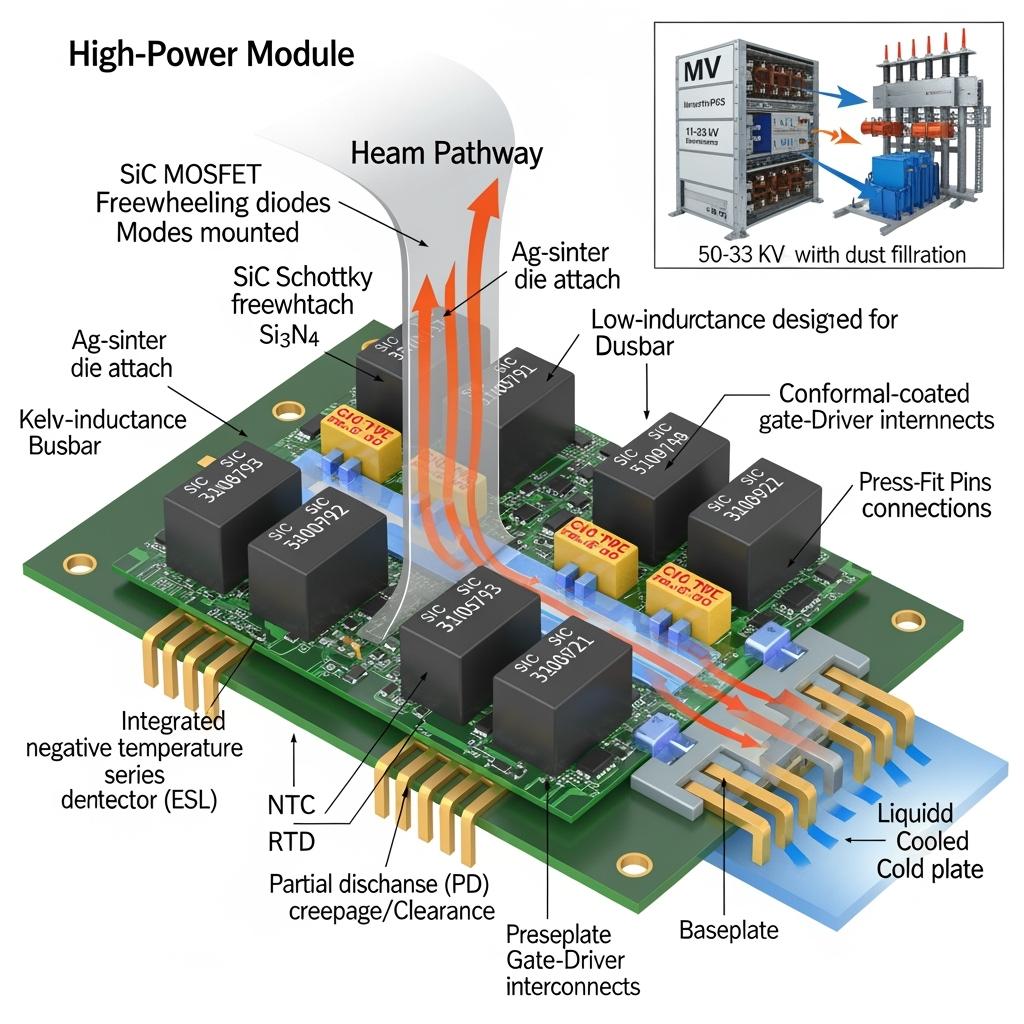

High-Voltage Silicon Carbide Power Modules (1200V–3300V) for MV Inverters and BESS PCS with Low-Inductance Packaging and Ag-Sinter Attach

Share

Product Overview and 2025 Market Relevance

High-voltage silicon carbide (SiC) power modules rated 1200V–3300V are the cornerstone of next-generation medium-voltage (MV) inverters and battery energy storage system (BESS) power conversion systems (PCS) in Pakistan’s textile, cement, steel, and emerging industrial sectors. By combining low-inductance module layouts, high-thermal-conductivity ceramic substrates (Si3N4/AlN), and silver (Ag) sinter die attach, these modules achieve ultra-low switching and conduction losses, exceptional thermal cycling endurance, and reliable operation up to +175°C junction. The result is ≥98% conversion efficiency, 1.8–2.2× power density, and robust performance in 45–50°C ambient and dusty environments typical of industrial parks in Sindh, Punjab, and Balochistan.

