Efficient SiC Extrusion for Custom Shapes & Profiles

Share

Efficient SiC Extrusion for Custom Shapes & Profiles

Introduction: The Power of Custom Silicon Carbide Extrusion

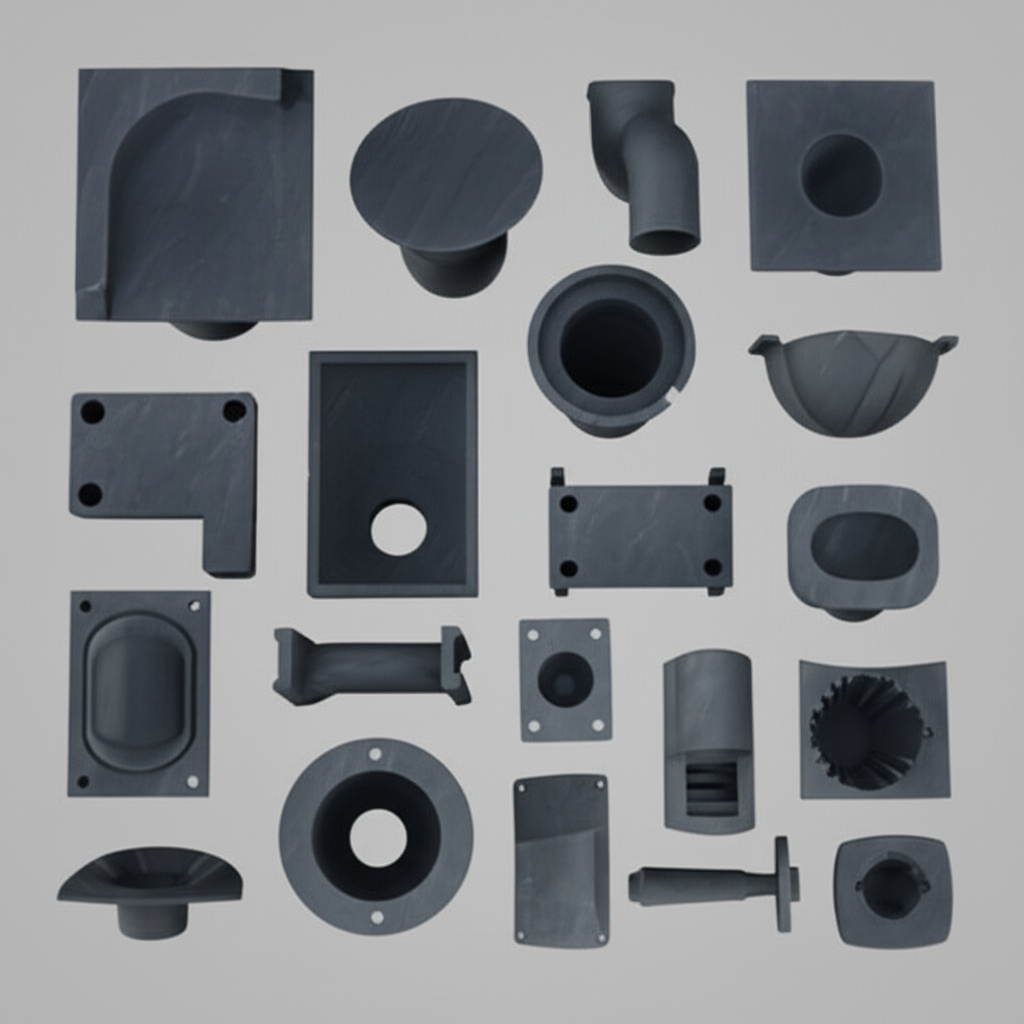

In the realm of high-performance industrial applications, materials that can withstand extreme conditions are paramount. Silicon Carbide (SiC) stands out as a premier technical ceramic, renowned for its exceptional hardness, high-temperature stability, superior thermal conductivity, and remarkable chemical inertness. While SiC components can be manufactured through various methods, silicon carbide extrusion offers a unique advantage for producing complex, continuous shapes and profiles with consistent cross-sections. This process is essential for industries demanding custom SiC parts tailored to specific operational needs, moving beyond standard off-the-shelf solutions.

