High-Temperature Reliability Test Systems for SiC Devices: HTGB/HTRB, Power Cycling, and Thermal Shock

Share

Product Overview and 2025 Market Relevance

High-temperature reliability test systems purpose-built for silicon carbide (SiC) devices combine HTGB (High-Temperature Gate Bias), HTRB (High-Temperature Reverse Bias), active power cycling, and thermal shock modules, enabling comprehensive lifetime validation under realistic electrical and thermal stress. For Pakistan’s textile, cement, and steel industries—where equipment rooms frequently see 45–50°C ambient temperatures and heavy dust—these systems are essential to qualify SiC diodes, MOSFETs, and modules for 11–33 kV distribution-level photovoltaic interconnection and industrial drives.

In 2025, market success hinges on demonstrating long service life at elevated junction temperatures and fast switching frequencies (50–150 kHz). SiC technology enables ≥98.5% inverter efficiency and up to 2× power density, but packaging fatigue, gate oxide reliability, and leakage stability must be proven. Reliability platforms featuring controlled ΔTj power cycling (e.g., 20–100 K), rapid thermal shock, and high-temperature bias stress allow manufacturers and integrators to build physics-of-failure models, reduce warranty risk, and accelerate utility and industrial approvals across Pakistan’s expanding PV pipeline and modernization of industrial drives.

