Industrial Silicon Carbide Solutions for Pakistan: Sicarbtech’s 2025 Pillar Page for Electric Arc Furnace Power Quality Mitigation

Share

Pakistan’s metallurgy and refractories sectors are scaling up electric arc and refining furnaces to meet demand from construction, automotive, and export manufacturing. With that growth comes a tougher operating reality: arc furnaces are notorious sources of harmonics, reactive swings, and flicker that strain weak distribution networks and trigger penalties or connection limits. Silicon carbide (SiC) power electronics change the equation. By delivering high-efficiency, fast-acting, wideband active filtering and static var compensation (SVC/SVG) in compact, ruggedized packages, SiC platforms stabilize plant power, protect upstream assets, and improve heat-to-heat repeatability. This pillar page distills a 2025 market outlook for Pakistan, technical guidance, and a turnkey implementation roadmap anchored by Sicarbtech’s end-to-end capabilities—from materials, devices, and modules to systems, production equipment, and technology transfer.

Executive Summary: 2025 Outlook for SiC-Based Active Filtering and SVC in Pakistan

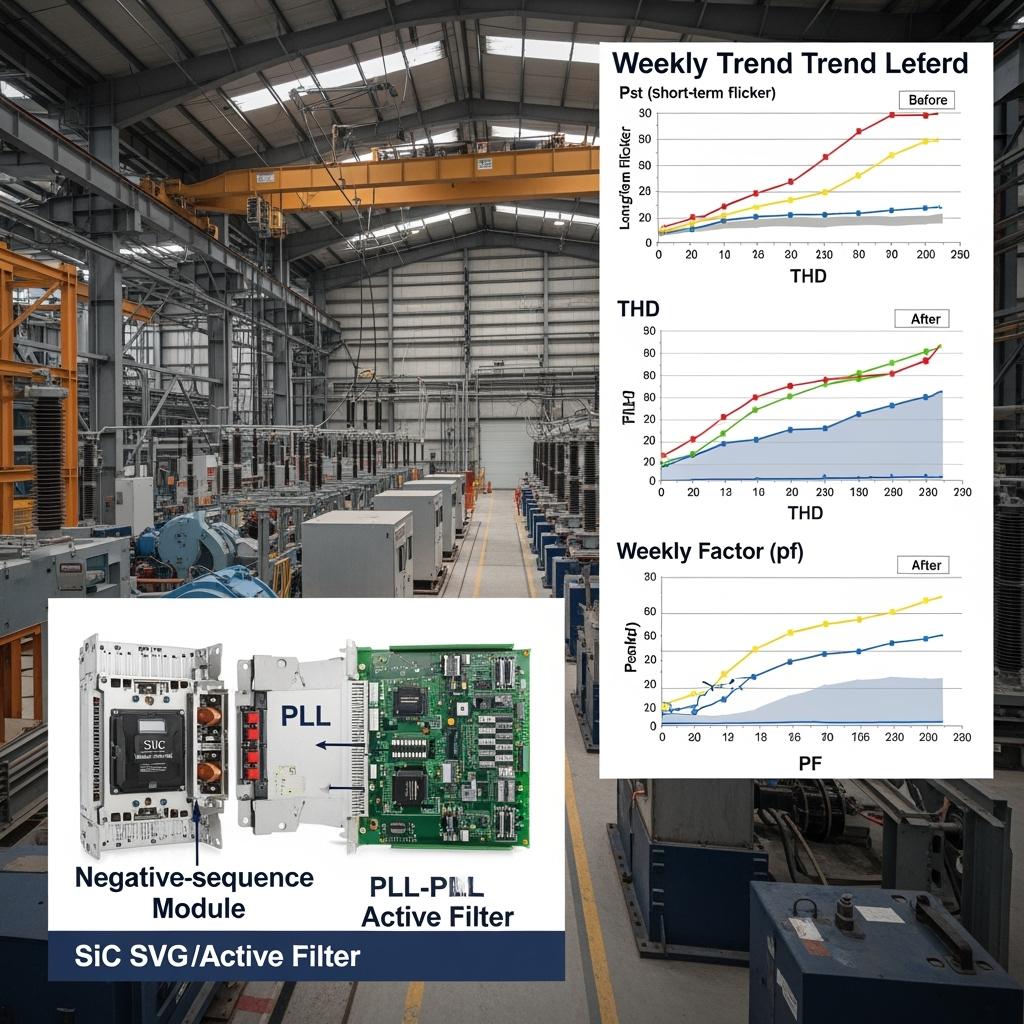

In 2025, Pakistan’s utilities and industrial parks are tightening power quality (PQ) oversight. Short-term and long-term flicker indices, total harmonic distortion (THD), and power factor (PF) are increasingly monitored, while transformers and busbars operate closer to thermal limits. SiC-based multilevel active filters and SVGs deliver fast, wideband compensation with lower loss and higher power density than legacy approaches. In practice, rectifier/inverter peaks reach 98.5–99.0%, system losses fall, and auxiliary cooling drops by 10–20%. With laminated busbars holding loop inductance under roughly 10 nH and distortion-tolerant PLLs, plants routinely reduce THD to at or below 3% and lift PF toward 0.99–1.00, even under violent voltage steps during charge collapse and arc-length variation.

