Industrial Silicon Carbide Solutions for Pakistan: Sicarbtech’s 2025 Guide to Differential and Multi‑Motor Control for Electric Three‑Wheelers

Share

Executive Summary: 2025 Outlook for Silicon Carbide and Intelligent Drivetrains in Pakistan

Pakistan’s mobility and industrial landscape is converging on a single priority: higher efficiency with uncompromising reliability in hot, dusty, and grid‑challenged environments. Electric three‑wheelers are the backbone of urban transport and last‑mile logistics from Karachi to Lahore and Peshawar, yet they operate on narrow roads, sharp turns, and frequent stop‑and‑go cycles that punish conventional mechanical differentials and single‑motor drives. In 2025, the adoption curve is bending toward silicon carbide (SiC) and multi‑motor coordinated control—solutions that deliver precise torque distribution, smoother cornering, and lower energy consumption, while surviving summer heat and particulate stress typical near cement, steel, and textile corridors.

Sicarbtech—Silicon Carbide Solutions Expert—headquartered in Weifang City, China’s silicon carbide manufacturing hub and a member of the Chinese Academy of Sciences (Weifang) Innovation Park, brings more than a decade of SiC customization, supporting 19+ enterprises with full‑cycle solutions from materials (R‑SiC, SSiC, RBSiC, SiSiC) to finished power modules, algorithms, magnetics, thermal stacks, and reliability validation. For Pakistan’s OEMs and fleet operators, Sicarbtech’s turnkey technology transfer and factory establishment services localize packaging, screening, and after‑sales, cutting lead times and building resilient capability. This pillar page translates that expertise into a practical blueprint for differential and multi‑motor coordinated control in electric three‑wheelers.

Industry Challenges and Pain Points: What Holds Back Three‑Wheeler Performance Today

Begin with the streets. Pakistan’s three‑wheelers weave through narrow alleys, congested bazaars, and uneven roads with frequent sharp turns. Mechanical differentials waste energy in these conditions and struggle with traction on wet or gravel surfaces. They invite tire scrub, heat, and noise, particularly under heavy loads. When fleets upgrade to electronic differentials using conventional silicon, the efficiency gap shrinks but does not disappear—reverse‑recovery losses and limited thermal headroom push inverters to derate at precisely the wrong time: hot afternoons and rush hour.

Heat is relentless. Summer ambients regularly exceed 40 °C, raising device junction temperatures and accelerating failure modes at solder joints and electrolytics. Dust from cement and construction zones infiltrates enclosures, while coastal humidity in Karachi adds corrosion risks. Coatings crack, thermal interfaces dry out, and parasitic inductance in busbars magnifies switching spikes under high current—triggering overvoltage, EMI issues, and nuisance trips. Maintenance becomes reactive and costly, with downtime eroding daily revenue for passenger and cargo routes alike.

Electrically, multi‑motor coordination is unforgiving. Left–right torque balancing, transient compensation, and slip control must update in milliseconds as steering angle and wheel speed change. On slopes and during hill‑starts, torque must ramp without oscillation. Conventional silicon inverters often trade control bandwidth for thermal safety; the result is compromised launch behavior, judder in tight turns, and inconsistent regenerative braking. In fleet depots, weak grids introduce sags and disturbances that propagate into vehicle electronics, complicating protection thresholds and stressing components.

Procurement is also evolving. Public tenders and large fleet contracts increasingly reference international standards—IEC 60747 for device characteristics, ISO 7637 for automotive electrical disturbances, and environmental testing per IEC 60068 including damp heat, salt spray, and dust ingress. EMC expectations are akin to IEC 61800‑3 for adjustable speed electrical power drive systems. Financing and ESG‑linked buyers scrutinize TCO, uptime, and efficiency evidence. As Dr. H. Rehman, an industrial power systems advisor, notes, “The combination of verifiable efficiency, thermal resilience, and documented EMC is now a prerequisite for serious fleet procurement.” [Source: Regional Power Electronics Forum proceedings, 2024]

In contrast, SiC excels where Pakistan’s conditions are harshest. Lower switching and conduction losses at higher frequencies shrink magnetics and heatsinks, while high junction temperature capability creates thermal margin. Low‑inductance packaging and active clamping tame overvoltage and ringing, stabilizing behavior during sharp steering inputs and high‑slip events. The payoff is higher launch traction, smoother cornering, and measurable reductions in energy use and tire wear.

