Mining Industry: SiC for Durability & Performance

Share

Unearthing Excellence: How Silicon Carbide Revolutionizes Durability and Performance in the Mining Industry

Silicon Carbide: The Unsung Hero of Modern Mining Operations

The mining industry stands as a cornerstone of global development, extracting essential raw materials that fuel countless other sectors. However, this vital work occurs in some of the planet’s most punishing environments. Equipment faces relentless abrasion, corrosion, high temperatures, and extreme mechanical stresses. In this unforgiving arena, material selection is not just critical—it’s paramount for operational efficiency, safety, and profitability. Traditional materials like steel alloys, rubber, and polyurethane often fall short, leading to frequent downtime, high maintenance costs, and compromised productivity. This is where advanced technical ceramics, particularly custom silicon carbide (SiC), emerge as a transformative solution.

Silicon carbide, a synthetic compound of silicon and carbon, is renowned for its exceptional hardness, second only to diamond, along with its outstanding wear resistance, high-temperature stability, chemical inertness, and excellent thermal conductivity. These properties make SiC components uniquely suited to withstand the severe conditions encountered in mineral processing, material handling, and other demanding mining applications. Unlike conventional materials that quickly degrade, engineered SiC ceramics offer significantly extended service life, translating directly into reduced operational expenditures and enhanced throughput. As mining operations dig deeper and tackle lower-grade ores, the need for materials that can deliver sustained performance and reliability has never been greater. Custom silicon carbide is stepping up to meet this challenge, proving itself to be an indispensable asset in the quest for more efficient and sustainable mining practices.

The Gauntlet: Why the Mining Industry Demands Superior Materials Like SiC

Mining operations are a veritable gauntlet of destructive forces. Equipment is constantly bombarded by abrasive ores, corrosive slurries, and often, high operational temperatures. Understanding these specific challenges underscores why materials like silicon carbide are not just beneficial, but increasingly essential.

- Extreme Abrasion: The constant movement of rock, sand, and slurry acts like sandpaper on equipment surfaces. Ores such as quartz, bauxite, and iron ore are highly abrasive. Components like pump linings, cyclone apexes, and pipe elbows made from conventional metals can wear out in weeks, or even days, leading to frequent and costly replacements. Silicon carbide’s inherent hardness provides exceptional resistance to this grinding wear.

- Corrosion: Chemical leaching and processing, common in mineral extraction (e.g., gold, copper), expose equipment to acidic or alkaline environments. These corrosive media can rapidly degrade metallic components. SiC, being chemically inert, withstands a wide pH range and aggressive chemical attack, ensuring longevity where metals would fail.

- High Impact and Mechanical Stress: Blasting, crushing, and grinding operations involve significant impact forces. While SiC is a ceramic and thus inherently more brittle than some metals, advanced SiC composites and careful design engineering allow for components that can withstand considerable mechanical stress and localized impacts, especially when properly supported or encased.

- Temperature Fluctuations: Certain mining processes, such as smelting or specific chemical extractions, involve high temperatures or rapid thermal cycling. SiC maintains its strength and structural integrity at elevated temperatures (often exceeding 1400°C for certain grades), and possesses good thermal shock resistance, preventing cracking or failure due to sudden temperature changes.

- Pressure Differentials: Slurry pumps and hydrocyclones operate under high pressures. Material integrity under these conditions is crucial to prevent blowouts or failures. The high compressive strength of SiC makes it suitable for such demanding applications.

The cumulative effect of these challenges is significant operational downtime, reduced processing efficiency, increased energy consumption (as worn parts perform poorly), and higher maintenance labor costs. The adoption of high-performance SiC wear parts directly addresses these pain points, offering a compelling case for its integration into modern mining infrastructure. The pursuit of custom SiC solutions allows for designs optimized for specific wear patterns and operational stresses, further enhancing their effectiveness.

