Silicon Carbide Power Conversion Units for Electric Furnaces with High Temperature and Dust Resistance

Share

Product Overview and 2025 Market Relevance

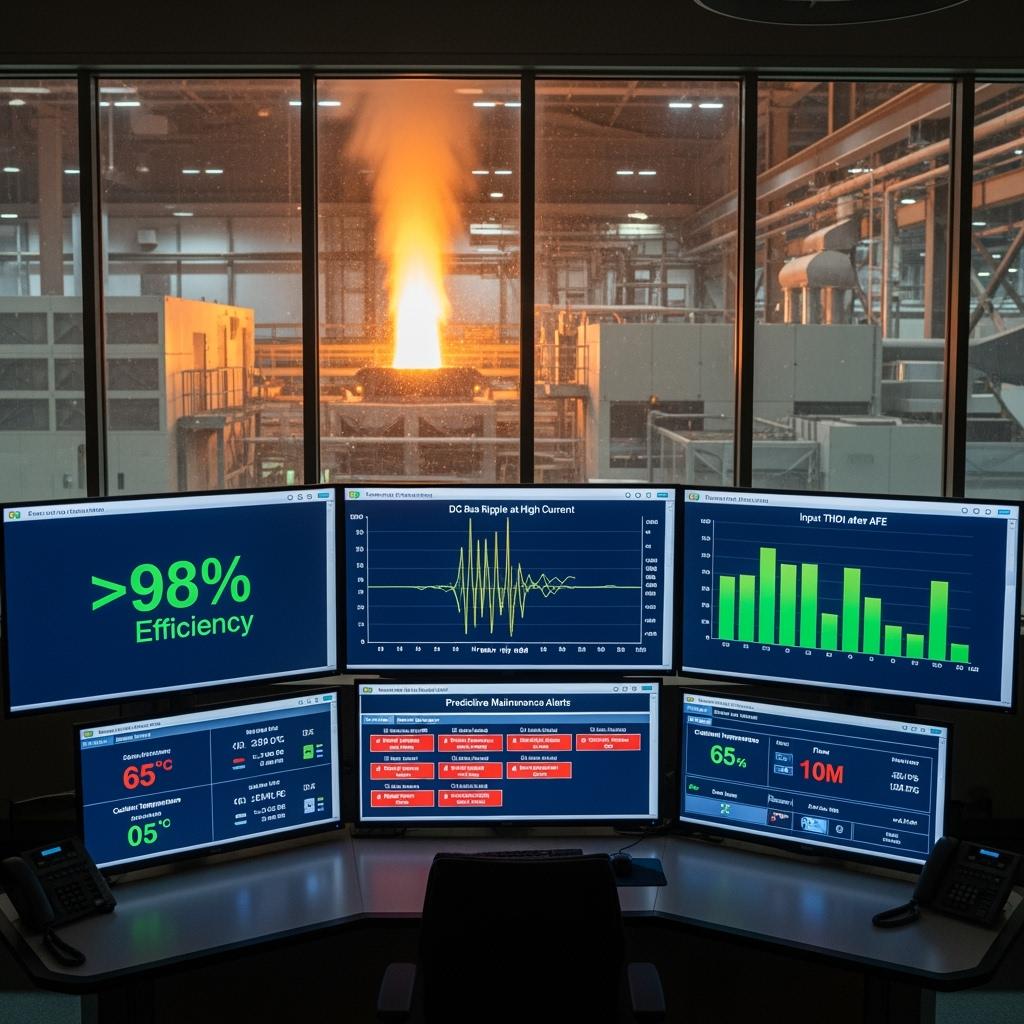

Silicon carbide (SiC) power conversion units are engineered to deliver stable, high-current DC or controlled AC power for electric furnaces operating in extreme heat and dust. For Pakistan’s cement, steel, and mining sectors—where clinker kilns, ladle heaters, and smelting furnaces run continuously—these units provide >98% conversion efficiency, robust high-temperature performance up to 175°C junction, and high reliability in particulate-laden environments.

