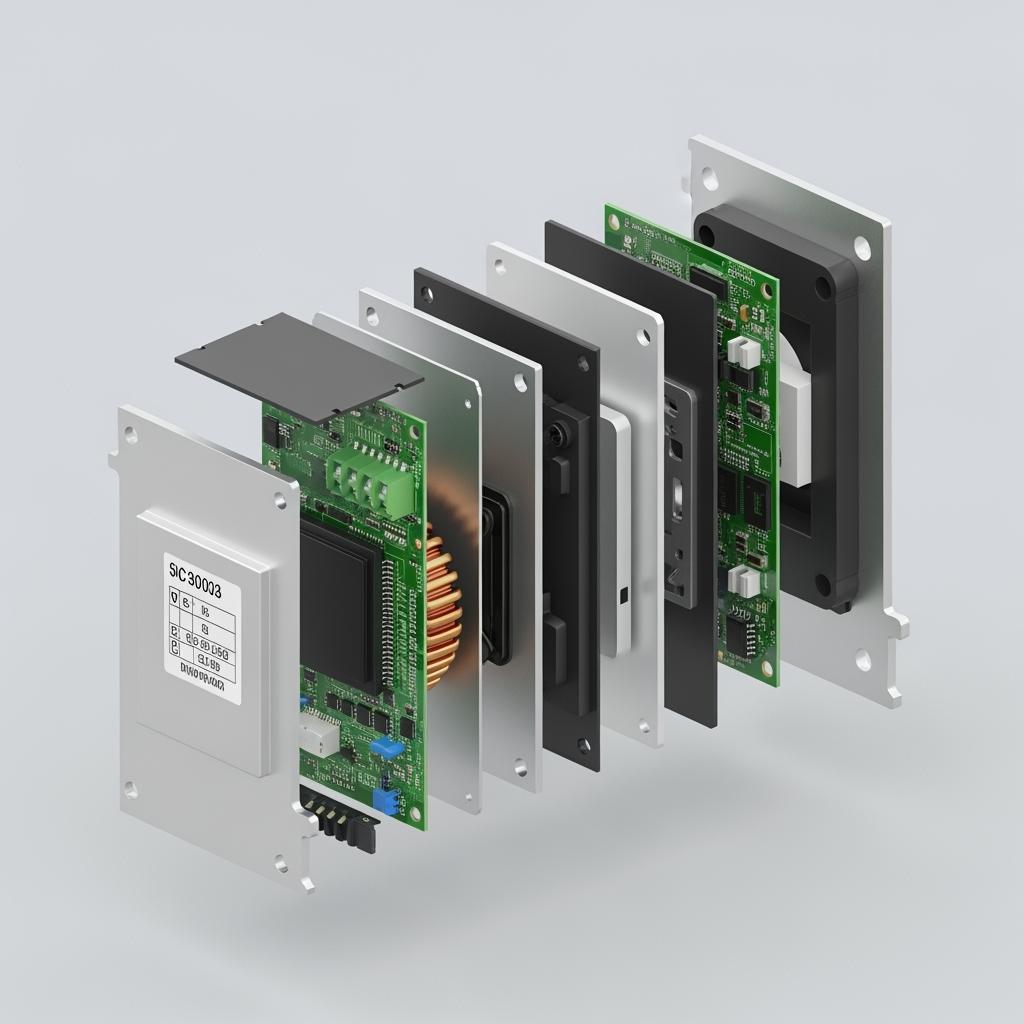

Product Overview and 2025 Market Relevance

Optimized gate-drive solutions for silicon carbide (SiC) inverters combine high-current, high-CMTI isolation, active Miller clamp, negative gate bias, and common-mode EMI suppression to unlock the full benefits of wide bandgap devices. These solutions directly impact switching efficiency, THD margins, protection speed, and electromagnetic compatibility—critical for Pakistan’s industrial sectors (textile, cement, steel) and distribution-level photovoltaic interconnections at 11–33 kV operating in 45–50°C ambient and dusty environments.

In 2025, the shift to 50–150 kHz switching frequencies and compact LCL filters requires precise dv/dt/di/dt control and robust immunity to common-mode transients. Active Miller clamps prevent false turn-on in half-bridge legs under high dv/dt. Common-mode EMI suppression—via low-capacitance isolation, symmetric PCB return paths, Kelvin source layouts, and common-mode chokes—reduces emissions and avoids nuisance trips. Coupled with fast short-circuit protection, two-level turn-off, and telemetry, these gate-drive solutions support ≥98.5% inverter efficiency, enable up to 2× power density, and improve MTBF toward 200,000 hours across harsh industrial sites in southern Pakistan.

