High Purity SiC for Critical Technological Needs

Share

High Purity SiC for Critical Technological Needs

Introduction: The Essential Role of Custom High Purity Silicon Carbide

In the ever-evolving landscape of advanced materials, high purity silicon carbide (SiC) stands out as a cornerstone material for industries demanding exceptional performance under extreme conditions. Custom silicon carbide products, engineered to precise specifications, are not merely components; they are critical enablers of innovation and efficiency in high-performance industrial applications. From the heart of semiconductor fabrication plants to the demanding environments of aerospace and energy production, SiC’s unique combination of properties makes it indispensable. Its ability to withstand soaring temperatures, resist harsh chemicals, and endure significant wear and tear allows engineers to push boundaries and achieve new levels of operational excellence. As technology advances, the need for materials that can meet increasingly stringent requirements grows, positioning custom SiC components at the forefront of technological progress. This article delves into the multifaceted world of high purity SiC, exploring its applications, the advantages of customization, and key considerations for procurement and design, particularly for B2B buyers and technical procurement professionals seeking reliable SiC solutions.

The demand for custom SiC solutions is driven by the understanding that off-the-shelf components often fall short in specialized applications. Tailoring the material grade, design, and finish of SiC parts allows for optimized performance, extended service life, and enhanced system reliability. This customization is particularly crucial for OEMs and industries where even marginal improvements in material performance can lead to significant competitive advantages and operational cost savings. Understanding the nuances of SiC properties and the benefits of bespoke solutions is key to harnessing its full potential.

Main Applications: High Purity SiC Across Diverse Industries

The versatility of high purity silicon carbide allows it to be a critical material in a wide array of demanding sectors. Its exceptional properties translate directly into performance gains and enhanced reliability in various industrial applications. Here’s a look at how SiC is revolutionizing key industries:

- Semiconductor Manufacturing: SiC is extensively used for wafer handling components, process chamber parts (e.g., etching rings, showerheads, susceptors), and CMP rings. Its high thermal conductivity, stiffness, and resistance to plasma erosion are vital for maintaining ultra-clean environments and precision in chip fabrication. The demand for SiC in semiconductor processing equipment continues to surge with the growth of the electronics market.

- Power Electronics: In power modules, inverters, and converters, SiC-based devices (MOSFETs, diodes) offer higher switching speeds, lower energy losses, and superior thermal management compared to traditional silicon. This is critical for electric vehicles, renewable energy systems (solar and wind power inverters), and industrial motor drives, leading to more efficient and compact designs.

- Aerospace and Defense: Lightweight mirrors and optical benches for satellites, components for rocket nozzles, and armor applications benefit from SiC’s high specific stiffness, thermal stability, and wear resistance. Aerospace-grade SiC contributes to reduced payload weight and enhanced performance in harsh environments.

- High-Temperature Furnaces and Heat Treatment: Kiln furniture, radiant tubes, nozzles, and thermocouple protection tubes made from SiC offer exceptional strength at elevated temperatures (up to 1600°C or higher), resistance to thermal shock, and longevity in aggressive furnace atmospheres. This improves energy efficiency and reduces downtime in metallurgical and ceramics industries.

- Automotive: Beyond power electronics, SiC is used in diesel particulate filters (DPFs), brake discs, and wear-resistant components for pumps and seals, offering durability and improved performance. Automotive SiC components are key to meeting emissions standards and enhancing vehicle efficiency.

- Chemical Processing: Seals, bearings, pump components, and heat exchangers made from SiC exhibit outstanding chemical inertness against highly corrosive acids and alkalis, even at high temperatures. This ensures process integrity and extends the lifespan of equipment in chemical processing SiC applications.

- LED Manufacturing: SiC substrates are used for growing GaN layers for high-brightness LEDs, offering good lattice matching and thermal conductivity, which is crucial for the performance and lifespan of LED chips.

- Metallurgy: Components like crucibles, thermocouple sheaths, and heating elements benefit from SiC’s high-temperature strength and resistance to molten metals.

- Renewable Energy: As mentioned, SiC is crucial for inverters in solar and wind power systems, improving conversion efficiency and reliability.

- Oil and Gas: Wear-resistant components for downhole tools, valves, and pumps utilize SiC’s hardness and corrosion resistance in demanding extraction and processing environments.