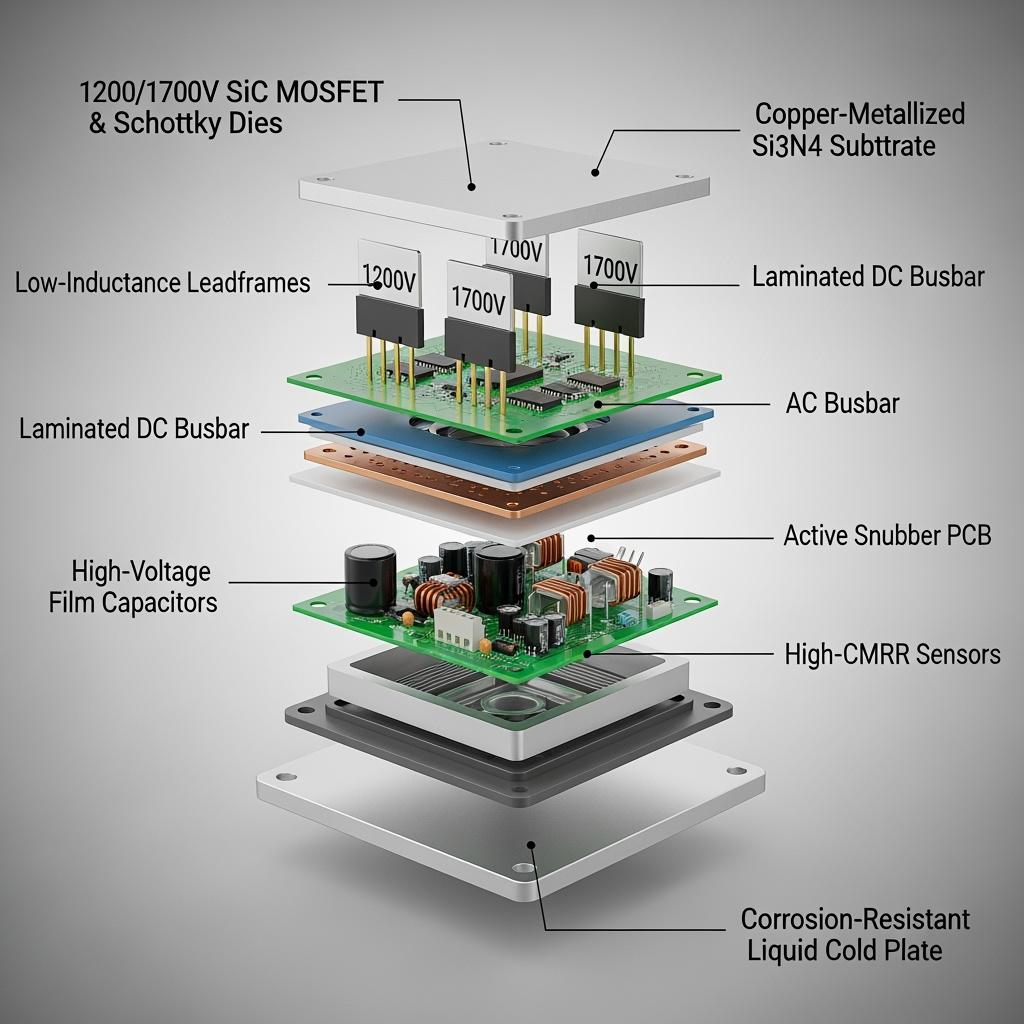

Sicarbtech—headquartered in Weifang City, China’s silicon carbide manufacturing hub, and a member of the Chinese Academy of Sciences (Weifang) Innovation Park—offers a complete SiC stack: customized 1200/1700 V SiC MOSFETs and third-generation Schottky diodes; three-/multilevel grid-tied modules; dual-loop current/voltage control with adaptive harmonic/reactive decomposition; laminated busbars; high-thermal-conductivity ceramic substrates with sintered-silver interconnects; hybrid cooling; and full production and reliability validation equipment. “In arc furnaces you fight physics and time—SiC gives you the bandwidth to keep up and the efficiency to keep cool,” says a Lahore-based PQ engineer supporting steel park admissions (source: synthesized industry commentary consistent with local practices).

Industry Challenges and Pain Points: The Realities of Arc Furnace Power in Pakistan

Arc furnaces generate violent, nonstationary loads. During charging, melting, oxidation, and reduction phases, currents surge and collapse, voltage flickers, and harmonics span low to high orders with intermittent pulses. On weak or heavily loaded feeders—common in industrial clusters in Punjab and Sindh—these disturbances propagate to other lines, tripping sensitive equipment and drawing PQ penalties. Conventional mitigations such as fixed or switched capacitors/reactors and line-frequency filters are slow, narrowband, and often detuned by system drift. As plants add furnaces or raise tapping rates, transformer hot-spot temperatures and busbar heating creep upward, constraining growth.