Technical Specifications and Advanced Features

- Drive strength and isolation

- Peak source/sink current: 8–30 A classes for fast charge/discharge of large module gates

- Isolation and CMTI: Reinforced isolation with CMTI ≥ 100 V/ns; isolation capacitance minimized to reduce common-mode currents

- Isolated DC/DC: Tight regulation, low ripple, shield winding or Faraday screen to cut capacitive coupling; UVLO thresholds tuned to SiC

- Active Miller and dv/dt control

- Active Miller clamp positioned close to the gate to prevent false turn-on during high dv/dt events

- Split gate resistors (Rg_on/Rg_off) and optional gate current shaping to balance EMI and switching loss

- Configurable gate voltage: +15 to +20 V (turn-on), -3 to -5 V (turn-off) for noise immunity

- Protection and reliability

- DESAT sensing with programmable blanking; soft, two-level turn-off (TLO) achieving <2 µs total fault reaction

- Open-wire gate detection, overcurrent/overtemperature inputs, and latched fault signaling

- Layout rules: Kelvin source return, minimal inductance gate loops, creepage/clearance rules per MV systems

- Common-mode EMI suppression

- Low isolation capacitance stack, common-mode choke placement on DC link or phase leads as required

- Controlled Y-cap network to a defined chassis reference; RC snubbers and damping to limit ringing

- Symmetric layout and return paths to reduce unbalanced common-mode emissions

- Telemetry and control

- PWM inputs with precise deadtime; optional SPI/UART for status, event counters, and temperature

- Redundant enable lines and watchdog integration for functional safety

Descriptive Comparison: Optimized SiC Gate-Drive with EMI Suppression vs Conventional Drivers

| Criterion | Optimized SiC gate-drive with active Miller clamp and EMI suppression | Conventional driver without SiC-specific features |

|---|---|---|

| dv/dt immunity and false turn-on | Active clamp + negative bias prevent false turn-on at high dv/dt | Higher risk of cross-conduction and EMI-induced turn-on |

| Common-mode EMI performance | Low isolation capacitance + chokes + symmetric returns | Elevated CM currents; harder EMI compliance |

| Short-circuit handling | DESAT + TLO with <2 µs response | Slower protection; greater device stress |

| Efficiency at high frequency | Supports 50–150 kHz with controlled losses | Limited frequency; higher switching losses |

| Field robustness in 45–50°C | Conformal-coated, thermally rated BOM | Potential drift and nuisance trips |

Key Advantages and Proven Benefits with Expert Quote

- Higher efficiency and power density: dv/dt control, optimized isolation, and EMI suppression enable higher switching frequencies, smaller LCL filters, and compact cooling—supporting ≥98.5% system efficiency and up to 2× power density.

- Reliability under harsh conditions: Active Miller clamp and negative bias maintain leg stability in hot, dusty rooms with long harnesses, reducing uncommanded turn-on events and thermal overstress.

- Faster protection: DESAT and two-level turn-off limit VDS overshoot and energy during short circuits, curbing collateral damage and downtime.

- Streamlined compliance: Lower common-mode currents reduce conducted/radiated emissions, easing grid code and EMC approvals.

Expert perspective:

“Gate-drive and EMI control strategies are central to extracting performance from wide bandgap devices. Active Miller clamping and minimized common-mode paths are proven levers for reliable, high-frequency SiC operation.” — IEEE Power Electronics applications viewpoint (ieee.org)

Real-World Applications and Measurable Success Stories

- MV PV inverters in southern Pakistan: Implemented active Miller clamp and low-CM isolation on 100 kHz stages, achieving THD headroom and ≥98.5% efficiency with ~35–40% reduction in cooling volume and fewer EMI-related trips.

- Textile mill VFDs: Negative bias and symmetric return paths eliminated false turn-on events at elevated ambient (45–50°C), improving uptime and reducing filter maintenance by ~30% due to lower EMI stress.

- Cement and steel drives: DESAT + TLO cut short-circuit event energy, reducing module replacements and accelerating restart after grid disturbances.