Custom SiC extrusions, such as tubes, rods, and intricate profiles, are pivotal in applications where performance, longevity, and reliability cannot be compromised. From semiconductor manufacturing to aerospace engineering, the ability to obtain SiC components precisely designed for an application unlocks new levels of efficiency and innovation. This blog post delves into the intricacies of the SiC extrusion process, its applications, design considerations, and how to partner with a knowledgeable supplier to leverage this advanced manufacturing technique effectively.

Key Industrial Applications of Extruded Silicon Carbide

The versatility of extruded silicon carbide parts allows them to serve a multitude of functions across diverse high-demand industries. The ability to create continuous profiles, long tubes, and custom cross-sections makes SiC extrusion an ideal solution where other manufacturing methods might fall short or be less cost-effective for specific geometries.

- Semiconductor Manufacturing: Extruded SiC tubes and profiles are used in wafer processing equipment, including furnace components, liners, and gas delivery systems, due to their high purity, thermal shock resistance, and stability at extreme temperatures.

- High-Temperature Furnaces & Kilns: SiC beams, rollers, support tubes, and thermocouple protection tubes are critical in industrial furnaces for their mechanical strength at elevated temperatures (up to 1600°C or higher), excellent wear resistance, and resistance to corrosive atmospheres.

- Automotive Industry: While not as prevalent as in other SiC applications, extruded components can find use in specialized high-performance automotive systems, such as wear-resistant parts in braking systems or components in exhaust gas recirculation (EGR) systems requiring high thermal and corrosion resistance.

- Aerospace & Defense: Lightweight yet robust SiC components, including structural elements, heat exchangers, and nozzle inserts, benefit from extrusion for creating near-net shapes with excellent thermal management capabilities.

- Power Electronics: Extruded SiC heat sinks and cooling channels offer superior thermal dissipation for high-power modules, IGBTs, and other power semiconductor devices, enhancing performance and reliability.

- Renewable Energy: Components for solar thermal systems and fuel cells, requiring high-temperature stability and chemical resistance, can be efficiently produced through extrusion.

- Chemical Processing: SiC tubes, nozzles, and linings are used in aggressive chemical environments due to their exceptional corrosion resistance against acids and alkalis, even at high temperatures.

- Metallurgy: Extruded SiC components like immersion heater tubes, crucibles, and degassing tubes are vital in molten metal handling for their non-wetting properties with many non-ferrous metals and resistance to thermal shock.

- LED Manufacturing: Certain components in MOCVD reactors and other LED production equipment leverage SiC for its thermal properties and purity.

- Industrial Machinery: Wear-resistant liners, guides, and nozzles in demanding industrial equipment extend service life and reduce maintenance.

The consistent geometry and material properties achieved through extrusion make it a go-to method for producing reliable, high-performance technical ceramic extrusions for these and other challenging industrial environments.

Why Opt for Custom Extruded Silicon Carbide?

Choosing custom extruded silicon carbide components over standard parts or alternative materials offers significant advantages, particularly when specific geometries and material characteristics are crucial for performance. The extrusion process is particularly well-suited for creating elongated parts with uniform cross-sections, a capability that can be more challenging or costly with other ceramic forming techniques like pressing or casting for such shapes.

Key Benefits of Custom SiC Extrusion:

- Complex Geometries & Profiles: Extrusion allows for the creation of intricate internal and external features along the length of the part, such as multi-lumen tubes, ribbed surfaces, or custom-designed profiles tailored to specific flow or structural requirements.

- Cost-Effectiveness for Specific Shapes: For long parts with consistent cross-sections (e.g., tubes, rods, beams), extrusion is often more economical than machining from a solid block, especially in medium to high-volume production, due to reduced material waste and machining time.

- Excellent Thermal Management: SiC’s inherent high thermal conductivity, combined with the ability to extrude custom cooling channels or heat sink profiles, makes it ideal for thermal management applications.

- Superior Wear and Abrasion Resistance: Extruded SiC parts maintain the material’s exceptional hardness, providing outstanding resistance to wear, erosion, and abrasion in demanding applications like nozzles, liners, and guides.

- Chemical Inertness and Corrosion Resistance: Silicon carbide is highly resistant to most chemicals, acids, and alkalis, even at elevated temperatures. Extruded components like chemical processing tubes and thermocouple sheaths benefit immensely from this property.

- High-Temperature Stability: Extruded SiC maintains its mechanical strength and structural integrity at very high temperatures, making it suitable for furnace components, burner nozzles, and heat exchangers.

- Consistent Material Properties: The extrusion process, when properly controlled, yields parts with uniform density and microstructure, leading to predictable and reliable performance.