Core Applications: Where Custom Silicon Carbide Excels in Mining

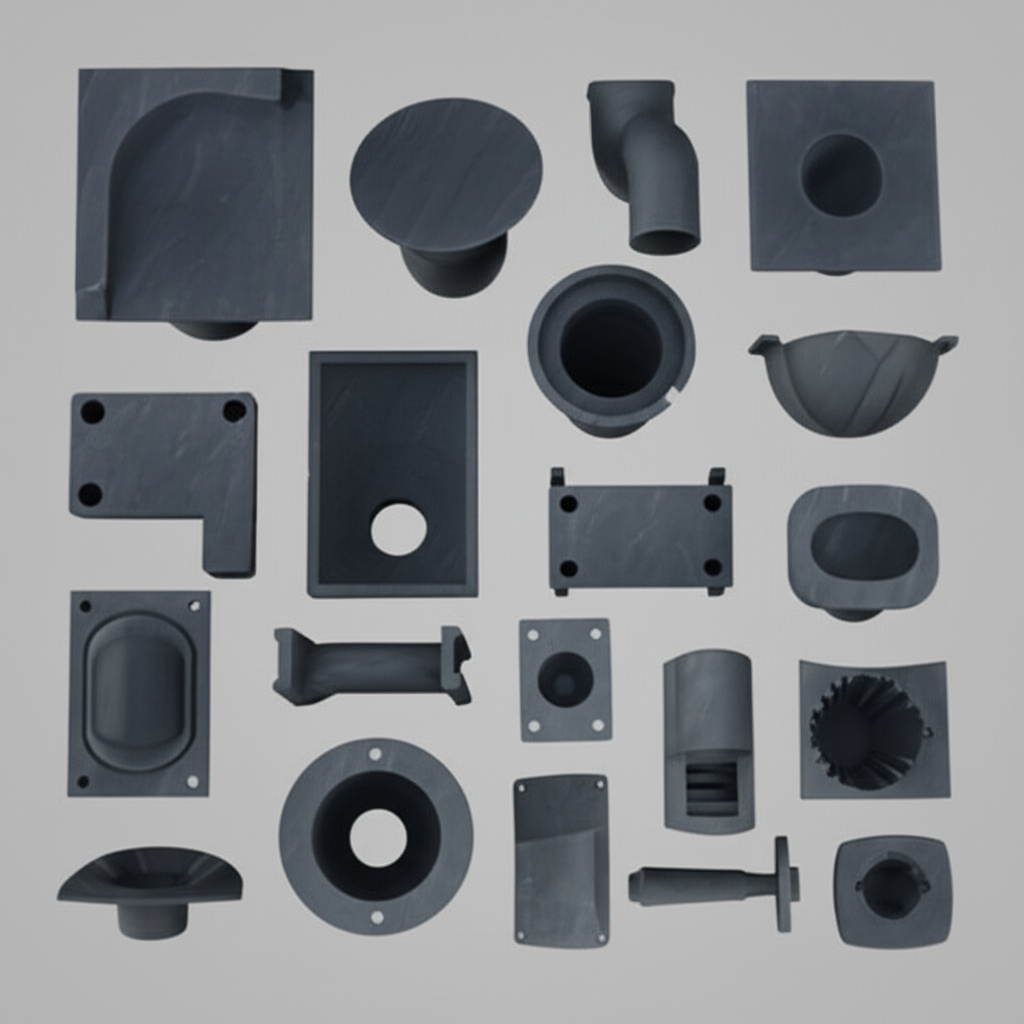

The remarkable properties of silicon carbide translate into tangible benefits across a wide spectrum of mining applications. Its ability to resist wear, corrosion, and high temperatures makes it an ideal material for components subjected to the harshest conditions. Custom silicon carbide parts are increasingly replacing traditional materials, leading to enhanced operational life and reduced maintenance cycles.

Key applications include:

- Hydrocyclone Components:

- SiC cyclone liners, spigots, apexes, and vortex finders are critical for classification and separation processes. The high-velocity, abrasive slurries inside hydrocyclones rapidly erode conventional materials. Custom-designed reaction-bonded silicon carbide (RBSiC) or sintered silicon carbide (SSiC) cyclone parts maintain their internal geometry for longer, ensuring consistent separation efficiency and significantly extending operational life.

- Slurry Pump Parts:

- Impellers, volutes, suction liners, and throatbushes in slurry pumps are prime candidates for SiC. These components handle abrasive and often corrosive slurries under high pressure. SiC pump components offer dramatically improved wear life compared to high-chrome iron or rubber, reducing downtime and improving pump efficiency.

- Piping and Elbows:

- Pneumatic and hydraulic conveying systems that transport abrasive materials benefit immensely from SiC lined pipes and elbows. Elbows, in particular, experience concentrated wear. Custom SiC tile linings or solid SiC elbow sections provide unparalleled abrasion resistance.

