SiC in Aerospace Turbines: Reaching Peak Performance

Share

SiC in Aerospace Turbines: Reaching Peak Performance

Introduction: SiC in Aerospace Turbines – The Quest for Peak Performance

The aerospace industry is in a relentless pursuit of higher performance, greater fuel efficiency, and reduced emissions. At the heart of this endeavor lies the turbine engine, a marvel of engineering that operates under extreme conditions. For decades, nickel-based superalloys have been the materials of choice for hot-section components. However, as operational temperatures continue to climb to extract more efficiency, even these advanced alloys are approaching their theoretical limits. This is where custom silicon carbide (SiC) products emerge as a transformative solution. SiC, an advanced technical ceramic, offers a unique combination of properties that make it exceptionally suited for the demanding environment within aerospace turbines. Its ability to withstand ultra-high temperatures, resist wear and corrosion, and maintain structural integrity under severe mechanical stress positions it as a key enabler for the next generation of aircraft engines. This article delves into the critical role of silicon carbide in aerospace turbines, exploring its applications, advantages, and the considerations for its successful implementation.

For engineers, procurement managers, and technical buyers in aerospace manufacturing, understanding the potential of industrial SiC components is crucial for staying ahead. The transition towards SiC is not just about incremental improvements; it’s about unlocking new paradigms in engine design and performance, leading to lighter, more powerful, and more sustainable aircraft.

Why Silicon Carbide is a Game-Changer for Aerospace Turbines

Silicon carbide’s prominence in aerospace turbine applications stems from its exceptional material properties, which offer significant advantages over traditional metallic superalloys. The primary drivers for adopting high-performance SiC ceramics include:

- High-Temperature Capability: SiC can operate at temperatures exceeding 1400°C (and even higher for certain grades like Ceramic Matrix Composites – CMCs), far surpassing the limits of most superalloys. This allows for higher turbine inlet temperatures, leading to increased thermodynamic efficiency and power output.

- Low Density: SiC is significantly lighter than superalloys (approximately one-third the weight). Replacing metallic components with SiC reduces the overall engine weight, contributing to improved fuel economy, increased payload capacity, and better aircraft maneuverability. Weight reduction in rotating parts also means lower centrifugal forces, potentially simplifying rotor design.

- Excellent Thermal Shock Resistance: Aerospace turbines experience rapid temperature changes during startup, operation, and shutdown. SiC exhibits good thermal shock resistance, crucial for maintaining component integrity and preventing catastrophic failure.

- High Thermal Conductivity: Certain grades of SiC possess high thermal conductivity, which helps in dissipating heat more effectively, reducing peak component temperatures and thermal gradients. This is vital for thermal management within the hot section of the engine.

- Superior Creep Resistance: At elevated temperatures, materials can deform permanently under sustained load, a phenomenon known as creep. SiC, particularly SiC/SiC CMCs, offers outstanding creep resistance, ensuring dimensional stability and long service life for critical turbine parts.

- Hardness and Wear Resistance: SiC is an extremely hard material, second only to diamond and boron carbide. This translates to excellent resistance against erosive wear from particulate matter in the gas path and abrasive wear in contact components.

- Oxidation and Corrosion Resistance: The hot gas environment within a turbine engine is highly corrosive. SiC forms a protective silica (SiO2) layer in oxidizing atmospheres, providing good resistance to oxidation and attack from combustion byproducts. Specialized coatings can further enhance this protection.

These properties collectively enable engine designs that are not only more efficient but also potentially more durable and requiring less cooling air, which further boosts efficiency. The shift to advanced SiC materials is a strategic move for aerospace manufacturers aiming for market leadership.

Key Applications of SiC in Aerospace Turbine Engines

The unique attributes of silicon carbide make it suitable for a range of demanding applications within the hot sections of aerospace gas turbine engines. As manufacturers push for higher thrust-to-weight ratios and improved specific fuel consumption, engineered SiC components are finding their way into:

- Turbine Vanes (Nozzles): Stationary vanes direct the hot gas flow onto the rotating turbine blades. SiC vanes can withstand higher temperatures than their metallic counterparts, allowing for increased turbine inlet temperatures. Their lower density also contributes to weight savings.

- Turbine Blades: While monolithic SiC blades face challenges due to brittleness, SiC-based Ceramic Matrix Composites (CMCs), particularly SiC/SiC CMCs, are increasingly being used. These offer a degree of toughness and damage tolerance that monolithic ceramics lack, combined with the high-temperature benefits of SiC. Lighter blades also reduce the stress on the turbine disk.

