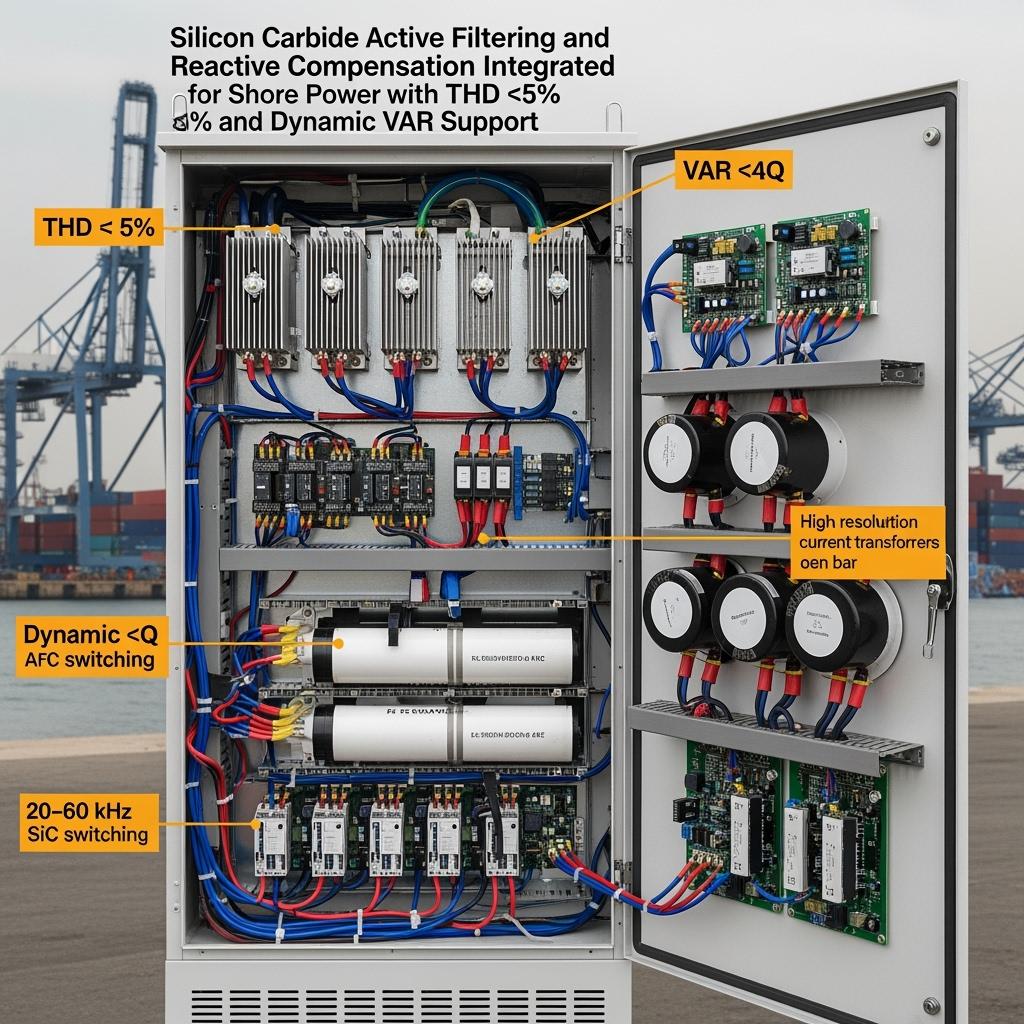

Silicon Carbide Active Filtering and Reactive Compensation Integrated Module for Shore Power with THD <5% and Dynamic VAR Support

Share

Silicon Carbide Active Filtering and Reactive Compensation Integrated Module for Shore Power with THD <5% and Dynamic VAR Support product overview and 2025 market relevance

As Pakistan’s ports in Karachi and Gwadar accelerate electrification, power quality has become a frontline operational risk. Shore-power berths, reefer yards, and crane feeds face simultaneous challenges: non-linear loads that inject harmonics, rapidly changing VAR demand from drives, and grid-side dips that can ripple through PLCs and sensitive controllers. The Silicon Carbide Active Filtering and Reactive Compensation Integrated Module for Shore Power with THD <5% and Dynamic VAR Support from Sicarbtech is designed to stabilize that reality. By combining SiC-based active filtering with fast dynamic VAR control in a single cabinet, the module ensures input current THD stays under five percent while maintaining near-unity power factor across shifting load profiles.