- Nuclear Energy: SiC and SiC-matrix composites are being explored for fuel cladding and structural components in next-generation nuclear reactors due to their high-temperature stability, radiation resistance, and chemical inertness.

The breadth of these applications underscores the importance of industrial SiC procurement for businesses looking to maintain a competitive edge through superior material performance.

Why Choose Custom High Purity Silicon Carbide?

While standard silicon carbide components serve many purposes, opting for custom high purity silicon carbide products offers a multitude of advantages, particularly for specialized and critical applications. Customization allows engineers and procurement managers to specify exact material properties, geometries, and finishes, leading to optimized performance, longer service life, and overall system efficiency. Here are key benefits:

- Tailored Thermal Management: Different applications have unique thermal load profiles. Customizing the SiC grade (e.g., sintered SiC for high thermal conductivity, reaction-bonded for complex shapes) allows for optimized heat dissipation or insulation, critical in power electronics, furnace components, and semiconductor processing. SiC thermal conductivity can be fine-tuned through material composition and density.

- Enhanced Wear and Abrasion Resistance: For components exposed to abrasive particles or high friction, such as seals, nozzles, and bearings, customizing the SiC type (e.g., dense SSiC) and surface finish can significantly improve SiC wear resistance, extending part lifetime and reducing maintenance cycles.

- Superior Chemical Inertness and Corrosion Resistance: In aggressive chemical environments found in chemical processing or semiconductor etching, the purity and density of SiC are paramount. Custom high purity grades ensure minimal contamination and maximum resistance to acids, alkalis, and reactive gases, safeguarding process integrity. SiC chemical inertness protects valuable equipment.

- Optimized Electrical Properties: Silicon carbide can range from a semiconductor to a resistor depending on its purity and additives. Customization allows for specific electrical resistivity, crucial for applications like heating elements, susceptors in semiconductor processing, or insulators.

