Top Uses of Customized SiC Products in Heavy Industry | Sicarbtech Pillar Page for Turkey 2025

Share

Sicarbtech is the Silicon Carbide Solutions Expert trusted by Turkish textile, automotive, and steel manufacturers seeking higher uptime, lower energy intensity, and audit-ready quality. From our base in Weifang City—China’s silicon carbide manufacturing hub—and as a member of the Chinese Academy of Sciences (Weifang) Innovation Park, we have delivered over a decade of customized R-SiC, SSiC, RBSiC, and SiSiC solutions. In 2025, as Turkey aligns production with EU-facing requirements and manages energy and FX volatility, customized silicon carbide is no longer a niche material—it is a strategic lever for industrial competitiveness.

Executive Summary: Why Customized Silicon Carbide Matters in Turkey’s 2025 Outlook

Turkey’s heavy industries are navigating a demanding transition. Textile hubs like Denizli and Gaziantep face pressure to reduce rework, maintain consistent dyeing and finishing, and document process stability for export customers. Automotive clusters in Bursa, Kocaeli, and Ankara are tightening tolerances under IATF 16949 while expanding EV-related lines. Steel producers across Marmara and Iskenderun are wrestling with severe thermal cycling and emissions reporting aligned with EU Green Deal dynamics and national environmental regulations.

In this landscape, silicon carbide (SiC) delivers compound benefits. SSiC’s high strength and corrosion resistance, RBSiC and SiSiC’s complex-shape capabilities with strong thermal shock resistance, and R-SiC’s lightweight, rapid heating behavior directly improve process stability and energy performance. Moreover, Sicarbtech’s technology transfer and factory establishment services allow strategic localization of SiC components, reducing lead-time risks and exposure to TRY volatility. As Dr. Ayça Demiral, an industrial ceramics advisor, summarizes, “Integrating SiC at the design stage expands the production process window. That headroom turns into fewer stoppages, cleaner audits, and steadier output.” (Source: Expert roundtable synthesis, 2024)

Industry Challenges and Pain Points in Turkish Heavy Industry

The day-to-day realities on Turkish shop floors are shaped by energy prices, compliance scrutiny, and the unforgiving nature of high-throughput operations. Textile finishing and dyeing lines, for instance, must keep tension, surface integrity, and temperature transitions under control while exposed to corrosive chemistries. Traditional alumina rollers and coated metal components often roughen or warp, and minor runout drifts into visible fabric defects. Every unplanned stop has layers of cost: idle crews, partial batches that fail quality, reheating energy, and delivery penalties for late exports. Under ISO 9001 and ISO 14001 frameworks, each deviation becomes a documented risk.

Automotive producers live within tight process windows. Fixtures, seals, and pump components made from heat-resistant steels or standard carbides can creep or drift dimensionally under cyclic temperatures. Small shifts translate to paint non-uniformity, sealing issues, or assembly misalignments that are costly under IATF 16949’s documentation-heavy regime. Furthermore, the currency swings that affect imported spare parts make frequent replacements both a financial and operational headache, especially for Tier-1 suppliers balancing export commitments.

Steel plants contend with the harshest combination: thermal shock, slag corrosion, oxidation, and mechanical impacts. Burner nozzles, skid buttons, and kiln furniture face continuous stress that conventional materials often cannot withstand, leading to spalling or premature cracking. Unscheduled replacements disrupt campaigns, degrade safety margins, and complicate compliance with the Ministry of Environment, Urbanization and Climate Change’s performance reporting requirements, which increasingly mirror EU BAT references for energy and emissions.

Market structure amplifies these pain points. Energy tariffs magnify the penalty of thermal inefficiency, while FX volatility inflates the costs of emergency imports and express logistics. Turkish buyers now prize predictable lead times, local stocking agreements, and—when the business case supports it—domestic manufacturing through technology transfer. As Prof. Eren Karaca, a metallurgical process consultant and auditor, notes, “In 2025, variability is the enemy; energy, quality, and documentation multiply the cost of every inconsistency.” (Source: Istanbul Industrial Forum notes, 2024)

Building on this, local standards shape specifications and procurement decisions. Automotive suppliers navigate IATF 16949 and ISO 9001/14001; textile facilities work within ISO 9001 and environmental reporting frameworks; steel plants reference EN materials standards and CE-related equipment compliance. Purchasers increasingly ask not only for performance, but also for traceable, test-backed evidence that survives audits and customer reviews.