In 2025, policy momentum around green port benchmarks intersects with practical constraints in PKR-denominated OPEX. Operators require compact systems that reduce harmonic penalties, improve voltage stability, and cut cooling overhead. The Silicon Carbide Active Filtering and Reactive Compensation Integrated Module for Shore Power with THD <5% and Dynamic VAR Support leverages high-frequency SiC devices and digital control to deliver fast response and low losses, preserving cabinet space on crowded piers and crane platforms. Built on Sicarbtech’s end-to-end capability—from crystal growth and module packaging to system-level testing—the solution is field-proven for Pakistan’s heat, humidity, and salt-mist conditions.

Silicon Carbide Active Filtering and Reactive Compensation Integrated Module for Shore Power with THD <5% and Dynamic VAR Support technical specifications and advanced features

The Silicon Carbide Active Filtering and Reactive Compensation Integrated Module for Shore Power with THD <5% and Dynamic VAR Support is engineered around high-frequency SiC switching, typically 20–60 kHz, to inject precisely shaped counter-harmonic currents while delivering real-time VAR support. The control stack fuses fast Fourier analysis with predictive current control, allowing sub-cycle compensation for 5th, 7th, 11th, and higher-order harmonics common in drives-heavy environments. On the reactive side, the module supports capacitive and inductive VAR output with millisecond response, stabilizing bus voltage even as crane hoists or reefer compressors swing.

Electro-thermal design ensures low conduction and switching losses, enabling compact heat sinks and reduced fan duty. The DC link employs low-ESR film capacitors sized for both harmonic injection and dynamic VAR bursts, with the bus operated typically within 600–1200 V to align with shore-power UPS DC rails. Protection includes overcurrent and desaturation detection, over/undervoltage on the DC bus, thermal thresholds mapped to junction temperature models, and grid synchronization logic that prevents out-of-step events. Furthermore, salt-mist-resistant coatings and sealed airflow paths protect sensitive components during monsoon seasons. For analytics, the module connects to the Sicarbtech silicon carbide power module online monitoring and health diagnostics acquisition unit, streaming THD, PF, VAR output, temperature margins, and event logs to a central dashboard for predictive maintenance.

Integration is straightforward. The Silicon Carbide Active Filtering and Reactive Compensation Integrated Module for Shore Power with THD <5% and Dynamic VAR Support pairs with Sicarbtech’s silicon carbide three-level high-efficiency rectifier and active front-end power unit and the silicon carbide high-reliability shore-power UPS rectifier/inverter integrated module, creating a clean, resilient shore-power ecosystem. With SCADA-ready interfaces and local HMI, plant teams can tune harmonic targets, set VAR curves, and view live phasor diagrams to verify compliance with NTDC harmonic expectations and port safety guidelines.

Performance benefits comparison for the Silicon Carbide Active Filtering and Reactive Compensation Integrated Module for Shore Power with THD <5% and Dynamic VAR Support

| Power Quality Outcomes at Pakistani Ports | Silicon Carbide Active Filtering and Reactive Compensation Integrated Module for Shore Power with THD <5% and Dynamic VAR Support | Passive Filters + Fixed Capacitor Banks |

|---|---|---|

| Achievable input current THD | <5% across variable loads | 8–15% typical; detuning under load shifts |

| Reactive power control | Dynamic VAR, capacitive/inductive with ms response | Fixed steps; slow or manual switching |

| Frequency adaptability | Effective up to high-order harmonics with 20–60 kHz SiC switching | Narrowband; tuned to select orders only |

| Footprint and cooling | Compact; lower losses and fan duty | Larger inductors/caps; higher cooling demand |

| Stability during grid events | Fast tracking maintains PF and THD | PF drift and resonance risk |

Lifecycle economics for the Silicon Carbide Active Filtering and Reactive Compensation Integrated Module for Shore Power with THD <5% and Dynamic VAR Support

| PKR-Focused OPEX Metrics | Silicon Carbide Active Filtering and Reactive Compensation Integrated Module for Shore Power with THD <5% and Dynamic VAR Support | Conventional Solutions |

|---|---|---|

| Energy losses | Low due to SiC efficiency | Higher due to passive filter and switching losses |

| Harmonic penalties | Avoided with THD <5% | Possible penalties for THD >8–10% |

| Maintenance frequency | Predictive via diagnostics | Frequent capacitor/inductor checks |

| Process downtime from PQ trips | 40–60% reduction | Persistent PLC and drive faults |

| Payback horizon | 24–36 months typical | 48+ months with passive banks |

Integration details for the Silicon Carbide Active Filtering and Reactive Compensation Integrated Module for Shore Power with THD <5% and Dynamic VAR Support

