Inverter Main Control Boards with SiC-Matched Algorithm Libraries for FRT, Reactive Power, and Grid Support

Share

Product Overview and 2025 Market Relevance

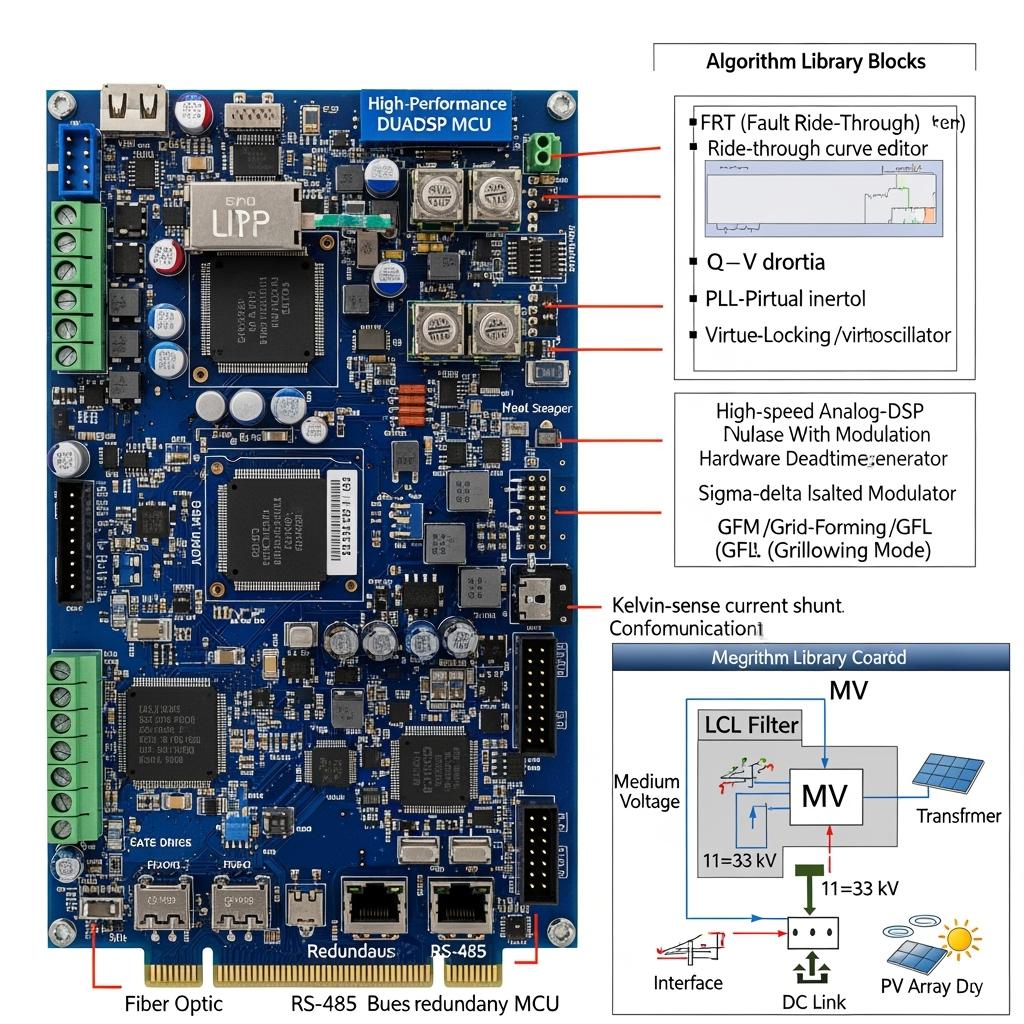

Inverter main control boards designed for silicon carbide (SiC) power stages are the central intelligence for medium-voltage (11–33 kV) photovoltaic and industrial drive systems. They integrate high-performance processors, time-deterministic PWM engines, multi-channel ADCs, and high-speed communications with SiC-matched control algorithms for low-loss operation, fast transient response, and advanced grid services. Purpose-built algorithm libraries—fault ride-through (FRT), reactive power and voltage control (Q–V), frequency response (P–f), grid-forming (GFM) and grid-following (GFL) modes, and black start—enable robust performance in Pakistan’s textile, cement, steel, and emerging industrial sectors operating in 45–50°C and dusty environments.