- Nozzles:

- Spray nozzles used for dust suppression, froth flotation, or chemical spraying in mining need to maintain precise orifice dimensions for optimal performance. SiC nozzles resist wear and corrosion, ensuring consistent spray patterns and flow rates over extended periods.

- Wear Liners & Tiles:

- Chutes, hoppers, bins, and transfer points handling abrasive ores can be lined with SiC wear tiles or custom-shaped liners. This protects the underlying steel structure from rapid degradation, reducing the need for frequent patching or replacement of large structural elements.

- Valve Components:

- Seats, discs, and balls in valves controlling abrasive or corrosive flows can be manufactured from SiC to provide tight shut-off and extended service life, crucial in mineral processing plants.

- Mining Drilling and Exploration Tools:

- Certain specialized drilling or cutting components can incorporate SiC for its hardness and wear resistance, particularly in abrasive rock formations. While not as widespread as diamond, its applications are growing.

The versatility of custom silicon carbide manufacturing allows for the creation of complex geometries tailored to specific equipment and wear patterns observed in these applications. This bespoke approach ensures optimal performance and longevity, making SiC a strategic material for cost-effective and reliable mining operations.

The Custom Advantage: Tailored SiC Components for Peak Mining Performance

While standard off-the-shelf SiC components can offer significant improvements over traditional materials, the true potential of silicon carbide in the mining industry is unlocked through customization. Mining operations are diverse, with unique ore characteristics, processing parameters, and equipment configurations. A one-size-fits-all approach rarely yields optimal results. Custom SiC solutions provide a pathway to components engineered precisely for the specific demands of an application, maximizing performance, lifespan, and return on investment.

Benefits of choosing custom silicon carbide components include:

- Optimized Wear Resistance: Custom designs can incorporate thicker SiC sections in areas of predictably high wear, or utilize specific SiC grades best suited for the type of abrasion (e.g., sliding vs. impact) encountered. This targeted approach ensures material is used most effectively.

- Improved Fit and Integration: Custom parts are designed to seamlessly integrate into existing equipment, minimizing installation challenges and ensuring proper alignment. This is crucial for components like SiC pump liners or cyclone inserts where precise fit affects overall system efficiency.

- Enhanced Performance Characteristics: Customization can address specific performance needs beyond just wear. For example, internal geometries of SiC hydrocyclones can be fine-tuned for better separation efficiency based on particle size distribution of the processed ore. Surface finishes can be tailored for optimal flow dynamics.

- Reduced System Downtime: Components engineered for maximum lifespan in their specific operational context directly translate to fewer shutdowns for replacement or maintenance. This boosts overall plant availability and productivity.

- Consolidation of Parts: In some cases, multiple smaller, wear-prone metallic parts can be redesigned and consolidated into a single, more robust custom SiC component, simplifying assembly and reducing potential failure points.

- Application-Specific Material Selection: Different grades of SiC (e.g., RBSiC, SSiC, Nitride-Bonded SiC) offer varying balances of properties like hardness, fracture toughness, and thermal shock resistance. Customization allows for the selection of the ideal grade, or even a composite structure, for the application’s unique challenges.

- Cost-Effectiveness in the Long Run: While the initial investment for a custom SiC part might be higher than a standard metal or rubber part, the significantly extended service life, reduced maintenance, and improved operational efficiency lead to a lower total cost of ownership (TCO).

Partnering with a supplier proficient in custom SiC design and manufacturing enables mining companies to move beyond simple material substitution and achieve genuine engineering improvements in their critical wear applications. This collaborative approach, focusing on understanding the specific challenges and operational goals, is key to harnessing the full power of silicon carbide.

Material Focus: Selecting the Right Silicon Carbide Grades for Mining Challenges

Silicon carbide is not a monolithic material; various manufacturing processes result in different grades of SiC, each with a unique profile of properties. Selecting the appropriate SiC grade is crucial for optimizing performance and cost-effectiveness in demanding mining applications. The primary grades relevant to the mining industry include Reaction-Bonded Silicon Carbide (RBSiC or SiSiC), Sintered Silicon Carbide (SSiC), and occasionally Nitride-Bonded Silicon Carbide (NBSiC).