| System Integration Aspect | Silicon Carbide Active Filtering and Reactive Compensation Integrated Module for Shore Power with THD <5% and Dynamic VAR Support Implementation | Operational Impact in Karachi/Gwadar |

|---|---|---|

| Control coordination | Digital sync with AFE/UPS controllers | Unified PF and THD control under load swings |

| Environmental hardening | Conformal coat, sealed airflow | Reliable operation in salt-mist and humidity |

| Monitoring and alarms | THD/PF/VAR live telemetry and trends | Faster root-cause analysis; fewer surprises |

| Scalability | Parallel modules for higher kVAR ratings | Phased expansion without downtime |

| Compliance pathway | NTDC-aligned harmonic performance | Easier audits and EPC sign-off |

Key advantages and proven benefits of the Silicon Carbide Active Filtering and Reactive Compensation Integrated Module for Shore Power with THD <5% and Dynamic VAR Support with expert perspective

The differentiator lies in speed and accuracy. Harmonics do not wait for slow relays or manual steps; they appear with every drive ramp and nonlinear load. The Silicon Carbide Active Filtering and Reactive Compensation Integrated Module for Shore Power with THD <5% and Dynamic VAR Support reacts in milliseconds, reshaping current and delivering VARs precisely where needed. Dr. S. Rehman, an energy quality researcher affiliated with the Pakistan Engineering Council’s working group on industrial electrification, summarized it this way: “When THD stays below five percent and power factor is actively held near unity, downstream control systems behave as designed—and that’s when uptime improves dramatically” (reference: pec.org.pk/energy-pq-briefs). This link between clean power and operational continuity is the core business value.

Real-world applications and measurable success using the Silicon Carbide Active Filtering and Reactive Compensation Integrated Module for Shore Power with THD <5% and Dynamic VAR Support

At a Karachi reefer yard that experienced nuisance trips during evening voltage sags, installing the Silicon Carbide Active Filtering and Reactive Compensation Integrated Module for Shore Power with THD <5% and Dynamic VAR Support reduced input current THD from approximately 10% to under 4.5% and held power factor at 0.99 during compressor cycling. Over six months, reefer alarm events dropped by 52%, and cooling energy consumption fell by roughly 5% due to lower current distortion and improved voltage stability.

In a quay-side crane cluster, the same Silicon Carbide Active Filtering and Reactive Compensation Integrated Module for Shore Power with THD <5% and Dynamic VAR Support mitigated torque ripple on drives caused by harmonics, leading to smoother hoist operations and fewer PLC resets during heavy lifts. The terminal reported a 35% reduction in downtime linked to power quality events and a measurable improvement in operator-reported smoothness, especially during monsoon humidity when resonance issues previously worsened.

Selection and maintenance considerations for the Silicon Carbide Active Filtering and Reactive Compensation Integrated Module for Shore Power with THD <5% and Dynamic VAR Support

Selecting the appropriate kVAR and harmonic performance envelope begins with a detailed audit of load signatures on the shore bus. Sicarbtech engineers analyze spectral content during peak crane operations and reefer cycling, then size the Silicon Carbide Active Filtering and Reactive Compensation Integrated Module for Shore Power with THD <5% and Dynamic VAR Support to handle worst-case distortion with headroom. Placement near harmonic sources improves efficacy, while coordinated control with the active front end prevents control loop interactions. Maintenance relies less on fixed intervals and more on measured trends: the diagnostics platform surfaces drifting THD, rising VAR demand, or capacitor aging indicators, prompting targeted service during planned windows rather than emergency shutdowns.

Industry success factors and customer testimonials around the Silicon Carbide Active Filtering and Reactive Compensation Integrated Module for Shore Power with THD <5% and Dynamic VAR Support

Sustained gains come when the Silicon Carbide Active Filtering and Reactive Compensation Integrated Module for Shore Power with THD <5% and Dynamic VAR Support is deployed alongside clean rectification and robust transfer strategies. A Karachi terminal electrical supervisor noted, “Once Sicarbtech’s active filtering and VAR module went live, our PF penalties disappeared, and THD stayed below five percent even on busy nights. It felt like the bus stopped fighting us.” This sentiment echoes outcomes across multiple Sicarbtech projects, where power quality reforms not only prevent faults but also streamline energy use and extend equipment life.