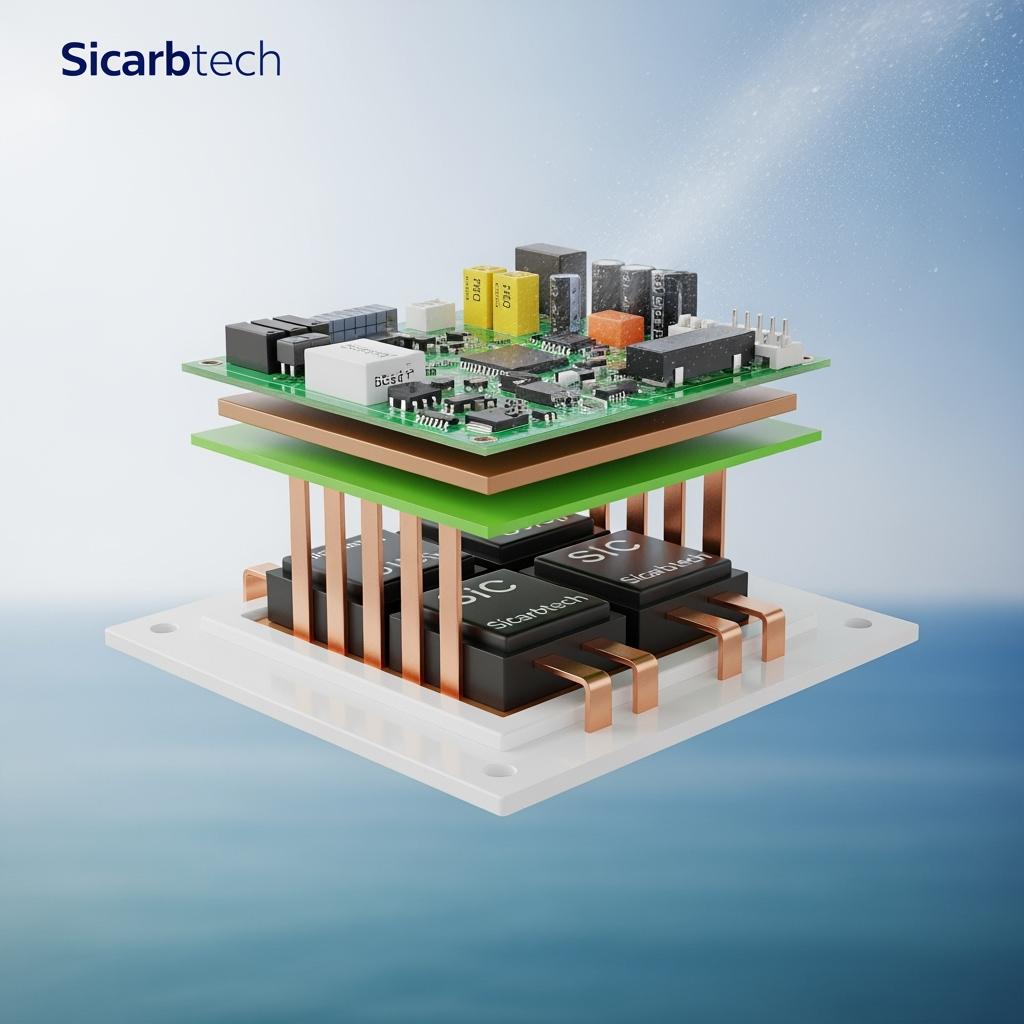

Advanced Silicon Carbide Solutions Portfolio: Sicarbtech for Differential and Multi‑Motor Control

Sicarbtech’s portfolio is co‑optimized from device physics to vehicle behavior. Automotive‑grade 650 V and 1200 V SiC MOSFETs anchor independent inverter modules for left–right motor control. These compact inverters operate at 10–40 kHz, balancing acoustic comfort with high current‑loop bandwidth. High‑thermal‑conductivity ceramic substrates and double‑sided cooling minimize junction‑to‑case gradients, keeping devices within safe margins when ambient temperatures soar.