In 2025, industrial facilities across Punjab and Sindh are prioritizing modernization to counter grid volatility, aging silicon-based converters, and escalating energy costs. SiC power conversion units rated at ≥1700 V and ≥500 A (module level) leverage ultra-low conduction and switching losses and operate at 20–50 kHz to shrink magnetics and cooling by 30%–40%. Plants realize 10%–15% annual energy savings, >50% failure-rate reductions, and extended lifetimes beyond 15 years. This aligns with ISO 50001 energy performance improvement plans and ISO 14001 environmental targets, while compliance documentation supports IEC 62477-1 (safety), IEC 61000 (EMC), and IEC 60747 (semiconductor devices). Integration support covers MODBUS TCP, PROFINET, EtherNet/IP, DNP3, and OPC UA for seamless SCADA/PLC connectivity.

Technical Specifications and Advanced Features

- Electrical ratings and topology

- Input: Three-phase 400–690 VAC (MV step-down optional)

- Output: Controlled DC for electric furnaces (EAF/ladle) or high-current AC with precision control

- Devices: ≥1700 V SiC MOSFETs and high-power Schottky diodes

- Module current: ≥500 A per module; scalable to multi-kA outputs via parallel modules

- Rectification schemes: 6/12/24-pulse; optional active front end (AFE) for low THD and power factor correction

- Switching and control

- Switching frequency: 20–50 kHz for reduced ripple and compact magnetics

- Control loops: Fast current regulation for arc stability; programmable ramp profiles; arc flash mitigation and soft-start/pre-charge

- Interfaces: MODBUS TCP, PROFINET, EtherNet/IP, DNP3, OPC UA with structured alarms and diagnostics

