SiC Granules: Effective Solutions for Various Applications

Share

SiC Granules: Effective Solutions for Various Applications

Introduction: The Indispensable Role of SiC Granules in Modern Industry

Silicon Carbide (SiC) granules, a synthetic material composed of silicon and carbon, stand as a cornerstone in modern industrial applications. Renowned for their exceptional hardness, high thermal conductivity, and superior chemical inertness, SiC granules are not just another industrial abrasive or refractory material; they are a critical enabler of performance and efficiency across a multitude of demanding sectors. From shaping the future of semiconductors to enhancing the durability of industrial machinery, the versatility of silicon carbide granules makes them an indispensable component for engineers, procurement managers, and technical buyers seeking high-performance material solutions. The consistent demand for materials that can withstand extreme conditions—be it thermal, mechanical, or chemical stresses—positions SiC granules at forefront of advanced ceramic materials. Their unique combination of properties allows for the development of more resilient, efficient, and cost-effective products and processes. As industries continue to push the boundaries of technology, the role of advanced materials like SiC granules will only become more pivotal, driving innovation and enabling breakthroughs in areas previously limited by material constraints. This blog post aims to provide a comprehensive overview of silicon carbide granules, exploring their properties, applications, and the crucial factors to consider when sourcing them for specialized industrial needs. We will delve into why these granules are more than just a commodity, but a strategic asset for businesses aiming for superior operational outcomes.

Decoding the Superior Properties of Silicon Carbide Granules

The remarkable performance of silicon carbide granules stems from a unique combination of physical and chemical properties. Understanding these attributes is key for technical professionals aiming to leverage SiC for optimal application results. SiC is one of “technical ceramics” known for outperforming traditional materials in harsh environments.

- Exceptional Hardness: Silicon carbide is one of the hardest commercially available materials, ranking just below diamond on the Mohs scale (around 9.0-9.5). This extreme hardness translates directly into superior wear and abrasion resistance, making SiC granules ideal for applications like grinding, lapping, sandblasting, and wear-resistant linings. Components made with or coated by SiC can withstand significant mechanical stress and particulate erosion.

- High Thermal Conductivity: SiC granules exhibit excellent thermal conductivity, allowing them to dissipate heat rapidly. This property is crucial in high-temperature applications such as heat exchangers, furnace components, and electronic substrates where managing thermal loads is critical for performance and longevity. For high-purity SiC granules, this conductivity can be further optimized.

- Low Thermal Expansion: Coupled with high thermal conductivity, SiC’s low coefficient of thermal expansion gives it outstanding thermal shock resistance. It can endure rapid temperature fluctuations without cracking or degrading, a vital characteristic for refractory materials and components used in cyclical heating and cooling processes.

- Chemical Inertness: Silicon carbide is highly resistant to corrosion by most acids, alkalis, and molten salts, even at elevated temperatures. This chemical stability makes SiC granules suitable for use in harsh chemical processing environments, handling corrosive fluids, and as components in chemical reactors.

- High-Temperature Strength and Stability: SiC maintains its mechanical strength and structural integrity at very high temperatures (up to 1600°C or higher in non-oxidizing atmospheres). This makes it an excellent choice for refractory applications, kiln furniture, burner nozzles, and other components operating in extreme thermal environments.

- Electrical Properties: Depending on its purity and crystalline structure, silicon carbide can behave as a semiconductor or a resistor. This versatility allows its use in a wide range of electrical applications, from power electronics (diodes, MOSFETs) to heating elements and varistors. Metallurgical grade SiC is often used for its deoxidizing and alloying properties in steel production.

- Density: SiC has a relatively low density (around 3.21 g/cm³) compared to other hard materials like tungsten carbide or alumina, which can be advantageous in applications where weight is a concern, such as aerospace components or lightweight armor.

These intrinsic properties make industrial SiC powders and granules a preferred choice for enhancing product performance, extending service life, and improving process efficiency in a wide array of industrial settings. The ability to tailor these properties through controlled manufacturing processes further adds to the versatility of SiC as a high-performance ceramic material.