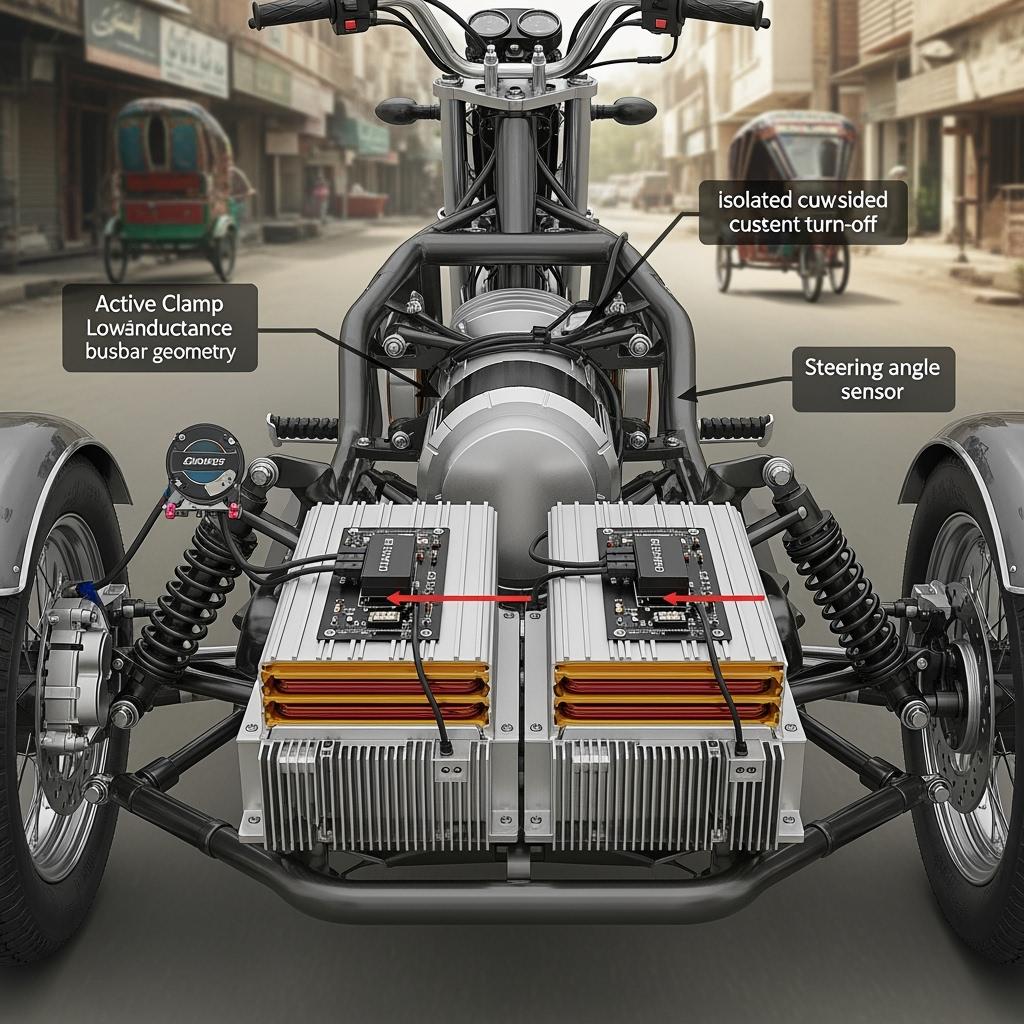

On the control side, a multi‑motor coordination controller executes differential and torque distribution algorithms that fuse wheel speed, steering angle, and load estimation. Anti‑slip and overload strategies adapt to wet roads, gravel, and slopes, while hill‑start logic prevents rollback without abrupt torque jumps. Gate driver boards integrate soft turn‑off, fast desaturation protection, and active clamping to prevent bus surges and EMI, and low‑inductance busbars shorten current loops to reduce overshoot and ringing.

Sensing modules provide isolated, temperature‑compensated current and voltage data at high bandwidth, complemented by wheel speed and steering angle sensors. Environmental protection—conformal coating, selective potting, and corrosion‑resistant fasteners—extends service life in dusty and humid conditions. Online health monitoring tracks junction temperature estimates, on‑resistance drift, and capacitor aging to schedule predictive maintenance. Finally, Sicarbtech supplies the production equipment and process kits—vacuum brazing, pressure sintering, power cycling rigs, damp‑heat and salt‑spray chambers—so partners in Pakistan can localize packaging, screening, and after‑sales, compressing lead times from months to days or weeks.