- Combustor Liners: The combustor is where fuel is burned, generating extreme temperatures. SiC and SiC CMC liners offer superior durability and can operate with less cooling air compared to metal liners. This reduction in cooling air allows more air to be used in the combustion process, improving efficiency and reducing emissions like NOx.

- Shroud Segments / Blade Outer Air Seals (BOAS): These components surround the turbine blades, controlling blade tip clearances for optimal aerodynamic efficiency. SiC’s thermal stability and wear resistance are advantageous here, helping to maintain tight clearances over a range of operating conditions.

- Heat Exchangers and Recuperators: For advanced engine cycles, compact and efficient high-temperature heat exchangers are needed. SiC’s thermal conductivity and high-temperature strength make it a prime candidate for such applications, improving overall engine cycle efficiency.

- Exhaust Nozzle Components: Parts of the exhaust nozzle, especially in high-performance military aircraft, experience extreme temperatures. SiC can provide the necessary thermal resistance and structural integrity.

The integration of aerospace-grade SiC parts into these critical areas is pivotal for achieving next-generation engine performance targets. The development often involves close collaboration between engine OEMs and specialized SiC component manufacturers.

The Advantages of Custom Silicon Carbide for Turbine Components

While standard SiC shapes and forms have their uses, the complex geometries and stringent performance requirements of aerospace turbines necessitate custom silicon carbide solutions. Tailoring SiC components offers several distinct advantages:

- Optimized Performance: Customization allows for the design of components that are precisely matched to the specific thermal, mechanical, and chemical environment they will encounter. This includes optimizing material grade, microstructure, and geometry for maximum efficiency and lifespan.