SiC Granules: Powering Innovation Across Diverse Industrial Sectors

The unique combination of hardness, thermal stability, and chemical resistance makes silicon carbide (SiC) granules an indispensable material across a wide spectrum of industries. Their application is critical in processes where conventional materials fall short. Here’s a look at how various sectors leverage SiC granules applications:

| Industry | Key Applications of SiC Granules | Benefits Delivered |

|---|---|---|

| Semiconductor Manufacturing | Wafer lapping and slicing, CMP (Chemical Mechanical Planarization) slurries, components for wafer processing equipment (e.g., chucks, rings, liners). | Precision surface finish, high removal rates, thermal stability, wear resistance in plasma environments. |

| Automotive | Brake discs and pads, clutch components, diesel particulate filters (DPFs), wear-resistant coatings for engine parts, components for EV power electronics. | Enhanced durability, improved braking performance, reduced emissions, higher efficiency in power modules. |

| Aerospace & Defense | Lightweight armor, components for rocket nozzles, turbine engine parts, mirrors for optical systems, wear-resistant coatings. | High strength-to-weight ratio, extreme temperature tolerance, superior wear and erosion resistance. |

| Power Electronics | Substrates for high-power/high-frequency devices, heat sinks, semiconductor raw material for SiC wafers. | High thermal conductivity, high breakdown voltage, improved efficiency and power density. |

| Renewable Energy | Components for solar panel manufacturing (e.g., slicing wires), parts for wind turbines, inverters for solar and wind energy systems. | Durability, efficiency in energy conversion, resistance to harsh environmental conditions. |

| Metallurgy & Foundries | Refractory linings for furnaces and kilns, crucibles, deoxidizing agent in steel production (metallurgical grade SiC), inoculant in iron casting. | Extreme temperature resistance, improved melt quality, enhanced furnace life, cost-effective deoxidation. |

| Chemical Processing | Pump seals and bearings, valve components, heat exchanger tubes, reactor linings, catalyst supports. | Excellent corrosion resistance, high-temperature stability, wear resistance in abrasive and corrosive media. |

| LED Manufacturing | Substrates for LED growth, components for MOCVD reactors. | Thermal management, structural stability at high processing temperatures. |

| Industrial Machinery & Manufacturing | Abrasives for grinding, sandblasting, waterjet cutting; wear-resistant nozzles, protective coatings, kiln furniture, sealing rings. | High material removal rates, extended tool life, improved precision, enhanced durability of equipment. |

| Oil and Gas | Components for downhole tools, erosion-resistant parts for pumps and valves, proppants in hydraulic fracturing (specialized SiC). | High wear and corrosion resistance in aggressive environments, thermal stability. |

The adaptability of SiC granules, available in various purities and particle sizes, including SiC grit and powders, allows for tailored solutions that meet the specific demands of each industry. As technology evolves, new applications for this versatile ceramic continue to emerge, underscoring its importance in driving industrial progress and efficiency.

Strategic Benefits of Sourcing High-Quality SiC Granules for B2B Operations

For businesses operating in competitive industrial landscapes, the choice of raw materials can significantly impact operational efficiency, product quality, and the bottom line. Sourcing high-quality SiC granules is not merely a procurement decision but a strategic investment that yields substantial B2B advantages. Procurement managers and technical buyers should consider the following benefits:

- Enhanced Product Performance and Reliability: Superior SiC granules with controlled purity and particle size distribution contribute directly to the enhanced performance of end products. Whether it’s the precision in semiconductor lapping or the lifespan of a refractory lining, high-grade SiC ensures optimal functionality and reliability, leading to greater customer satisfaction and reduced warranty claims.

- Increased Operational Efficiency: In manufacturing processes like grinding, cutting, or surface treatment, the quality of SiC abrasives directly affects processing speed, material removal rates, and tool life. High-quality granules perform consistently, reducing downtime for tool changes and optimizing production throughput.

- Extended Equipment Lifespan: When used in wear-resistant components or protective coatings, premium SiC granules significantly extend the service life of machinery and equipment operating in harsh environments. This translates to lower maintenance costs, reduced capital expenditure on replacements, and improved overall equipment effectiveness (OEE).

- Improved Cost-Effectiveness in the Long Run: While the initial cost of high-purity or specially graded SiC granules might be higher, the long-term economic benefits often outweigh this. These benefits include reduced consumption of abrasives due to higher efficiency, lower frequency of component replacement, and minimized production losses due to material failures. This is a key consideration for wholesale silicon carbide buyers looking at total cost of ownership.

