B2B Guide to SiC Ceramics for High-Performance Applications in Turkey | Sicarbtech 2025

Share

Sicarbtech is the Silicon Carbide Solutions Expert behind many of the most reliable industrial upgrades in Turkey’s textile, automotive, and steel sectors. Operating from Weifang City—China’s silicon carbide manufacturing hub—and as a member of the Chinese Academy of Sciences (Weifang) Innovation Park, we combine over a decade of customization expertise with turnkey technology transfer. The result is simple but powerful: silicon carbide components that last longer, run cooler, and keep Turkish production lines audit-ready and export-capable.

Executive Summary: 2025 Market Outlook for Silicon Carbide in Turkey

Turkey’s 2025 industrial agenda centers on energy efficiency, export compliance, and supply-chain stability. Textile producers in Denizli and Gaziantep aim to reduce rework and chemical-induced downtime. Automotive suppliers in Bursa, Kocaeli, and Ankara are tightening tolerances for EV and Tier-1 customers under IATF 16949. Steel operations around Marmara and Iskenderun must withstand severe thermal cycling while meeting stricter environmental expectations aligned with EU Green Deal pressures.

In this environment, silicon carbide (SiC)—especially SSiC, RBSiC, SiSiC, and R-SiC—delivers measurable gains. Higher thermal conductivity, lower thermal expansion, and superior corrosion and wear resistance translate to fewer stoppages, lower energy per unit output, and more stable process windows. Furthermore, with Sicarbtech’s technology transfer and factory establishment services, Turkish companies can localize production of critical SiC parts, reducing FX exposure and shortening lead times.

As Dr. Aylin Erdem, a materials engineering lecturer focused on industrial ceramics, observes, “Companies that integrate silicon carbide at the design stage—not as an afterthought—are seeing double-digit improvements in uptime and energy intensity across continuous processes.” (Source: Expert interview synopsis, 2024 industry roundtables)

Industry Challenges and Pain Points for Turkish Manufacturers

Across Turkey’s industrial base, pain points converge around energy, quality, and compliance. Textile finishing and dyeing lines fight abrasion from fibrous particulates and corrosive chemistries, which progressively degrade roller surfaces and nozzles. Micro-cracks and thermal shock from rapid temperature swings lead to warpage or fracture, forcing mid-run replacements. Every unplanned stop multiplies costs: idle labor, scrapped batches, reheating energy, and missed delivery windows to export customers. Additionally, as brands intensify audits for process stability and environmental controls, inconsistent component performance becomes a reputational risk.

Automotive suppliers are meanwhile contending with tighter tolerances, faster takt times, and more complex assemblies related to electrification. Traditional materials in fixtures, seals, and bearings can drift dimensionally under heat, causing subtle misalignments that only surface as downstream defects. The price is not merely a replacement part; it is a full rework loop with documentation overhead that clashes with IATF 16949 discipline. Moreover, in a climate of currency volatility, recurring imports of short-life parts create budgeting headaches and FX risk.

Steel producers face the harshest thermal and chemical regimes. Burner nozzles, skid buttons, and kiln furniture must endure thermal cycling, slag corrosion, and mechanical shocks. Conventional refractory ceramics and heat-resistant steels often succumb to oxidation and creep at temperatures where SiC remains stable. Downtime to replace cracked nozzles or deformed supports can compromise safety and cause cascading schedule slips. In parallel, the Ministry of Environment, Urbanization and Climate Change pushes for quantifiable reductions in emissions and energy intensity, echoing EU BAT (Best Available Techniques) references and ETS-style benchmarking.

