SiC Composites: The Future of Advanced Materials

Share

SiC Composites: The Future of Advanced Materials

Introduction: The Prowess of SiC Composites in Demanding Applications

In the relentless pursuit of materials that can withstand extreme conditions, Silicon Carbide (SiC) composites have emerged as a frontrunner, heralding a new era in advanced materials science. These are not monolithic SiC ceramics, but rather sophisticated materials where SiC is typically reinforced with fibers (often carbon or SiC itself) or forms a matrix around a reinforcing phase. This composite structure unlocks a combination of properties previously unattainable, making them essential for high-performance industrial applications. Industries grappling with intense heat, corrosive environments, high wear, and the need for lightweight yet strong components are increasingly turning to custom SiC composites. Their unique ability to maintain structural integrity and performance under duress positions them as critical enablers for innovation across sectors like aerospace, automotive, energy, and semiconductor manufacturing. As operational demands intensify, the intrinsic value and strategic importance of SiC composites continue to grow, driving the development of even more tailored and robust solutions.

The core advantage of SiC composites lies in their enhanced fracture toughness compared to traditional monolithic ceramics, which are notoriously brittle. By incorporating reinforcing elements, SiC composites can deflect cracks, absorb energy, and exhibit a more “graceful” failure mode, rather than catastrophic shattering. This toughness, combined with SiC’s inherent high-temperature stability, exceptional hardness, chemical inertness, and excellent thermal conductivity, makes these composites indispensable for applications where reliability and longevity are paramount. The ability to customize the composition and structure of these composites allows engineers to fine-tune material properties to meet the specific, often severe, demands of their unique applications, pushing the boundaries of what’s technologically achievable.

Diverse Industrial Applications of SiC Composites

The versatility and superior performance characteristics of Silicon Carbide (SiC) composites have led to their adoption in a wide array of demanding industrial applications. Their unique combination of high-temperature resistance, wear resistance, chemical inertness, and favorable thermal and electrical properties makes them ideal for components operating in extreme environments. From the depths of oil wells to the vastness of space, industrial SiC solutions are proving their mettle.

Here’s a look at how various industries leverage SiC composites:

- Semiconductor Manufacturing: SiC composites are used for wafer handling components, chucks, etching equipment parts, and chamber components due to their high purity, stiffness, thermal stability, and resistance to plasma erosion. These applications demand materials that won’t contaminate processes and can withstand harsh chemical and thermal cycling.

- Aerospace and Defense: Lightweight yet incredibly strong, SiC composites find applications in rocket nozzles, missile components, leading edges for hypersonic vehicles, and high-performance braking systems. Their ability to withstand extreme temperatures and thermal shock is critical for aerospace grade SiC components. Turbine engine components like shrouds and combustor liners made from Ceramic Matrix Composites (CMCs) with SiC fibers and/or matrix are prime examples.

- Automotive: Particularly in high-performance and electric vehicles, SiC composites are explored for brake rotors (offering significant weight savings and improved fade resistance compared to cast iron), clutch components, and parts for exhaust systems. Automotive SiC components contribute to efficiency and durability.

- Power Electronics: For advanced power modules and inverters, SiC composites serve as heat sinks and baseplates due to their excellent thermal conductivity and electrical insulation. This is crucial for effective thermal management SiC in compact, high-power density devices.

- Renewable Energy: In solar power generation, components in concentrated solar power (CSP) systems, such as receivers and heat exchangers, benefit from SiC composites’ high-temperature capability and thermal shock resistance. In nuclear energy, they are considered for fuel cladding and core structures due to their radiation stability and high-temperature strength.

- Metallurgy and High-Temperature Furnaces: Kiln furniture, burner nozzles, radiant tubes, crucibles, and thermocouple protection tubes made from SiC composites offer extended service life in aggressive, high-temperature environments found in metal processing, glass manufacturing, and ceramics firing.

- Chemical Processing: Components like pump seals, bearings, valve parts, and heat exchanger tubes benefit from the exceptional chemical resistant ceramics nature of SiC composites, which can handle corrosive acids, alkalis, and abrasive slurries at elevated temperatures.