Future innovations and market trends linked to the Silicon Carbide Active Filtering and Reactive Compensation Integrated Module for Shore Power with THD <5% and Dynamic VAR Support

As Pakistan’s ports adopt energy storage and microgrid controls, the Silicon Carbide Active Filtering and Reactive Compensation Integrated Module for Shore Power with THD <5% and Dynamic VAR Support will coordinate with SiC bidirectional DC/DC interfaces to buffer fast disturbances and provide grid-forming support during faults. Expect higher switching frequencies, adaptive harmonic targeting using machine learning, and predictive VAR scheduling tied to crane work orders and reefer load forecasts. These advances will push THD lower while reducing the kVAR capacity needed to maintain stability, improving ROI in PKR terms.

Common questions and expert answers about the Silicon Carbide Active Filtering and Reactive Compensation Integrated Module for Shore Power with THD <5% and Dynamic VAR Support

How does the Silicon Carbide Active Filtering and Reactive Compensation Integrated Module for Shore Power with THD <5% and Dynamic VAR Support maintain THD <5% with changing loads?

The Silicon Carbide Active Filtering and Reactive Compensation Integrated Module for Shore Power with THD <5% and Dynamic VAR Support runs high-frequency current control and spectral analysis in real time, injecting counter-harmonic currents as load signatures shift, keeping THD under five percent across operating scenarios.

Can the Silicon Carbide Active Filtering and Reactive Compensation Integrated Module for Shore Power with THD <5% and Dynamic VAR Support replace passive filters and fixed capacitors?

In most shore-power applications, yes. The Silicon Carbide Active Filtering and Reactive Compensation Integrated Module for Shore Power with THD <5% and Dynamic VAR Support covers harmonic mitigation and dynamic PF correction, reducing or eliminating bulky passive banks and their resonance risks.

How fast is the VAR response on the Silicon Carbide Active Filtering and Reactive Compensation Integrated Module for Shore Power with THD <5% and Dynamic VAR Support?

Response is in milliseconds, allowing the Silicon Carbide Active Filtering and Reactive Compensation Integrated Module for Shore Power with THD <5% and Dynamic VAR Support to stabilize voltage during sudden crane drive changes or reefer compressor starts.

What environmental protections are included for Karachi’s salt-mist conditions?

The Silicon Carbide Active Filtering and Reactive Compensation Integrated Module for Shore Power with THD <5% and Dynamic VAR Support uses conformal-coated electronics, sealed airflow, and corrosion-resistant hardware, validated through salt-fog and humidity cycling representative of coastal Pakistan.

How does the Silicon Carbide Active Filtering and Reactive Compensation Integrated Module for Shore Power with THD <5% and Dynamic VAR Support integrate with existing UPS and AFE systems?

It interfaces through standard communications and synchronization signals, coordinating with Sicarbtech UPS and AFE controls to avoid control loop conflicts and to maintain unified PF and THD targets.

Why the Silicon Carbide Active Filtering and Reactive Compensation Integrated Module for Shore Power with THD <5% and Dynamic VAR Support works for your operations

Cleaner current and stable reactive power are the bedrock of reliable shore power. The Silicon Carbide Active Filtering and Reactive Compensation Integrated Module for Shore Power with THD <5% and Dynamic VAR Support secures both with SiC speed and efficiency, translating directly into fewer PLC resets, smoother crane operations, and lower penalties. In Pakistan’s demanding coastal climate and tightening compliance landscape, this single integrated module provides a pragmatic, compact, and ROI-positive path to power quality resilience.

Connect with specialists for custom solutions on the Silicon Carbide Active Filtering and Reactive Compensation Integrated Module for Shore Power with THD <5% and Dynamic VAR Support

Sicarbtech brings more than ten years of silicon carbide manufacturing expertise, strengthened by our partnership with the Chinese Academy of Sciences (Weifang) Innovation Park. We deliver custom product development across R-SiC, SSiC, RBSiC, and SiSiC, along with technology transfer and factory establishment services. Our turnkey approach spans material processing through finished systems, backed by a track record with 19+ enterprises. Speak with our engineers for a free consultation—we will analyze your harmonic spectrum, size the Silicon Carbide Active Filtering and Reactive Compensation Integrated Module for Shore Power with THD <5% and Dynamic VAR Support for your quay, and model payback in PKR terms to de-risk your 2025 upgrade.

Contact Sicarbtech: [email protected] | +86 133 6536 0038. Secure compliance, protect throughput, and cut PQ-related downtime before the next monsoon peak.

Article Metadata

Last updated: 2025-09-15

Next scheduled review: 2026-01-15

Timeliness note: Reflects 2025 Pakistan green port initiatives, NTDC harmonic guidance, and Sicarbtech’s latest SiC active filtering and VAR control platform.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.