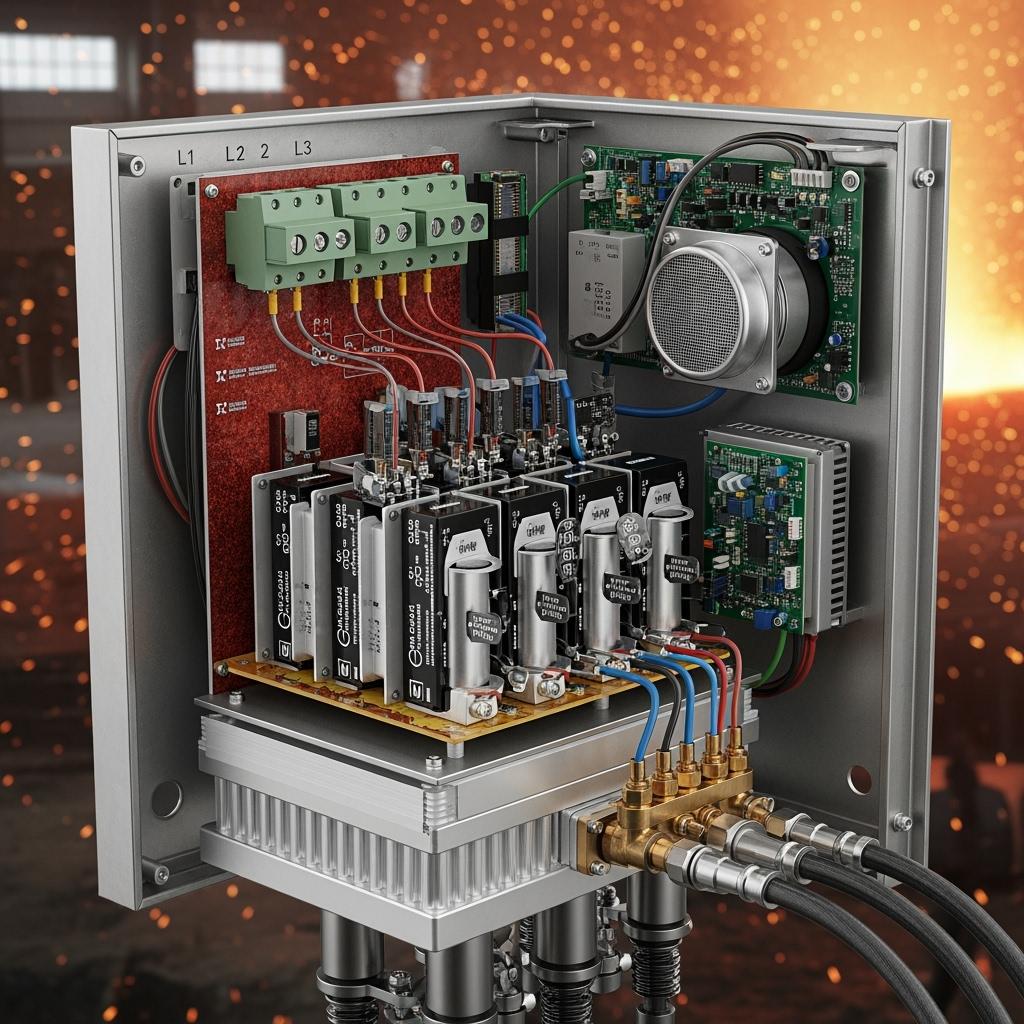

- Thermal and mechanical design

- Junction temperature: -55°C to 175°C for high-ambient endurance

- Thermal resistance: <0.2°C/W at module level with optimized baseplates

- Cooling options: Liquid-cooled plates or sealed air-to-air exchangers; 30%–40% smaller than silicon equivalents

- Enclosure: IP54+ with overpressure dust protection, stainless hardware, vibration-resistant mounts

- Protection and diagnostics

- Surge and arc suppression, fast short-circuit protection, desaturation, and overtemperature shutdown

- DC link pre-charge, crowbar options, and redundant sensing

- Intelligent monitoring and remote diagnostics with predictive maintenance analytics

- Compliance support

- IEC 62477-1 safety; IEC 61000 EMC; IEC 60747 semiconductors

- Documentation supporting ISO 50001 energy and ISO 14001 environmental programs

Efficiency and Reliability Advantages for Furnace Power Systems

| Attribute | SiC Power Conversion Units for Electric Furnaces | Conventional Silicon Converter Systems |

|---|---|---|

| System efficiency | >98% with ultra-low conduction/switching losses | 90%–94% typical in high-current duty |

| Thermal management | 30%–40% smaller cooling systems; lower heat load | Large skids; higher coolant flow and HVAC demand |

| Operating temperature | Junction -55°C to 175°C; reliable in radiant heat and dust | Typically -40°C to 150°C with derating |

| Arc stability and response | Fast current regulation at 20–50 kHz; improved arc stability | Slower response; more flicker and trips |

| Reliability in dust/heat | >50% failure-rate reduction with ceramic substrates and coatings | Elevated failure rates; frequent maintenance |

| Maintenance interval | Once every 2 years | About twice per year |

| Payback period | 2–3 years via energy and OPEX savings | Longer due to higher OPEX and downtime |

Key Advantages and Proven Benefits with Expert Insight

- High-current density and fast control loops stabilize furnace arcs, improving melt consistency and reducing electrode consumption.

- Ultra-low losses cut electrical consumption by 10%–15% annually and reduce heat rejection into MCC/control rooms.

- Dust- and heat-resilient design using ceramic substrates, conformal coatings, and sealed enclosures increases uptime.

- Modular power blocks simplify scaling and maintenance; hot-swap submodules and standardized busbars accelerate repairs.

Expert quote:

“Wide bandgap devices like SiC deliver superior efficiency and transient performance, enabling more compact and reliable converters for harsh furnace environments.” — Power Electronics Magazine, Industrial WBG Converters (2023)

Authority reference:

“System-level savings from SiC adoption continue to drive industrial uptake through 2025, especially where reliability and power density deliver measurable OPEX reductions.” — Yole Group, Power SiC Market Monitor (2024)

Real-World Applications and Measurable Success Stories

- Steel melt shop ladle furnace conversion

- Outcome: Efficiency uplift from 92.3% to 98.1%. Annual electricity savings exceeded 120,000 USD. Operating hours increased from 8,000 to 8,760 per year after reducing heat-related trips and stabilizing arc strikes.

- Cement kiln auxiliary furnaces and preheaters

- Benefit: 35% reduction in cooling skid footprint and improved power factor with optional AFE configuration; lower MCC room HVAC loads.

- Mining site smelting and calcination furnaces

- Benefit: Dust-sealed IP54 cabinets with liquid cooling maintained stable operation during blasting and crushing phases; predictive maintenance flagged coolant filter clogging before trips.

Selection and Maintenance Considerations

- Power quality and harmonics: Choose multi-pulse or AFE based on plant THD limits; coordinate with utility requirements in industrial estates.