In 2025, the market demands compact, high-efficiency SiC inverters operating at 50–150 kHz switching frequencies with LCL filters optimized for low THD and reduced cooling footprints. SiC-specific control adapts to faster device dynamics by coordinating PWM deadtime, dv/dt constraints, and gate-drive telemetry. Embedded FRT profiles aligned with medium-voltage interconnection rules maintain synchronization during voltage dips, while reactive power support strengthens feeder voltage stability. With integrated cybersecurity, remote diagnostics, and condition monitoring, these control boards shorten commissioning, ensure ≥98.5% system efficiency, and help achieve up to 2× power density and MTBF targets of 200,000 hours.

Technical Specifications and Advanced Features

- Processing and timing

- Dual-core DSP/MCU or FPGA+MCU architecture with deterministic real-time tasks at 50–200 µs loop times

- PWM resolution to <50 ns with programmable deadtime; synchronized multi-channel operation for 3P/6P bridges

- Measurement and protection I/O

- 16–24 bit isolated current and voltage measurement (sigma-delta or precision ADC) with hardware overcurrent comparators

- High-speed fault bus from SiC gate drivers (DESAT/TLO status) for sub-µs protection coordination

- SiC-matched algorithm libraries

- FRT profiles: configurable voltage sag/swell ride-through with dynamic current limits and PLL/GFM control

- Reactive power control: Q–V droop, Volt/VAR/Volt/Watt, fast Q ramp for MV feeder support

- Frequency support: P–f droop, synthetic inertia, ROCOF ride-through, under/over-frequency curtailment

- Grid-forming/grid-following: Virtual synchronous machine (VSM), droop-based GFM, adaptive PLL-based GFL

- LCL filter control: Active damping, PR/RES controllers for THD compliance at 50–150 kHz switching

- SiC device coordination: Deadtime optimization, dv/dt shaping interfaces, temperature-aware current limits

- Communications and cybersecurity

- Ethernet, fiber, and RS-485 with Modbus/TCP, IEC 61850 gateway options; secure boot and firmware signing

- Remote diagnostics: event logs, waveform capture, SOH indicators (switching counts, thermal cycles)

- Environmental and reliability

- Wide-temperature industrial rating; conformal coating; surge and ESD protection

- Redundant enable lines, watchdog, brownout protection; field-upgradable firmware with rollback

Descriptive Comparison: SiC-Matched Control Boards vs Generic Inverter Controllers

| Criterion | SiC-matched main control board with grid support libraries | Generic inverter controller |

|---|---|---|

| Switching frequency and loss control | 50–150 kHz with deadtime/dv/dt coordination | Limited to lower frequencies; less efficient |

| Grid support features | Built-in FRT, Q–V/P–f droops, GFM/GFL, virtual inertia | Basic PLL and reactive setpoints only |

| Protection coordination | Fast fault bus with DESAT/TLO awareness | Slower, non-coordinated trips |

| THD and filter size | Active damping tuned to LCL for compact filters | Larger filters to meet THD |

| Commissioning in harsh environments | Conformal-coated, remote diagnostics, secure updates | Minimal remote tools; slower commissioning |

Key Advantages and Proven Benefits with Expert Quote

- Efficiency and density: Tight coupling of PWM, deadtime, and SiC switching behavior reduces losses, enabling ≥98.5% inverter efficiency and smaller thermal systems.

- Grid stability: FRT, Q–V, and P–f responses maintain service during voltage dips and frequency excursions on MV feeders, supporting continuous operation in industrial parks.

- Rapid commissioning: Pre-validated parameter sets for 11–33 kV transformer interfaces, LCL filters, and SiC gate-drive stacks reduce integration time.

- Reliability: Condition monitoring and coordinated protection with DESAT/TLO minimize fault energy and downtime, driving MTBF improvements.

Expert perspective:

“Advanced control strategies—grid-forming, fast reactive support, and robust ride-through—are essential to fully realize wide bandgap inverter potential and ensure grid resilience.” — IEEE Power Electronics applications guidance (ieee.org)

Real-World Applications and Measurable Success Stories

- MV PV inverter rollout in southern Pakistan: Deployments using SiC-matched boards at 100 kHz achieved ≥98.5% efficiency and decreased cooling volume by ~40%. FRT-enabled control maintained operation during feeder sags without nuisance tripping.

