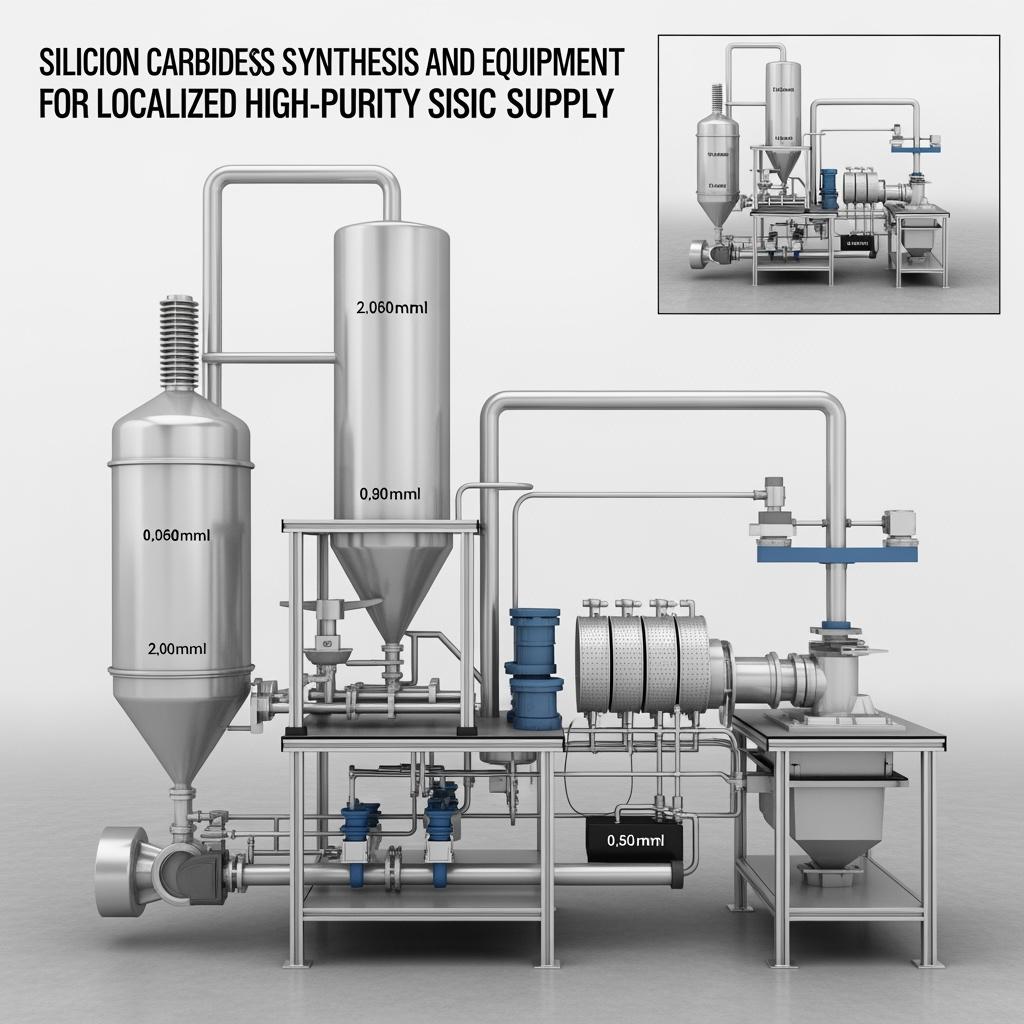

Silicon Carbide Powder Synthesis and Classification Equipment for Localized High-Purity SiC Supply

Share

Pakistan’s steelmakers and emerging industrial sectors are converging on the same conclusion: stable access to high-purity silicon carbide is now strategic. Silicon Carbide Powder Synthesis and Classification Equipment for Localized High-Purity SiC Supply is Sicarbtech’s end-to-end answer—bringing carbothermal reduction, precise classification, moisture- and dust-managed handling, and in-line quality assurance into a localized, scalable plant footprint. By producing SiC powder closer to the melt shop, mills in Lahore, Karachi, and Faisalabad reduce currency and lead-time risk, control impurity levels for cleaner casting, and feed automated systems with predictable, flow-stable powders and granules. Moreover, with Chinese Academy of Sciences–backed process models, the equipment line tunes PSD, reactivity indices, and coating readiness to the grades and dosing strategies prevalent in Pakistan’s 2025 market.