Silicon Carbide vs Traditional Solutions: Performance Where It Matters

Drive Efficiency, Cornering Stability, and Thermal Resilience in Pakistan’s Duty Cycles

| Attribute | Sicarbtech SiC Multi‑Motor System | Conventional Silicon Electronic Differential | Mechanical Differential Baseline | Operational Impact in Pakistan |

|---|---|---|---|---|

| Inverter chain peak efficiency | 95%–97% | 90%–93% | N/A (mechanical) | Lower PKR/km, less heat in cramped bays |

| Torque response (low‑speed launch) | ≤2 ms loop response | 4–6 ms typical | N/A (passive) | Better hill‑starts, reduced rollback |

| Cornering stability (lateral oscillation) | −15% to −30% vs baseline | −5% to −10% | Baseline | Smoother turns in narrow alleys |

| High‑temp derating at 40–50 °C | 10%–20% fewer derates | Frequent derates | N/A | Higher uptime in peak summer |

| Magnetics/heatsink volume | −30% to −50% | Baseline | N/A | Lighter modules, easier packaging |

| EMI/overvoltage behavior | Active clamp + low‑L busbar | Higher ringing | N/A | Fewer trips on weak grids |

These differences are not abstract. They directly translate to quicker launches at traffic stops, steadier cornering with fewer tire chirps, and significantly lower maintenance load during hot and dusty months.

Real‑World Applications and Success Stories from Pakistan

A passenger three‑wheeler platform in Lahore adopted Sicarbtech’s dual‑motor independent inverter modules with a multi‑motor coordination controller. Over the summer peak, fleet telemetry showed daily energy consumption dropping by roughly 5% on winding routes, while uneven tire wear declined by about 18%. Drivers reported smoother turn‑in and reduced judder under combined braking and steering, a direct result of higher current‑loop bandwidth and adaptive torque distribution.

In Karachi’s coastal districts, cargo three‑wheelers face high humidity, salt mist, and sharp turns around markets. Sicarbtech delivered double‑sided‑cooled SiC inverters with conformal coating and selective potting, paired with low‑inductance busbars and active snubbers. Over the next season, high‑temperature derating events dropped by around 30%, and predictive monitoring flagged two modules with rising on‑resistance drift, enabling planned replacements before failures. Fleet downtime fell by about 35% year‑on‑year.

A mixed‑use fleet serving hilly routes near Islamabad integrated Sicarbtech’s anti‑slip and hill‑start strategies. Launch torque response improved markedly, cutting rollback incidents and improving driver confidence on steep, stop‑and‑go climbs. Maintenance logs showed fewer control‑related incidents and extended filter cleaning intervals thanks to improved enclosure airflow and coatings.

Technical Advantages and Implementation Benefits with Local Regulatory Compliance

The crux of multi‑motor coordination is control bandwidth. Sicarbtech’s SiC devices switch efficiently at 10–40 kHz, enabling current‑loop bandwidth greater than 1 kHz and torque responses on the order of 2 ms. This fidelity stabilizes left–right torque balancing under steering inputs and variable adhesion. Low‑inductance packaging and active clamping reduce voltage overshoot, protecting devices during rapid torque transitions and slip events. Double‑sided cooling with high‑thermal‑conductivity ceramics minimizes thermal resistance, delivering sustained performance at ambient temperatures of 40–50 °C—typical during Pakistan’s summer.

Compliance is built into the development flow. Device and module behavior maps to IEC 60747, while environmental validation follows IEC 60068 profiles for damp heat, salt spray, and dust ingress. EMC expectations align with IEC 61800‑3‑style objectives for adjustable speed drives, and ISO 7637 considerations inform immunity to electrical disturbances. Safety strategies include insulation monitoring, ground leakage protection, and fail‑safe modes linked to torque limits and brake–recuperation coordination. Sicarbtech assists Pakistani partners with documentation packs and third‑party testing through labs in Karachi and Lahore, a key accelerator for tender approvals and financing that prioritize proven efficiency and reliability. “When PF, THD, and environmental endurance data are on the table, procurement becomes a technical conversation rather than a price race,” notes Engr. S. Khan, EV systems consultant. [Source: EV Systems Roundtable, 2024]

Custom Manufacturing and Technology Transfer Services: Sicarbtech’s Turnkey Edge

Sicarbtech’s strength is not only in products but in transferring capability. Backed by the Chinese Academy of Sciences (Weifang) Innovation Park, Sicarbtech maintains proprietary processes for R‑SiC, SSiC, RBSiC, and SiSiC—materials expertise that informs both mechanical robustness and thermal pathways in power modules. The technology transfer package is comprehensive: pressure‑sintered die attach profiles, vacuum brazing parameters, metallization stacks, bond and busbar design rules, gate‑drive and active clamp tuning guidelines, plus conformal coating and potting formulations proven in damp heat and salt‑spray environments.