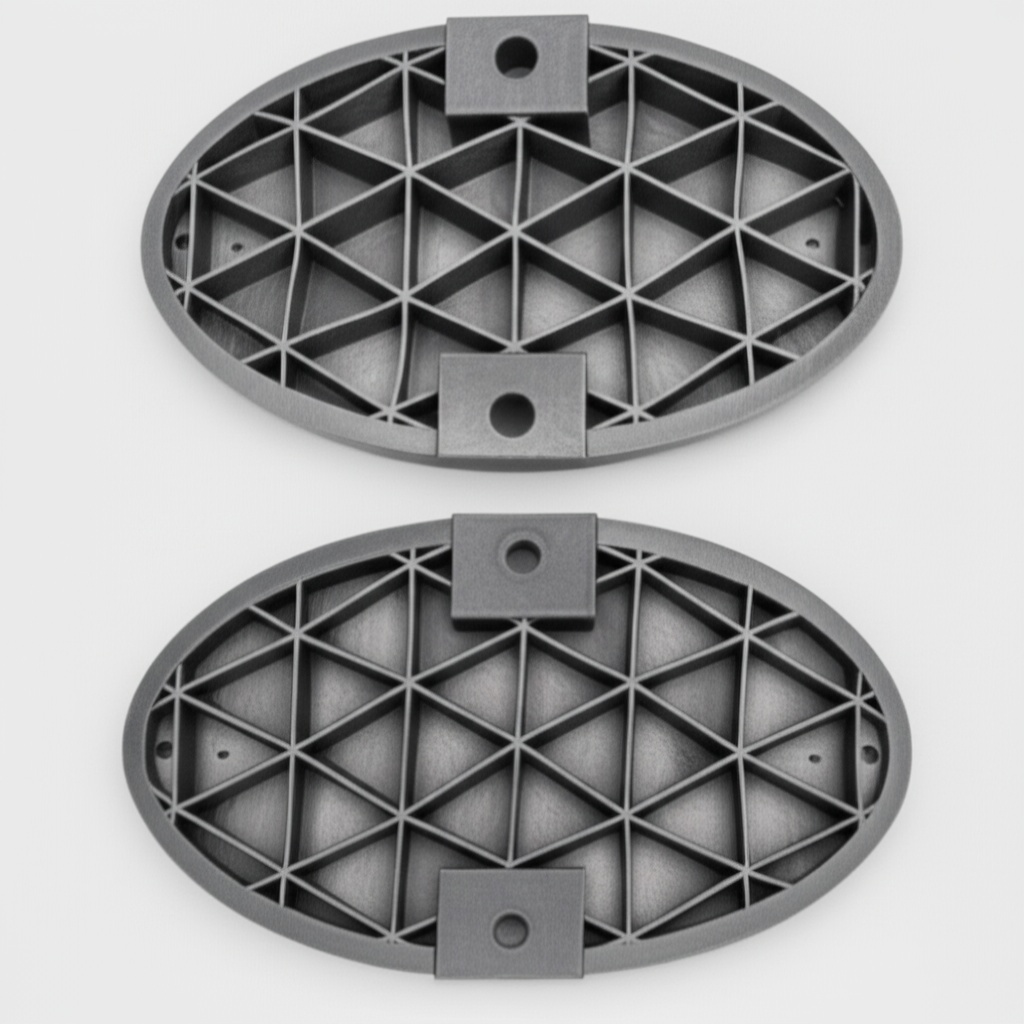

- Complex Geometries: Aerospace components often feature intricate shapes, cooling channels, and attachment points. Advanced manufacturing techniques for SiC, such as near-net-shape forming, additive manufacturing (for certain SiC types), and precision machining, enable the production of highly complex custom designs that would be impossible or prohibitively expensive with traditional materials or methods.

- Improved Thermal Management: Custom designs can incorporate sophisticated cooling features or tailored thermal conductivity pathways, essential for managing the extreme heat in turbine hot sections. This can lead to reduced cooling air requirements, directly boosting engine efficiency.

- Weight Reduction: Customization allows engineers to strategically remove material where it’s not needed, further enhancing the inherent lightweight advantage of SiC. This is critical for rotating components and overall engine weight.

- Integration with Existing Systems: Custom SiC parts can be designed to seamlessly integrate with surrounding metallic or composite components, addressing challenges related to differential thermal expansion and joining.

- Specific Material Property Tailoring: Depending on the application (e.g., high thermal conductivity for heat spreaders vs. low thermal conductivity for insulators, or high wear resistance for seals), the SiC material itself can be customized through choice of sintering aids, purity levels, and reinforcement (as in CMCs).

Partnering with a supplier capable of providing highly customized SiC components is therefore essential. Companies like Sicarb Tech offer extensive customizing support, working closely with aerospace clients to develop SiC solutions tailored to their unique application demands, from initial design to final production. This collaborative approach ensures that the final product delivers peak performance and reliability.

Recommended Silicon Carbide Grades for Aerospace Turbines

Several types of silicon carbide and SiC-based composites are utilized in aerospace, each offering a unique balance of properties, manufacturability, and cost. The selection of the optimal SiC material grade is critical for component success.

| SiC Grade/Type | Key Characteristics | Typical Aerospace Turbine Applications | Pros | Cons |

|---|---|---|---|---|

| Sintered Silicon Carbide (SSiC) | High purity (typically >98% SiC), fine grain size, excellent strength and hardness at high temperatures, good oxidation resistance. Formed by pressureless sintering or hot pressing. | Static components like vanes, combustor liners, seal rings, heat exchanger elements. | Very high operating temperature, excellent wear and corrosion resistance, good thermal shock resistance. | Relatively brittle, can be challenging and costly to machine complex shapes from fully sintered blanks. |

| Reaction-Bonded Silicon Carbide (RBSiC or SiSiC) | SiC grains bonded by silicon metal. Contains free silicon (typically 8-15%). Good thermal conductivity, good wear resistance, easier to form complex shapes. | Structural components, wear parts, some combustor components. Less common for highest temperature zones due to Si melting point. | Lower manufacturing cost for complex shapes (near-net-shape capability), good thermal conductivity. | Lower maximum service temperature (limited by melting point of silicon, ~1414°C), lower creep resistance than SSiC at high temperatures. |

| Silicon Carbide Fiber-Reinforced Silicon Carbide Matrix Composites (SiC/SiC CMCs) | SiC fibers embedded in a SiC matrix. Offers pseudo-ductility and damage tolerance, significantly higher fracture toughness than monolithic SiC. | Turbine blades, vanes, shrouds, combustor liners, exhaust nozzle components. Considered the most advanced option for dynamic parts. | Lightweight, excellent high-temperature strength and creep resistance, significantly improved toughness and non-catastrophic failure mode. | High manufacturing cost, complex fabrication processes (e.g., Chemical Vapor Infiltration – CVI, Polymer Infiltration and Pyrolysis – PIP, Melt Infiltration – MI). Environmental Barrier Coatings (EBCs) often required to prevent water vapor recession. |