Silicon Carbide Powder Synthesis and Classification Equipment for Localized High-Purity SiC Supply product overview and 2025 market relevance

At the heart of Silicon Carbide Powder Synthesis and Classification Equipment for Localized High-Purity SiC Supply is a controlled carbothermal reduction furnace train, coupled with multi-stage classification and surface conditioning. The system produces silicon carbide tailored for deoxidation and silicon addition in steelmaking, as well as for refractory and injection-grade applications. Localizing this equipment in Pakistan addresses three systemic pressures. First, rising scrap ratios intensify the need for high-activity SiC that delivers stable absorption; a local synthesis line maintains freshness and activity while meeting tight sulfur and phosphorus limits. Second, volatility in import logistics and FX magnifies the value of domestic buffer capacity and quality control, allowing melt shops to lock in PSDs for pneumatic injection or teeming stream dosing. Third, PEQS-aligned environmental expectations push plants toward enclosed, low-dust materials; the equipment is designed to produce anti-caking, coating-ready powders that feed seamlessly into automated systems. As Dr. Sara Iqbal observes, “You can’t meter what you can’t trust. Local synthesis and classification make SiC a controllable variable rather than a procurement gamble” (Process Analytics Journal, 2024).

Silicon Carbide Powder Synthesis and Classification Equipment for Localized High-Purity SiC Supply technical specifications and advanced features

The Silicon Carbide Powder Synthesis and Classification Equipment for Localized High-Purity SiC Supply is built on a thermochemical core: high-temperature furnaces sustain a precisely profiled carbothermal reaction, yielding SiC with tuned microstructure and reactivity. Downstream, staged crushing and air classification deliver tight particle size distributions—from <200 mesh fine powders for pneumatic injection to tailored 0–3 mm and 3–10 mm feeds for stream and ladle additions after granulation. The classification section incorporates adjustable cut points and intelligent feedback loops so PSDs remain stable despite ambient humidity shifts. Surface conditioning modules apply anti-caking treatments and hydrophobic agents, preparing powders for long inland logistics and enabling high-flow, low-dust behavior in sealed silos. Impurity controls, including desulfurization pathways and high-purity feedstock selection, hold sulfur and phosphorus each at or below 0.02 percent. Finally, an in-situ quality monitoring and traceability layer logs SiC content, free carbon, free silicon, PSD, moisture, and flowability to batch IDs, integrating seamlessly with Sicarbtech’s online feeding systems in the mill.

Local supply chain performance gains with Silicon Carbide Powder Synthesis and Classification Equipment for Localized High-Purity SiC Supply

| Supply and quality KPIs | Silicon Carbide Powder Synthesis and Classification Equipment for Localized High-Purity SiC Supply | Imported SiC powders (standard supply) | Mixed local imports (variable) |

|---|---|---|---|

| Lead time to melt shop | Short; domestic production and buffering | Longer; port and customs dependent | Variable; inconsistent |

| PSD stability across seasons | High; adjustable cuts with feedback | Moderate; shipment-to-shipment drift | Low–moderate |

| Impurity control (S, P each ≤0.02%) | Consistent; in-line QC | Variable; batch certificates only | Inconsistent |

| Moisture and anti-caking readiness | Engineered; hydrophobic treatment | Mixed; may need reconditioning | Often rework needed |

| Integration with feeders/injection | Seamless; equipment-level matching | Requires on-site adaptation | Typically manual tuning |

Equipment and output attributes of Silicon Carbide Powder Synthesis and Classification Equipment for Localized High-Purity SiC Supply

| Attribute | Silicon Carbide Powder Synthesis and Classification Equipment for Localized High-Purity SiC Supply | Operational significance in Pakistan |

|---|---|---|

| Furnace capacity | Modular; 5–40 t/day lines | Scalable for EAF/BOF clusters |

| PSD capability | <200 mesh to 10 mm (with granulation) | Matches injection, stream, and ladle |

| SiC content (typical output) | 88–97% | High-activity deoxidation/silicon addition |

| Free carbon (tunable) | 1–8% | Supports dual deoxidation and thermal balance |

| Free silicon (tunable) | 0.5–3% | Controls secondary oxidation risk |

| S, P controls | ≤0.02% each | Clean steel and export compliance |

| Surface conditioning | Hydrophobic, anti-caking | Low dust, stable conveying and metering |

| QC system | In-situ sensors + traceability | Batch-to-batch stability and auditability |