- Textile mill power quality: Reactive power droop reduced voltage fluctuations on weak feeders, improving production uptime and reducing motor thermal stress.

- Cement and steel drives: Virtual inertia and P–f support smoothed load-induced frequency dips, reducing flicker complaints and enhancing grid compliance.

Selection and Maintenance Considerations

- System definition

- Define MV interface (transformer ratio, impedance), LCL filter targets, and switching frequency (50–150 kHz).

- Identify grid code requirements for ride-through, reactive power, and THD.

- Hardware pairing

- Ensure ADC isolation bandwidth matches PWM rates; select drivers with CMTI ≥ 100 V/ns and fault bus compatibility.

- Provide robust EMC layout and shielding for encoder/CT/voltage sense lines.

- Control parameterization

- Configure FRT curves, Q–V and P–f droops, and damping gains via guided commissioning tools.

- Tune deadtime and dv/dt limits against EMI and efficiency trade-offs using double-pulse and THD tests.

- Operational upkeep

- Monitor event logs, SOH metrics, and thermal cycles; schedule firmware and parameter reviews.

- Validate protection triggers and communications annually; inspect conformal coating integrity in dusty rooms.

Industry Success Factors and Customer Testimonials

- Co-design with power stage and grid teams aligns filter design, dv/dt, and control loops to meet THD and EMC targets with minimal rework.

- Standardized parameter packs enable fast replication across multiple sites and transformer types.

Customer feedback:

“The SiC-matched control board’s FRT and reactive support stabilized our MV interconnections. Commissioning time dropped, and EMC challenges were easier to resolve.” — Technical director, regional C&I PV integrator

Future Innovations and Market Trends

- Enhanced grid-forming controls with adaptive droop and virtual oscillator control for weak grids and microgrids

- Model-predictive control and harmonic compensation for ultra-low THD with even smaller LCL filters

- Edge AI diagnostics correlating gate-drive events, temperature, and grid disturbances for predictive maintenance

- Localization of firmware profiles aligned with Pakistan’s projected >5 GW MV PV expansion and approximately USD 500 million inverter market

Common Questions and Expert Answers

- Do I need grid-forming or grid-following mode?

Use grid-following for strong grids with accurate PLL tracking; deploy grid-forming for weak feeders or microgrids needing voltage/frequency reference and islanding capability. - How are FRT settings configured?

Through a parameterized editor mapping voltage sag depth/duration to current limits, mode behavior (GFM/GFL), and reactive priority per grid codes. - How does the board help with THD at high switching frequency?

Active damping and PR controllers are tuned to the LCL resonance and sampling rates compatible with 50–150 kHz switching, enabling smaller filters. - Can the controller coordinate with DESAT/TLO in the gate drivers?

Yes. A high-speed fault bus captures DESAT/TLO events, forcing controlled shutdown and post-fault restart sequences. - What communications are supported for utility integration?

Ethernet/Modbus-TCP and optional IEC 61850 gateway for SCADA integration, with secure firmware updates and signed configurations.

Why This Solution Works for Your Operations

SiC-matched main control boards translate the intrinsic speed and efficiency of SiC power stages into grid-compliant, reliable systems tailored for Pakistan’s conditions. Integrated FRT, reactive support, and frequency response stabilize MV feeders, while high-frequency control and coordinated protection deliver ≥98.5% efficiency, up to 2× power density, and long service life in 45–50°C and dusty environments across textile, cement, and steel facilities.

Connect with Specialists for Custom Solutions

Accelerate your SiC inverter roadmap with application-tuned controls:

- 10+ years of SiC manufacturing expertise

- Backing from a leading research ecosystem for control algorithms, isolation, and protection innovation

- Custom product development across R-SiC, SSiC, RBSiC, and SiSiC components to enhance thermal and structural reliability

- Technology transfer and factory establishment services for local control board assembly and test

- Turnkey delivery from materials and devices to drivers, control boards, filters, cooling, and compliance

- Proven results with 19+ enterprises improving efficiency, reliability, and time-to-market

Request a free consultation and a tailored control algorithm and commissioning package:

- Email: [email protected]

- Phone/WhatsApp: +86 133 6536 0038

Reserve 2025–2026 co-design and deployment slots now to secure grid code compliance, EMC validation, and rapid field rollouts.

Article Metadata

Last updated: 2025-09-10

Next scheduled update: 2026-01-15

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.