- Consistency and Predictability in Manufacturing: Reputable silicon carbide suppliers provide granules with consistent physical and chemical properties from batch to batch. This consistency is crucial for maintaining stable manufacturing processes and predictable product quality, which is particularly important for industries with stringent quality control standards like aerospace and medical devices.

- Access to Technical Expertise and Support: Partnering with a knowledgeable supplier of high-quality SiC granules often comes with the added benefit of technical support. This can include assistance with material selection, process optimization, and troubleshooting, helping businesses to maximize the value derived from SiC materials.

- Compliance with Industry Standards: High-quality SiC granules are more likely to meet or exceed stringent industry-specific standards (e.g., for purity in electronics or consistency in refractories). This ensures that the final products are compliant and safe for their intended applications.

In essence, opting for high-quality SiC granules is a proactive approach to risk mitigation and performance enhancement. It allows businesses to build more robust products, streamline operations, and ultimately achieve a stronger competitive position in their respective markets. For technical procurement professionals, focusing on quality and supplier reliability is paramount when dealing with critical materials like silicon carbide.

A Guide to SiC Granule Grades, Types, and Technical Specifications

Silicon Carbide (SiC) granules are not a one-size-fits-all material. They are available in various grades, types, and sizes, each tailored for specific industrial applications. Understanding these classifications is crucial for engineers and procurement specialists to select the most appropriate material for their needs. Key differentiating factors include purity, crystal structure, color, and particle size (grit).

Major Types of Silicon Carbide Granules:

- Black Silicon Carbide: Produced from petroleum coke and high-quality silica sand, black SiC is extremely hard (around 9.2 on Mohs scale) and tough. It contains at least 98.5% SiC, with common impurities being free silicon and carbon, iron, and aluminum. It’s generally more friable than green SiC under certain conditions but is a cost-effective choice for many applications.

- Typical Applications: Grinding low-tensile-strength materials (cast iron, brass, aluminum, non-metallic materials like stone and ceramics), refractory materials, metallurgical additives, lapping, wire sawing.

- Green Silicon Carbide: Manufactured from similar raw materials as black SiC but with added salt and at higher temperatures, resulting in higher purity (typically >99% SiC) and greater hardness (around 9.5 on Mohs scale). It is also more friable than black SiC, meaning it fractures more easily to expose new sharp cutting edges, which is beneficial in precision grinding of hard materials.

- Typical Applications: Grinding hard and brittle materials (cemented carbides, optical glass, technical ceramics), precision lapping, honing, semiconductor wafer slicing, high-performance refractories.

Common Grades Based on Application:

- Abrasive Grade SiC: Characterized by controlled particle size distribution (grit size according to FEPA, ANSI, or JIS standards), shape, and hardness. Used for bonded abrasives (grinding wheels), coated abrasives (sandpaper), blasting media, and lapping compounds. Both black and green SiC are used.

- Refractory Grade SiC: Selected for its high-temperature stability, thermal shock resistance, and corrosion resistance. Purity and particle size are critical. Used in kiln furniture, crucibles, furnace linings, burner nozzles, and other high-temperature structural components. Refractory grade SiC often requires specific grain sizing and low impurity levels to prevent reactions at high temperatures.

- Metallurgical Grade SiC: Primarily black silicon carbide with lower SiC purity (often 88-90%, though higher grades are also used). Used as a deoxidizer, fuel source, and silicon/carbon additive in the iron and steel industry. It helps improve melt quality and reduce costs.