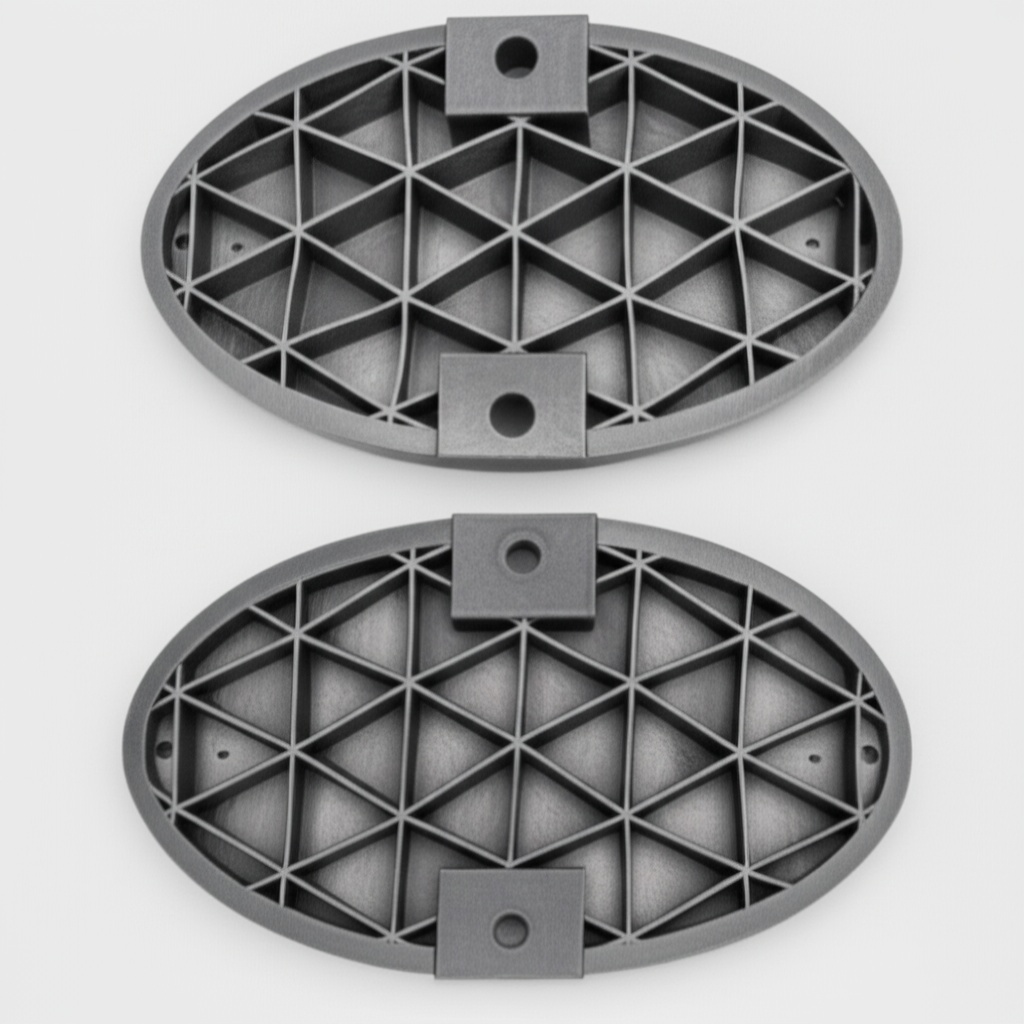

- Complex Geometries and Precision: Many advanced systems require SiC components with intricate designs and tight tolerances that are not available off-the-shelf. Specialized SiC parts manufacturing processes, like those for reaction-bonded SiC (RBSC) or advanced sintering techniques, enable the production of complex shapes that meet precise dimensional requirements.

- Improved System Integration and Performance: Components designed to exact specifications integrate more seamlessly into larger systems, reducing assembly challenges and improving overall operational performance. This is vital for OEMs seeking to enhance their product offerings.

- Cost-Effectiveness in the Long Run: While custom components may have a higher initial cost, their optimized performance, extended lifespan, and reduced system downtime often result in a lower total cost of ownership. Investing in high-quality custom SiC is a strategic decision for critical applications.

For businesses looking to leverage these benefits, partnering with a supplier offering comprehensive customizing support is essential. This ensures that the final SiC product perfectly aligns with the application’s unique demands.

Recommended SiC Grades and Compositions

Selecting the appropriate grade of silicon carbide is crucial for achieving desired performance characteristics in specific applications. Each type offers a unique balance of properties, manufacturing capabilities, and cost. Here are some commonly used SiC grades and compositions:

| SiC Grade | Abbreviation | Key Manufacturing Process | Primary Properties | Typical Applications |

|---|---|---|---|---|

| Sintered Silicon Carbide | SSiC | Solid-state sintering of fine SiC powder at high temperatures (2000-2200°C) with sintering aids (e.g., boron, carbon). | High density (typically >98%), excellent wear and corrosion resistance, high strength, good thermal conductivity, maintains strength at high temperatures. | Mechanical seals, bearings, pump shafts, nozzles, semiconductor wafer processing components, armor. |

| Reaction-Bonded Silicon Carbide (Silicon Infiltrated Silicon Carbide) | RBSC or SiSiC | Infiltration of molten silicon into a porous preform made of SiC grains and carbon. The silicon reacts with carbon to form new SiC, bonding the original grains. Contains some free silicon (typically 8-15%). | Complex shape capability with minimal firing shrinkage, good thermal shock resistance, excellent thermal conductivity, moderate wear resistance, good strength. Not suitable for very high temperatures where silicon might melt or react. | Kiln furniture (beams, rollers, setters), heat exchangers, wear liners, large structural components, rocket nozzles. |

| Nitride-Bonded Silicon Carbide | NBSC | SiC grains bonded by a silicon nitride (Si3N4) phase, formed in situ by nitriding silicon mixed with SiC grains. | Good thermal shock resistance, good resistance to molten non-ferrous metals, moderate strength. | Kiln furniture, components for aluminum and copper industries, thermocouple protection tubes, burner nozzles. |

| Recrystallized Silicon Carbide | RSiC or RXSIC | High-purity SiC grains are heated to very high temperatures (around 2500°C) causing them to bond without significant shrinkage or densification. Highly porous. | Exceptional thermal shock resistance, high operating temperature, high purity, porous structure. | Kiln furniture (plates, saggers), high-temperature supports, filters for molten metals. |

| Chemical Vapor Deposited Silicon Carbide | CVD SiC | Deposition of SiC from gaseous precursors (e.g., methyltrichlorosilane) onto a substrate. | Ultra-high purity (99.999%+), fully dense, excellent corrosion and erosion resistance, superior thermal conductivity, smooth surfaces. Higher cost. | Semiconductor process components (susceptors, focus rings, gas distribution plates), optical mirrors, protective coatings. |

| Hot-Pressed Silicon Carbide | HPSiC | SiC powder is densified under high temperature and pressure. | Very high strength and hardness, excellent wear resistance. Can be expensive and limited in shape complexity. | Cutting tools, armor, specialized wear parts. |