- Scalability for Production: Once a die is developed, the extrusion process can be scaled for efficient production of large quantities of identical profiles.

By opting for custom SiC extruded profiles, engineers and procurement managers can specify exact dimensions, tolerances, and material grades, ensuring that the component perfectly integrates into their system and delivers optimal performance and longevity. This tailored approach minimizes compromises often encountered with standard parts, leading to improved overall system efficiency and reliability.

Recommended SiC Grades and Compositions for Extrusion

Several types of silicon carbide can be processed via extrusion, each offering a unique set of properties suitable for different applications. The choice of SiC grade is critical and depends on the specific service conditions, such as temperature, chemical environment, mechanical stress, and electrical requirements.

Here are some common SiC grades used in extrusion and their characteristics:

| SiC Grade | Key Characteristics for Extrusion & Application | Typical Extruded Applications |

|---|---|---|

| Reaction-Bonded Silicon Carbide (RBSC / SiSiC) | Good mechanical strength, excellent thermal shock resistance, high thermal conductivity, relatively easier to form complex shapes. Contains some free silicon (typically 8-15%). Operating temperature generally up to 1350-1380°C. | Kiln furniture (beams, rollers, supports), heat exchangers, burner nozzles, wear-resistant liners, molten metal handling components. |

| Sintered Silicon Carbide (SSiC) | Very high purity (typically >99% SiC), excellent corrosion resistance, superior wear resistance, maintains strength at very high temperatures (up to 1600°C or higher). More challenging to extrude complex shapes compared to RBSC but offers superior performance in extreme environments. | Chemical processing tubes, high-temperature furnace parts, mechanical seals, bearings, semiconductor processing components requiring high purity. |

| Nitride-Bonded Silicon Carbide (NBSC) | Good thermal shock resistance, good abrasion resistance, good strength at moderate temperatures. Often more cost-effective for certain applications. Formed by SiC grains bonded by silicon nitride. | Kiln furniture, linings for cyclones and pipes in abrasive environments, some molten metal contact applications. Extrusion is feasible but might be less common than for RBSC or dense SSiC for highly complex profiles. |

| Clay-Bonded Silicon Carbide | Lower SiC content, bonded with ceramic clays. More economical but with lower performance characteristics compared to RBSC or SSiC, particularly in terms of temperature limit and chemical resistance. Easier to extrude. | Lower-temperature kiln furniture, refractories, crucibles for some specific applications. |

| Oxide-Bonded Silicon Carbide (OBSiC) | SiC grains bonded by oxide phases. Offers good thermal shock resistance and can be an economical choice for applications up to around 1300-1400°C. | Specialized kiln furniture, heat exchanger elements. |

The selection of the appropriate SiC grade involves a careful analysis of the application’s demands versus the material’s properties and cost. For instance, while SSiC offers the highest performance in terms of temperature and corrosion resistance, RBSC might be a more practical and cost-effective choice for applications where its slightly lower operating temperature and presence of free silicon are acceptable. Consulting with experienced silicon carbide manufacturing specialists is crucial to select the optimal grade for your extruded components.

The Silicon Carbide Extrusion Process: A Step-by-Step Overview

The extrusion of silicon carbide is a sophisticated manufacturing process that transforms SiC powder into precise, continuous profiles. Understanding this process helps appreciate the complexities involved in producing high-quality custom SiC components.

- Raw Material Preparation:

- High-purity silicon carbide powder of a specific grain size distribution is selected based on the desired final properties of the extruded part. Different SiC types (alpha-SiC, beta-SiC) and particle morphologies can be used.

- For reaction-bonded SiC (RBSC), carbon sources are also incorporated into the initial mix.

- Mixing and Compounding:

- The SiC powder is thoroughly mixed with various organic or inorganic binders, plasticizers, lubricants, and other additives. These additives are crucial for creating a deformable, extrudable paste or dough.

- The type and amount of binder system significantly influence the extrusion behavior, green strength (strength of the part before sintering), and burnout characteristics during firing.

- Water is often used as a solvent for aqueous extrusion systems.

- De-airing (Pugging):

- The mixed batch is processed through a pug mill or vacuum extruder to remove trapped air. Air bubbles can cause defects such as voids or cracks in the final sintered product. This step also homogenizes the mixture further.

- Extrusion:

- The de-aired, plasticized SiC mixture is fed into an extruder.