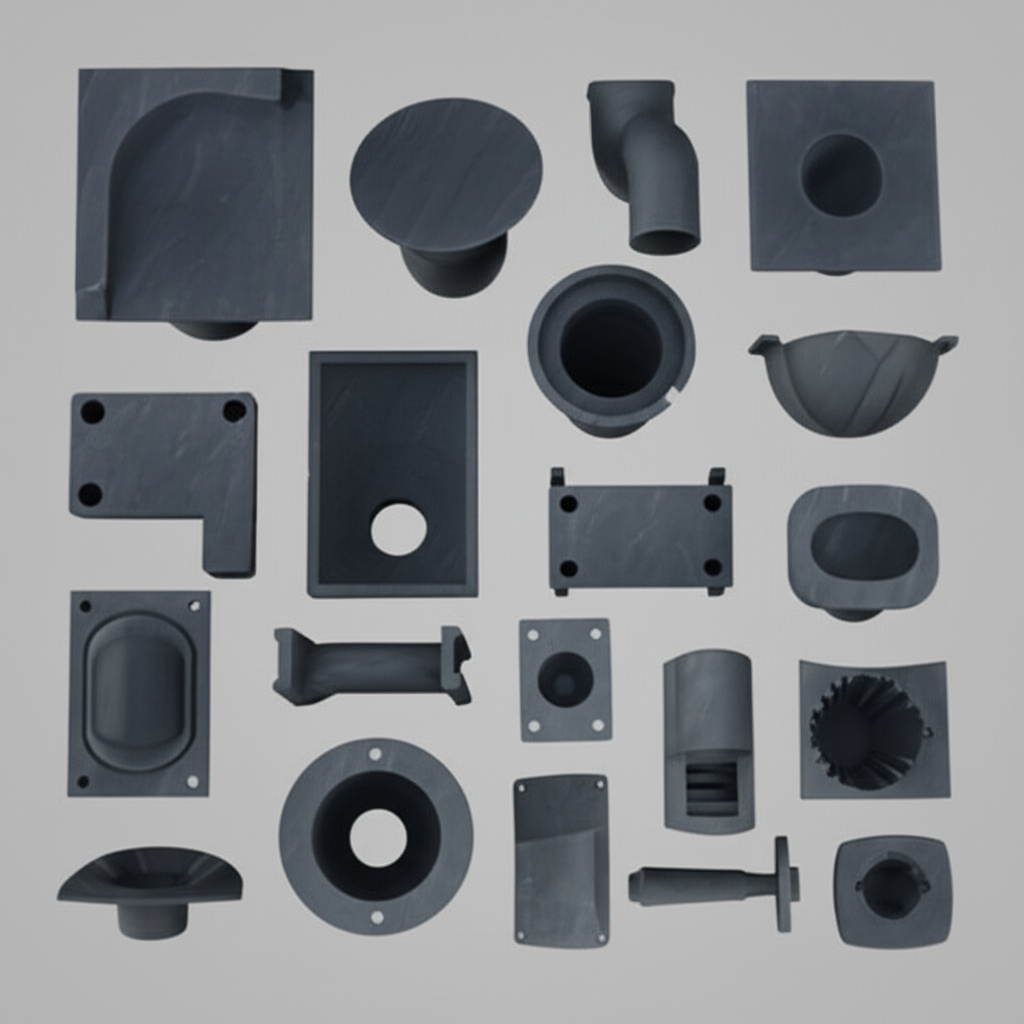

- Technical or Advanced Ceramics Grade SiC: High-purity SiC (often green SiC or specially processed black SiC) used as a raw material for producing dense SiC ceramic parts through sintering, reaction bonding, or CVD processes. These parts find use in demanding applications requiring extreme wear resistance, thermal management, or chemical stability.

Key Technical Specifications to Consider:

| Specification | Description | Importance |

|---|---|---|

| SiC Purity (%) | The percentage of silicon carbide in the granules. Higher purity generally means better performance in specific applications (e.g., electronics, high-temp refractories). | Affects thermal conductivity, electrical properties, chemical resistance, and maximum operating temperature. |

| Particle Size Distribution (Grit Size) | The range and average size of the granules. Standardized by FEPA (Europe), ANSI (USA), JIS (Japan). Can range from coarse grits (e.g., F12) to fine powders (e.g., F1200 and finer microgrits). | Critical for abrasives (determines removal rate and surface finish), refractories (affects density and porosity), and ceramic production (influences sintering). |

| Crystal Structure | Mainly alpha-SiC (hexagonal, more common and stable at high temperatures) and beta-SiC (cubic, forms at lower temperatures, can convert to alpha-SiC). | Affects properties like hardness and electrical behavior. Alpha-SiC is predominant in commercial granules. |

| Bulk Density (g/cm³) | The mass of granules per unit volume, including inter-particle voids. | Important for refractory mix calculations, packaging, and handling. |

| Friability | The tendency of the granules to fracture under stress, exposing new cutting edges. | Important for abrasive applications. Green SiC is generally more friable than black SiC. |

| Impurity Levels | Presence of free silicon, free carbon, iron oxide (Fe₂O₃), aluminum oxide (Al₂O₃), etc. | Can affect high-temperature performance, color, electrical conductivity, and reactivity in specific environments. |