Common SiC Grades for Mining Applications:

| SiC Grade | Key Characteristics | Typical Mining Applications | Considerations |

|---|---|---|---|

| Reaction-Bonded Silicon Carbide (RBSiC / SiSiC) | Good hardness and wear resistance, excellent thermal conductivity, relatively lower manufacturing cost, good dimensional stability, moderate strength. Contains some free silicon (typically 8-15%). | SiC cyclone liners, pump components (volutes, impellers), wear plates, nozzles, larger structural parts. | Free silicon may be attacked by certain highly corrosive chemicals (strong alkalis or hydrofluoric acid). Maximum service temperature is limited by the melting point of silicon (~1410°C). |

| Sintered Silicon Carbide (SSiC) | Extremely high hardness, superior wear and corrosion resistance, high strength at elevated temperatures, high purity (no free silicon). | Demanding slurry pump parts, valve components, mechanical seals, bearings, applications requiring maximum chemical resistance or higher temperature capability than RBSiC. | Generally higher manufacturing cost than RBSiC. Can be more challenging to produce very large or highly complex shapes, though advancements are mitigating this. |

| Nitride-Bonded Silicon Carbide (NBSiC) | Good abrasion resistance, excellent thermal shock resistance, good strength, relatively porous compared to SSiC and RBSiC unless sealed. | Kiln furniture, burner nozzles, applications with extreme thermal cycling. Less common for direct slurry abrasion compared to RBSiC/SSiC but used in some high-temperature wear zones. | Porosity can be a concern for corrosive environments unless a dense variant or sealant is used. Not as inherently hard as SSiC. |

| Advanced Composites (e.g., SiC-SiC, C/SiC) | Enhanced fracture toughness compared to monolithic SiC, good wear resistance, high-temperature stability. | Specialized applications requiring higher damage tolerance, such as certain cutting tools or high-impact wear zones. More niche in bulk mining applications currently due to cost. | Higher cost and specialized manufacturing. |

Key Factors in Grade Selection for Mining:

- Nature of Wear: Is it sliding abrasion, impact, or erosion by fine particles? SSiC often excels in fine particle erosion, while RBSiC provides a robust, cost-effective solution for general abrasion.

- Chemical Environment: The presence of corrosive acids or alkalis will dictate whether the purity of SSiC is needed over RBSiC.

- Operating Temperature: For very high-temperature applications, SSiC or NBSiC might be preferred.

- Impact Levels: While SiC is inherently brittle, component design and system integration can mitigate this. Some grades or composites offer slightly better toughness.

- Complexity and Size of the Component: Manufacturing constraints and costs can vary between grades for large or intricate shapes. RBSiC is often favored for larger, complex components due to its near-net-shape forming capabilities.

- Cost Considerations: A balance must be struck between the upfront material cost and the expected service life and performance benefits. RBSiC components often provide the best overall value for many abrasive wear applications in mining.

Consulting with experienced silicon carbide specialists is vital. They can help analyze the specific application conditions and recommend the most suitable SiC grade and design to ensure optimal performance and longevity in the challenging mining environment.

Blueprint for Durability: Key Design Considerations for SiC Mining Parts

Successfully implementing silicon carbide components in the mining industry goes beyond simply selecting the right material grade. Thoughtful design is paramount to harness SiC’s strengths while mitigating its inherent ceramic brittleness. Designing for manufacturability, stress management, and the specific wear mechanisms of the application are crucial for creating durable and reliable SiC mining parts.

Important design considerations include:

- Managing Brittleness:

- Avoid Sharp Corners and Stress Concentrators: Generous radii and fillets should be used to distribute stress and reduce the risk of chipping or cracking. Sharp internal corners are particular points of weakness.

- Compressive Loading: SiC is significantly stronger in compression than in tension. Designs should aim to keep SiC components under compressive loads where possible.

- Support Structures: Encasing SiC components in metallic housings or using backing materials can provide support, absorb impact energy, and constrain the ceramic, improving overall toughness and preventing catastrophic failure.

- Wall Thickness and Geometry:

- Adequate Thickness: Wall thickness must be sufficient to withstand operational stresses and wear, but excessive thickness can increase cost and sometimes thermal stress. Finite Element Analysis (FEA) can help optimize thickness.

- Uniformity:尽量保持壁厚均匀,避免因烧结或冷却不均引起的应力。 (Try to maintain uniform wall thickness to avoid stress caused by uneven sintering or cooling.)