When selecting a SiC grade, procurement professionals and engineers should consider the operating temperature, mechanical stress, chemical environment, thermal shock conditions, required dimensional tolerances, and, of course, budget. Consulting with experienced SiC manufacturers who can provide guidance on material selection is highly recommended to ensure the optimal choice for your application.

Design Considerations for Custom SiC Products

Designing components with custom silicon carbide requires careful consideration of its unique material properties and manufacturing processes. Unlike metals, SiC is a brittle ceramic, which means design rules common for ductile materials may not apply. Effective design ensures manufacturability, optimal performance, and longevity of the SiC part. Here are key design considerations:

- Simplicity and Manufacturability:

- Strive for simple geometries where possible. Complex features like sharp internal corners, very thin walls, or drastic changes in cross-section can create stress concentrations and increase manufacturing difficulty and cost.

- Understand the manufacturing capabilities of the chosen SiC grade. For example, RBSC allows for more complex net-shape forming than SSiC before firing.

- Avoiding Stress Concentrators:

- Radii, not sharp corners: Generous radii should be incorporated on all internal and external corners to distribute stress and reduce the risk of fracture.

- Hole placement: Holes should be located away from edges and other stress-concentrating features. Consider the ratio of hole diameter to wall thickness.

- Wall Thickness and Aspect Ratios:

- Maintain uniform wall thickness to prevent distortion or cracking during drying and firing.

- Avoid extremely thin sections or high aspect ratios unless absolutely necessary and discussed with the manufacturer, as these can be fragile and difficult to produce. Minimum achievable wall thickness depends on the SiC grade and manufacturing method.

- Tolerances and Machinability:

- SiC is very hard, making post-firing machining (grinding) expensive and time-consuming. Design parts as close to net-shape as possible.

- Specify realistic tolerances. Tighter tolerances typically mean higher costs due to increased machining. Discuss achievable tolerances with your SiC supplier early in the design phase.

- Joining and Assembly:

- If the SiC component needs to be assembled with other parts (ceramic or metallic), consider differences in thermal expansion coefficients. Design appropriate interfaces or use compliant layers to accommodate mismatches.

- Mechanical fastening methods should be designed to distribute loads evenly and avoid point stresses on the ceramic.

- Surface Finish Requirements:

- Specify the required surface finish (Ra value). Highly polished surfaces can improve strength and wear resistance but add to the cost. An as-fired surface might be sufficient for some applications.

- Thermal Management Design:

- For applications requiring heat dissipation, design features like fins or channels to maximize surface area, considering manufacturing constraints.

- For thermal shock resistance, smooth transitions in thickness and minimizing constraints are beneficial.

- Load Conditions:

- Design SiC components to be loaded in compression whenever possible, as ceramics are significantly stronger in compression than in tension or bending.

- Clearly define the type, magnitude, and direction of loads the component will experience.

Collaborating closely with experienced custom SiC component manufacturers during the design phase is crucial. They can provide valuable insights into design for manufacturability (DFM) specific to silicon carbide, helping to optimize the design for performance, reliability, and cost-effectiveness.

Tolerance, Surface Finish & Dimensional Accuracy in SiC Manufacturing

Achieving precise dimensional accuracy, specified tolerances, and desired surface finishes are critical aspects of manufacturing high-quality silicon carbide components. Given SiC’s extreme hardness, these parameters significantly influence both the performance of the part and its manufacturing cost. Understanding the capabilities and limitations is essential for engineers and procurement managers.

Dimensional Accuracy and Tolerances:

The achievable dimensional accuracy for SiC parts depends heavily on the manufacturing process (e.g., RBSC, SSiC, NBSC), the size and complexity of the component, and whether post-firing machining is employed.

- As-Fired Tolerances: For parts used in their as-fired state (without grinding), tolerances are generally looser.