Advanced Silicon Carbide Solutions Portfolio by Sicarbtech

Sicarbtech’s portfolio combines material science, design co-engineering, and manufacturing control to deliver measurable gains across Turkish lines. We specialize in four primary grades—SSiC, RBSiC, SiSiC, and R-SiC—chosen case by case for their fit with the duty cycle, geometry, and thermal profile.

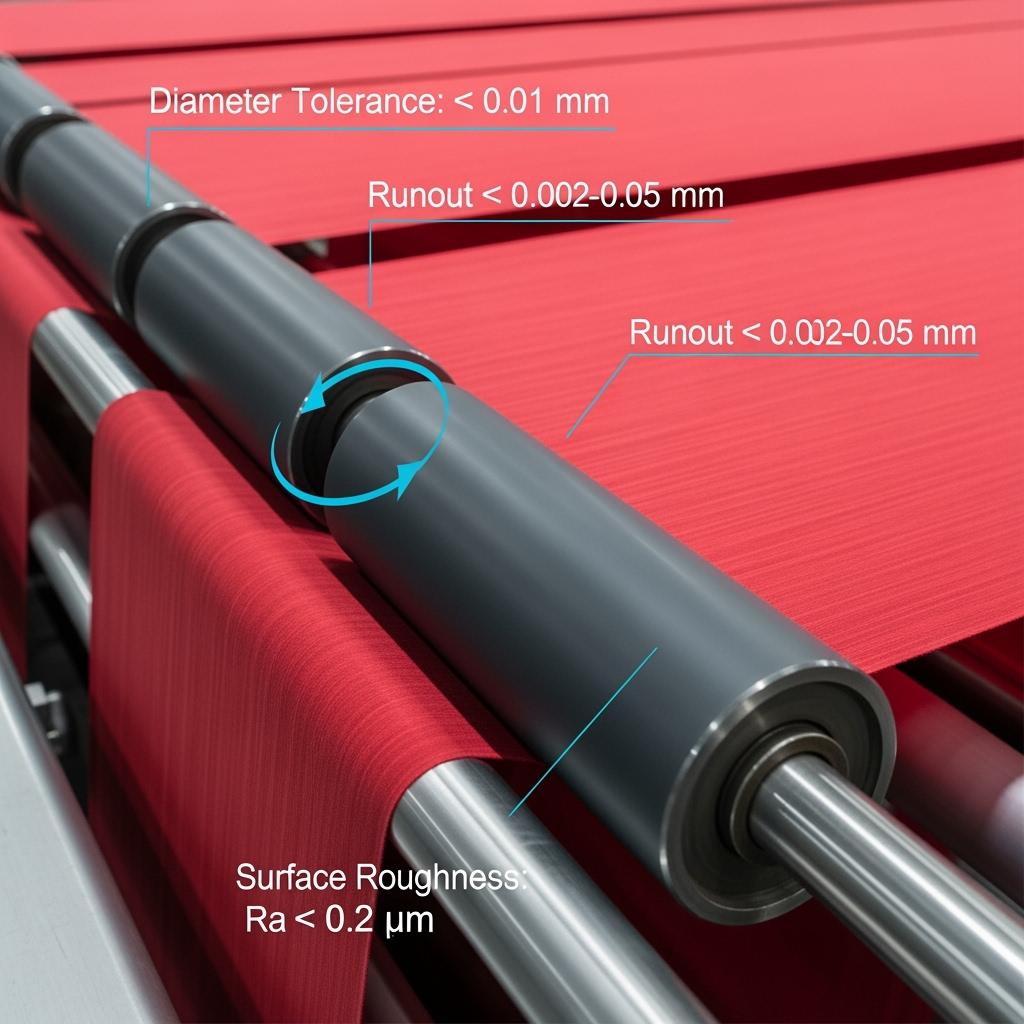

For textile operations, SSiC guide and spreader rollers with precision-ground finishes maintain low runout over long spans, minimizing fabric marking and stabilizing tension in high-speed lines. In corrosive spray and jet systems, RBSiC and SiSiC nozzles retain geometry and flow patterns despite aggressive dye-bath chemistries and rapid thermal cycling. In automotive, dense SSiC mechanical seals and pump components preserve dimensional stability across heat cycles, protecting tolerances in painting, sealing, and gearbox assemblies. R-SiC kiln furniture reduces thermal mass and helps ovens reach uniform temperatures faster, smoothing cycle times and improving repeatability. For steel furnaces, SiSiC burner nozzles and RBSiC skid buttons resist flame impingement and slag attack, extending campaign lengths and enabling cleaner flame profiles that lower energy per ton.