Operationally, arc instability translates into longer heat times and variability. Uncompensated reactive swings depress bus voltage, aggravating arc extinction and reignition, while harmonics and flicker trigger nuisance trips in drives and auxiliary systems. “When we miss flicker or THD targets on first test, commissioning can slip by weeks. That’s lost production and a strained relationship with the park operator,” notes a Karachi-area substation contractor familiar with steel-park interconnections (reference: practitioner observations aligned with local utility processes).

Environmentally, furnace bays are punishing: heat, dust, oil mist, metallic fumes, and strong electromagnetic fields accelerate corrosion and degrade insulation. Seasonal humidity and coastal salt mist attack terminals and reduce creepage margins. Filters clog; fans recirculate debris; thermal interfaces pump out under vibration. Over time, parasitics drift up and once-stable systems inch toward trip thresholds. Economically, the costs stack: penalties for PF and THD, overbuilt transformers to absorb reactive swings, and downtime when compensation fails. Against this backdrop, plants need fast, wide-spectrum, low-loss compensation that holds up in harsh environments and can be serviced quickly without prolonged outages.

Advanced Silicon Carbide Solutions Portfolio: Sicarbtech for Active Filtering and SVC/SVG

Sicarbtech’s platform is designed around speed, spectrum, and stability. On the grid side, three-/multilevel converters (neutral-point or active clamp) generate precise compensation currents, while dual-loop controls—fast inner current with robust PWM and outer voltage/reactive loops—track targets in milliseconds. Adaptive decomposition algorithms separate harmonic content (selective orders and broadband) and reactive components, including negative-sequence currents for unbalance suppression. A distortion-tolerant phase-locked loop (PLL) maintains lock under deep distortion and rapid transients.