- Environmental protection: Specify IP rating, positive-pressure ventilation, and filtration; consider liquid cooling for high-radiant-heat zones.

- Electrical interface: Validate transformer sizing, short-circuit withstand, and protection coordination; ensure adequate DC link energy for arc stability.

- Cabling and EMC: Use laminated busbars, short return paths, shielded control cables, and EMI gaskets; perform conducted/radiated emission checks.

- Preventive maintenance (24-month interval): Inspect thermal interfaces, busbar torque, filter media/coolant quality, sensors, and firmware versions.

Industry Success Factors and Customer Testimonials

- Success factors: Pre-install power-quality audit, arc stability modeling, thermal simulation for enclosure placement near hot zones, and operator training for diagnostics and ride-through settings.

- Customer voice: “The SiC furnace converter stabilized our ladle heating cycles and reduced electrode consumption, while cutting cooling complexity.” — Electrical Manager, integrated steel complex in Punjab.

Future Innovations and 2025+ Market Trends

- Higher-voltage SiC device classes (up to 3.3 kV) enabling fewer series elements and simpler medium-voltage front ends.

- Embedded intelligence with edge analytics and digital twins for arc optimization, electrode wear prediction, and cycle-time reduction.

- Localization via technology transfer and onshore assembly/testing to shrink lead times and enhance service responsiveness in Pakistan.

- Sustainability integration: Direct alignment to ISO 50001 KPIs and decarbonization roadmaps for export-oriented steel and cement groups.

Industry outlook:

“Industrial decarbonization hinges on power conversion efficiency gains and digital monitoring—areas where SiC provides immediate, bankable improvements.” — International Energy Agency, Technology Perspectives (2024)

Common Questions and Expert Answers

- Can SiC converters replace existing silicon-based furnace power supplies without major rewiring?

- Yes. Retrofit kits include mechanical adapters, busbar interfaces, and control integration, minimizing downtime.

- How do these units handle arc flash and voltage dips?

- Fast current control, DC link stabilization, ride-through algorithms, and surge/arc suppression mitigate dips and transient events.

- What cooling strategy is recommended near furnaces?

- Liquid cooling with sealed enclosures or air-to-air heat exchangers to avoid dust ingress; monitor coolant purity and flow.

- What are typical delivery timelines for customized configurations?

- Standard builds ship in 6–10 weeks; custom enclosures/ratings in 10–14 weeks with local partner commissioning support.

- Which standards and documentation are provided for acceptance testing?

- Reports aligned to IEC 62477-1, IEC 61000 series, and IEC 60747; guidance for ISO 50001/14001 documentation.

Why This Solution Works for Your Operations

SiC power conversion units provide the efficiency, thermal resilience, and dust resistance essential for electric furnace uptime in Pakistan’s harsh industrial environments. By delivering >98% efficiency, compact cooling, and fast current control, these systems reduce energy costs, stabilize arcs, and increase throughput—while integrating smoothly with existing infrastructure and meeting local compliance expectations. The result is a lower total cost of ownership and a future-ready platform for growth.

Connect with Specialists for Custom Solutions

Accelerate your furnace power modernization with end-to-end silicon carbide expertise and turnkey delivery.

- 10+ years of SiC manufacturing expertise

- Backing from a leading research ecosystem for rapid innovation

- Custom product development across R-SiC, SSiC, RBSiC, and SiSiC materials

- Technology transfer and factory establishment services to localize capability

- Turnkey solutions from material processing to packaged, tested power conversion units

- Proven track record with 19+ industrial enterprises

Request a free consultation, feasibility assessment, and furnace-specific ROI model. Secure a phased retrofit plan with performance guarantees tailored to your melt shop conditions.

- Email: [email protected]

- Phone/WhatsApp: +86 133 6536 0038

Recommended next steps: Share single-line diagrams, furnace duty cycles, and site environmental conditions; schedule a power-quality audit; plan a pilot retrofit for data-driven validation.

Article Metadata

- Last updated: 2025-09-12

- Next scheduled update: 2026-03-31

- References: IEEE Power Electronics Magazine (2023) Industrial WBG Converters; Yole Group Power SiC Market Monitor (2024); International Energy Agency Technology Perspectives (2024)

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.