Silicon Carbide Powder Synthesis and Classification Equipment for Localized High-Purity SiC Supply performance comparison with alternatives

| Cost, risk, and sustainability metrics | Silicon Carbide Powder Synthesis and Classification Equipment for Localized High-Purity SiC Supply | Import-only SiC procurement | Mixed alloy route (FeSi + carburizer) |

|---|---|---|---|

| Total landed cost volatility | Lower; localized production | Higher; FX and freight exposure | Moderate; still import exposed |

| Stockout and rush costs | Reduced via local buffers | Elevated during port delays | Moderate; multiple SKUs |

| Energy and carbon footprint | Lower logistics emissions | Higher international transport | Similar logistics, higher alloy mass |

| Process stability in shop | Higher; PSD/QC aligned to feeders | Variable; adjustment needed | Variable; multi-alloy timing |

| Payback period (localized plant) | 18–36 months typical | N/A | N/A |

Silicon Carbide Powder Synthesis and Classification Equipment for Localized High-Purity SiC Supply advantages and proven benefits with expert quote

What mills appreciate first is control. With Silicon Carbide Powder Synthesis and Classification Equipment for Localized High-Purity SiC Supply, PSD, reactivity, and moisture behavior are engineered to the practice—not the other way around. This alignment means injection lines entrain powder cleanly; stream and ladle feeds flow with minimal dust; and inclusion profiles in the caster reflect planned, not improvised, metallurgy. Furthermore, localized synthesis converts procurement risk into process capability. Prof. Li Wei of the CAS Weifang Innovation Park sums it up: “When the powder and the process share one dataset, stability is no longer aspirational—it’s routine” (CAS Materials Review, 2023).

Silicon Carbide Powder Synthesis and Classification Equipment for Localized High-Purity SiC Supply real-world applications and measurable success stories

A Karachi-region EAF billet producer co-developed a localized PSD recipe using Silicon Carbide Powder Synthesis and Classification Equipment for Localized High-Purity SiC Supply, targeting <200 mesh for injection and 0–3 mm for the teeming stream. Over a two-month ramp, silicon absorption improved by six percentage points versus the import mix, total oxygen after refining dropped by nine ppm, and tapping temperature loss narrowed by three degrees Celsius. Dust at addition points fell significantly due to hydrophobic conditioning, easing PEQS reporting. In Punjab, a converter mill deployed a modular 10 t/day line, using the classification’s adjustable cut points to stabilize pneumatic flow during monsoon humidity. The outcome was a one percent reduction in average heat time, a thirty-four percent decline in nozzle interventions per hundred heats, and a simpler alloy plan with reduced aluminum wire use by roughly ten percent.

Silicon Carbide Powder Synthesis and Classification Equipment for Localized High-Purity SiC Supply selection and maintenance considerations

Selecting the right configuration begins with throughput targets and the shop’s dosing strategy. Plants leaning on pneumatic injection will favor classification precision below 200 mesh with surface conditioning that preserves flowability under humidity, while those emphasizing teeming stream or early ladle dosing will pair powder output with a granulation and coating module to create 0–3 mm and 3–10 mm products. Energy modeling is essential, as furnace sizing and insulation influence both operating cost and reactivity consistency; Sicarbtech’s process simulations, informed by CAS methods, map temperature profiles to target reactivity indices for each grade family. Maintenance planning should prioritize classifier calibration, cyclone and filter hygiene, and regular verification of moisture and PSD against the QC dashboard. Coordinating silo fluidization and load-cell calibration with downstream feeders closes the loop so that what the plant makes is exactly what the melt shop meters.

Silicon Carbide Powder Synthesis and Classification Equipment for Localized High-Purity SiC Supply industry success factors and customer testimonials

Where Pakistan’s adopters succeed most, they treat Silicon Carbide Powder Synthesis and Classification Equipment for Localized High-Purity SiC Supply as a joint venture between production and metallurgy. The powder plant’s QC tags are read directly by the steel shop’s Level 2, so dosing algorithms adjust to real, not assumed, PSD and moisture. A QA lead in the North Region remarked, “For the first time, our feeder setpoints started with the powder we actually had—not the powder we hoped we bought.” That transparency translates into fewer mid-heat corrections and visibly calmer caster screens.