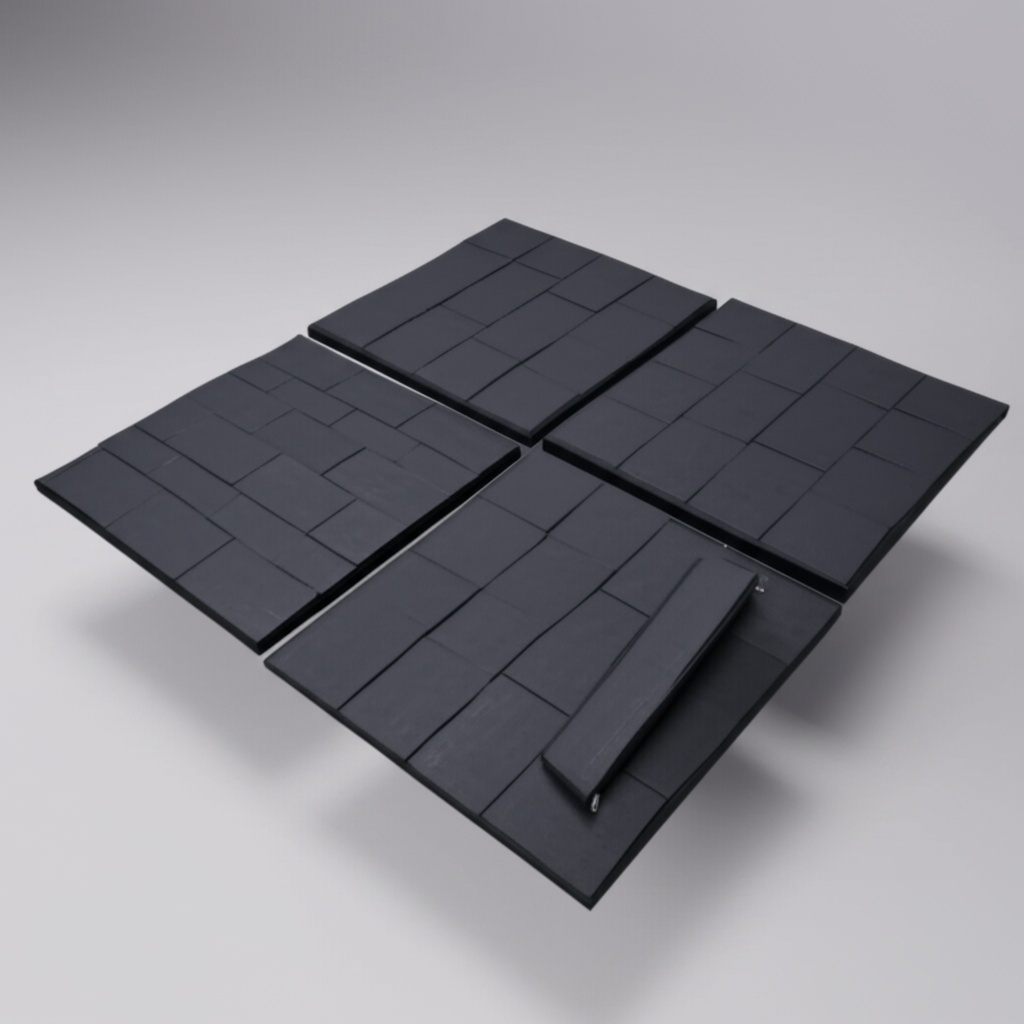

- LED Manufacturing: Susceptors and carrier plates for MOCVD reactors used in LED production utilize SiC composites for their thermal uniformity, chemical stability, and resistance to reactant gases.

- Industrial Machinery: Wear-resistant components such as nozzles for abrasive blasting, bearings for aggressive media, and seals for high-pressure pumps leverage the hardness and durability of SiC composites.

This widespread adoption underscores the transformative impact of SiC composites, enabling advancements and operational efficiencies previously unachievable with conventional materials.

The Unmatched Advantages of Custom SiC Composites

While standard SiC materials offer remarkable properties, custom SiC composites elevate these benefits by allowing tailoring to specific application needs, providing a distinct competitive edge. This customization can involve altering the type and orientation of reinforcement, modifying the matrix composition, or designing complex geometries that optimize performance. The ability to engineer these materials at a microstructural level unlocks a new dimension of material solutions.

Key advantages of opting for custom SiC composites include:

- Optimized Thermal Management: Customization allows for the modulation of thermal conductivity. For instance, aligning continuous SiC fibers can enhance heat dissipation in specific directions, crucial for electronics or heat exchangers. Conversely, porosity can be engineered for thermal insulation. This tailored thermal shock resistance SiC is a significant benefit.