- A piston or screw forces the material through a hardened steel or tungsten carbide die. The die’s orifice has the precise cross-sectional shape of the desired profile (e.g., tube, rod, honeycomb, custom shape).

- Continuous lengths of the “green” (unfired) SiC extrudate emerge from the die. These are carefully supported to prevent distortion.

- Cutting and Handling:

- The continuous extrudate is cut to desired lengths, either during or immediately after extrusion.

- Green parts are delicate and must be handled carefully to avoid damage or deformation.

- Drying:

- The green extruded parts are slowly and carefully dried to remove moisture and volatile components from the binder system.

- Controlled drying is critical to prevent cracking, warping, or distortion due to differential shrinkage. This can be done at room temperature or in controlled humidity and temperature ovens.

- Binder Burnout (Debinding):

- After drying, the parts are heated at a slow, controlled rate in a kiln or furnace to thermally decompose and remove the organic binders and plasticizers. This step must be managed carefully to avoid defects.

- Sintering (Firing):

- The debound (“brown”) parts are then sintered at very high temperatures (often exceeding 2000°C for SSiC, or around 1400-1500°C for RBSC infiltration) in a controlled atmosphere (e.g., inert, vacuum, or reactive gas for RBSC).

- During sintering, the SiC particles bond together, leading to densification and the development of the material’s final mechanical, thermal, and chemical properties. Significant shrinkage occurs during this stage.

- For RBSC, molten silicon infiltrates the porous preform (SiC + Carbon) and reacts with the carbon to form secondary SiC, bonding the primary SiC grains.

- Cooling and Finishing:

- After sintering, the SiC components are slowly cooled to room temperature.

- Further post-processing steps, such as grinding, machining, or lapping, may be required to meet precise dimensional tolerances or surface finish requirements (discussed in a later section).

Each step in the SiC extrusion process requires meticulous control to ensure the production of high-quality, defect-free components that meet stringent industrial specifications. This complex process underscores the importance of partnering with manufacturers possessing deep expertise in advanced ceramic processing.

Design Considerations for Custom Extruded SiC Products

Designing components for silicon carbide extrusion requires a different mindset than designing for metals or plastics due to the unique characteristics of ceramics and the specifics of the extrusion process. Adhering to Design for Manufacturability (DfM) principles is crucial for achieving cost-effective, high-quality extruded SiC parts.

Key Design Considerations:

- Uniform Wall Thickness: Maintaining a consistent wall thickness throughout the profile is highly desirable. Variations can lead to uneven drying and sintering, causing stress, warping, or cracking. If variations are necessary, they should be gradual.

- Aspect Ratios: Extremely thin walls or very high aspect ratios (length vs. width/thickness) can be challenging to extrude and handle without distortion or damage. Consult with your supplier on practical limits.

- Corner Radii: Sharp internal and external corners are prone to stress concentrations and can be points of failure or chipping. Incorporating generous radii on all corners is recommended to improve strength and manufacturability. Minimum radii depend on the die manufacturing and material flow.

- Hollow Sections and Internal Features: Extrusion is excellent for producing hollow sections (like tubes) and parts with internal webs or channels. However, the complexity of these internal features impacts die design and cost. Ensure that internal passages are large enough for consistent material flow and to allow for binder burnout.

- Symmetry: Symmetrical profiles are generally easier to extrude and are less prone to distortion during drying and sintering. If asymmetry is required, careful process control is needed.

- Tolerances: Understand the achievable tolerances for extruded and sintered SiC. While SiC is a precision material, the extrusion process itself has inherent variability, followed by significant shrinkage during sintering. Tighter tolerances often require post-sintering machining, which adds cost.

- Length Limitations: While extrusion can produce continuous profiles, practical lengths are limited by handling, drying, and furnace capacities. Discuss maximum feasible lengths with your supplier.

- Surface Finish: The as-extruded surface finish is typically good, but specific requirements might necessitate post-processing like grinding or lapping.

- Draft Angles: While less critical than in molding, slight draft angles can sometimes aid in material flow for certain complex profiles, although true extrusion relies on pushing material through a constant cross-section die.

- Feature Size and Detail: Very fine details or extremely small features might be difficult to consistently achieve and maintain through the drying and sintering stages. The minimum feature size depends on the SiC mix, die technology, and overall part size.

- Material Selection: The chosen SiC grade can influence design possibilities due to differences in shrinkage, sinterability, and achievable complexity.