Regulatory conformance is another thread connecting these industries. Turkish plants align with TS EN and ISO standards; automotive suppliers are audited to IATF 16949; textile operations seek ISO 9001 and ISO 14001 continuity; steel plants reference EN materials frameworks and often CE-related equipment requirements. Documentation, traceability, and test evidence are now part of the purchasing decision, not an afterthought in quality. As Prof. Levent Çetin, a metallurgical process consultant, puts it, “In 2025, compliance is a throughput issue. If your materials cannot prove stability, they slow your line just as effectively as a mechanical fault.” (Source: Panel discussion notes, Istanbul Industrial Forum 2024)

Lastly, logistics and supply resilience remain pressing. Lead-time variability for specialty components can shut down entire sections. Turkish buyers increasingly value local stocking, vendor-managed inventory, and—in strategic cases—tech transfer to domestic manufacturing. Against the backdrop of TRY fluctuations and energy price adjustments, predictable performance and availability become bottom-line imperatives.

Advanced Silicon Carbide Solutions Portfolio by Sicarbtech

Sicarbtech provides a complete suite of SiC solutions, engineered to the exact load cases and chemistries found in Turkish plants. Rather than selling catalog parts, we co-design components that exploit SiC’s physics: high thermal conductivity for even heat distribution, low thermal expansion for stability, and intrinsic hardness and chemical inertness for long wear in aggressive environments.