- Manufacturability: Extremely complex geometries, very thin walls, or high aspect ratios can be challenging and costly to produce. Design with the manufacturing process (e.g., slip casting, pressing, green machining) in mind.

- Attachment and Interfacing:

- Avoid Direct Bolting Where Possible: Clamping mechanisms or specialized adhesives are often preferred over bolting directly through SiC, which can create stress points. If bolting is necessary, use sleeves and compliant washers.

- Thermal Expansion Mismatch: When interfacing SiC with metals, the difference in thermal expansion coefficients must be accounted for, especially in applications with temperature variations. Flexible interlayers or appropriate clearances may be needed.

- Designing for Wear:

- Wear-Resistant Profiles: Shape the component to promote favorable wear patterns. For example, in SiC lined elbows, the outer radius, which sees the most wear, can be made thicker or with a specific SiC grade.

- Ease of Replacement: Design for modularity where possible, allowing for easier replacement of worn SiC segments rather than entire assemblies.

- Tolerance for Impact:

- While not its strong suit, designs can incorporate features to improve impact resistance. This might involve using tougher SiC grades in impact zones or designing the surrounding structure to absorb initial shock.

- Collaboration with SiC Manufacturer:

- Early engagement with your custom SiC parts supplier is critical. Their expertise in SiC manufacturing limitations and design best practices can prevent costly redesigns and ensure a successful outcome. They can advise on practical tolerances, achievable features, and cost-effective design modifications.

By carefully considering these design principles, engineers can create robust SiC components that not only survive but thrive in the abrasive and demanding environments of the mining industry. This proactive approach to design is essential for maximizing the longevity and performance of silicon carbide solutions, ultimately leading to more efficient and cost-effective mining operations. Finite Element Analysis (FEA) is often employed to simulate stresses and optimize designs before manufacturing, ensuring the final product meets the rigorous demands of the application.

Precision & Endurance: Tolerances, Surface Finish, and Longevity of SiC in Mining

The performance and lifespan of silicon carbide components in mining applications are significantly influenced by achievable manufacturing tolerances, surface finish, and the inherent dimensional accuracy of the parts. While SiC is exceptionally hard, this also presents challenges in machining and finishing. Understanding these aspects is key for engineers and procurement managers specifying SiC parts.

Manufacturing Tolerances:

The achievable tolerances for SiC components depend on the manufacturing method (RBSiC, SSiC, etc.), the size and complexity of the part, and the extent of post-sintering machining.

- As-Sintered Tolerances: For parts used in their “as-sintered” state (without extensive machining after firing), tolerances are generally wider.

- RBSiC (Reaction-Bonded Silicon Carbide): Typically offers good dimensional control due to low shrinkage during firing. Tolerances can be around ±0.5% to ±1.5% of the dimension, or tighter for specific features with careful process control.

- SSiC (Sintered Silicon Carbide): Experiences more shrinkage during sintering (15-20%), making precise as-sintered tolerances more challenging. Tolerances might be in the range of ±1% to ±2%, but can be improved with sophisticated tooling and process control.

- Machined Tolerances: For applications requiring high precision, SiC components are machined after sintering using diamond grinding, lapping, or polishing.

- Diamond Grinding: Can achieve much tighter tolerances, often down to ±0.01 mm to ±0.05 mm (±0.0004″ to ±0.002″), or even better for critical dimensions on smaller parts.

- This precision is vital for SiC pump shaft sleeves, mechanical seals, and other components requiring exact fits.

Surface Finish:

Surface finish is critical for wear characteristics, friction, and sealing capabilities.

- As-Sintered Finish: The surface roughness (Ra) of as-sintered parts varies. RBSiC might have an Ra of 1-5 µm, while SSiC can be smoother. This is often adequate for bulk wear liners or cyclone bodies.

- Ground Finish: Diamond grinding can achieve surface finishes with Ra typically between 0.4 µm and 0.8 µm. This is suitable for many dynamic sealing surfaces and components where smooth flow is desired.

- Lapped/Polished Finish: For very demanding applications like mechanical seal faces or high-precision bearings, lapping and polishing can produce exceptionally smooth surfaces, with Ra values below 0.1 µm, even down to nanometer-scale smoothness.

A smoother surface generally reduces friction and can enhance wear resistance against fine abrasive particles. For SiC slurry pump components, a well-finished surface can also improve hydraulic efficiency.

