Reliable SiC Testing Equipment for Quality Assurance

Share

Reliable SiC Testing Equipment for Quality Assurance

The ascent of silicon carbide (SiC) as a cornerstone material in high-performance industrial applications is undeniable. From revolutionizing power electronics to enabling breakthroughs in aerospace and automotive sectors, SiC’s exceptional properties demand equally exceptional quality assurance processes. Central to this is the deployment of reliable SiC testing equipment. This blog post delves into the critical world of silicon carbide testing, exploring its importance, the types of equipment involved, and how to navigate the complexities of ensuring material integrity and performance for demanding applications across diverse industries like semiconductors, high-temperature processing, energy, and industrial manufacturing.

1. Introduction: The Critical Role of SiC Testing Equipment in Modern Industries

Silicon carbide is renowned for its superior hardness, high thermal conductivity, excellent chemical inertness, and robust electrical properties, making it an indispensable material for components operating under extreme conditions. However, these very attributes mean that imperfections or deviations in material quality can lead to significant performance issues or catastrophic failures in critical systems. Therefore, rigorous testing is not just a quality control measure; it’s a fundamental necessity to guarantee the reliability and longevity of SiC components.

SiC testing equipment plays a pivotal role in verifying that silicon carbide materials and the devices fabricated from them meet stringent specifications. For B2B stakeholders—including engineers, procurement managers, and technical buyers in industries such as Semiconductor Manufacturing, Automotive Companies, Aerospace Companies, Power Electronics Manufacturers, and Renewable Energy Companies—understanding the nuances of SiC testing is crucial. It ensures that the SiC products they procure or integrate into their systems will perform as expected, maintaining operational integrity and safety. The insights gained from precise testing drive innovation, optimize manufacturing processes, and ultimately deliver superior end-products. Without reliable testing, the full potential of SiC’s advanced properties cannot be confidently harnessed, impacting everything from production yields to the safety of high-power transistors in electric vehicles or the efficiency of solar inverters.

2. Understanding Silicon Carbide: Properties Demanding Rigorous Testing

The unique combination of physical, electrical, and thermal properties of silicon carbide necessitates specialized and precise testing methodologies. Generic material testing approaches often fall short in adequately characterizing SiC. Key properties that demand rigorous testing include:

- High Hardness and Mechanical Strength: SiC is one of the hardest synthetic materials, approaching diamond. Testing its flexural strength, fracture toughness, and wear resistance requires equipment capable of applying significant forces and accurately measuring minute deformations or wear patterns. This is critical for applications like bearings, seals, and abrasive components.

- Exceptional Thermal Properties:

- High Thermal Conductivity: Essential for heat dissipation in power electronics and heat exchangers. Testing equipment must accurately measure thermal conductivity across a range of temperatures.

- Low Thermal Expansion: Ensures dimensional stability under thermal cycling. Dilatometers and thermomechanical analyzers are used for this.

- Excellent Thermal Shock Resistance: Vital for components in furnaces or engines. Testing involves subjecting samples to rapid temperature changes.

- Advanced Electrical Characteristics:

- Wide Bandgap: Allows for higher breakdown voltages, operating temperatures, and frequencies in semiconductor devices. Testing includes dielectric strength, resistivity, carrier mobility, and leakage current measurements, often at elevated temperatures and voltages.

- Controllable Resistivity: SiC can be doped to be a semiconductor or produced as a highly resistive material. Accurate resistivity measurements are key for its diverse applications.

- Chemical Inertness and Corrosion Resistance: SiC resists most acids and alkalis, even at high temperatures. Corrosion testing in specific chemical environments is necessary for applications in chemical processing and oil and gas industries.