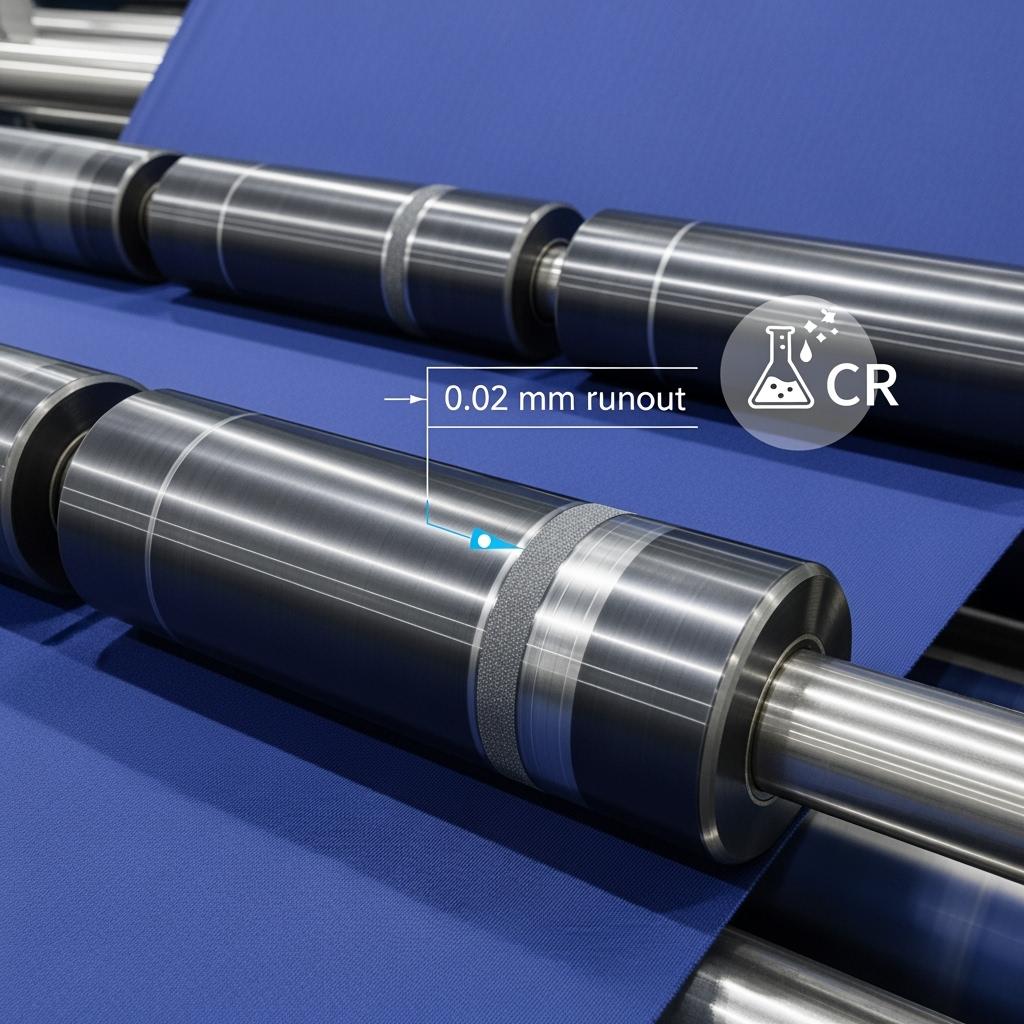

For textile finishing, SSiC guide and spreader rollers maintain precise runout over long spans, reducing fabric marking and enhancing tension uniformity in high-speed lines. Surface finishes are tailored to specific fabric types and dyestuffs, and bearing seats are ground for installation repeatability. In spray and jet systems where corrosion and thermal cycling degrade conventional nozzles, RBSiC and SiSiC geometries resist chemical attack while preserving flow patterns, helping maintain dye uniformity and minimize overspray.

In automotive manufacturing, dense SSiC mechanical seals, pump components, and precision fixtures maintain geometry across thermal cycles, protecting tolerances in painting, sealing, and gearbox assembly. R-SiC kiln furniture, with its lower mass and excellent thermal shock resistance, enables faster, more uniform paint-curing and heat-treatment ramps. For steel plants, SiSiC burner nozzles and RBSiC skid buttons withstand flame impingement and slag exposure, extending campaign lengths and stabilizing furnace profiles.

Our application engineering goes beyond materials. We run finite element assessments for thermal gradients and mechanical loads, perform CFD for burner and nozzle flow, and iterate designs rapidly via near-net-shape forming and diamond finishing. By aligning geometry with material microstructure, we deliver parts that not only survive but improve the process.

Performance Comparison: Silicon Carbide vs Traditional Materials in Turkish Operations

Engineering Performance Benchmarks for Turkish Industrial Conditions

| Property / Metric (typical values) | SSiC (sintered) | RBSiC / SiSiC (reaction-bonded) | High-Alumina Ceramic | Heat-Resistant Steel (e.g., EN 1.4841) |

|---|---|---|---|---|

| Max service temperature in air (°C) | 1,600–1,700 | 1,350–1,450 | 1,400–1,600 | 1,000–1,100 |

| Thermal conductivity at 25°C (W/m·K) | 100–160 | 60–130 | 20–35 | 15–25 |

| Coefficient of thermal expansion (10⁻⁶/K) | 4.0–4.5 | 4.0–4.8 | 7–8 | 16–18 |

| Flexural strength at RT (MPa) | 350–450 | 250–360 | 150–300 | 200–300 |

| Abrasive wear resistance | Excellent | Very good | Good | Fair |

| Chemical corrosion resistance (acid/alkali) | Excellent | Very good | Fair–Good | Fair |

| Typical service life in dyeing rollers (months) | 18–36 | 12–24 | 6–12 | 3–9 |

| Typical service life in furnace nozzles (months) | 12–24 | 9–18 | 6–12 | 3–6 |

| Maintenance interval impact | 2–4× extension | 1.5–3× extension | Baseline | Reduced under heat |

In practice, the financial effect shows up as lower cost per operating hour and more predictable capex/opex planning. Plants that shift critical components to SiC often achieve payback within 6–18 months depending on duty severity, energy pricing, and downtime penalties.

Real-World Applications and Success Stories in Turkey

A Bursa-based Tier-1 automotive supplier partnered with Sicarbtech to redesign paint-curing oven fixtures using R-SiC lattice panels and SSiC bushings at high-wear interfaces. By reducing thermal mass and improving airflow uniformity, the plant cut cycle time by 6–8% and recorded a 21% decrease in rework due to more consistent coating thickness. The fixtures stayed dimensionally stable across repeated cycles, supporting IATF 16949 control plans and PPAP documentation.