- Superior Wear and Abrasion Resistance: The type and volume fraction of SiC particles or fibers can be adjusted to maximize hardness and toughness, leading to components that withstand highly abrasive environments, extending service life and reducing downtime in machinery and processing equipment.

- Enhanced Chemical Inertness and Corrosion Resistance: While SiC is inherently resistant to many chemicals, custom composites can further enhance this by selecting specific SiC grades and minimizing porosity, ensuring longevity in aggressive chemical processing or high-temperature corrosive gas environments.

- Tailored Mechanical Strength and Toughness: Unlike brittle monolithic ceramics, SiC composites can be designed for improved fracture toughness. Fiber reinforcement, for example, introduces mechanisms for crack deflection and energy absorption, making parts more resilient to impact and mechanical stresses. This is critical for structural components in aerospace or automotive applications.

- Lightweighting Potential: SiC composites offer high stiffness-to-weight and strength-to-weight ratios. Custom designs can further optimize component geometry to reduce mass without compromising performance, a vital factor in aerospace, defense, and automotive sectors aiming for fuel efficiency and increased payload.

- Complex Geometries and Near-Net Shape Manufacturing: Advanced fabrication techniques for custom SiC composites allow for the creation of intricate shapes that might be difficult or impossible to achieve with traditional machining of monolithic SiC. This can reduce material waste and subsequent machining costs.

- Application-Specific Electrical Properties: The electrical conductivity of SiC composites can be tailored. While generally an insulator or semiconductor, doping or incorporating specific conductive phases can create materials suitable for heating elements, sensors, or electrostatic discharge (ESD) applications.

- Improved Cost-Effectiveness for Demanding Roles: While initial costs might be higher, the extended lifespan, reduced maintenance, and improved operational efficiency offered by custom SiC composites often result in a lower total cost of ownership in critical applications.

By partnering with a knowledgeable supplier capable of developing custom SiC composite solutions, industries can overcome the limitations of off-the-shelf materials and achieve new levels of performance and reliability.

Key SiC Composite Grades: Properties and Selection Guide

Silicon Carbide composites are not a one-size-fits-all solution. Various manufacturing processes result in different grades of SiC composites, each with a unique set of properties tailored for specific applications. Understanding these distinctions is crucial for selecting the optimal material. The primary methods include Reaction Bonding (RB-SiC), Sintering (SSiC, LP-SiC), and Chemical Vapor Infiltration/Deposition (CVI/CVD SiC), often used for fiber-reinforced SiC-SiC composites (CMC).

Here’s a comparative look at common SiC composite types and their characteristics:

| SiC Composite Type | Manufacturing Process Highlights | Key Properties | Typical Applications |

|---|---|---|---|

| Reaction-Bonded SiC (RB-SiC) / Silicon Infiltrated SiC (SiSiC) | Porous SiC preform (often SiC particles mixed with carbon) is infiltrated with molten silicon. The silicon reacts with carbon to form new SiC, bonding the original particles. Typically contains 8-15% free silicon. |

|

Wear parts (nozzles, seals, liners), kiln furniture, pump components, heat exchangers, mechanical seals. |

| Sintered SiC (SSiC) / Pressureless Sintered SiC (LP-SiC) | Fine SiC powder with sintering aids (e.g., boron, carbon) is compacted and fired at high temperatures (2000-2200°C) in an inert atmosphere, causing particles to bond. No free silicon. |

|

Chemical pump parts, bearings, seals, semiconductor processing equipment, ballistic armor, heat exchanger tubes in highly corrosive environments. |

| Nitride-Bonded SiC (NB-SiC) | SiC grains bonded by a silicon nitride (Si3N4) phase. Formed by nitriding a mixture of SiC and silicon. |

|

Kiln furniture, components for aluminum and other non-ferrous metal contact, cyclone liners. |

| SiC Fiber-Reinforced SiC Matrix Composites (SiC/SiC CMCs) | SiC fibers are embedded in a SiC matrix, often formed via Chemical Vapor Infiltration (CVI), Polymer Impregnation and Pyrolysis (PIP), or melt infiltration. |

|

Aerospace engine components (turbines, nozzles), thermal protection systems, fusion reactor components, high-performance brake discs. |

| