Industrial SiC Power Module Burn-In and Reliability Test Platforms (HTRB/HTGB, Power Cycling) for QA

Share

Product Overview and 2025 Market Relevance

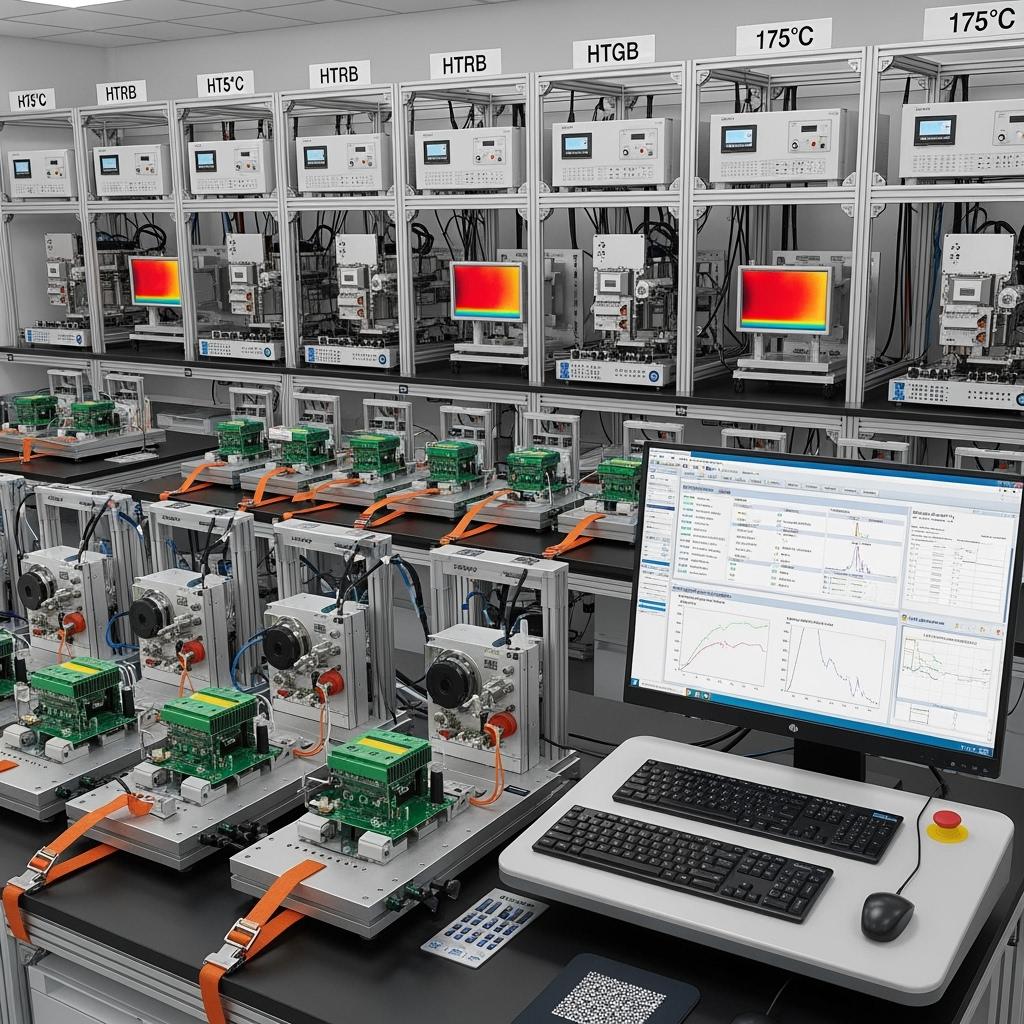

Industrial burn-in and reliability test platforms purpose-built for silicon carbide (SiC) power modules are critical to deliver dependable performance in Pakistan’s textile, cement, steel, and emerging industrial sectors. These platforms execute high-temperature reverse bias (HTRB), high-temperature gate bias (HTGB), and power cycling with precise thermal and electrical stress control, ensuring that SiC modules achieve long lifetimes under harsh heat, dust, and vibration.