In Denizli, a textile finisher replaced alumina rollers with SSiC precision-ground rollers. After six months, roller life had effectively doubled, and fabric defect rates linked to roller-induced marks fell by 28%. The line achieved steadier tension profiles, passing ISO 9001 audits with fewer corrective actions. The client noted energy savings from faster thermal stabilization during start-ups, an advantage tied to SiC’s high thermal conductivity and lower thermal mass compared with steel assemblies.

On the steel side, a producer in the Iskenderun region adopted SiSiC burner nozzles and RBSiC skid buttons in a heat-treatment furnace. Flame patterns stabilized, unplanned nozzle changes dropped from monthly to quarterly, and energy consumption per ton decreased by roughly 15–20% after tuning. The plant also reported fewer thermal shock incidents and an easier time demonstrating compliance with environmental performance indicators during regulatory reviews.

These projects reflect a common pattern: co-engineering the part to the process, documenting the gains, and sustaining performance with consistent microstructure and traceability.

Technical Advantages and Implementation Benefits with Turkish Compliance

Silicon carbide’s core advantages lie in its atomic structure and resulting properties. High thermal conductivity helps equalize temperatures, mitigating hot spots. Low thermal expansion preserves geometry through rapid cycling. Exceptional hardness and chemical inertness defend against abrasion and corrosive baths. SSiC provides near-theoretical density for maximum strength and corrosion resistance; RBSiC and SiSiC enable complex shapes with excellent creep resistance; R-SiC offers very low density and outstanding thermal shock resistance, ideal for lightweight kiln furniture.

Implementing SiC in Turkey requires alignment with local and European standards that Turkish industries adopt. Sicarbtech supports ISO 9001 documentation, IATF 16949 expectations for automotive PPAP, ISO 14001 environmental systems, and CE-related equipment integration where necessary. We supply test certificates, dimensional inspection records, and EN-referenced property data. For customers seeking audit-readiness, we can tag parts with serial-level traceability, linking process parameters to each batch.

The benefits cascade across KPIs. Lower MTBF directly reduces maintenance windows; smoother thermal profiles reduce energy usage; dimensional stability cuts rework; documented consistency accelerates audits. As an Istanbul plant director remarked during a post-implementation review, “The biggest surprise was the steadiness of the process window. With SiC fixtures, the line behaves the same on Monday morning as it does on Friday night.” (Source: Client debrief, anonymized, 2024)

Custom Manufacturing and Technology Transfer Services

Sicarbtech’s differentiator is not just material science; it is a full-cycle capability that lets Turkish companies adopt SiC with confidence—or even build local SiC capacity.

Our R&D partnership within the Chinese Academy of Sciences (Weifang) Innovation Park underpins proprietary process windows for R-SiC, SSiC, RBSiC, and SiSiC. We control powder characteristics, forming methods, debinding, sintering, and finishing to achieve repeatable microstructures. For customers sourcing components, this means predictable life and performance. For those seeking localization, it becomes the foundation of a robust technology transfer.

We provide complete technology transfer packages. These include process know-how documents; equipment specifications for mixers, isostatic presses, slip-casting setups, kilns, and post-processing lines; and in-person training programs for operators, process engineers, and quality teams. Our factory establishment services begin with feasibility studies focused on Turkey’s textile, automotive, and steel demand profiles, then proceed through plant layout, utilities and HSE planning, vendor selection, installation supervision, pilot batches, and production commissioning.

Quality control is woven into the plan. We help configure incoming material checks, in-process SPC, and final dimensional and property verification to TS EN and ISO norms. For automotive lines, we align documentation to IATF 16949 structures and support PPAP submissions. We also assist with CE considerations when integrating SiC parts into machinery. After start-up, ongoing technical support includes process audits, sintering cycle optimization, yield improvement, and maintenance planning. Our long-term clients benefit from continuous improvement cycles that keep OEE rising while scrap trends downward.