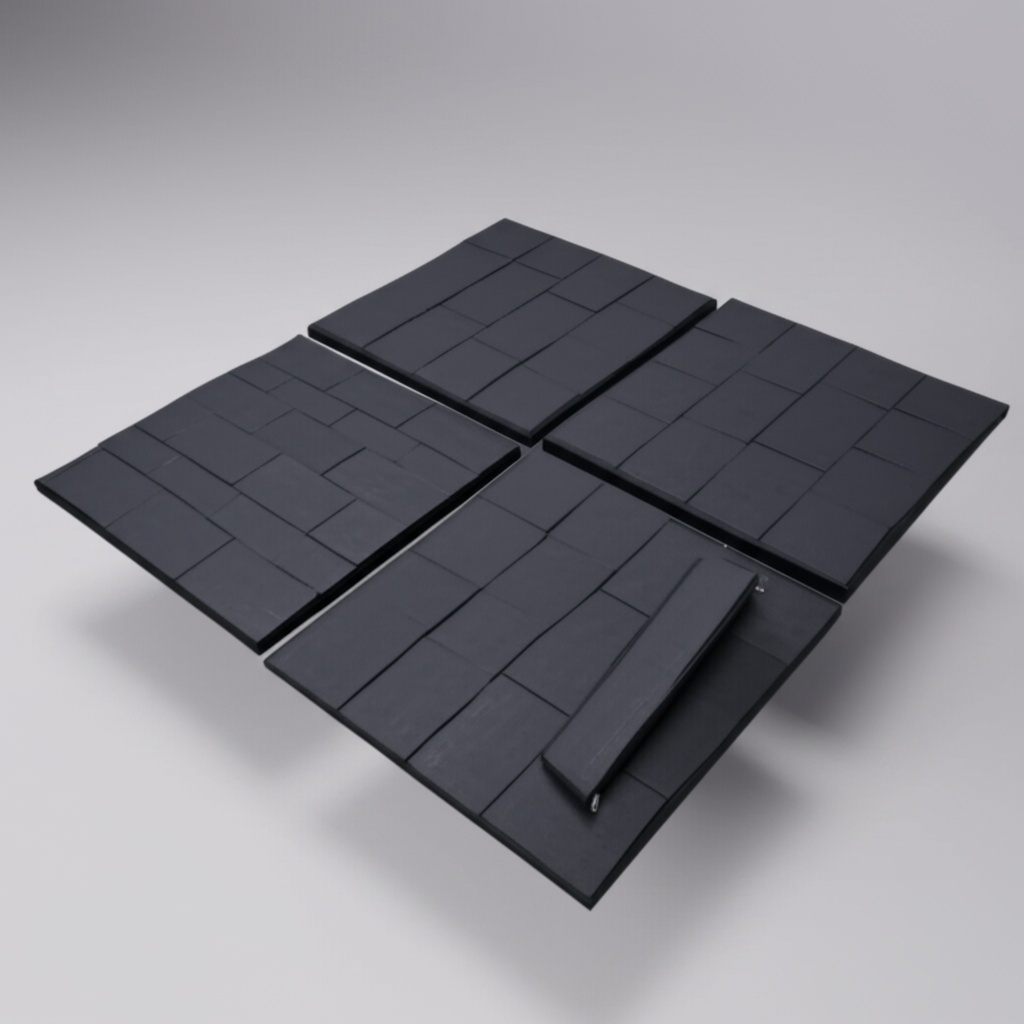

- Purity and Microstructure: The presence of impurities, porosity, grain size, and crystal defects (like micropipes in single-crystal SiC wafers) can significantly impact all other properties. Microscopic analysis, X-ray diffraction (XRD), and non-destructive testing (NDT) methods are employed to assess these aspects.

The performance of SiC components in sectors like Metallurgy, Defense, LED Manufacturing, and Nuclear Energy hinges on these properties being within tight specifications. Therefore, the testing equipment must be sensitive, accurate, and capable of simulating relevant operational conditions.

3. Key Applications Driving the Need for Advanced SiC Testing

The demand for sophisticated SiC testing equipment is directly proportional to the expanding applications of silicon carbide across high-stakes industries. Each application has unique performance criteria and failure modes, necessitating tailored testing protocols.

| Industry | Key SiC Applications | Critical Parameters & Testing Needs |

|---|---|---|

| Semiconductors | Power MOSFETs, Schottky diodes, high-frequency devices, wafer substrates | Electrical properties (breakdown voltage, on-state resistance, switching speed, leakage current), defect density in wafers (micropipes, stacking faults), surface planarity, thermal impedance. Equipment: Parameter analyzers, C-V/I-V testers, defect scanners. |

| Automotive | Inverters for EVs/HEVs, on-board chargers, DC-DC converters, brake discs, particulate filters | High-temperature electrical performance, power cycling reliability, mechanical strength and wear resistance (for brakes), thermal shock resistance. Equipment: High-voltage testers, thermal cyclers, dynamometers. |