In 2025, plants in Punjab and Sindh are accelerating upgrades to SiC-based rectifiers, inverters, DC drives, and furnace converters. To validate long-term reliability and reduce warranty risk, quality assurance workflows require standardized screening and life testing aligned with IEC and JEDEC practices. SiC reliability platforms help manufacturers and integrators screen out infant mortality, characterize wear-out mechanisms, and certify modules with junction temperatures up to 175°C, power densities >8 kW/L, and thermal resistance <0.2°C/W. The result is >50% failure-rate reduction in the field, >98% conversion efficiency maintained over life, and service intervals extended to once every two years—directly supporting 2–3 year ROI models and ISO 50001/14001 objectives.

These platforms are engineered for high throughput and data integrity, with automated test scheduling, environmental enclosures, and integration to LIMS/MES systems. Detailed reports support IEC 62477-1 (safety of power electronic equipment), IEC 61000 (EMC test environments), and IEC 60747 (semiconductor devices) documentation requirements for local acceptance.

Technical Specifications and Advanced Features

- Test stress capabilities

- HTRB: Up to device maximum rated reverse voltage (≥1700 V), chamber temperatures up to 175°C, leakage current logging down to nA resolution

- HTGB: Positive and negative gate bias up to ±30 V, high-temperature operation with threshold voltage drift monitoring

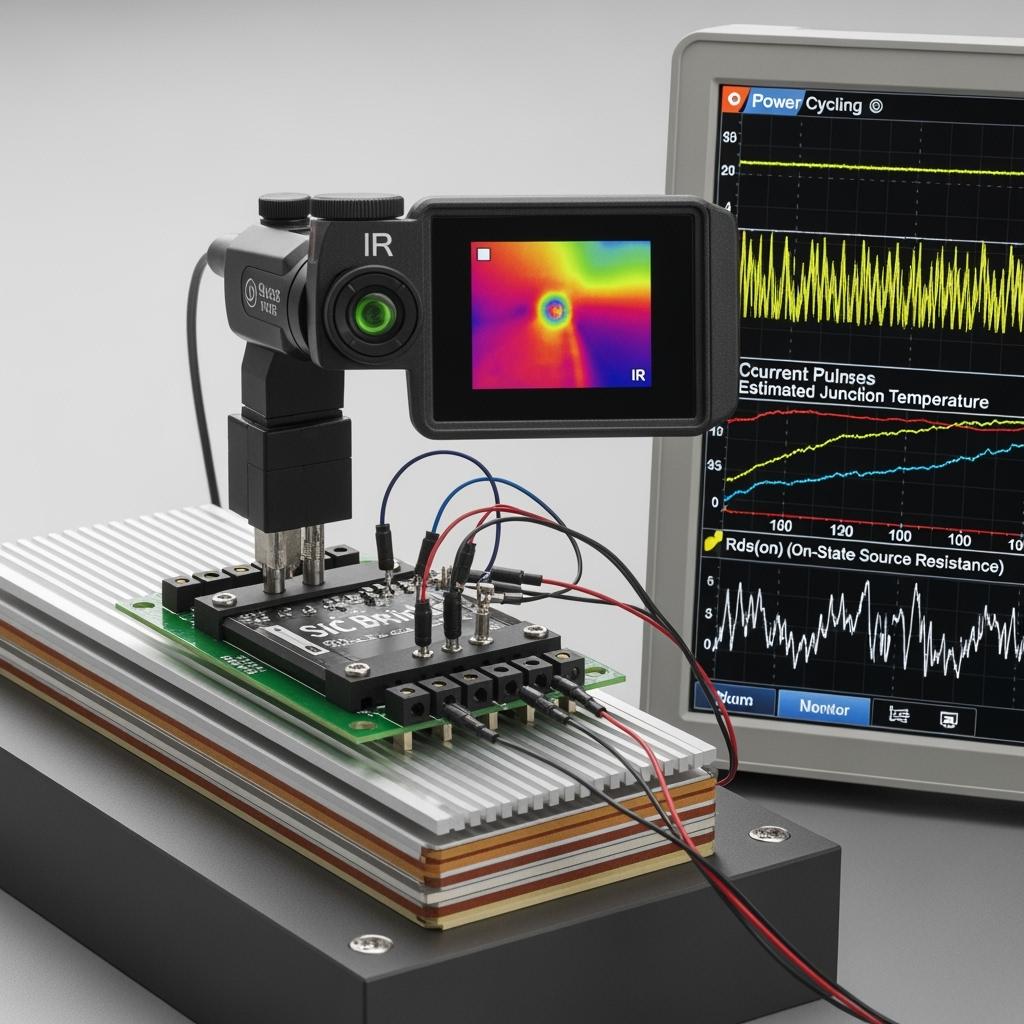

- Power cycling: Programmable current pulses and duty cycles; ΔTj from 40–100 K; cycle counts exceeding 1e6 with real-time thermal impedance extraction

- Measurement and analytics

- Parameters: Leakage current (IR), threshold voltage (Vth), on-resistance (Rds(on)), forward voltage (Vf), dynamic Rds(on), short-circuit withstand behavior, thermal impedance Zth(j-c)

- Sensing: 4-wire Kelvin connections, high-bandwidth current/voltage probes, fiber-isolated sensors, NTC/RTD arrays for junction and case temperature estimation

- Data: High-frequency sampling, automated outlier detection, Weibull/Arrhenius life modeling, Coffin–Manson analysis for wire-bond/sinter fatigue

- Thermal and mechanical control

- Chambers: 25–175°C programmable, controlled humidity options for condensation avoidance

- Cooling: Liquid-cooled plates with calibrated flow and coolant quality monitoring; fan-cooled fixtures for air-based cycling

- Fixtures: Low-inductance laminated busbars, interchangeable DUT plates for half-bridge, full-bridge, and rectifier modules

- Automation and integration

- Orchestration: Recipe-driven tests, batch scheduling, barcode/RFID sample tracking

- Connectivity: OPC UA/MQTT APIs to MES/LIMS/SCADA; secure remote access with role-based permissions

- Reporting: IEC-aligned templates, raw waveform data export, audit trails for QA and customer acceptance

- Safety and compliance

- Interlocks: Door and thermal interlocks, HV discharge, ground fault monitoring, E-stop

- EMC: Shielded racks and filtered interfaces to maintain IEC 61000 test environment integrity

- Documentation: Supports IEC 62477-1, IEC 61000, IEC 60747 reporting needs and ISO 50001/14001 programs

Reliability Screening Benefits Compared to Minimal QA Approaches

| Quality outcome | SiC Burn-In and Reliability Platforms (HTRB/HTGB, Power Cycling) | Minimal Screening/Test Bench Only |

|---|---|---|

| Field failure rate | Reduced by >50% through infant mortality screening and life testing | Higher early-life failures and warranty claims |

| Parameter stability over life | Controlled drift of Vth, Rds(on), Vf, and leakage; verified Zth(j-c) | Unverified parameter drift; unknown thermal margins |

| Thermal fatigue robustness | Quantified via power cycling (ΔTj 40–100 K, >1e6 cycles) | No fatigue data; unpredictable wear-out |

| Data integrity and traceability | Automated logs, audit trails, MES/LIMS integration | Manual records; limited traceability |

| Compliance and acceptance | IEC/JEDEC-aligned reports for customer QA | Additional testing required by customers |

| Time to qualification | Faster sign-offs with standardized recipes | Longer trials and repeated re-tests |

Key Advantages and Proven Benefits with Expert Insight

- Predictable lifetime: Power cycling validates solder/sinter interfaces, bond wires, and baseplate reliability under realistic ΔTj.

- Stable performance: HTRB/HTGB screens for leakage and gate drift to keep efficiency >98% and maintain safe switching margins.

- Faster customer acceptance: Standardized data packs support industrial audits and reduce project lead times.

- Lower total cost of ownership: Screening prevents costly downtime in cement kilns, steel mills, and mining conveyors.

Expert quote:

“Reliability qualification for SiC must include high-temperature bias and power cycling to capture unique failure mechanisms and ensure stable operation at elevated junction temperatures.” — IEEE Power Electronics Magazine, Reliability of Wide Bandgap Devices (2023)

Authority reference:

“Industrial adoption of SiC through 2025 is propelled by proven system-level OPEX savings—anchored by robust qualification and reliability data.” — Yole Group, Power SiC Market Monitor (2024)

Real-World Applications and Measurable Success Stories

- Cement plant rectifier upgrades

- Outcome: Modules screened with HTRB/HTGB and ΔTj=60 K power cycling showed zero early-life failures over the first 12 months post-install. Chain efficiency sustained at 98.1%, saving >120,000 USD annually and enabling continuous 8,760-hour operation in a Karachi clinker workshop.

- Steel mill inverter modernization

- Outcome: Reliability-qualified SiC modules reduced drive trips during thermal peaks; maintenance intervals extended to 24 months; cooling skid footprint reduced by ~35%.