Technical Specifications and Advanced Features

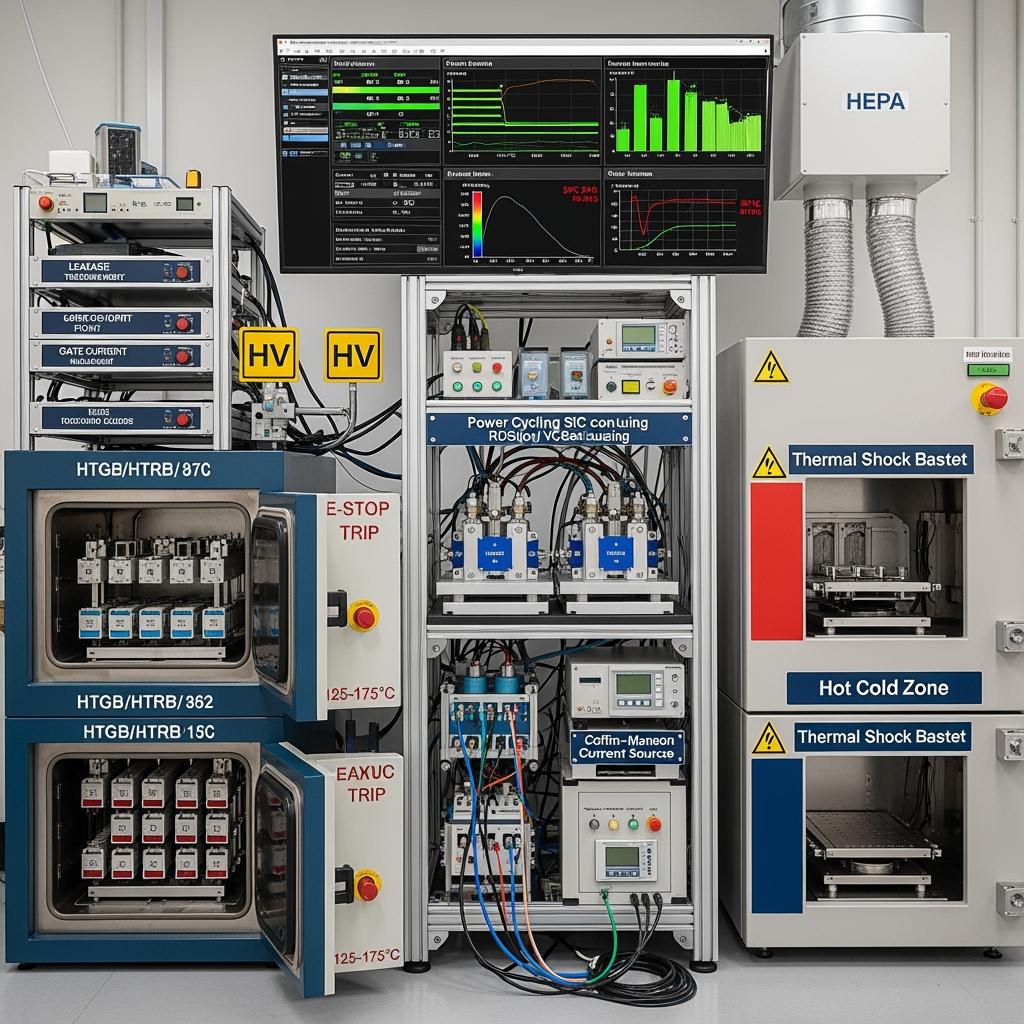

- HTGB/HTRB stress capability

- Temperature range: 125–175°C chamber control with ±1–2°C stability

- Voltage stress: Up to device-rated BV for HTRB; gate bias per datasheet max for HTGB (positive/negative for MOSFETs)

- Measurements: Sub-nA leakage resolution, gate current monitoring, time-to-failure logging with programmable limits

- Power cycling and thermal shock

- ΔTj control: 20–100 K range; Tj,max up to +175°C using on-state parameter thermometry (RDS(on)/VCEsat/VF) with Kelvin connections

- Current capability: Pulsed and continuous, waveform shaping with controlled rise/fall for realistic di/dt

- Thermal shock: Rapid transfer between hot/cold zones with programmable dwell; thermal ramp profiling

- Data acquisition and analytics

- High-speed digitization of electrical/thermal parameters; synced event markers for degradation precursors

- Lifetime modeling: Coffin–Manson for solder/attach fatigue, Arrhenius temperature acceleration, Weibull statistics with confidence bounds

- Mission-profile synthesis: Rainflow counting from field data (PV irradiance/load cycles) to lab stress translation

- Safety and compliance

- Fully interlocked HV enclosures, E-Stop, over-current/over-temp protection, and arc-detection as applicable

- Traceability: Lot IDs, barcode tracking, audit-ready electronic records and calibration certificates

- Environmental robustness for Pakistan use cases

- Dust mitigation: Sealed rack intake with replaceable pre-filters/HEPA; positive pressure airflow

- Remote monitoring: Ethernet/Modbus interfaces, automated test reports for rapid decision-making

Descriptive Comparison: SiC-Focused Reliability Platforms vs Generic Power Test Rigs

| Criterion | SiC-focused high-temperature reliability systems | Generic power test rigs |

|---|---|---|

| ΔTj and Tj,max capability | Controlled ΔTj to 100 K, Tj up to +175°C with Kelvin sensing | Case temperature control; limited Tj visibility |

| HTGB/HTRB precision | Sub-nA leakage and gate current tracking at 125–175°C | Coarse leakage, limited gate bias features |

| Fault and stress realism | Programmable di/dt, surge options, thermal shock integration | Basic static tests; minimal stress fidelity |

| Lifetime modeling | Built-in Coffin–Manson/Arrhenius, Weibull analytics | External/manual analysis; lower confidence |

| Throughput and traceability | Multi-DUT parallel testing, MES connectivity, SPC | Single/low channel, limited traceability |

Key Advantages and Proven Benefits with Expert Quote

- Predictive lifetime assurance: Correlates material and packaging choices (e.g., Ag sinter, Si3N4/AlN substrates) with cycles-to-failure under realistic ΔTj and high-temperature bias.

- Faster qualification: Parallel channel counts and automated analytics compress DVT timelines for MV PV and industrial drives.

- Lower warranty risk: Early detection of leakage growth, Vth shift, and bond/attach degradation enables corrective action before mass deployment.

- Environmental readiness: Dust-controlled enclosures and remote monitoring support reliable operation in Pakistan’s industrial settings.

Expert perspective:

“Reliable deployment of wide bandgap power electronics depends on systematic HTGB/HTRB and power cycling to capture gate oxide behavior and packaging fatigue at elevated temperatures.” — IEEE Power Electronics reliability guidance (ieee.org)

Real-World Applications and Measurable Success Stories

- MV PV inverter modules (southern Pakistan): ΔTj-controlled power cycling at 60 K identified optimal Ag-sinter profiles, extending median life by ~25% and supporting ≥98.5% system efficiency with ~40% smaller cooling systems.