Collaborating closely with your silicon carbide components wholesale supplier or custom manufacturer early in the design phase is essential. Their expertise can guide you in optimizing your design for the extrusion process, ensuring functionality while minimizing manufacturing challenges and costs. Many advanced suppliers offer customizing support to help refine designs for optimal production.

Tolerance, Surface Finish & Dimensional Accuracy in SiC Extrusion

Achieving precise dimensional accuracy, specific tolerances, and desired surface finishes are critical aspects of manufacturing custom extruded silicon carbide components. These parameters are influenced by the extrusion process itself, the behavior of the SiC material during drying and sintering, and any post-processing operations.

Tolerances:

- As-Sintered Tolerances: Due to the significant and somewhat variable shrinkage (typically 15-20%) that occurs during drying and sintering, as-sintered SiC extrusions will have wider tolerances compared to machined metal parts. Typical as-sintered dimensional tolerances for SiC extrusions might range from ±0.5% to ±2% of the dimension, depending on the complexity, size, and specific SiC grade. For example, a 100mm dimension might have an as-sintered tolerance of ±0.5mm to ±2mm.

- Machined Tolerances: For applications requiring tighter control, post-sintering grinding and machining are necessary. Diamond grinding can achieve very precise tolerances, often in the range of ±0.01mm to ±0.05mm, or even tighter for critical features. However, this significantly increases the cost.

- Straightness and Camber: Long extruded parts, such as tubes or rods, can develop some degree of bow or camber during processing. Tolerances for straightness are important to specify if critical, and may necessitate post-sintering straightening or grinding.

Surface Finish:

- As-Extruded/Sintered Surface: The surface finish of as-sintered extruded SiC is generally smooth but will reflect the texture of the extrusion die and the microstructure of the sintered ceramic. Typical Ra (average roughness) values might be in the range of 0.8 µm to 5 µm, depending on the SiC grade and processing.

- Ground/Lapped/Polished Surfaces:

- Grinding: Diamond grinding can achieve smoother surfaces, often with Ra values from 0.2 µm to 0.8 µm.

- Lapping: For applications requiring very smooth, flat surfaces (e.g., seals, bearings), lapping can achieve Ra values below 0.1 µm.

- Polishing: Mirror finishes can be achieved through specialized polishing techniques, resulting in extremely low Ra values, sometimes down to nanometer-scale roughness.

Dimensional Accuracy:

- Achieving high dimensional accuracy begins with precise die design and meticulous control over the entire extrusion and sintering process.

- Predicting and compensating for shrinkage is a key aspect of SiC manufacturing. Suppliers use historical data and modeling to estimate shrinkage, but test runs may be needed for new or complex profiles.

- Consistency in raw materials, mixing, extrusion parameters, and firing schedules is crucial for maintaining dimensional repeatability from batch to batch.

It is vital for procurement managers and engineers to clearly define their tolerance and surface finish requirements early in the discussion with their industrial SiC parts supplier. Over-specifying these parameters can lead to unnecessary costs, while under-specifying can result in parts that do not perform as intended. A collaborative approach ensures that the final components meet both functional needs and budget constraints.

Post-Processing Options for Extruded SiC Components

While the SiC extrusion process aims to produce near-net-shape components, many applications require additional post-processing steps to meet final specifications for dimensions, surface finish, or functionality. Silicon carbide’s extreme hardness means that most machining operations require diamond tooling, which can be time-consuming and costly.

Common Post-Processing Operations:

- Cutting to Length: Although green extrusions are often cut to approximate lengths, precise final lengths are typically achieved by diamond saw cutting after sintering.

- Grinding:

- Surface Grinding: To achieve flat surfaces and precise thickness.

- Cylindrical Grinding (OD/ID): To achieve precise outer and inner diameters for tubes and rods, and to improve concentricity.

- Profile Grinding: To refine complex extruded shapes or add features not possible through extrusion alone.

- Machining:

- Drilling: Creating precise holes, often with diamond core drills or ultrasonic machining.

- Milling: Adding slots, grooves, or other features. This is generally limited due to the hardness of SiC but possible with specialized equipment.

- Threading: While challenging, internal or external threads can sometimes be machined into SiC components. Alternatively, metallic inserts can be designed in.

- Lapping and Polishing: For applications demanding exceptionally smooth and flat surfaces, such as mechanical seals, bearings, or optical components (though extrusion is less common for optical grades). Lapping uses abrasive slurries to achieve fine finishes, followed by polishing for mirror-like surfaces if needed.