- Mining conveyor and crusher drives

- Outcome: Predictive analysis from power cycling data aligned with field thermal profiles; unplanned downtime cut significantly due to early detection of outliers in Rds(on) drift.

Selection and Maintenance Considerations

- Test coverage definition: Align HTRB/HTGB stress levels to device ratings and application mission profiles (temperature, duty cycle, overloads).

- ΔTj targeting: Choose 40–100 K based on expected field thermal swings; correlate with lifetime models for solder/sinter and bond wires.

- Fixture design: Ensure low inductance and proper Kelvin sensing; validate thermal uniformity across DUT.

- Data and cybersecurity: Implement secure remote access, encrypted databases, and role-based permissions; maintain calibration records for sensors and supplies.

- Maintenance schedule: Quarterly calibration of HV sources and sensors; semi-annual coolant quality checks; annual chamber validation.

Industry Success Factors and Customer Testimonials

- Success factors: Upfront mission-profile derivation, recipe standardization, golden-sample baselines, and integrated MES reporting.

- Customer voice: “The SiC burn-in and cycling reports shortened our approval cycle and minimized early failures in high-torque drives.” — QA Director, integrated steel producer in Punjab.

Future Innovations and 2025+ Market Trends

- Higher-voltage readiness: Platforms evolving to 3.3 kV-class devices with extended HV isolation and precision leakage measurement.

- Digital twins: Closed-loop linkage between field telemetry and lab stress recipes for continuous reliability improvement.

- Local capability development: Technology transfer and regional test centers in Pakistan to cut logistics time and enable rapid pilot runs.

- Sustainability alignment: Test energy metering and optimization to support ISO 50001 and reduce lab energy intensity.

Industry outlook:

“Linking qualification data to operational analytics is the next frontier—turning reliability testing into a predictive maintenance asset.” — International Energy Agency, Technology Perspectives (2024)

Common Questions and Expert Answers

- Which tests are essential for SiC module qualification?

- HTRB for leakage stability, HTGB for gate integrity, and power cycling for thermo-mechanical fatigue. Complement with HTRB+surge and short-circuit robustness where applicable.

- How do we set ΔTj for power cycling?

- Base it on measured field thermal swings. Typical heavy-industry values are 40–80 K; use up to 100 K for accelerated life models.

- Can platforms handle parallel-module testing?

- Yes. Multi-bay systems support synchronized cycling and independent parameter logging per DUT with barcode tracking.

- What documentation is delivered?

- IEC-aligned reports including test conditions, parametric drift plots, failure analysis summaries, and traceable calibration certificates.

- Typical lead times for test campaigns?

- Standard screening: 2–4 weeks depending on sample count and recipe length; extended life tests: 6–10 weeks.

Why This Solution Works for Your Operations

Deploying SiC burn-in and reliability test platforms ensures that power modules integrated into rectifiers, inverters, DC drives, and furnace converters meet the performance and longevity needed for Pakistan’s demanding industrial environments. By screening out early failures, validating lifetime under real ΔTj, and documenting parameter stability, you protect production uptime, maintain >98% efficiency, and reduce lifecycle costs—while accelerating project approvals and compliance.

Connect with Specialists for Custom Solutions

Strengthen your QA with end-to-end SiC reliability expertise and turnkey test platforms.

- 10+ years of SiC manufacturing expertise

- Chinese Academy of Sciences backing and innovation

- Custom product development across R-SiC, SSiC, RBSiC, and SiSiC

- Technology transfer and factory establishment services

- Turnkey solutions from material processing to finished products

- Track record with 19+ enterprises

Request a free consultation, tailored test recipes, and a reliability plan mapped to your mission profile. Reserve lab capacity now to support upcoming retrofit projects and minimize time-to-acceptance.

- Email: [email protected]

- Phone/WhatsApp: +86 133 6536 0038

Recommended next steps: Share module datasheets and mission profiles, define ΔTj targets and stress levels, and schedule a pilot qualification with milestone reviews.

Article Metadata

- Last updated: 2025-09-12

- Next scheduled update: 2026-03-31

- References: IEEE Power Electronics Magazine (2023) Reliability of Wide Bandgap Devices; Yole Group Power SiC Market Monitor (2024); International Energy Agency Technology Perspectives (2024)

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.