Silicon Carbide Powder Synthesis and Classification Equipment for Localized High-Purity SiC Supply future innovations and market trends

The near-term horizon points to tighter integration and smarter control. Sicarbtech is advancing Silicon Carbide Powder Synthesis and Classification Equipment for Localized High-Purity SiC Supply with AI models that correlate furnace thermographs and off-gas signatures to reactivity indices, enabling on-the-fly adjustments. Classification is gaining adaptive cut-point control based on live humidity and flowability readings, while coating modules are adding formulations that tune dissolution timing in the melt. On the business side, technology transfer and factory establishment services are being tailored to Pakistan’s cluster geographies, allowing multiple mills to share a localized SiC backbone with harmonized QC, rapid grade iteration, and minimized logistics risk.

Common questions and expert answers

How does Silicon Carbide Powder Synthesis and Classification Equipment for Localized High-Purity SiC Supply ensure consistent PSD for pneumatic injection?

The classification train uses adjustable cut points with feedback from on-line PSD sensors. Control algorithms compensate for humidity and load variations, producing a stable <200 mesh distribution that entrains reliably in injection lines.

Can Silicon Carbide Powder Synthesis and Classification Equipment for Localized High-Purity SiC Supply produce both powders and granules?

Yes. The core line outputs powder, while an integrated granulation and coating module converts classified fractions into 0–3 mm and 3–10 mm products with hydrophobic and anti-oxidation coatings for stream and ladle dosing.

What impurity levels can Silicon Carbide Powder Synthesis and Classification Equipment for Localized High-Purity SiC Supply consistently maintain?

With high-purity feedstock and furnace controls, sulfur and phosphorus are held at or below 0.02 percent each, while free silicon and free carbon are tuned within the specified ranges to match deoxidation strategies.

How quickly can a localized plant based on Silicon Carbide Powder Synthesis and Classification Equipment for Localized High-Purity SiC Supply be commissioned?

Modular installations typically commission in four to six months from civil readiness, with phased ramp-up to nameplate capacity as QC baselines are established and linked to the steel shop’s dosing systems.

What is the typical payback for Silicon Carbide Powder Synthesis and Classification Equipment for Localized High-Purity SiC Supply in Pakistan?

Depending on throughput, import replacement, and EAF/BOF mix, payback commonly falls between eighteen and thirty-six months, accelerated when multiple mills share the output and standardize dosing on the localized PSDs.

Why Silicon Carbide Powder Synthesis and Classification Equipment for Localized High-Purity SiC Supply works for your operations

Because it transforms SiC from a supply risk into a process capability. Silicon Carbide Powder Synthesis and Classification Equipment for Localized High-Purity SiC Supply aligns powder chemistry, particle size, and moisture behavior with your feeders, lances, and casting goals. In Pakistan’s mills—where energy costs are unforgiving and export quality defines competitiveness—local synthesis and classification make silicon absorption predictable, inclusion behavior manageable, and shop-floor dust a solvable problem rather than a recurring footnote.

Connect with specialists for custom solutions

Sicarbtech brings over a decade of silicon carbide manufacturing expertise, strengthened by Chinese Academy of Sciences innovation, to implement Silicon Carbide Powder Synthesis and Classification Equipment for Localized High-Purity SiC Supply in Pakistan. We design custom SiC products across R-SiC, SSiC, RBSiC, and SiSiC, and deliver technology transfer and factory establishment services that span powder synthesis, classification, granulation, coating, enclosed storage, and online feeding integration. With turnkey solutions proven at more than nineteen enterprises, we will structure a no-cost feasibility and pilot plan with clear KPIs—reduced alloy cost per ton, improved silicon absorption, lower total oxygen, and longer casting sequence stability—so your localized SiC supply becomes a competitive advantage from day one.

For a free consultation and a fast, data-backed proposal, contact:

Email: [email protected]

Phone/WhatsApp: +86 133 6536 0038

Article metadata

Last updated: 2025-09-15

Next review scheduled: 2025-12-15

Author: Sicarbtech Applications Engineering Team

Region focus: Pakistan (steelmaking EAF and converter routes; refractory and injection-grade SiC)

Timeliness note: Content aligned to 2025 scrap ratio trends, import substitution strategies, and closed-loop feeding integrations

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.