Dimensional Accuracy and Longevity:

The key benefit of SiC in mining is its ability to maintain its dimensions and surface profile over long periods of service in abrasive conditions. This dimensional stability directly contributes to:

- Consistent Performance: In components like SiC hydrocyclone apexes or nozzles, maintaining precise orifice dimensions is crucial for consistent process output. SiC’s wear resistance ensures these dimensions hold far longer than metals or elastomers.

- Extended Service Life: The superior hardness and wear resistance mean that custom SiC wear parts can last 3 to 10 times longer (or even more) than conventional materials in the same application. This drastically reduces replacement frequency and associated downtime.

- Reduced Maintenance Costs: Longer life means less labor for change-outs, reduced inventory of spare parts, and lower overall maintenance budgets.

- Predictable Wear: While SiC does wear eventually, its wear patterns are often more predictable than those of rapidly degrading materials, allowing for better maintenance scheduling.

Achieving the right balance of tolerance, surface finish, and cost requires close collaboration with the SiC manufacturer. Specifying overly tight tolerances or finishes where they are not functionally necessary can significantly increase the cost of engineered SiC ceramics due to the intensive diamond machining required.

Beyond the Mold: Post-Processing for Enhanced SiC Performance in Abrasive Environments

While the inherent properties of silicon carbide provide a strong foundation for durability, various post-processing techniques can further enhance the performance and longevity of SiC components in the fiercely abrasive environments typical of the mining industry. These steps, applied after the initial forming and sintering of the SiC part, are aimed at refining dimensions, improving surface characteristics, or adding protective layers.

Common post-processing needs and techniques include:

- Diamond Grinding:

- Purpose: To achieve precise dimensional tolerances, critical fits, and desired surface finishes that cannot be met by as-sintered parts. Given SiC’s extreme hardness, diamond is the abrasive of choice.

- Applications: Shaft sleeves, bearing surfaces, mechanical seal faces, high-precision SiC nozzles, and mating surfaces of custom SiC pump parts.

- Benefits: Improved efficiency (e.g., in pumps due to tighter clearances), better sealing, and interchangeability of parts.

- Lapping and Polishing:

- Purpose: To achieve exceptionally smooth, mirror-like surface finishes (low Ra values) and extreme flatness.

- Applications: Primarily for mechanical seal faces where a near-perfect sealing surface is required to prevent leakage of aggressive media. Also used for some high-performance bearing components.

- Benefits: Reduced friction, minimized wear rates in dynamic contact, superior sealing integrity.

- Edge Chamfering/Radiusing:

- Purpose: To remove sharp edges which can be points of stress concentration and prone to chipping, especially in a brittle material like SiC.

- Applications: Applied to most SiC components, particularly those handled frequently or subject to minor impacts during assembly or operation.

- Benefits: Improved handling safety, increased chip resistance, and enhanced durability.

- Sealing (for porous grades):

- Purpose: Some SiC grades, like certain types of NBSiC or less dense RBSiC, may have residual porosity. Sealing treatments (e.g., with glass, resin, or further Si infiltration) can fill these pores.

- Applications: Components exposed to corrosive gases or liquids where impermeability is critical.

- Benefits: Improved corrosion resistance, reduced permeability. Less common for the dense RBSiC and SSiC typically used in mining slurry applications.

- Coatings (Specialized Applications):

- Purpose: While SiC itself is highly wear-resistant, specialized coatings (e.g., diamond-like carbon – DLC, or other hard materials) can sometimes be applied for very specific tribological enhancements or to modify surface energy.

- Applications: Niche applications where extreme surface properties are needed beyond what monolithic SiC offers. Not commonly used for bulk wear parts in mining due to cost and the excellent intrinsic properties of SiC.

- Assembly and Integration:

- Purpose: Many SiC components are part of larger assemblies, often involving metallic housings or support structures. Post-processing can include precision fitting into these housings, adhesive bonding, or shrink-fitting.

- Applications: SiC lined pipes, pump casings with SiC liners, cyclone assemblies.

- Benefits: Ensures structural integrity of the final assembly, protects the SiC from tensile stresses, and facilitates installation.

The choice and extent of post-processing depend heavily on the specific application requirements, the SiC grade used, and the desired balance between performance enhancement and cost. For instance, a simple SiC wear tile for a chute might only require basic cutting and edge finishing, while a high-performance SiC mechanical seal face will undergo extensive grinding, lapping,

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.