| Aerospace & Defense | Mirrors for telescopes, lightweight armor, rocket nozzles, high-temperature sensors, radomes | Dimensional stability, thermal shock resistance, high-temperature mechanical strength, radiation hardness, microwave transparency. Equipment: Thermomechanical analyzers, high-temp tensile testers, environmental chambers. |

| Power Electronics | Industrial motor drives, power supplies, FACTS devices, high-voltage DC transmission | Efficiency, switching characteristics, thermal management, reliability under high voltage and current stress. Equipment: Power device analyzers, dynamic characterization systems. |

| Renewable Energy | Solar inverters, wind turbine converters | Efficiency at high switching frequencies, long-term reliability, thermal performance. Equipment: Similar to power electronics, with emphasis on long-duration testing. |

| Metallurgy & High-Temperature Processing | Furnace components (beams, rollers, tubes), kiln furniture, crucibles, thermocouple sheaths | High-temperature strength, creep resistance, oxidation resistance, thermal shock resistance. Equipment: High-temperature furnaces with mechanical testing capabilities, corrosion test rigs. |

| Chemical Processing | Pump seals, valve components, heat exchangers, wear parts | Chemical inertness, corrosion resistance, wear resistance under abrasive/corrosive media. Equipment: Autoclaves, wear testers with controlled chemical environments. |

Other industries like LED Manufacturing (for substrates and MOCVD components), Industrial Machinery (for precision components and wear parts), Telecommunications (for high-frequency device substrates), Oil and Gas (for downhole tools and wear components), Medical Devices (for biocompatible wear-resistant parts), Rail Transportation (for power modules in traction systems), and Nuclear Energy (for fuel cladding and structural components) also rely heavily on the verified quality of SiC, driving the need for specialized testing equipment.

4. Types of Silicon Carbide Testing Equipment and Their Functions

A comprehensive suite of testing equipment is required to fully characterize silicon carbide and ensure its suitability for specific applications. These can be broadly categorized based on the properties they measure:

-

Electrical Testing Equipment:

- Parameter Analyzers / Semiconductor Characterization Systems: Measure I-V (current-voltage) and C-V (capacitance-voltage) characteristics, breakdown voltage, leakage current, on-state resistance (RDS(on)), threshold voltage, etc., for SiC devices like MOSFETs and diodes. Essential for Power Electronics Manufacturers.

- Resistivity Meters: Determine the electrical resistivity of SiC materials, crucial for both semiconductor and structural applications. Four-point probes are common.

- Dielectric Strength Testers: Measure the voltage at which SiC insulators break down.

- Hall Effect Measurement Systems: Characterize carrier concentration, mobility, and type in SiC semiconductors.

-

Mechanical Testing Equipment:

- Universal Testing Machines (UTMs): Used for tensile, compressive, and flexural strength testing. Specialized fixtures are needed for brittle SiC.

- Hardness Testers: Vickers or Knoop hardness testers to measure the material’s resistance to indentation.

- Fracture Toughness Testers: Evaluate SiC’s resistance to crack propagation.

- Wear and Tribology Test Rigs: Simulate wear conditions (e.g., pin-on-disk) to measure friction coefficients and wear rates, important for industrial machinery and seals.

-

Thermal Analysis Equipment:

- Thermal Conductivity Analyzers: (e.g., Laser Flash Apparatus) Measure how well SiC conducts heat. Critical for thermal management applications.

- Dilatometers: Measure thermal expansion coefficients.

- Thermogravimetric Analyzers (TGA) / Differential Scanning Calorimeters (DSC): Study material stability, phase transitions, and oxidation behavior at high temperatures.

- Thermal Shock Test Chambers: Subject samples to rapid temperature cycling to assess resistance.

-

Non-Destructive Testing (NDT) and Microstructural Analysis Equipment:

- X-ray Diffraction (XRD): Identifies crystal phases, measures residual stress, and assesses crystal quality.

- Scanning Electron Microscopes (SEM) / Transmission Electron Microscopes (TEM): Provide high-magnification imaging of surface morphology, grain structure, and defects. Often coupled with Energy Dispersive X-ray Spectroscopy (EDS) for elemental analysis.

- Atomic Force Microscopy (AFM): For high-resolution surface topography and defect mapping on wafers.

- Ultrasonic Testing (UT): Detects internal flaws like cracks, voids, or delaminations.

- Optical Inspection Systems / Defect Scanners: Automated systems for identifying surface defects, micropipes, and other imperfections on SiC wafers and substrates. Crucial for Semiconductor Manufacturers.

-

Dimensional Metrology Equipment:

- Coordinate Measuring Machines (CMMs): For precise 3D dimensional verification of complex SiC parts.

- Profilometers and Surface Roughness Testers: Measure surface finish and profile.

The selection of appropriate SiC testing equipment depends on the specific SiC product type (e.g., bulk ceramic, thin film, single crystal wafer, finished component) and its intended application.

5. Ensuring Reliability: Core Benefits of High-Quality SiC Testing Equipment

Investing in high-quality, reliable SiC testing equipment offers substantial benefits that extend far beyond simple pass/fail decisions. These benefits are particularly impactful for B2B clients who stake their reputations and product performance on the quality of the SiC components they utilize.

- Enhanced Product Quality and Consistency: Rigorous testing identifies material variations and manufacturing defects early, ensuring that only components meeting strict quality standards reach the end-user or the next stage of assembly. This consistency is paramount for high-volume production in industries like automotive and consumer electronics.

- Reduced Failure Rates and Warranty Costs: By weeding out substandard SiC components, manufacturers can significantly lower the risk of premature field failures. This translates to reduced warranty claims, repair costs, and reputational damage. For critical applications in aerospace or medical devices, preventing failure is a matter of safety.

- Improved Product Performance and Efficiency: Testing verifies that SiC components exhibit the desired electrical, thermal, and mechanical properties. For example, in power electronics, accurately characterized SiC devices lead to higher efficiency, reduced energy loss, and more compact systems.

- Accelerated Research and Development: Precise testing equipment provides researchers and engineers with accurate data to understand material behavior, validate new SiC formulations, and optimize device designs. This speeds up innovation cycles.

- Compliance with Industry Standards and Regulations: Many industries, particularly automotive, aerospace, and nuclear, have stringent standards for material and component qualification. Reliable testing provides the necessary documentation and assurance of compliance.

- Process Optimization and Yield Improvement: Data from testing can be fed back into the manufacturing process to identify areas for improvement, optimize parameters, and increase production yields of high-quality SiC.

- Increased Customer Confidence and Trust: Demonstrating a commitment to thorough testing builds confidence with customers, assuring them of the reliability and performance of your SiC products. This is a key differentiator in a competitive market.

- Long-Term Cost Savings: While advanced testing equipment represents an upfront investment, the long-term savings from reduced failures, optimized processes, and improved product quality often outweigh the initial cost.

For procurement managers and technical buyers, sourcing SiC components from suppliers who utilize state-of-the-art testing equipment provides a higher degree of assurance and reduces downstream risks.

6. Design and Specification Considerations for SiC Testing Systems

When selecting or designing SiC testing equipment, several critical factors must be considered to ensure the system is fit for purpose and provides accurate, repeatable results. These considerations are vital for both equipment manufacturers and end-users in industries like Industrial Equipment Manufacturing and Telecommunications Companies.

- Sample Compatibility and Fixturing:

- Material Form: The equipment must accommodate the SiC form being tested (e.g., wafers, bars, discs, finished components of complex shapes).

- Fixturing: Proper fixtures are crucial, especially for brittle materials like SiC, to ensure correct load application, minimize stress concentrations, and prevent premature sample failure. Fixtures may need to be made of materials compatible with high temperatures or specific chemical environments.

- Test Range and Sensitivity: The equipment must cover the expected range of property values for the SiC being tested and possess sufficient sensitivity and resolution to detect subtle variations critical for performance. For instance, leakage current testers for SiC MOSFETs need picoampere sensitivity.

- Accuracy and Precision: Regular calibration against traceable standards is essential. The inherent accuracy and precision of the measurement system directly impact the reliability of the test data.

- Environmental Controls:

- Temperature: Many SiC applications involve high operating temperatures. Testing equipment may need integrated heating (furnaces, chucks) or cooling systems to evaluate performance across a relevant temperature range (e.g., -55°C to +200°C for automotive, up to 1700°C or higher for furnace components).

- Atmosphere: For oxidation or corrosion testing, controlled atmosphere chambers (e.g., inert gas, specific reactive gases, humidity) are necessary.