- Chamfering and Edge Radiusing: To remove sharp edges, improve strength, and prevent chipping. This can be done by grinding or specialized tumbling.

- Cleaning: Removing any residues from machining or handling processes to ensure parts meet purity requirements, especially for semiconductor or medical applications.

- Joining/Assembly: In some cases, extruded SiC parts may be joined to other SiC components or different materials (e.g., metals, other ceramics) using brazing, specialized adhesives, or mechanical fastening.

- Glazing or Sealing: For certain SiC grades like RBSC, which may have some porosity or free silicon, a ceramic glaze can be applied and fired to seal the surface. This can improve oxidation resistance, chemical resistance, or reduce gas permeability. Some SSiC parts might also be sealed for ultra-high vacuum applications.

- Coating: Applying specialized coatings (e.g., CVD SiC, PyC) to further enhance surface properties like wear resistance, corrosion resistance, or biocompatibility.

The extent of post-processing depends heavily on the specific application requirements and the capabilities of the chosen SiC extrusion technology. Each additional step adds to the overall cost and lead time, so it’s crucial to specify only necessary operations. Discussing these needs with your SiC supplier early in the project lifecycle will help optimize the manufacturing route for both performance and cost-effectiveness.

Overcoming Common Challenges in Silicon Carbide Extrusion

The extrusion of silicon carbide, like any advanced manufacturing process, comes with its set of challenges. Understanding these potential hurdles and how experienced manufacturers address them is key to procuring high-quality, reliable SiC components.

Common Challenges and Mitigation Strategies:

- Die Design and Wear:

- Challenge: SiC is highly abrasive, leading to rapid wear of extrusion dies, especially those made from standard tool steels. Complex die profiles are also expensive to manufacture.

- Solution: Utilize highly wear-resistant die materials such as tungsten carbide or specialized hardened steels. Employ advanced die design software and simulation to optimize material flow and reduce stress on the die. Regular die maintenance and replacement schedules are essential.

- Material Consistency and Flow:

- Challenge: Achieving a homogenous mix of SiC powder, binders, and plasticizers is critical for uniform extrusion. Inconsistent material can lead to variations in density, shrinkage, and defects. Poor flow can cause blockages or uneven extrusion.

- Solution: Implement stringent quality control for raw materials. Utilize advanced mixing and pugging equipment to ensure thorough homogenization and de-airing. Precisely control the rheology (flow characteristics) of the SiC paste.

- Cracking During Drying and Binder Burnout:

- Challenge: Rapid or uneven removal of moisture or binders can create internal stresses, leading to cracks, warping, or distortion in the green or brown parts.

- Solution: Employ carefully controlled drying and binder burnout cycles with slow temperature ramps and controlled atmospheres. Optimize binder systems for gradual decomposition. Ensure uniform airflow and temperature distribution in ovens and kilns.

- Shrinkage Control and Dimensional Stability:

- Challenge: SiC parts undergo significant shrinkage (15-20%) during sintering. Predicting and controlling this shrinkage to achieve final dimensional accuracy is complex, especially for intricate or long profiles.

- Solution: Develop precise shrinkage models based on material composition, part geometry, and processing parameters. Utilize consistent raw materials and tightly control all process steps from mixing to sintering. For very tight tolerances, design for post-sintering machining.

- Maintaining Profile Integrity for Long Extrusions:

- Challenge: Long, thin extrusions can sag, warp, or twist during handling, drying, and firing.

- Solution: Use specialized handling supports for green extrudates. Optimize drying and firing setups to provide uniform support and heat distribution. For very long components, consider segmenting the design if feasible or discuss specific support strategies with the manufacturer.

- Sintering Issues (e.g., Incomplete Densification, Grain Growth):

- Challenge: Achieving full densification without excessive grain growth is crucial for optimal mechanical properties. Improper sintering can lead to porous parts or compromised strength.

- Solution: Precisely control sintering temperature, time, atmosphere, and heating/cooling rates. Use appropriate sintering aids if required for the SiC grade. Conduct microstructural analysis to optimize sintering cycles.

- Cost of Complex or Small-Batch Extrusions:

- Challenge: Tooling (die) costs can be high, making small batches of custom profiles expensive. Highly complex profiles also increase die manufacturing costs and processing difficulty.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.