In 2025, MV interconnections at 11–33 kV demand more than raw efficiency. They require fault ride-through (FRT), reactive power and frequency support, low THD with compact LCL filters, and fast protection. SiC modules enable higher switching frequencies (50–200 kHz) that shrink magnetics and cooling hardware, while low-inductance packaging mitigates overshoot and EMI. Ag-sintered attaches and Si3N4 substrates extend lifetime under ΔTj cycling, supporting MTBF targets near 200,000 hours—a critical factor where service logistics and downtime costs are high.

Technical Specifications and Advanced Features

- Electrical performance

- Voltage ratings: 1200V, 1700V, 2200V, 3300V classes for MV drives, PV, and BESS PCS

- Current capability: Optimized per package; low RDS(on) and minimal reverse recovery (Qrr) via SiC diode co-optimization

- Switching frequency: 50–200 kHz operation with controlled dv/dt and low overshoot due to low loop inductance

- Packaging and interconnects

- Low-inductance layouts with laminated busbars and Kelvin source for precise gate control

- Ag-sinter die attach for high thermal conductivity and superior power cycling life

- Ceramic substrates: Si3N4 for cycling strength or AlN for maximum thermal conductivity

- Press-fit or solder-pin terminals; PD-optimized creepage/clearance for HV reliability

- Thermal management readiness

- Baseplate and pin-fin liquid cooling options; compatible with modular cold plates

- Embedded temperature sensing and thermal impedance characterization for digital twins

- Protection and sensing

- Gate-driver interface supporting DESAT detection and two-level turn-off

- Integrated NTC/RTD for real-time thermal monitoring and derating strategies

- Reliability and standards alignment

- Qualified via HTGB/HTRB, power cycling (ΔTj up to 60–100 K), and thermal shock protocols

- EMC-aware design with minimized common-mode capacitance; RoHS-compliant materials

Descriptive Comparison: SiC HV Modules vs Conventional Silicon IGBT Modules in MV PCS and Inverters

| Criterion | SiC high-voltage modules (low-inductance + Ag-sinter) | Conventional silicon IGBT modules |

|---|---|---|

| Conversion efficiency | ≥98% at 50–200 kHz | 95%–96% at lower frequencies |

| Power density | 1.8–2.2× higher | Baseline |

| Thermal cycling endurance | Ag-sinter + Si3N4/AlN for extended life | Solder fatigue limits in harsh duty |

| Cooling requirements | Compact liquid/air options | Larger, heavier heat sinks |

| THD and filter size | Smaller LCL with active damping | Larger filters required |

| Commissioning on weak feeders | Lower EMI, better dv/dt control | Higher overshoot and EMC challenges |

Key Advantages and Proven Benefits with Expert Quote

- Higher efficiency and compactness: SiC’s fast switching and low loss reduce filter and cooling size, enabling ≥98% PCS efficiency and >30% system volume reduction.

- Extended lifetime in harsh environments: Ag-sinter and Si3N4/AlN substrates withstand ΔTj cycling and dust-constrained cooling, supporting MTBF toward 200,000 hours.

- Better grid compatibility: Low-inductance layouts and dv/dt control mitigate EMI and overshoot, accelerating compliance and reducing nuisance trips on MV feeders.

Expert perspective:

“Wide bandgap modules with advanced packaging—low-inductance interconnects and high-reliability sintered attaches—unlock high-frequency operation without sacrificing lifetime.” — IEEE Power Electronics Magazine, device packaging insights (https://ieeexplore.ieee.org)

Real-World Applications and Measurable Success Stories

- BESS PCS in a Punjab industrial park (2 MW/4 MWh): SiC modules operating near 100 kHz delivered 98.2% system efficiency and 35% equipment volume reduction; improved uptime during feeder sags thanks to coordinated protection and control.

- Textile drives in Sindh: Transition to SiC modules with Ag-sinter and Si3N4 substrates reduced thermal trips during 45–50°C heatwaves; maintenance intervals extended due to dust-tolerant cooling and lower ΔTj.

- MV PV in southern Pakistan: SiC-based inverters with low-inductance modules cut LCL filter size and cooling volume by ~40% while maintaining ≥98.5% efficiency and meeting reactive power requirements.