- Textile drives: HTGB sequences reduced gate-threshold drift dispersion by ~30%, stabilizing control margins in 45–50°C ambient conditions.

- Cement and steel drives: Thermal shock plus HTRB screening lowered early-life leakage-related returns and cut nuisance trips during grid disturbances.

Selection and Maintenance Considerations

- Define mission profiles

- Convert PV irradiance/load data and ambient temperatures into rainflow-counted ΔTj and temperature duty cycles; include grid fault scenarios.

- Choose stress coverage

- Combine HTGB/HTRB for device-level integrity with power cycling for packaging reliability and thermal shock for interconnect resilience.

- Measurement fidelity

- Use Kelvin sensing for on-state parameter thermometry; calibrate Tj estimation against IR or embedded sensors when available.

- Environmental controls

- Ensure dust filtration and periodic filter replacement; maintain chamber uniformity verification at 125–175°C.

- Calibration and upkeep

- Schedule annual calibration of voltage/current sources, thermal sensors, and leakage measurement paths; perform periodic interlock tests and software validation.

Industry Success Factors and Customer Testimonials

- Cross-functional collaboration: Reliability, device design, packaging, and gate-drive teams co-own stress recipes linked to intended switching frequency (50–150 kHz) and thermal targets.

- Documentation rigor: Clear acceptance criteria, traceable records, and statistical confidence accelerate customer approvals and utility certifications.

Customer feedback:

“By integrating HTGB/HTRB and ΔTj power cycling early, we eliminated gate drift issues and stabilized attach reliability. Our MV inverter qualification moved from months to weeks.” — Reliability manager, regional PV OEM

Future Innovations and Market Trends

- Digital twins linking lab stress data with finite element thermo-mechanical models for design-of-experiments optimization

- Machine learning analytics for real-time anomaly detection and remaining useful life predictions from multi-sensor streams

- Expanded short-circuit and avalanche stress modules aligned with evolving protection standards for MV networks

- Local test centers and rental platforms to support Pakistan’s >5 GW MV PV pipeline and approximately USD 500 million inverter market

Common Questions and Expert Answers

- What ΔTj is appropriate for accelerated power cycling?

Typical accelerated tests use 40–80 K, with Tj,max up to +175°C. Select based on field thermal swings and desired acceleration. - How long should HTGB/HTRB runs last?

Durations vary by qualification plan; many programs run from hundreds to thousands of hours at 125–175°C with periodic parametric checks and pass/fail thresholds. - How are results extrapolated to field life?

Use Arrhenius (temperature) and Coffin–Manson (strain/ΔTj) models, with Weibull statistics to quantify confidence; calibrate using any field return data. - Can these systems emulate dusty, hot environments?

Yes. Cabinets feature filtered, positive-pressure airflow and allow high ambient tests while focusing on electrical and thermal stress realism. - What failure precursors are most informative?

Leakage growth, Vth shift, RDS(on) drift, and increased thermal impedance indicate gate oxide stress, defect activation, and packaging fatigue.

Why This Solution Works for Your Operations

These high-temperature reliability systems translate Pakistan’s real operating conditions into controlled, reproducible stress tests that reveal device and packaging limits before field deployment. The outcome is actionable lifetime data that supports ≥98.5% inverter efficiency, up to 2× power density, and 200,000-hour MTBF targets for MV PV inverters and industrial drives in textile, cement, and steel facilities.

Connect with Specialists for Custom Solutions

Partner with a team focused on materials-to-systems reliability:

- 10+ years of SiC manufacturing expertise

- Backing from a leading research ecosystem to advance HTGB/HTRB, power cycling, and analytics

- Custom product development across R-SiC, SSiC, RBSiC, and SiSiC for thermal paths and mechanical integrity

- Technology transfer and factory establishment services, including reliability lab setup

- Turnkey solutions from materials and devices to packaging, testing, and field validation

- Proven track record with 19+ enterprises delivering measurable reliability and ROI improvements

Request a free consultation and a tailored reliability test plan aligned with your mission profile:

- Email: [email protected]

- Phone/WhatsApp: +86 133 6536 0038

Secure your 2025–2026 qualification slots now to de-risk MV inverter and industrial drive launches and accelerate approvals.

Article Metadata

Last updated: 2025-09-10

Next scheduled update: 2026-01-15

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.