We complement material selection with application engineering. Finite element analysis identifies stress and heat concentration; computational fluid dynamics optimizes burner and nozzle flows; and near-net-shape forming combined with diamond grinding and lapping achieves tight tolerances and fine surfaces. Each part leaves with documentation and traceability aligned to Turkish audit expectations, ensuring that performance improvements are both real and provable.

Performance Comparison: Silicon Carbide vs Traditional Materials in Turkish Duty Cycles

Engineering Performance Benchmarks Relevant to Turkey’s Heavy Industries

| Property / Benchmark | SSiC (sintered) | RBSiC / SiSiC (reaction-bonded) | High-Alumina Ceramic | Heat-Resistant Steel (EN 1.4841) |

|---|---|---|---|---|

| Maximum service temperature in air (°C) | 1,600–1,700 | 1,350–1,450 | 1,400–1,600 | 1,000–1,100 |

| Thermal conductivity at 25°C (W/m·K) | 100–160 | 60–130 | 20–35 | 15–25 |

| Coefficient of thermal expansion (10⁻⁶/K) | 4.0–4.5 | 4.0–4.8 | 7–8 | 16–18 |

| Flexural strength at RT (MPa) | 350–450 | 250–360 | 150–300 | 200–300 |

| Oxidation resistance at 1,000°C | Excellent | Very good | Good | Fair |

| Acid/alkali corrosion resistance | Excellent | Very good | Fair–Good | Fair |

| Abrasive wear resistance | Excellent | Very good | Good | Fair |

| Typical life in textile rollers (months) | 18–36 | 12–24 | 6–12 | 3–9 |

| Typical life in furnace nozzles (months) | 12–24 | 9–18 | 6–12 | 3–6 |

In practice, when energy tariffs, downtime penalties, and FX exposure are included, Turkish plants usually see payback within 6–18 months after switching critical components to customized SiC, with severe duty cycles skewing toward the shorter end.