- Automation and Throughput: For production environments, automated sample handling, test sequencing, and data acquisition can significantly improve throughput and reduce operator variability.

- Data Acquisition and Analysis Software: Sophisticated software is needed for controlling test parameters, logging data in real-time, performing calculations, generating reports, and potentially integrating with statistical process control (SPC) systems. User-friendly interfaces and advanced analysis capabilities are key.

- Safety Features: Particularly for high-voltage or high-temperature testing, robust safety interlocks, emergency stops, and protective enclosures are mandatory.

- Modularity and Upgradability: Systems that can be upgraded or reconfigured to accommodate future testing needs or new SiC materials offer better long-term value.

- Footprint and Facility Requirements: Space, power, cooling water, exhaust, and other utility requirements must be considered.

- Compliance with Standards: Equipment should facilitate testing according to relevant ASTM, ISO, IEC, JEDEC, or MIL standards where applicable.

Careful consideration of these factors ensures that the chosen SiC testing system aligns with the specific quality assurance goals and technical requirements of the application.

7. Precision and Accuracy in SiC Material Characterization

The terms precision and accuracy are often used interchangeably, but in the context of SiC material characterization, they have distinct meanings, both critical for reliable quality assurance. Understanding and achieving high levels of both is paramount for industries that depend on the consistent performance of silicon carbide, such as Medical Device Manufacturers and Rail Transportation Companies.

Accuracy refers to how close a measured value is to the true or accepted value. For example, if a SiC wafer has a known resistivity of 0.02 Ω·cm, an accurate resistivity tester will provide readings very close to this value.

Precision (or repeatability) refers to how close repeated measurements on the same sample under the same conditions are to each other. A precise testing system will yield consistent results, even if those results are not perfectly accurate (though ideally, they should be both).

Achieving high precision and accuracy in SiC characterization involves several key aspects:

- Calibration and Standards: Testing equipment must be regularly calibrated using traceable standards (e.g., NIST-traceable resistance standards, certified reference materials for chemical composition). Calibration compensates for instrument drift and ensures accuracy.

- Minimizing Measurement Uncertainty: All measurements have some degree of uncertainty. Identifying and quantifying sources of uncertainty (e.g., instrument limitations, environmental factors, sample preparation, operator influence) is crucial. Good testing practices aim to minimize this uncertainty.

- Proper Sample Preparation: The condition of the SiC sample can significantly affect test results. Surface finish, cleanliness, geometry, and contact quality (for electrical measurements) must be carefully controlled. For instance, inconsistent probe contact can lead to erroneous resistivity readings.

- Controlled Test Environment: Variations in ambient temperature, humidity, or electromagnetic interference can impact sensitive measurements. Testing labs often have controlled environments.

- Operator Skill and Training: Well-trained operators who follow standardized test procedures are essential for obtaining reliable results, especially for tests that are not fully automated.

- Equipment Design and Quality: High-quality components, robust design, and advanced sensor technology within the testing equipment itself are foundational to achieving precision and accuracy. For example, in thermal conductivity testing using the laser flash method, precise measurement of temperature rise and sample thickness is critical.

- Data Validation and Statistical Analysis: Applying statistical methods to test results can help identify outliers, assess variability, and determine confidence intervals for the measured properties.

For SiC used in demanding applications like power modules for rail traction or components in nuclear reactors, the margin for error is extremely small. Therefore, the emphasis on precise and accurate characterization using state-of-the-art testing equipment cannot be overstated. This data forms the bedrock for material certification, device qualification, and process control.

8. Integrating SiC Testing into the Manufacturing Workflow: Best Practices

Effectively integrating silicon carbide testing into the manufacturing workflow is essential for proactive quality control, process optimization, and ensuring that final products meet specifications. This integration should be strategic, considering various stages from raw material inspection to final component verification. Best practices include:

- Incoming Material Inspection:

- Test raw SiC powders for purity, particle size distribution, and morphology.

- Verify properties of purchased SiC substrates or wafers (e.g., resistivity, defect density, orientation) before they enter the production line. This is critical for LED Manufacturers and semiconductor fabs.

- In-Process Testing (IPT):

- Monitor critical parameters at intermediate manufacturing steps. For example, after sintering ceramic SiC, test density and shrinkage. After epitaxial growth on SiC wafers, measure layer thickness and doping concentration.