- Reaction-Bonded Silicon Carbide (RBSC/SiSiC): Known for its excellent dimensional control due to low firing shrinkage (typically <1%). Tolerances can be around ±0.5% to ±1% of the dimension, or even tighter for smaller, simpler parts.

- Sintered Silicon Carbide (SSiC): Undergoes significant shrinkage during sintering (15-20%). While predictable, this leads to wider as-fired tolerances, often in the range of ±1% to ±2%.

- Nitride-Bonded Silicon Carbide (NBSC): Dimensional changes are moderate, typically with tolerances around ±1%.

- Ground Tolerances: For applications requiring high precision, SiC components are machined after firing using diamond grinding techniques. This allows for much tighter tolerances.

- Standard ground tolerances can be in the range of ±0.025 mm to ±0.05 mm (±0.001″ to ±0.002″).

- With specialized grinding and lapping, even tighter tolerances down to a few microns (e.g., ±0.005 mm or ±0.0002″) can be achieved for critical dimensions, especially on smaller parts or specific features. However, this significantly increases cost.

It’s crucial to specify only the necessary tolerances. Over-tolerancing can drastically increase the cost of SiC machining.

Surface Finish:

The surface finish (roughness) of a SiC component impacts its frictional properties, wear resistance, sealing capability, and sometimes its mechanical strength (by reducing surface flaws).

- As-Fired Surface Finish:

- RBSC typically has a relatively smooth as-fired surface, often around Ra 1.0-3.0 µm, due to the presence of free silicon.

- SSiC as-fired surfaces are generally rougher, depending on the initial powder size and sintering process, often Ra 2.0-5.0 µm.

- Ground Surface Finish: Diamond grinding can produce much smoother surfaces.

- Typical ground finishes range from Ra 0.4 µm to Ra 0.8 µm.

- Lapping and polishing can achieve exceptionally smooth surfaces, down to Ra 0.02 µm or better. Such finishes are required for applications like high-performance seals, bearings, or optical components.

The required surface finish should be clearly specified on drawings, often using parameters like Ra (average roughness). Similar to tolerances, demanding an unnecessarily fine surface finish will add to the cost. Discussing requirements with your technical ceramics supplier ensures that the specified finish is both achievable and functional for the intended application.

Achieving high dimensional accuracy and specific surface finishes in high purity SiC components relies on advanced manufacturing equipment, precise process control, and skilled metrology. Reputable suppliers will have robust quality assurance systems to verify these critical parameters.

Post-Processing Needs for Enhanced SiC Performance and Durability

While the inherent properties of silicon carbide are outstanding, certain applications benefit from or require post-processing treatments to further enhance performance, durability, or functionality. These steps are typically performed after the primary shaping and firing (sintering/reaction bonding) of the SiC components.

Common post-processing techniques include:

- Grinding and Lapping:

- Purpose: To achieve tight dimensional tolerances, specific geometric features (flats, chamfers, grooves), and improved surface finishes. Given SiC’s hardness (second only to diamond and boron carbide), diamond abrasives are exclusively used.

- Process: Involves various grinding machines (surface, cylindrical, CNC) and lapping machines using diamond slurries. Lapping is used for achieving very flat surfaces and fine finishes.

- Benefits: Enhanced precision, improved sealing surfaces, reduced friction, increased mechanical strength by removing surface flaws.

- Polishing:

- Purpose: To produce an extremely smooth, mirror-like surface finish (low Ra value).

- Process: Follows grinding and lapping, using progressively finer diamond pastes or slurries on specialized polishing equipment.

- Benefits: Minimizes friction and wear in dynamic seals and bearings, crucial for optical components (mirrors), and can improve corrosion resistance in some environments. Required for many semiconductor SiC parts.

- Edge Chamfering/Radiusing:

- Purpose: To remove sharp edges which can be prone to chipping in brittle materials like SiC.

- Process: Can be done during grinding or as a separate step using diamond tools.

- Benefits: Improved handling safety, increased resistance to chipping and fracture initiation, better fit in assemblies.

- Cleaning:

- Purpose: To remove any contaminants, machining fluids, or particulate matter from the manufacturing process. This is especially critical for high-purity applications like semiconductor components.

- Process: May involve ultrasonic cleaning, solvent cleaning, or specialized chemical cleaning protocols depending on the purity requirements.