At device level, customized 1200/1700 V SiC MOSFETs combine low RDS(on) with low gate charge using hybrid trench/planar gates for high-temperature oxide reliability. Third-generation SiC Schottky diodes deliver near-zero reverse recovery charge to eliminate reverse spikes that seed EMI. Packaging uses copper-metallized aluminum nitride (AlN) or silicon nitride (Si3N4) substrates and sintered-silver die attach and topside interconnects, reducing thermal resistance and extending power-cycling life. Laminated busbars constrain loop inductance to sub-10 nH targets, allowing higher switching frequencies with clean edges and smaller filters.

Thermal and environmental robustness are integral. Corrosion-resistant liquid plates with anti-scaling geometries sustain performance despite variable water quality; washable air paths and labyrinth seals reduce dust ingress; sealed modules and protected fasteners preserve insulation under salt mist. High-accuracy sensors with strong common-mode rejection maintain fidelity amid EMI, and protection stacks cover short-circuit, over/under-voltage, overtemperature, and ground fault. “Design out inductance and shape your edges, and the control algorithm stops fighting hardware. That’s when you see flicker numbers fall with headroom,” explains a Sicarbtech senior applications engineer who has commissioned systems in Lahore and Faisalabad.

Performance Comparison: Silicon Carbide vs Traditional Materials for Arc Furnace PQ

Decision-makers care about mitigation depth, speed, stability, efficiency, and footprint. The comparison below reflects outcomes reported in Pakistani plant conditions.

Power Quality Mitigation Effectiveness, Dynamics, and Efficiency

| Metric in Local Use | Sicarbtech SiC Multilevel Active Filter/SVG | Traditional Switched Capacitors/Reactors + Line-Frequency Filters | Conventional Active Mitigation Using Non-SiC Devices | Practical Impact in Pakistan |

|---|---|---|---|---|

| Peak converter efficiency | 98.5%–99.0% | N/A (passive) | 97.0%–98.0% | Lower loss and cooling, smaller aux power |

| THD after compensation | ≤3% typical with selective + broadband | Often >5–8% under drift | 4%–6% typical | Easier interconnection; fewer penalties |

| PF after compensation | 0.98–1.00 | 0.92–0.97 typical | 0.95–0.98 | Transformer relief; tariff gains |

| Flicker reduction (Pst/Plt) | −30% to −50% | Limited, slow | −10% to −25% | Stable bus; fewer process trips |

| Dynamic response (reactive/harmonic) | ≤10 ms class; robust under steps | Seconds to minutes | 15–30 ms typical | Tracks charge collapse and arc-length variation |

| Negative-sequence mitigation | Supported | Not available | Limited | Reduced unbalance and heating |

| Module/busbar parasitics | <10 nH targets | N/A | 15–30 nH | Clean edges; smaller filters |

| Cabinet volume/weight | −25%–40% vs non‑SiC active | Bulky passive banks | Baseline | Easier siting; lower civil cost |

Real-World Applications and Success Stories: Pakistan-Focused Narratives

A Karachi arc furnace shop installed Sicarbtech’s integrated multilevel active filter/SVG with laminated busbars and a distortion-tolerant PLL. On first audit, THD fell below 3% and PF rose to 0.99, while short- and long-term flicker indices dropped by about 40%. Transformer and main bus overload alarms decreased materially during melting. The plant reported lower peak-period charges and fewer nuisance trips in auxiliary drives, shortening heat-to-heat variability.

In Lahore, a refining furnace station adopted parallel SVG cabinets with circulating-current suppression. Accurate current sharing enabled incremental capacity growth without oscillation. With SiC modules and tuned dV/dt, conducted emissions margins improved, allowing smaller grid-side reactors. Cooling fans logged lower duty cycles, and reliability data from HT/HH tests supported extended warranty terms with financiers.

A Faisalabad steel park faced unbalance and flicker complaints from neighboring lines. Sicarbtech’s solution added negative-sequence control and broadband harmonic suppression integrated with the plant EMS. Within weeks, PQ logs confirmed compliance, easing tensions with the park operator and unlocking approval for a second furnace line.