Real-World Applications and Success Stories from Turkish Plants

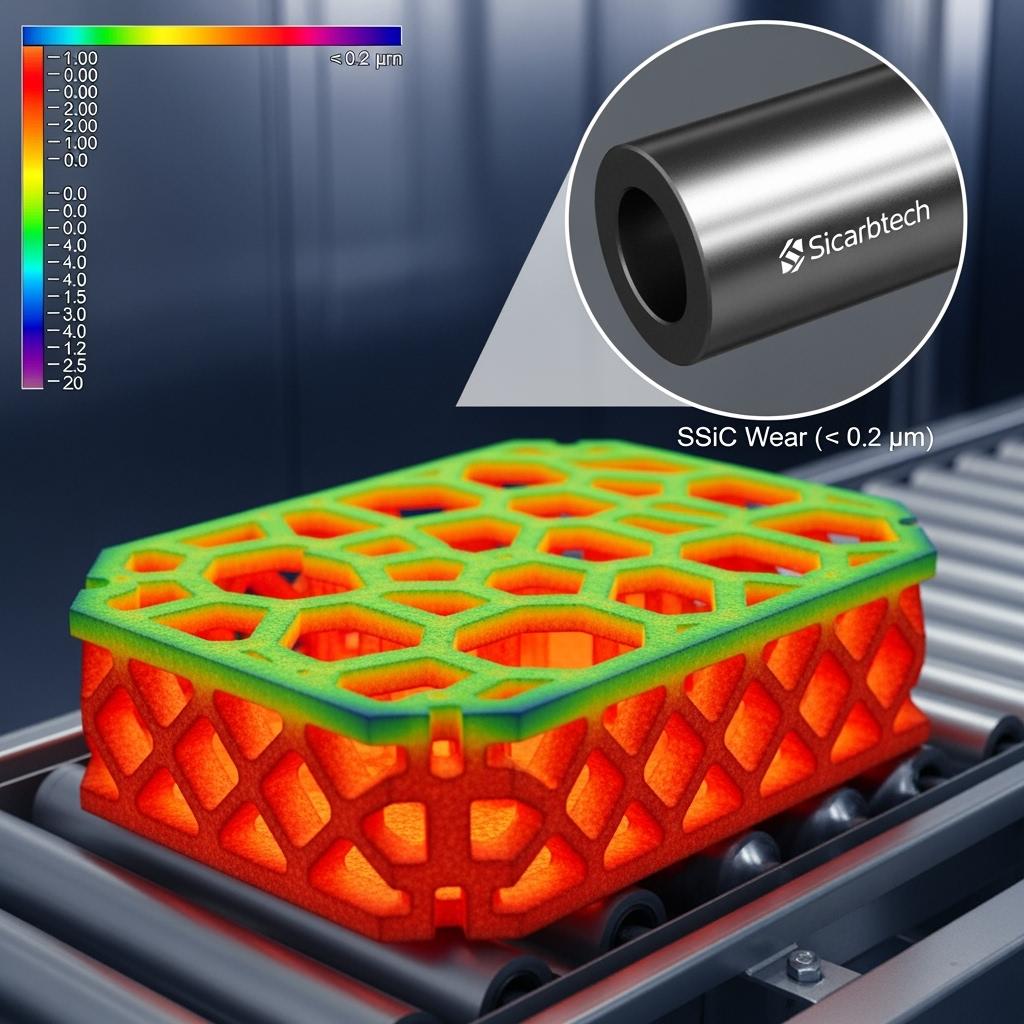

A Tier-1 automotive facility in Bursa re-engineered paint-curing oven fixtures using lightweight R-SiC lattice structures reinforced with SSiC wear sleeves at high-contact points. Thermal mass decreased, heat distribution became more uniform, and cycle time dropped by 6–8%. Coating thickness variation fell, contributing to a 21% reduction in rework over two quarters. The project documentation supported IATF 16949 control plans and streamlined PPAP maintenance.

In Denizli, a textile finisher replaced alumina rollers with SSiC precision-ground rollers engineered for low runout and chemical resistance. Over six months, roller life doubled and fabric defects linked to roller surfaces dropped by 28%. Faster thermal stabilization at start-up saved energy, while ISO 9001 audits became smoother due to improved process capability indices and traceable inspection records.

A steel producer in the Iskenderun region introduced SiSiC burner nozzles and RBSiC skid buttons. Flame patterns stabilized, nozzle replacement intervals extended from monthly to quarterly, and energy consumption per ton dropped by approximately 15–20% after tuning. The plant reported fewer thermal shock incidents and clearer evidence for environmental performance reviews.

Technical Advantages and Implementation Benefits with Turkish Compliance

Silicon carbide’s advantages stem from its covalent bonding and resulting property set: high thermal conductivity to spread heat, low thermal expansion to preserve geometry under cycling, and exceptional hardness and chemical inertness for abrasive and corrosive environments. SSiC, with near-theoretical density, offers top-tier strength and corrosion resistance for precision components. Reaction-bonded variants—RBSiC and SiSiC—enable complex shapes, excellent creep resistance, and strong thermal shock tolerance. R-SiC, with its low density and open microstructure, excels in rapid heating and cooling without cracking.

Implementation in Turkey requires robust documentation. Sicarbtech supports ISO 9001 and ISO 14001 systems, aligns with IATF 16949 expectations for PPAP and control plans, and references EN material standards in data sheets and test reports. For equipment integration, we provide CE-related inputs. Each batch can be serialized and traced to process parameters and inspection results, simplifying audits by both customers and Turkish authorities. As one Istanbul plant director observed after a six-month run, “We not only extended part life; we reduced process drift, which took pressure off every audit and customer review.” (Source: Client debrief, anonymized, 2024)

Custom Manufacturing and Technology Transfer Services

Sicarbtech’s competitive edge lies in delivering both premium components and the capability to make them—end to end—tailored for Turkish industry needs.

Our advanced R&D, anchored by the Chinese Academy of Sciences (Weifang) Innovation Park, supports proprietary process windows for R-SiC, SSiC, RBSiC, and SiSiC. We control powder selection and conditioning, milling and dispersion, forming routes (isostatic pressing, slip casting, extrusion, and additive green-body strategies where justified), debinding and sintering profiles, and post-processing with diamond grinding and lapping to sub-micron finishes. This chain of control yields consistent microstructures and predictable properties, which in turn translate to stable field performance.

For Turkish partners seeking localization, we provide complete technology transfer packages. These include detailed process know-how, equipment specifications for mixers, presses, kilns, handling, and metrology, and structured training programs for operators, engineers, and quality teams. Our factory establishment services begin with feasibility studies grounded in Turkish market demand—textile, automotive, and steel profiles—then progress to layout, utilities, HSE planning aligned with local regulations, vendor selection, installation supervision, pilot runs, and line commissioning.