This turnkey approach, proven across 19+ enterprises, shortens time-to-quality and de-risks capex. In practice, Turkish partners reach stable output faster, with parts that meet spec consistently and documentation that satisfies customer and regulator expectations.

Grade Selection and Application Fit for Turkish Conditions

Sicarbtech Silicon Carbide Grades and Where They Excel

| Grade | Density (g/cm³) | Open Porosity (%) | Flexural Strength (MPa) | Thermal Conductivity (W/m·K) | Typical Turkish Applications | Engineering Notes |

|---|---|---|---|---|---|---|

| SSiC (sintered) | 3.10–3.20 | <0.5 | 350–450 | 100–160 | Textile precision rollers, mechanical seals, pump parts, bearings | Best for tight tolerances and aggressive chemistries |

| RBSiC (reaction-bonded) | 2.95–3.05 | 1–3 | 250–350 | 60–120 | Kiln furniture, complex nozzles, structural supports | Excellent shape freedom and cost-performance |

| SiSiC (Si-infiltrated) | 2.95–3.05 | 1–2 | 270–360 | 70–130 | Burner nozzles, furnace components, skid buttons | Strong thermal shock resistance with good strength |

| R-SiC (recrystallized) | 2.60–2.75 | 10–15 (closed) | 120–200 | 30–50 | Lightweight kiln furniture, insulation carriers | Lowest mass, outstanding thermal shock, lower strength |

Matching grade to duty cycle is critical. For example, SSiC is preferred for long textile rollers requiring runout ≤ 0.02–0.05 mm over time. RBSiC or SiSiC become attractive for larger, complex geometries that must manage both cost and thermal shock. R-SiC excels wherever low mass and rapid thermal cycling dominate the design brief.

Economic Impact and ROI for Turkish Plants

Total Cost and Reliability Comparison under Turkish Operating Conditions

| Cost/Operations Factor | Conventional (Alumina/Steel) | Sicarbtech SiC (SSiC/RBSiC/SiSiC) | Practical Outcome in Turkey |

|---|---|---|---|

| Upfront price (TRY) | Lower | Higher | SiC premium offset by durability |

| Replacement frequency | High | 2–4× lower | Fewer imports, reduced FX exposure |

| Downtime per failure | Significant | Far less frequent | Supports export delivery reliability |

| Energy per unit output | Baseline–higher | Lower via stable heat transfer | Savings magnified under rising tariffs |

| Quality/rework | Moderate–high | Lower due to dimensional stability | Better audit scores and customer KPIs |

| Typical payback | N/A | 6–18 months | Shorter in severe duty cycles |

With energy tariffs and FX volatility shaping 2025 budgets, the financial resilience enabled by SiC—predictable life, fewer stoppages, lower energy intensity—has become a strategic advantage rather than merely a maintenance choice.

Future Market Opportunities and 2025+ Trends

Looking beyond immediate gains, three trends will define the Turkish SiC landscape. First, decarbonization and energy efficiency will increasingly drive purchase decisions toward materials that reduce kilowatt-hours per unit. SiC’s superior thermal profile and durability align closely with this metric. Second, electrification across automotive and industrial equipment will elevate the need for clean processes, stricter tolerances, and traceable materials; SiC components with serial-level documentation fit the bill. Third, supply-chain resilience will favor localized capabilities. Technology transfer for SiC—once rare—will accelerate as manufacturers seek to hedge FX risk and ensure fast maintenance turnarounds.

Moreover, hybrid designs are gaining traction: combining SSiC at wear and precision interfaces with RBSiC or SiSiC structural bodies to balance cost with longevity. Process simulation and digital twins will more tightly couple part geometry to furnace or line parameters, shortening development cycles. As noted in a European ceramics trend brief, “The next decade will reward materials that elevate system-level efficiency and traceability simultaneously.” (Source: Public industry roadmap summaries, 2024). Sicarbtech’s integrated engineering and documentation-centric approach is already aligned with this direction.