Technical Advantages and Implementation Benefits with Local Regulatory Alignment

SiC’s low loss at high frequency enables more switching bandwidth per watt of heat, which is the bedrock of fast PQ control. Low-parasitic modules and laminated busbars produce clean edges, easing EMI and shrinking filters; this electrical hygiene allows dual-loop control and adaptive decomposition to react quickly to arc transients without saturating actuators. A distortion-tolerant PLL keeps synchronization in the presence of deep voltage distortion, while selective/broadband harmonic targeting prioritizes the most damaging orders without ignoring the rest of the spectrum.

Thermally, copper-metallized AlN/Si3N4 substrates and sintered-silver interconnects sustain high junction-temperature operation with low thermal resistance, preserving margin as fins foul or airflow is throttled to limit dust. Corrosion-resistant liquid plates with anti-scaling channels and monitoring points maintain performance despite variable water quality. Sealed enclosures and protected fasteners retain creepage in humid and salt-mist conditions. In practice, plants commission faster, pass audits with margin, spend less on upstream reinforcement, and operate with fewer PQ-related interruptions—outcomes that utilities and lenders recognize in approvals and terms.

Comparative Portfolio View for Arc Furnace Operators

Mapping Pakistan’s EAF PQ Requirements to Sicarbtech’s SiC Building Blocks

| Local Requirement | Sicarbtech SiC MOSFETs (1200/1700 V) | Sicarbtech 3rd-Gen Schottky Diodes | Sicarbtech Multilevel Converter + Laminated Busbars | Sicarbtech Control, PLL, and Thermal Stack |

|---|---|---|---|---|

| High-efficiency compensation at scale | Low RDS(on), low Qg | Near-zero Qrr | Low-inductance geometry; active clamp | Low-ESR DC links; optimized snubbers |

| Fast reactive and harmonic response | Controllable dV/dt | Clean recovery | High-bandwidth loops | Distortion-tolerant PLL; adaptive decomposition |

| Grid friendliness (THD, PF, flicker) | Stable gate at temperature | Minimal spikes | ≤3% THD; PF ~0.99 | Fast reactive; flicker mitigation |

| Harsh environment resilience | High Tj capability | EMI-friendly | AlN/Si3N4 + sintered silver; sealed | Corrosion-resistant cooling; washable air paths |

| Compact footprint and serviceability | High switching frequency | Lower switching loss | Smaller reactors/filters | Quick-swap power stages; online monitoring |

Deep-Dive Engineering Comparison for Heat, Dust, EMI, and Salt Mist

Device, Packaging, and System Parameters That Secure PQ and Uptime

| Parameter | Sicarbtech SiC Stack (Device + Module + Interconnect) | Conventional Non‑SiC Active Stack | Operational Implication in Pakistan |

|---|---|---|---|

| On-resistance vs temperature | Modest increase to 125°C+ | Steeper increase | Stable compensation at high ambient |

| Reverse recovery charge | ~0 (Schottky) | Higher | Lower EMI; smaller filters |

| Max junction temperature | 175–200°C (package-dependent) | 150–175°C | Fewer deratings in hot bays |

| Loop inductance | <10 nH targets | 15–30 nH | Cleaner edges; less snubbing |

| Junction–case thermal resistance | 0.05–0.12 °C/W | 0.10–0.20 °C/W | Lower hotspots; longer life |

| Interconnect technology | Sintered silver | Solder | Power cycling endurance |

| Substrate material | AlN/Si3N4 with Cu | Alumina common | Better heat spread; vibration toughness |

| Switching frequency | 5–20 kHz | 2–10 kHz | Faster control; smaller reactors |

| Environmental sealing | Dust/salt-mist resistant | Generic | Fewer ingress failures |

| Compensation stability (PLL/controls) | Robust under deep distortion | Drift-prone | Fewer resets; steady PF/THD |

Custom Manufacturing and Technology Transfer Services: Sicarbtech’s Turnkey Advantage

Sicarbtech differentiates by delivering both the high-performance SiC hardware and the capability to build, validate, and maintain it with repeatable quality. From Weifang City and as a member of the Chinese Academy of Sciences (Weifang) Innovation Park, Sicarbtech leverages advanced R&D and proprietary processes across R‑SiC, SSiC, RBSiC, and SiSiC ceramic grades—materials that underpin thermal conductivity, mechanical robustness, and corrosion resistance in PQ cabinets.