| Nitride-Bonded Silicon Carbide (NBSiC) | SiC grains bonded by a silicon nitride (Si3N4) phase. Good thermal shock resistance and strength. | Primarily used in non-aerospace high-temperature applications but has potential for specific aerospace components where its unique property balance is beneficial. | Good thermal shock resistance, moderate cost. | Generally lower mechanical properties compared to SSiC or SiC/SiC CMCs at the highest temperatures. |

| Recrystallized Silicon Carbide (RSiC) | High purity SiC formed by firing compacted SiC grains at very high temperatures, causing them to bond without additives. Often porous. | Kiln furniture, radiant tubes. Less common for highly stressed aerospace structural parts but could be used for specific static thermal components. | Excellent thermal shock resistance, very high service temperature. | Typically lower strength and density due to porosity compared to SSiC. |

The choice among these technical ceramic materials depends on a thorough analysis of the component’s operating environment, stress levels, lifetime requirements, and cost targets. For instance, SSiC might be chosen for static parts requiring extreme temperature and wear resistance, while SiC/SiC CMCs are favored for rotating components or those needing higher damage tolerance. Consulting with experienced SiC component suppliers is crucial in making this selection.

Critical Design Considerations for SiC Turbine Components

Designing components with silicon carbide for aerospace turbines requires a different mindset compared to working with ductile metals. The inherent brittleness of monolithic ceramics and the unique failure modes of CMCs necessitate careful attention to design details to ensure reliability and longevity. Key considerations include:

- Stress Concentrations: Sharp corners, notches, and small holes can act as stress concentrators, leading to premature failure in brittle materials. Designs should incorporate generous radii and smooth transitions to distribute stresses more evenly. Finite Element Analysis (FEA) is indispensable for identifying and mitigating high-stress regions.

- Attachment and Joining: Connecting SiC components to metallic structures or other ceramic parts is a significant challenge due to differences in thermal expansion coefficients and stiffness. Design of attachment points must accommodate these mismatches. Techniques include compliant interlayers, interference fits, brazing (with active braze alloys), or mechanical fastening designed to minimize stress.

- Manufacturing Constraints (Design for Manufacturability – DfM): The chosen SiC grade and its manufacturing process (e.g., pressing, casting, green machining, sintering, CMC layup and infiltration) impose limitations on achievable geometries, feature sizes, and internal complexities. Early collaboration with the SiC manufacturer is vital to ensure the design is producible.

- Thermal Management and Gradients: While SiC withstands high temperatures, severe thermal gradients can induce internal stresses. Designs should aim to minimize these gradients. For CMCs, anisotropy in thermal conductivity (different in through-thickness vs. in-plane directions) must also be considered.

- Probabilistic Design and Lifing: Unlike metals, the strength of ceramics is often described by Weibull statistics due to the distribution of inherent microscopic flaws. Probabilistic design approaches and rigorous lifing methodologies are essential to ensure component reliability at the required safety levels. This includes NDE (Non-Destructive Evaluation) to screen out parts with critical flaws.

- Impact Resistance and Damage Tolerance: For components like blades that might encounter foreign object damage (FOD), the limited impact resistance of monolithic SiC is a concern. SiC/SiC CMCs offer better damage tolerance, but this still needs to be a key design driver, potentially incorporating features that deflect or absorb impact energy.

- Environmental Protection: While SiC has good oxidation resistance, at very high temperatures in the presence of water vapor (a combustion byproduct), SiC can experience volatilization (recession). Environmental Barrier Coatings (EBCs) are often required for long-duration applications, and the design must accommodate the application and behavior of these coatings.

- Cost vs. Performance Trade-offs: Highly complex designs or extremely tight tolerances will increase manufacturing costs. Engineers must balance the desired performance gains with practical manufacturing capabilities and budget constraints.

Successfully navigating these design considerations for precision SiC parts often involves an iterative process of design, analysis, manufacturing trials, and testing.

Achievable Tolerances, Surface Finish, and Dimensional Accuracy in SiC Machining

Achieving tight tolerances and specific surface finishes on silicon carbide components is critical for their performance in aerospace turbines, especially for aerodynamic surfaces and interfaces. However, SiC’s extreme hardness makes it one of the most challenging materials to machine.

Machining Processes:

- Grinding: Diamond grinding is the most common method for shaping and finishing SiC parts after sintering or densification. Various grinding techniques (surface, cylindrical, creep-feed) are used to achieve precise dimensions.