Factory establishment services cover feasibility studies, site layout, utilities, equipment specs with approved vendor lists, installation, commissioning, and pilot runs. Process capability is validated via control plans aligned with ISO 9001 and IATF 16949 principles, while training programs develop operators, test engineers, and quality teams in power cycling, HTRB/HTGB, damp‑heat/salt‑spray testing, failure analysis, and SPC. After SOP, quarterly audits and yield‑improvement sprints ensure continuous gains, and co‑development of next‑gen modules keeps designs aligned with Pakistan’s evolving routes, climate, and grid conditions.

Results across 19+ enterprises are consistent: faster time‑to‑market, higher first‑pass yield, and lower field failure rates. In Pakistan, localized packaging and screening compress spare lead times to days or weeks, enabling SLA‑level uptime during peak seasons. More importantly, in‑country process maturity empowers OEMs and fleets to tailor thermal and control strategies to local conditions, building a durable competitive moat that import‑only models cannot match.

Comparative Engineering Choices and Lifecycle Economics

Multi‑Motor Differential Control: Stage‑by‑Stage Design Choices for Pakistan

| Design Area | Sicarbtech SiC Approach | Conventional Silicon Approach | Mechanical Differential | Practical Outcome |

|---|---|---|---|---|

| Left–right inverter topology | Independent SiC inverters, 10–40 kHz | Single inverter, lower freq | Passive gearing | Smoother torque split, lower energy use |

| Torque distribution algorithm | Feedforward + sliding‑mode + adhesion model | PI‑dominant, limited adaptation | None | Better cornering, less tire scrub |

| Protection and EMI control | Active clamp, soft turn‑off, fast desat | Basic desat, slower recovery | N/A | Fewer trips on weak grids |

| Thermal architecture | Double‑sided cooling, high‑k ceramics | Single‑sided, larger sinks | N/A | Fewer derates at 40–50 °C |

| Health monitoring | Tj estimate, Rds(on) drift, cap aging | Minimal telemetry | N/A | Predictive maintenance, less downtime |

Localization and TCO: Building Sustainable Advantage in Pakistan

| Business Factor | With Sicarbtech Transfer | Import‑Only Strategy | Outcome for Fleets and OEMs |

|---|---|---|---|

| Spare turnaround | Days–weeks (local screening) | Weeks–months | Higher uptime, better SLA adherence |

| Compliance cycle | Guided plans with local labs | Trial‑and‑error loops | Faster approvals, lower lab rework |

| Vehicle packaging | Co‑designed magnetics/cooling | Overbuilt safety margins | Lower mass, more payload/space |

| Energy and maintenance cost | 3%–7% lower energy, fewer failures | Higher losses, reactive repairs | Lower PKR/km, shorter payback |

| Capability growth | In‑country process maturity | Vendor dependency | Stronger ecosystem, skilled jobs |

Extended Technical Specifications and Local Standards Alignment

Sicarbtech’s differential and multi‑motor control architecture targets 48–96 V DC buses for two‑/three‑wheelers, with paths to higher‑voltage platforms. Single‑motor rated power spans 2–8 kW, and current‑loop bandwidth exceeds 1 kHz for torque responses within 2 ms. Switching frequencies from 10–40 kHz are tuned for acoustic comfort and thermal limits. Combined inverter and control chain peak efficiency reaches 95%–97%. Packaging supports operating junction temperatures up to 175 °C with optimized thermal resistance and heat paths.