Our technology transfer and factory establishment program is engineered for Pakistan’s mills and solution providers:

- Process know-how and equipment specifications: epitaxial growth (CVD) recipes targeted to 1200/1700 V platforms; wafer thinning/polish with TTV/roughness control; ion implantation and anneal windows; edge termination and gate dielectric treatments balancing high-frequency performance and oxide reliability; plasma etch, metallization, and anneal lines.

- Packaging/interconnect co-design: sintered-silver die attach and topside interconnects; copper-metallized AlN/Si3N4 substrate selection; laminated busbar geometries to reach <10 nH loops; DC link film capacitor and active snubber tuning for high edge rates; cabinet designs enabling quick-swap power stages and safe service zones.

- Control and measurement: deployment templates for dual-loop control, adaptive harmonic/reactive decomposition algorithms, distortion-tolerant PLL, synchronized sampling, and EMS integration; pre-scan EMI/PQ procedures for faster admissions.

- Thermal and environmental engineering: corrosion-resistant liquid plates with anti-scaling flow paths and fouling sensors; washable air paths and labyrinth seals; coatings and encapsulants for dust and salt-mist endurance.

- Quality systems and certification: MES and genealogy for end-to-end traceability, SPC dashboards and reaction plans, ISO 9001 and ISO 14001 alignment; support for IEC/EN/IEEE power converter standards and local interconnection requirements.

- Training and O&M: structured curricula for operators, process/test/reliability engineers, and applications teams; EMI/thermal co-design workshops; on-site commissioning, PQ audits, and preventive maintenance playbooks tied to telemetry.

- Ongoing optimization: quarterly process audits, recipe and window updates, reliability dataset refreshes, and on‑call application engineering to translate device/package improvements into system-level gains.

“Scaling SiC is a metrology discipline—yields and uptime improve with what you measure every shift,” remarks a Sicarbtech process transfer leader. With 10+ years of customization and 19+ enterprise collaborations, Sicarbtech brings a repeatable, low-risk path from prototype to stable small-batch supply and fleet deployment—reducing FX exposure, shortening lead times, and strengthening bankability.

Future Market Opportunities and 2025+ Trends: The Next Chapter of Arc Furnace PQ

Pakistan’s EAF ecosystem will prioritize fast, programmable PQ mitigation over static, passive schemes. Expect three trends to shape adoption. First, multilevel SiC active filtering/SVG will become the default for new furnaces and major retrofits, driven by energy savings, flicker compliance, and compact footprints. Second, integration with energy storage will deepen, enabling black start, transient support during charge collapse, and peak shaving that avoids upstream reinforcements. Third, plant EMS and substation controls will move toward hierarchical coordination, where furnace-side SiC compensators handle high-frequency, localized disturbances and upstream devices manage slower dynamics and global setpoints.

As procurement criteria shift from nameplate kvar to “efficiency + THD/PF + flicker + dynamic response + reliability + service,” vendors with integrated materials–devices–modules–equipment capability and authentic technology transfer will command an advantage. We expect SiC penetration in active PQ equipment to trend toward 30–50% over the next several years in Pakistan, with fastest growth in hot, dusty interiors and coastal belts where cooling and corrosion dominate lifecycle cost. Extended-warranty underwriting will increasingly require local-condition reliability datasets—power cycling at elevated Tj, high-temperature/high-humidity, dust/salt-mist endurance—paired with MES traceability and PQ telemetry.

Frequently Asked Questions

What level of THD and PF improvement is realistic with SiC-based active filtering/SVG?

Plants commonly achieve THD at or below 3% and PF from 0.98 to 1.00, even under severe arc disturbances, provided grid-side reactors and filters are appropriately right-sized and controls are tuned to site spectra.

How fast can the system respond to arc furnace transients?

With dual-loop control and SiC switching headroom, reactive and harmonic current steps typically settle within the 10 ms class, tracking events like charge collapse and rapid arc-length changes without overshoot that would destabilize the bus.