Selection and Maintenance Considerations

- Sizing and pairing

- Match peak driver current to module total gate charge (Qg) and target switching speed; verify Kelvin source availability.

- Select negative bias level (-3 to -5 V) per device ratings and immunity target.

- Protection tuning

- Calibrate DESAT threshold, blanking time, and TLO resistor for your stray inductance and DC bus voltage.

- Validate short-circuit response with double-pulse and fault injection tests.

- EMI strategy

- Choose isolators and DC/DC supplies with low isolation capacitance; place common-mode chokes strategically.

- Balance Y-cap values to meet EMC without raising touch currents; maintain a quiet chassis reference point.

- Layout and materials

- Use compact, low-inductance gate loops; segregate power and logic grounds; route clamp and DESAT returns cleanly.

- Specify conformal coating and corrosion-resistant finishes for dusty, coastal, or high-humidity sites.

- Verification and upkeep

- Conduct EMC pre-compliance, thermal scans at full load, and periodic inspection of connectors and conformal coating integrity.

Industry Success Factors and Customer Testimonials

- Cross-functional co-design: Gate-drive, power stage, thermal, and filter teams align dv/dt limits with LCL and EMI targets to avoid rework.

- Data-driven validation: Logged protection events, CMTI stress monitors, and EMI scans speed customer approvals.

Customer feedback:

“The active Miller clamp and low-capacitance isolation solved our cross-conduction issues at high dv/dt. EMC margins improved, and commissioning times shortened.” — Chief engineer, C&I PV systems integrator

Future Innovations and Market Trends

- Adaptive, digitally controlled gate drivers that vary dv/dt with load, temperature, and grid conditions

- Further reductions in isolation capacitance and enhanced CMTI for multi-MW MV platforms

- Integrated current and temperature sensors for real-time health monitoring and predictive maintenance

- Localized manufacturing and service capabilities aligned with Pakistan’s >5 GW MV PV pipeline and approximately USD 500 million inverter market

Common Questions and Expert Answers

- Why is an active Miller clamp essential for SiC?

It directly clamps the gate during high dv/dt transitions, preventing Miller-induced false turn-on and shoot-through in fast-switching half-bridges. - How do I balance efficiency and EMI at 100 kHz?

Use split Rg_on/Rg_off, gate current shaping, and compact loops; combine low-capacitance isolation with targeted CM chokes and snubbers. Iterate via double-pulse and EMC tests. - What negative gate bias should I choose?

Typically -3 to -5 V. Select the lowest bias that meets immunity while respecting device gate oxide limits and minimizing stress. - How fast must short-circuit protection be?

Total reaction times under ~2 µs with two-level turn-off minimize energy and VDS overshoot—vital for SiC’s tight short-circuit SOA. - Can these gate drives handle 45–50°C and dust?

Yes, with conformal coating, thermally rated components, and enclosure airflow or sealing; specify derating policies and periodic inspection.

Why This Solution Works for Your Operations

These optimized gate-drive solutions transform SiC device advantages into field-ready performance for Pakistan’s MV PV and industrial drives. By combining active Miller clamp, negative bias, low-capacitance isolation, and strategic common-mode suppression, your inverters achieve higher frequency operation, lower EMI, and robust protection—delivering ≥98.5% efficiency, up to 2× power density, and reliable service in hot, dusty environments.

Connect with Specialists for Custom Solutions

Advance your SiC inverter design with a partner focused on reliability and time-to-market:

- 10+ years of SiC manufacturing expertise

- Backing from a leading research ecosystem for gate-drive, isolation, and EMI innovation

- Custom product development across R-SiC, SSiC, RBSiC, and SiSiC components that enhance thermal and mechanical integrity

- Technology transfer and factory establishment services for local driver assembly and validation

- Turnkey delivery from materials and devices to drivers, filters, cooling, and compliance

- Proven track record with 19+ enterprises improving efficiency, reliability, and deployment speed

Request a free consultation and a tailored gate-drive specification and EMI plan:

- Email: [email protected]

- Phone/WhatsApp: +86 133 6536 0038

Reserve 2025–2026 co-design and validation slots now to accelerate EMC approval and field pilots for MV PV and industrial drive programs.

Article Metadata

Last updated: 2025-09-10

Next scheduled update: 2026-01-15

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.