- Lapping and Polishing: For applications requiring exceptionally smooth surfaces and ultra-fine tolerances (e.g., seal faces, optical components), diamond lapping and polishing are employed. This can achieve surface roughness (Ra) values in the nanometer range.

- Electrical Discharge Machining (EDM): While conventional SiC is an electrical insulator, certain grades with sufficient electrical conductivity (like some RBSiC grades or specially formulated SiC) can be machined using EDM. This is useful for creating complex shapes or small features.

- Ultrasonic Machining (USM): USM uses high-frequency vibrations and an abrasive slurry to remove material. It’s suitable for brittle materials like SiC and can create holes and cavities.

- Laser Machining: Lasers can be used for cutting, drilling, and scribing SiC, particularly in its “green” (unsintered) state or for thin sections. However, thermal damage can be a concern.

Achievable Tolerances and Surface Finish:

- Dimensional Tolerances: With precision diamond grinding, dimensional tolerances in the range of ±0.005 mm to ±0.025 mm (±0.0002 to ±0.001 inches) are often achievable, depending on the part size, complexity, and specific SiC grade. Tighter tolerances are possible but significantly increase cost.

- Surface Roughness (Ra):

- Standard ground finishes: Ra 0.2 to 0.8 µm (8 to 32 µin).

- Fine ground finishes: Ra 0.1 to 0.4 µm (4 to 16 µin).

- Lapped/Polished finishes: Ra <0.05 µm (<2 µin) can be achieved.

- Geometric Tolerances: Features like flatness, parallelism, and perpendicularity can also be controlled to high precision through careful machining and metrology.

It’s important to note that machining fully dense SiC is time-consuming and expensive due to high diamond tool wear and slow material removal rates. Therefore, near-net-shape forming techniques are highly preferred to minimize the amount of final machining required. Discussing SiC machining capabilities with your supplier early in the design phase is crucial for managing expectations and costs.

Essential Post-Processing for SiC Aerospace Parts

After primary fabrication and machining, silicon carbide aerospace components often require additional post-processing steps to meet final performance, durability, and assembly requirements. These steps are crucial for optimizing the component for the harsh turbine environment.

- Cleaning: Thorough cleaning is essential to remove any residues from machining coolants, abrasive particles, or handling. This ensures proper adhesion for subsequent coatings and prevents contamination in the engine.

- Edge Chamfering/Radiusing: Sharp edges on ceramic components can be prone to chipping and can act as stress risers. Precise edge treatments (e.g., slight chamfers or radii) are often applied to improve handling robustness and mechanical integrity.

- Annealing/Stress Relief: In some cases, particularly after aggressive grinding, an annealing step might be performed to relieve internal stresses induced during machining, though this is less common for SiC than for some other ceramics or metals.

- Non-Destructive Evaluation (NDE): Before installation, critical SiC components undergo rigorous NDE to detect any internal or surface flaws (cracks, pores, inclusions) that could compromise performance. Common NDE techniques include:

- Visual Inspection (VI)

- Fluorescent Penetrant Inspection (FPI) – for surface-breaking cracks

- X-ray Computed Tomography (CT) – for internal defects and density variations

- Ultrasonic Testing (UT) – for internal flaws

- Acoustic Emission (AE) – during proof testing

- Environmental Barrier Coatings (EBCs): For long-duration use at very high temperatures in moisture-rich combustion environments, SiC components (especially CMCs) require EBCs. These multi-layer coatings protect the SiC from water vapor recession and oxidation, significantly extending component life. Common EBC materials include rare-earth silicates. The application of EBCs is a highly specialized process (e.g., plasma spray, CVD).

- Wear-Resistant or Functional Coatings: In some applications, specific coatings might be applied to further enhance wear resistance, reduce friction, or provide other functional properties. Diamond-Like Carbon (DLC) or other hard coatings could be considered for specific contact surfaces if compatible with temperatures.

- Proof Testing: Components may be subjected to mechanical or thermal proof tests that simulate or exceed expected operating loads. This helps to screen out weaker parts and validate the design and manufacturing process.

- Assembly and Joining Preparations: If the SiC part is to be joined to other components (metallic or ceramic), surfaces might require special preparation (e.g., metallization for brazing) as part of the post-processing stage.

Each of these SiC finishing techniques adds value and ensures the reliability and performance of the final aerospace product. The specific post-processing regimen is determined by the application, the SiC grade, and the operational requirements.