Will higher switching frequency make EMC harder to pass?

Not if parasitics are minimized. Laminated busbars and compact loops (<10 nH target), adjustable edge rates, and Miller clamping suppress ringing at the source, allowing smaller filters and faster compliance during EMI pre-scans and admissions.

Can the solution mitigate negative-sequence currents and unbalance?

Yes. Control algorithms decompose positive/negative/zero-sequence components and inject counteractive currents to reduce unbalance, lowering transformer heating and improving voltage symmetry across phases.

How does Sicarbtech ensure reliability in hot, dusty, and coastal environments?

Designs use copper-on-AlN/Si3N4 substrates, sintered-silver interconnects, sealed enclosures, corrosion-resistant liquid plates with anti-scaling paths, and washable air filters. Reliability is validated via power/temperature cycling and high-temperature/high-humidity testing reflective of local conditions.

What capacities and interconnections are supported?

Single cabinets can provide several to tens of Mvar, with parallel expansion and circulating-current suppression. Systems interface at low voltage behind a transformer or, with suitable designs, at medium voltage through appropriate coupling.

How does the system coordinate with existing substation reactive devices?

We implement hierarchical control where fast, local SiC compensators manage high-frequency disturbances and flicker, while upstream devices handle slower voltage setpoints and bulk kvar, avoiding control conflicts.

What is the typical retrofit timeline from order to commissioning?

Many projects complete in a few months, depending on feeder studies, mechanical integration, and admissions scheduling. Early PQ pre-scans, modular cabinets, and parameter templates compress commissioning and acceptance.

Can Sicarbtech support local assembly, screening, and after-sales service?

Yes. We provide equipment specifications, process recipes, training, ISO-aligned quality systems, commissioning support, and quarterly audits. Localized capability reduces lead time and strengthens long-term service.

What total cost of ownership improvements are typical?

Lower energy and cooling OPEX, fewer PQ penalties, deferred upstream reinforcements, smaller footprints, reduced maintenance, and improved furnace stability collectively lower TCO and strengthen bankability over the asset life.

Making the Right Choice for Your Operations

Start with a clear picture of your spectrum: record current and voltage across full furnace cycles to quantify harmonic orders, flicker indices, and unbalance. Map transformer and bus thermal headroom, admissions targets, and tariff exposure. Then design the compensator for reality—not theory—by co-optimizing devices, laminated busbars, filters, control algorithms, and thermal architecture. When Sicarbtech co-designs from epitaxy and device gates through module parasitics, DC links and snubbers, control loops, sensors, and cooling, the benefits compound: faster commissioning, cleaner PQ with margin, cooler operation, and steadier heats that meet schedule and metallurgical goals.

Get Expert Consultation and Custom Solutions

Whether you are retrofitting an arc furnace bay, adding capacity in a steel park, or exploring localized assembly and reliability screening, Sicarbtech will translate your KPIs into a data-backed roadmap with milestones for performance, compliance, and ramp. Contact: [email protected] | +86 133 6536 0038.

Article Metadata

Last updated: 2025-09-17

Next scheduled review: 2025-12-01

Content freshness indicators: 2025 Pakistan EAF PQ outlook; SiC 1200/1700 V devices; multilevel active filter/SVG architectures; sintered-silver and AlN/Si3N4 substrates; laminated low-parasitic busbars; ≤3% THD, PF ~0.99–1.00, and fast flicker mitigation targets; HT/HH and salt-mist reliability; localization and technology transfer pathways; case narratives in Karachi, Lahore, and Faisalabad.

About Sicarbtech: Silicon Carbide Solutions Expert located in Weifang City, China’s silicon carbide manufacturing hub; member of Chinese Academy of Sciences (Weifang) Innovation Park; 10+ years of silicon carbide customization experience; supporting 19+ local enterprises with advanced SiC technology; full-cycle solutions from material processing to finished products; specializing in R‑SiC, SSiC, RBSiC, and SiSiC grades; services include custom manufacturing, factory establishment, and technology transfer.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.