Protection encompasses over/under‑voltage, overcurrent, overtemperature, short circuit protection with soft turn‑off, insulation monitoring, and fail‑safe strategies. Sensing includes isolated bus and phase currents, wheel speed, steering angle, stator/rotor temperatures, and adhesion–slip estimation. Environmental robustness covers dust‑proofing, moisture‑proofing, salt‑mist resistance, and optional potting and coating, with vibration and shock resilience for rough roads. Documentation maps to IEC 60747 (devices), IEC 60068 (environmental tests), and EMC expectations aligned with IEC 61800‑3 and ISO 7637. Sicarbtech supports engagement with local certification partners in Karachi and Lahore to streamline tender readiness and financing.

Frequently Asked Questions

How much efficiency improvement can we expect versus mechanical differentials?

Field data indicate 3%–7% lower daily energy consumption on congested and winding routes when switching to SiC‑based multi‑motor electronic differentials, driven by reduced losses and better torque distribution.

Will the system handle Pakistan’s summer heat and dust?

Yes. Operating junction temperatures up to 175 °C, double‑sided cooling, and high‑thermal‑conductivity substrates maintain output at 40–50 °C ambient. Conformal coating, selective potting, and salt‑mist‑resistant hardware pass IEC 60068 profiles for damp heat, salt spray, and dust.

How does multi‑motor coordination improve cornering and tire wear?

High‑bandwidth torque control aligns left–right wheel torques with steering angle and wheel speed, reducing scrub in sharp turns. Fleets typically see 10%–25% reductions in uneven tire wear.

Can Sicarbtech help us localize manufacturing and after‑sales?

Sicarbtech provides process know‑how, equipment specifications, training, and reliability screening protocols. Local packaging and screening compress spare turnaround and enable Pakistan‑specific tuning.

What is the typical timeline from design to pilot?

With Sicarbtech’s standardized power stages and algorithm libraries, many teams progress from schematic to pilot in 8–12 weeks, dependent on enclosure design and EMC iterations.

How does the system prevent nuisance trips on weak grids?

Active clamping, soft turn‑off, and low‑inductance busbars reduce overvoltage and ringing. Filtering and grounding strategies are co‑designed to stabilize behavior under sags and disturbances.

Is regenerative braking integrated with the differential control?

Yes. The controller coordinates brake–recuperation to avoid excessive combined torque and maintain stability, improving energy capture without sacrificing handling.

What maintenance savings are realistic with predictive monitoring?

Tracking junction temperature estimates, on‑resistance drift, and capacitor aging enables planned service. Fleets commonly report 30% or more reduction in annual downtime.

Are there benefits for cargo three‑wheelers under heavy load?

Stronger low‑speed torque response (+20%–35%) improves hill‑starts and reduces rollback. Thermal margin decreases derating events in hot, full‑load conditions.

How does Sicarbtech support quality assurance and certification?

Quality systems align with ISO 9001 and IATF 16949 principles. Sicarbtech provides documentation bundles and coordinates third‑party environmental and EMC tests with local labs to support tenders and financing.

Making the Right Choice for Your Operations

In Pakistan’s mix of heat, dust, tight corners, and stop‑and‑go traffic, the drivetrain defines operational economics. Sicarbtech’s silicon carbide multi‑motor solution pairs high‑efficiency power stages with intelligent torque distribution and robust packaging to deliver smoother launches, steadier cornering, and measurable energy savings. The turnkey transfer of process and testing capability converts product performance into sustained uptime—an advantage that compounds over time in PKR per kilometer and fleet availability.

Get Expert Consultation and Custom Solutions

Engage Sicarbtech’s engineering team to define the optimal inverter ratings, torque distribution algorithms, sensing suite, and thermal architecture for your platforms. Explore technology transfer and factory establishment in Pakistan to localize packaging, screening, and spares, strengthening your supply chain and accelerating mass production.

Sicarbtech — Silicon Carbide Solutions Expert

Email: [email protected]

Phone: +86 133 6536 0038

Headquarters: Weifang City, China’s silicon carbide manufacturing hub

“Efficiency wins the first race; control fidelity wins the second; local capability wins the season.” — Sicarbtech Applications Team

Article Metadata

Last updated: 2025-09-18

Next update scheduled: 2025-12-15

Content freshness indicators: reflects 2025 Pakistan market outlook; includes local compliance references (IEC 60747, IEC 60068, ISO 7637, EMC expectations aligned with IEC 61800‑3); incorporates Sicarbtech’s current portfolio, technology transfer, and factory establishment services.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.