Overcoming Common Challenges in SiC Turbine Component Manufacturing

While the benefits of silicon carbide in aerospace turbines are compelling, its adoption is not without challenges. Manufacturers and engineers must address several hurdles related to material properties, fabrication, and cost.

- Brittleness and Low Fracture Toughness (Monolithic SiC):

- Challenge: Monolithic SiC is inherently brittle, meaning it has little ability to deform plastically before fracture. This makes it susceptible to catastrophic failure from small defects or impacts.

- Mitigation: Designing to minimize stress concentrations, using probabilistic design methodologies, rigorous NDE to screen flaws, implementing damage-tolerant designs where possible (e.g., segmented components), and transitioning to SiC/SiC CMCs for toughness-critical applications.

- Machining Complexity and Cost:

- Challenge: SiC’s extreme hardness makes it difficult and expensive to machine to tight tolerances. Diamond tooling wears quickly, and material removal rates are slow.

- Mitigation: Employing near-net-shape forming techniques (e.g., slip casting, injection molding for green bodies) to minimize final machining, optimizing grinding parameters, exploring advanced machining techniques (laser-assisted grinding, EDM for conductive grades), and designing for manufacturability from the outset.

- High Material and Processing Costs:

- Challenge: High-purity SiC powders, complex CMC fabrication processes (like CVI), and specialized EBC applications contribute to high component costs compared to traditional superalloys.

- Mitigation: Process optimization to improve yields and reduce cycle times, development of lower-cost manufacturing routes (e.g., PIP or MI for CMCs where applicable), strategic material selection, and focusing on high-value applications where the performance benefits justify the cost. The overall lifecycle cost, including fuel savings and potentially longer maintenance intervals, should also be considered.

- Joining SiC to Other Materials:

- Challenge: Differences in thermal expansion coefficients, stiffness, and chemical compatibility make robustly joining SiC to metallic structures a significant engineering problem.

- Mitigation: Development and use of advanced joining techniques such as active metal brazing, transient liquid phase (TLP) bonding, diffusion bonding, mechanical attachments designed to accommodate mismatches, and functionally graded interlayers.

- Reproducibility and Quality Control:

- Challenge: Ensuring consistent material properties and defect-free components across production batches can be demanding for advanced ceramics.

- Mitigation: Strict control over raw material quality, precise process parameter control during all manufacturing stages (forming, sintering, infiltration), comprehensive NDE at multiple points, and robust quality management systems (e.g., AS9100).

- Environmental Degradation (Water Vapor Recession):

- Challenge: At very high temperatures (typically >1200°C) in environments containing water vapor, SiC can react to form volatile silicon hydroxide species, leading to material loss (recession).

- Mitigation: Application of advanced Environmental Barrier Coatings (EBCs) specifically designed to protect SiC from water vapor attack. Continuous research is focused on developing more durable and higher-temperature EBCs.

Addressing these challenges requires ongoing research and development, close collaboration between material scientists, design engineers, and manufacturing specialists, and partnerships with expert SiC solutions providers.

Choosing Your Strategic Partner for Custom SiC Aerospace Components: Introducing Sicarb Tech

Selecting the right supplier for custom silicon carbide aerospace components is a critical decision that can significantly impact project success, component quality, and overall engine performance. The ideal partner should possess deep material expertise, advanced manufacturing capabilities, a commitment to quality, and the ability to collaborate effectively on complex engineering challenges.

This is where Sicarb Tech stands out. As you may be aware, the hub of China’s silicon carbide customizable parts manufacturing is situated in Weifang City of China. This region has been home to over 40 silicon carbide production enterprises of various sizes, collectively accounting for more than 80% of the nation’s total SiC output. We, Sicarb Tech, have been instrumental in this development, introducing and implementing advanced silicon carbide production technology since 2015. Our efforts have assisted local enterprises in achieving large-scale production and significant technological advancements in product processes. We have proudly witnessed and contributed to the emergence and ongoing evolution of this vital SiC industrial base.

Sicarb Tech operates under the umbrella of the Chinese Academy of Sciences (Weifang) Innovation Park, an entrepreneurial park that collaborates closely with the National Technology Transfer Center of the Chinese Academy of Sciences. This affiliation provides us with unparalleled access to the robust scientific, technological capabilities, and talent pool of the Chinese Academy of Sciences. Functioning as a national-level innovation and entrepreneurship service platform, we integrate innovation, technology transfer, and scientific services, acting as a crucial bridge for the commercialization of cutting-edge research.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.