Selection and Maintenance Considerations

- Module selection and pairing

- Choose voltage rating (1200–3300V) per DC-link and MV transformer interface; verify surge margins and PD performance.

- Match current ratings to thermal design; prefer Si3N4 substrates for heavy cycling, AlN for peak thermal conductivity.

- Gate-drive and layout

- Use drivers with active Miller clamp, negative bias, and CMTI ≥ 100 V/ns; connect via Kelvin source to minimize gate ringing.

- Keep DC-link loops ultra-short; deploy laminated busbars to reduce ESL and common-mode emissions.

- Cooling and environment

- Specify liquid cold plates or high-performance fin stacks sized for 50°C ambient and dust filtration; ensure serviceable filters.

- Implement conformal coating and corrosion-resistant finishes where humidity is high.

- Reliability validation

- Conduct double-pulse tests to calibrate dv/dt and Rg; run ΔTj power cycling (e.g., 40–80 K) and HTGB/HTRB for lifetime confidence.

- Integrate thermal sensors into digital monitoring for predictive maintenance.

Industry Success Factors and Customer Testimonials

- Cross-functional co-design aligns module, gate drive, LCL filter, and control algorithms to meet THD and EMC targets without oversizing.

- Data-driven commissioning with parameter packs and remote diagnostics shortens grid acceptance cycles.

Customer feedback:

“Low-inductance SiC modules with sintered attaches stabilized our high-frequency PCS design. We hit efficiency targets and cut commissioning time on weak feeders.” — Head of Engineering, regional energy storage integrator

Future Innovations and Market Trends

- Higher-voltage SiC modules with further reduced stray inductance and integrated current/temperature sensing

- Advanced sintering and substrate options improving power cycling beyond current limits

- Digital twins that fuse module thermal impedance models with real-time telemetry for predictive maintenance

- Localization initiatives to establish packaging and test capacity in Pakistan, improving lead times and service responsiveness

Common Questions and Expert Answers

- Which voltage class should I choose for MV interconnections?

Select 1200–1700V for transformer-coupled LV/MV interfaces; consider 2200–3300V for higher DC links or reduced series count, subject to insulation and PD constraints. - Can SiC modules handle 50–200 kHz without excessive EMI?

Yes. Low-inductance packaging, dv/dt shaping, and laminated busbars minimize overshoot and EMI; active damping allows compact LCL filters. - Do Ag-sinter and Si3N4/AlN significantly improve lifetime?

Ag-sinter enhances thermal conductivity and fatigue resistance; Si3N4 provides superior cycling robustness, extending lifetime under large ΔTj. - How do I ensure reliable operation at 45–50°C ambient?

Design for adequate coolant flow and filter maintenance, verify ΔTj margins, and use conformal coating and corrosion-resistant materials. - Are these modules compatible with existing drivers?

They pair best with SiC-optimized drivers featuring active clamp, negative bias, and fast DESAT/TLO coordination; verify pinout and Kelvin source availability.

Why This Solution Works for Your Operations

SiC high-voltage modules with low-inductance packaging and Ag-sinter attaches translate into tangible field gains for Pakistan’s MV inverters and BESS PCS: ≥98% efficiency, compact cooling and filters, and strong reliability in hot, dusty environments. Optimized dv/dt control and robust packaging minimize commissioning friction and lifecycle costs, enabling faster ROI and sustained performance across textile, cement, steel, and emerging industrial applications.

Connect with Specialists for Custom Solutions

Partner with a team delivering end-to-end SiC excellence:

- 10+ years of SiC manufacturing expertise

- Backing from a leading research ecosystem for packaging, substrates, and reliability

- Custom product development across R-SiC, SSiC, RBSiC, and SiSiC to optimize thermal and mechanical integrity

- Technology transfer and factory establishment services for local packaging and test

- Turnkey delivery from materials and devices to modules, cooling, drivers, and compliance

- Proven track record with 19+ enterprises achieving efficiency, reliability, and time-to-market goals

Request a free consultation and a tailored module selection and integration plan:

- Email: [email protected]

- Phone/WhatsApp: +86 133 6536 0038

Reserve 2025–2026 co-design and validation slots now to accelerate grid acceptance, EMC compliance, and field deployment for MV PCS and inverter programs.

Article Metadata

Last updated: 2025-09-10

Next scheduled update: 2026-01-15

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.