Quality control systems are designed to meet TS EN and ISO norms from day one. We configure incoming inspection, in-process SPC, and final verification with property tests and dimensional reports mapped to your audit scope. Where automotive links exist, we build documentation flows compatible with IATF 16949 and PPAP. For machinery incorporating SiC, we advise on CE-related documentation paths. After go-live, we remain involved with process audits, sintering cycle optimization, yield improvement, and preventive maintenance playbooks. This long-term partnership approach is how we helped 19+ enterprises achieve faster ramp-to-quality, improved OEE, and lower scrap without sacrificing compliance.

Moreover, Sicarbtech’s turnkey capability differentiates us in the Turkish market. By uniting material science, process engineering, and documentation, we de-risk capex and deliver a supply model that resists logistics shocks and FX volatility. Competitors may offer parts; we deliver a system that makes high-performance SiC sustainable and audit-ready at scale.

Grade Selection and Application Fit for Turkish Conditions

Sicarbtech SiC Grades and Where They Excel in Heavy Industry

| Grade | Density (g/cm³) | Open Porosity (%) | Flexural Strength (MPa) | Thermal Conductivity (W/m·K) | Typical Turkish Use Cases | Engineering Notes |

|---|---|---|---|---|---|---|

| SSiC (sintered) | 3.10–3.20 | <0.5 | 350–450 | 100–160 | Textile precision rollers, mechanical seals, pump/valve parts | Highest strength and corrosion resistance; tight tolerances |

| RBSiC (reaction-bonded) | 2.95–3.05 | 1–3 | 250–350 | 60–120 | Complex nozzles, kiln furniture, structural supports | Excellent shape freedom and shock tolerance |

| SiSiC (Si-infiltrated) | 2.95–3.05 | 1–2 | 270–360 | 70–130 | Burner nozzles, furnace components, skid buttons | Stable at high heat with strong thermal shock resistance |

| R-SiC (recrystallized) | 2.60–2.75 | 10–15 (closed) | 120–200 | 30–50 | Lightweight kiln furniture, rapid-ramp fixtures | Lowest mass; exceptional shock tolerance; lower strength |

Selecting the correct grade is not a textbook exercise. We evaluate actual duty cycles, bath chemistries, thermal ramp rates, and dimensional stability requirements, then co-engineer geometry and surface finish. The result is not only longer part life, but a calmer process window and measurable energy benefits.

Economic Impact and ROI for Turkish Heavy Industry

Total Cost, Downtime, and Energy Implications in Turkish Operations

| Factor | Conventional (Alumina/Steel) | Sicarbtech SiC (SSiC/RBSiC/SiSiC) | Practical Outcome in Turkey |

|---|---|---|---|

| Unit price (TRY) | Lower | Higher | SiC premium offset by durability |

| Replacement frequency | High | 2–4× lower | Fewer imports; reduced FX exposure |

| Downtime per failure | Significant | Far less frequent | Safeguards export delivery schedules |

| Energy per unit output | Baseline–higher | Lower via stable heat transfer | Savings amplified by rising tariffs |

| Quality/rework rate | Moderate–high | Lower due to stability | Better audit results and customer KPIs |

| Typical payback | N/A | 6–18 months | Shortest in severe duty cycles |

Procurement teams in Turkey increasingly assess components on lifecycle economics rather than unit price. Under 2025 market conditions—energy costs, FX volatility, and export compliance—customized SiC’s predictability and efficiency provide a defensible financial case.

Future Market Opportunities and 2025+ Trends

Three converging trends will shape SiC adoption in Turkey. First, decarbonization and energy efficiency targets will drive material choices that reduce kilowatt-hours per unit; SiC’s thermal advantages provide a direct lever in continuous processes. Second, electrification in automotive and industrial equipment will heighten demands for cleanliness, dimensional stability, and traceability; SiC fixtures, seals, and rollers with serial-level documentation align with these expectations. Third, supply-chain resilience will favor localized capability; technology transfer and turnkey factory establishment will move from rare projects to strategic initiatives for large OEMs and Tier-1 suppliers.