- Benefits: Ensures component cleanliness, prevents contamination in sensitive processes.

- Sealing (for porous grades):

- Purpose: Some SiC grades (e.g., certain RSiC or NBSC grades if porosity is an issue for gas/liquid tightness) might require sealing to reduce permeability.

- Process: Impregnation with resins, glasses, or other ceramic materials. For RBSC, the free silicon generally fills much of the porosity.

- Benefits: Improved gas/liquid tightness, enhanced chemical resistance in specific cases.

- Coatings:

- Purpose: To impart additional surface properties not inherent to the bulk SiC, or to protect it in extreme environments beyond its native capability.

- Process: Techniques like Chemical Vapor Deposition (CVD) or Physical Vapor Deposition (PVD) can be used to apply thin films of other materials (e.g., diamond-like carbon, other ceramics, or even specific types of SiC like CVD SiC for ultra-high purity).

- Benefits: Enhanced wear resistance, modified electrical properties, improved corrosion/oxidation resistance, biocompatibility. Often used for advanced SiC solutions.

- Annealing:

- Purpose: To relieve internal stresses induced during rapid cooling after sintering or during aggressive machining.

- Process: Controlled heating to an appropriate temperature followed by slow cooling.

- Benefits: Improved mechanical integrity and reduced risk of delayed fracture.

The necessity and type of post-processing depend heavily on the application’s specific requirements. Each step adds to the cost and lead time, so they should be specified only when functionally justified. Clear communication with your SiC components supplier about these post-processing needs is essential for producing parts that meet all performance criteria.

Common Challenges in SiC Manufacturing and How to Overcome Them

Manufacturing components from high purity silicon carbide presents unique challenges due to its inherent material properties. Understanding these hurdles and the strategies to overcome them is crucial for both manufacturers and end-users to ensure the successful application of SiC parts.

- Brittleness and Low Fracture Toughness:

- Challenge: SiC is a ceramic and thus inherently brittle, meaning it has low resistance to fracture propagation once a crack initiates. This can lead to catastrophic failure under impact or excessive tensile stress.

- Mitigation Strategies:

- Design: Employ ceramic-friendly design principles: use generous radii, avoid sharp corners and stress concentrators, design for compressive loads where possible.

- Material Selection: Choose SiC grades with optimized toughness or consider SiC matrix composites for critical applications.

- Handling: Implement careful handling protocols throughout manufacturing, assembly, and use.

- Proof Testing: For critical components, proof testing can help weed out parts with critical flaws.

- Machining Complexity and Cost:

- Challenge: The extreme hardness of SiC makes it very difficult and expensive to machine. Only diamond tooling can effectively cut or grind SiC, leading to high tooling wear and long machining times.

- Mitigation Strategies:

- Net-Shape Forming: Utilize manufacturing processes like RBSC or advanced powder metallurgy techniques that produce parts as close to the final dimensions (net-shape or near-net-shape) as possible, minimizing the need for post-firing grinding.

- DFM: Design for Manufacturability – simplify designs and specify tolerances and surface finishes only as tight as absolutely necessary.

- Advanced Machining: Employ advanced grinding techniques, EDM (Electrical Discharge Machining) for certain SiC types, or laser machining for specific features, though these also have cost implications.

- Thermal Shock Sensitivity:

- Challenge: While SiC generally has good thermal shock resistance compared to many other ceramics (due to high thermal conductivity and moderate thermal expansion), rapid and extreme temperature changes can still induce cracking, especially in complex shapes or constrained parts.

- Mitigation Strategies:

- Material Selection: Grades like RSiC or NBSC are specifically known for excellent thermal shock resistance. Dense SSiC also performs well.

- Design: Avoid sharp changes in thickness, ensure uniform heating/cooling if possible, and allow for thermal expansion in assemblies.

- Operational Control: Manage heating and cooling rates in application where feasible.

- Controlling Shrinkage and Dimensional Stability During Sintering:

- Challenge: Sintered SiC (SSiC) undergoes significant linear shrinkage (15-20%) during densification. Controlling this precisely to achieve tight dimensional tolera

- Challenge: Sintered SiC (SSiC) undergoes significant linear shrinkage (15-20%) during densification. Controlling this precisely to achieve tight dimensional tolera

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.