- Use non-destructive testing (NDT) methods like X-ray or ultrasonic inspection to check for internal flaws in structural SiC components before costly final machining.

- Implement real-time or near real-time feedback loops where IPT data is used to adjust process parameters, improving yield and consistency.

- Final Product Testing (Acceptance Testing):

- Perform comprehensive testing on finished SiC components or devices to ensure they meet all performance and reliability specifications. This might include electrical testing under operational conditions, mechanical proof testing, or thermal cycling.

- Statistical sampling plans can be used for high-volume production, but 100% testing may be required for critical applications.

- Reliability Testing:

- Conduct accelerated life testing, high-temperature reverse bias (HTRB) testing, power cycling, and other stress tests on representative samples to predict long-term reliability and identify potential failure mechanisms. This is crucial for automotive and power electronics applications.

- Data Management and Traceability:

- Implement a robust system for collecting, storing, and analyzing test data. Ensure traceability of test results back to specific material batches, production lots, and process parameters.

- Utilize Manufacturing Execution Systems (MES) or Laboratory Information Management Systems (LIMS) for efficient data handling.

- Correlation of Test Data: Correlate data from different test stages (e.g., in-process defects with final device performance) to gain deeper insights into the manufacturing process and its impact on product quality.

- Standardized Test Procedures: Develop and adhere to well-documented, standardized test procedures (SOPs) to ensure consistency and comparability of results across different operators and equipment.

- Continuous Improvement: Regularly review test data and quality metrics to identify trends, areas for improvement, and opportunities to optimize testing strategies (e.g., reducing redundant tests or implementing more effective ones).

By strategically embedding SiC testing throughout the manufacturing workflow, companies can move from a reactive “inspect and reject” model to a proactive “predict and prevent” quality management approach.

9. Overcoming Common Challenges in Silicon Carbide Testing

Testing silicon carbide presents unique challenges due to its extreme properties. Addressing these challenges is key to obtaining accurate and meaningful data for quality assurance and R&D purposes.

- Material Brittleness and Sample Preparation:

- Challenge: SiC is very hard but also brittle, making it prone to fracture during handling, machining, or improper clamping in test fixtures. Sample preparation (cutting, grinding, polishing) can induce surface flaws that affect test results.

- Mitigation: Use specialized diamond tooling for machining. Employ careful handling protocols. Design test fixtures that distribute load evenly and avoid stress concentrations. Implement meticulous surface preparation and inspection techniques.

- High-Temperature Testing:

- Challenge: Many SiC applications involve extreme temperatures. Testing under these conditions requires specialized furnaces, extensometers, and loading systems capable of operating reliably at temperatures often exceeding 1500°C. Material interactions between the sample and fixtures can also occur.

- Mitigation: Utilize high-temperature furnaces with controlled atmospheres. Employ non-contact strain measurement techniques (e.g., laser speckle interferometry). Use fixture materials that are stable and non-reactive at test temperatures (e.g., graphite, other ceramics).

- Electrical Contacting for Characterization:

- Challenge: Achieving low-resistance, stable ohmic contacts to SiC for electrical testing (especially at high temperatures or for wide bandgap characterization) can be difficult. Contact resistance can mask the true material properties.

- Mitigation: Develop optimized metallization schemes and annealing processes for contacts. Use specialized probing techniques (e.g., Kelvin probes) to eliminate contact resistance effects from measurements. Perform testing in controlled atmospheres to prevent contact degradation.

- Detecting and Quantifying Defects:

- Challenge: Critical defects in SiC, such as micropipes in wafers or sub-surface cracks in structural ceramics, can be small and difficult to detect reliably. Quantifying their impact on device performance or material strength requires sophisticated techniques.

- Mitigation: Employ advanced NDT methods like X-ray topography, scanning acoustic microscopy, or high-resolution optical defect scanners. Develop correlations between defect characteristics (size, density, location) and performance parameters.

- Interpreting Complex Data:

- Challenge: The anisotropic nature of SiC crystals or the complex interplay of factors affecting performance (e.g., temperature, frequency, electric field) can lead to complex test data that requires expert interpretation.

- Mitigation: Utilize advanced analytical software. Employ personnel with deep knowledge of SiC materials science and device physics. Correlate test data with simulation models.

- Cost and Complexity of Equipment:

- Challenge: Specialized SiC testing equipment can be expensive to acquire and maintain. It often requires skilled operators.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.