Choosing the right grade and type of SiC grit or granules requires a thorough understanding of the application’s demands and the specific properties offered by each variant. Consulting with a knowledgeable silicon carbide supplier can provide valuable insights and help in selecting the optimal material for performance and cost-effectiveness.

Critical Selection Factors for SiC Granules: An Engineer’s Handbook

Selecting the appropriate silicon carbide (SiC) granules is a critical decision that directly influences the performance, longevity, and cost-effectiveness of an industrial application. Engineers and technical buyers must meticulously evaluate several factors to ensure the chosen SiC material aligns perfectly with their specific requirements. Here’s an engineer’s handbook to navigating these critical selection factors:

- Application Environment and Operating Conditions:

- Temperature: Will the SiC granules be exposed to extreme temperatures? For refractory applications or high-temperature processing, select grades with high thermal stability and low impurities that could cause degradation.

- Chemical Exposure: What corrosive agents (acids, bases, molten metals) will the SiC encounter? High-purity SiC generally offers better chemical resistance.

- Mechanical Stress: What type of mechanical load (abrasion, impact, pressure) will be present? Hardness, toughness, and particle shape are key. For instance, blocky grains are more durable in some wear applications than sharp, angular ones.

- Required Material Properties:

- Hardness and Abrasiveness: For grinding, cutting, or lapping, consider the hardness of the material being processed. Green SiC is harder and suited for very hard materials, while black SiC is a versatile abrasive for general purposes.

- Thermal Conductivity: For heat dissipation applications (e.g., heat sinks, electronic substrates), high thermal conductivity SiC is essential. Purity and density play a significant role here.

- Electrical Conductivity/Resistivity: Is the application for heating elements (conductive SiC) or insulators/semiconductors? The SiC’s doping and purity level determine its electrical behavior.

- Particle Size (Grit Size) and Distribution: This is paramount. Coarse grits for high stock removal, fine grits for polishing and precision finishes. A narrow particle size distribution ensures consistent performance. For refractories, a specific mix of sizes is needed for optimal packing density.

- SiC Grade and Purity:

- Match the SiC grade (abrasive, refractory, metallurgical, technical ceramic) to the application.

- Higher purity (e.g., >99% for green SiC) is often required for demanding applications like semiconductors or advanced ceramics to minimize unwanted reactions or contamination. Lower purity (e.g., 90% for metallurgical grade) can be cost-effective for its intended use.

- Particle Shape and Friability:

- Shape: Grains can be blocky, angular, or sharp. Angular, sharp grains are good for fast cutting, while blockier grains might offer longer life in some wear applications.

- Friability: The ability of grains to fracture and expose new cutting edges. More friable grains (like green SiC) are good for grinding hard materials as they stay sharp but may wear faster. Less friable grains are tougher.

- Supplier Credentials and Consistency:

- Quality Control: Does the supplier have robust quality control measures to ensure consistent purity, particle size, and properties from batch to batch? Request certifications or test data.

- Technical Support: Can the supplier offer technical assistance in selecting the right SiC and optimizing its use?

- Supply Reliability: Ensure the supplier can meet volume requirements and maintain a stable supply chain.

- Cost vs. Performance (Total Cost of Ownership):

- While initial price is a factor, evaluate the total cost of ownership. A slightly more expensive but higher-performing SiC granule might lead to reduced consumption, longer tool life, or better end-product quality, ultimately saving costs. Consider the cost of bulk SiC granules versus specialized, smaller batches.

- Compatibility with Existing Processes and Equipment:

- Ensure the chosen SiC granules are compatible with your current manufacturing processes, handling equipment, and safety protocols. For example, finer powders may require specialized handling to manage dust.