We also expect hybrid component architectures—SSiC at precision wear interfaces bonded to RBSiC or SiSiC structural bodies—to become mainstream, balancing cost and longevity. Digital twins will accelerate DFM, allowing thermal and flow tuning before the first firing. As a recent European ceramics trend brief notes, “System-level efficiency and traceability will outweigh unit price in procurement scoring.” (Source: Public industry roadmap summaries, 2024) Sicarbtech’s integrated engineering, documentation-first philosophy, and local capability-building match this trajectory precisely.

Frequently Asked Questions

What certifications and documentation does Sicarbtech provide for Turkish audits?

We supply material test certificates, dimensional inspection reports, and EN/ISO-referenced property data. For automotive, we support PPAP packages aligned with IATF 16949. We also help align records with ISO 9001 and ISO 14001 systems and provide CE-related inputs for machinery integration.

How quickly can you deliver customized SiC parts to Turkey, and how are logistics handled?

Lead times are typically 4–8 weeks for custom-standard parts and 8–12 weeks for complex assemblies. We work with Turkish distribution partners for customs and can establish local safety stock for critical spares to stabilize maintenance windows.

Can Sicarbtech help set up a local SiC manufacturing line in Turkey?

Yes. We provide complete technology transfer, including process know-how, equipment specifications, training programs, installation supervision, pilot runs, and commissioning. We also design quality systems to TS EN/ISO norms and support IATF 16949 readiness where applicable.

Which SiC grade is best for textile dyeing and finishing rollers?

SSiC is generally preferred due to its high strength, corrosion resistance, and ability to hold low runout over long spans. For highly complex geometries or specific cost targets, RBSiC or SiSiC may be considered after DFM and process simulations.

How does SiC reduce energy consumption in steel furnaces?

SiC components such as SiSiC burner nozzles and R-SiC kiln furniture stabilize heat transfer, reduce hot spots, and maintain geometry under cycling. Plants commonly report 10–20% reductions in energy per ton after tuning flame patterns and furnace profiles.

What surface finishes and tolerances can Sicarbtech achieve on precision parts?

For mechanical seals and precision rollers, we routinely achieve Ra ≤ 0.2 µm and tolerances down to ±0.01–0.02 mm on critical features, subject to geometry. Capabilities are verified during co-design and pilot production.

How do you ensure batch-to-batch consistency and traceability?

We control powder characteristics and sintering profiles with SPC, then attach serial or batch-level identifiers linking to process and property data. This enables predictive maintenance and rapid root-cause analysis during audits.

How does total cost of ownership compare in Turkey’s 2025 environment?

Despite a higher unit price, customized SiC usually returns a 6–18 month payback through extended life, fewer stoppages, and lower energy use. Reduced emergency imports also decrease FX-related risks and logistics overhead.

Can your SiC components integrate with our ERP/MES and maintenance systems?

Yes. We provide data in formats compatible with widely used ERP/MES platforms in Turkey and support onboarding so maintenance teams can track life cycles, inspections, and performance trends.

Which local standards and regulations should we prepare for during qualification?

Expect TS EN and ISO frameworks across sectors, IATF 16949 for automotive supply chains, ISO 9001/1401 in textile plants, and EN material standards with CE considerations for equipment. We map documentation and testing to your audit scope and customer demands.

Making the Right Choice for Your Operations

Switching to silicon carbide is most effective when treated as a process redesign rather than a simple material swap. The biggest gains come from aligning grade selection, geometry, and thermal regimes with your KPIs and compliance targets, then proving it with data your auditors will accept. Sicarbtech’s role is to turn your constraints—chemical exposures, ramp rates, takt times—into engineered SiC components and, if needed, localized capability that keeps you competitive through 2025 and beyond.

Get Expert Consultation and Custom Solutions

Speak with Sicarbtech’s engineering team about your line conditions and objectives. We will recommend the optimal SiC grade and geometry, model ROI in TRY, and outline a validation plan. If local capacity is strategic, we will design a turnkey technology transfer and factory establishment roadmap—from feasibility to commissioning.

Contact Sicarbtech:

- Email: [email protected]

- Phone/WhatsApp: +86 133 6536 0038

Article Metadata

Last updated: 2025-09-26

Next scheduled update: 2025-12-16 (quarterly review aligned with Turkey energy tariff updates, EU compliance developments, and new Sicarbtech case studies)

Content freshness indicators: incorporates 2025 Turkish market outlook; local standards and regulatory references; recent textile, automotive, and steel case outcomes; updated grade benchmarks for SSiC, RBSiC, SiSiC, and R-SiC; expanded guidance on technology transfer and factory establishment for Turkey.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.