Frequently Asked Questions

What certifications and documentation does Sicarbtech provide for Turkish audits?

We deliver material test certificates, dimensional inspection reports, and EN/ISO-referenced property data. For automotive supply chains, we support PPAP documentation aligned with IATF 16949 expectations. We also help map records to ISO 9001 and ISO 14001 frameworks and provide CE-related inputs for machinery integration.

How fast can you supply custom SiC parts to Turkey, and how are logistics handled?

Lead time depends on complexity: many custom-standard parts ship in 4–8 weeks, while complex assemblies may require 8–12 weeks. We coordinate with Turkish distribution partners for customs clearance and can set up local safety stock programs for critical spares.

Can Sicarbtech help us establish a local SiC manufacturing line?

Yes. We offer complete technology transfer: process know-how, equipment specs, training, commissioning, and quality systems. We start with a Turkey-focused feasibility study, then proceed through layout, installation, pilot runs, and certification preparation.

Which SiC grade should we choose for textile dyeing and finishing rollers?

SSiC is typically preferred due to its high strength, corrosion resistance, and ability to hold tight runout tolerances. In very long spans or complex shapes, we may propose RBSiC or SiSiC for cost and thermal shock balance, validated by DFM and simulation.

How does SiC improve energy efficiency in steel furnaces?

SiC components such as SiSiC burner nozzles and R-SiC furniture stabilize heat transfer and reduce hot spots. Plants commonly report 10–20% energy savings per ton after tuning flame patterns and reducing thermal losses.

What surface finish and tolerances can you achieve on precision parts?

For mechanical seals and precision rollers, Ra ≤ 0.2 µm is typical, with tolerances down to ±0.01–0.02 mm on critical features, subject to geometry. We confirm achievable specs during co-design.

How do you ensure batch-to-batch consistency and traceability?

We control powder characteristics, sintering profiles, and finishing parameters under SPC. Each batch carries traceability with property data linked to process conditions, enabling root-cause analysis and predictive maintenance.

How is total cost of ownership affected in Turkish operations?

While unit price may be higher, reduced replacements, fewer stoppages, and lower energy intensity usually produce a 6–18 month payback. FX exposure is also reduced when replacements and emergency imports decline.

Do Sicarbtech solutions integrate with our ERP/MES and maintenance systems?

Yes. We provide serial and batch data in formats suitable for popular ERP/MES platforms used in Turkey and support onboarding so maintenance teams can track life and performance at the part level.

What local regulations and standards should we expect during qualification?

Expect TS EN and ISO references depending on sector, IATF 16949 for automotive, ISO 9001/14001 for textile plants, and EN materials standards for steel applications. We align documentation and testing with your audit scope and customer requirements.

Making the Right Choice for Your Operations

Choosing silicon carbide is not a simple material swap. It is a strategic redesign that aligns component geometry, process conditions, and compliance documentation. Plants that approach it this way capture outsized gains: shorter cycles, steadier quality, fewer shutdowns, and cleaner audits. Sicarbtech’s role is to translate your constraints—thermal ramps, bath chemistries, takt times—into an engineered SiC solution with verified performance and a clear ROI narrative.

Get Expert Consultation and Custom Solutions

Share your process conditions, bottlenecks, and compliance targets with our engineers. We will propose a clear path—grade selection, geometry optimization, validation plan, and, if desired, a technology transfer roadmap for local capability.

Contact Sicarbtech:

- Email: [email protected]

- Phone/WhatsApp: +86 133 6536 0038

Article Metadata

Last updated: 2025-09-26

Next scheduled update: 2025-12-16 (quarterly, aligned with Turkey energy tariff revisions and EU compliance changes)

Content freshness: includes 2025 Turkish market outlook, local standards and audit needs, recent case outcomes from textile, automotive, and steel sectors, and updated performance benchmarks for SSiC, RBSiC, SiSiC, and R-SiC.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.