By systematically evaluating these factors, engineers can confidently select the optimal silicon carbide granules that will deliver the desired performance and contribute to the overall success of their projects and products. Consulting with experts and conducting trials can also be invaluable steps in this selection process.

Advancements in SiC Granule Manufacturing and Quality Control

The consistent demand for higher-performance silicon carbide (SiC) granules across various industries has spurred significant advancements in their manufacturing processes and quality control methodologies. These innovations aim to produce SiC with enhanced purity, more precise particle size distributions, tailored crystal structures, and improved overall consistency, ensuring they meet the increasingly stringent requirements of modern applications like advanced electronics, high-efficiency abrasives, and ultra-high temperature refractories.

Innovations in SiC Synthesis and Production:

- Optimized Acheson Process: While the Acheson process (heating petroleum coke and silica sand in an electric resistance furnace) remains the primary method for bulk SiC production, refinements continue to be made. These include better control of raw material quality, optimized furnace design for more uniform temperature distribution, and improved energy efficiency. These lead to higher yields of specific SiC grades and more consistent crystal growth.

- Alternative Synthesis Routes: Research is ongoing into alternative, potentially more controlled synthesis methods, such as chemical vapor deposition (CVD) for ultra-high purity SiC powders, self-propagating high-temperature synthesis (SHS), and sol-gel methods. While not yet mainstream for bulk granule production, these methods offer pathways to specialized SiC materials with unique properties.

- Recycling and Sustainability: Increasing focus is placed on recycling SiC from used refractory materials or grinding sludges. Advanced separation and purification techniques are being developed to recover high-quality SiC, reducing waste and reliance on virgin raw materials, contributing to a more sustainable supply chain for industrial SiC powders.

Precision in Crushing, Milling, and Sizing:

- Advanced Milling Technologies: Sophisticated milling equipment, including jet mills and attritor mills, allows for finer and more controlled particle size reduction. This is crucial for producing SiC microgrits with tight particle size distributions required for applications like semiconductor wafer lapping and fine polishing.

- Sophisticated Classification Systems: Modern classification techniques, such as multi-stage air classifiers and sieving systems with high-precision screens, enable the separation of SiC granules into very specific size fractions (e.g., FEPA F, P, and microgrit standards). This precision ensures consistent performance in applications where particle size is critical.

- Particle Shape Control: Some advanced processing techniques aim to control the morphology (shape) of SiC grains. For instance, processes can be optimized to produce more blocky or more angular particles depending on whether durability or aggressive cutting action is prioritized.

Enhanced Purification and Surface Treatment:

- Chemical Leaching and Washing: To achieve higher purities, especially for green SiC or electronic-grade SiC, manufacturers employ rigorous chemical leaching processes to remove metallic impurities, free silicon, and excess carbon. This can involve treatment with acids and other chemical agents.

- Surface Modification: For specialized applications, SiC granule surfaces can be modified. This might include treatments to improve bonding with matrix materials in composites, enhance dispersion in slurries, or alter surface reactivity.

Rigorous Quality Control Measures:

- Advanced Analytical Techniques: Manufacturers of high-quality SiC granules employ a suite of advanced analytical tools:

- X-Ray Diffraction (XRD): To verify crystal structure (alpha or beta SiC) and phase purity.

- Inductively Coupled Plasma (ICP) or Atomic Absorption Spectroscopy (AAS): For precise chemical analysis and determination of impurity levels.

- Laser Diffraction Particle Size Analyzers: For accurate measurement of particle size distribution, down to the sub-micron range.

- Scanning Electron Microscopy (SEM): To examine particle morphology, surface characteristics, and detect microstructural defects.

- Automated Chemical Titration: For routine checks of key chemical parameters.

- Statistical Process Control (SPC): SPC methods are widely implemented throughout the manufacturing process to monitor key parameters and ensure consistency, reducing batch-to-batch variability.

- Certifications and Traceability: Reputable suppliers provide certificates of analysis (CoA) for each batch, detailing key properties and ensuring traceability of materials. Compliance with ISO quality management standards is also common.

These advancements in manufacturing and quality control ensure that end-users receive SiC granules that not only meet their specifications but also deliver reliable and consistent performance, enabling technological progress across demanding industries. Companies investing in these advanced processes are better positioned to meet the evolving needs of the market for high-performance technical ceramics.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.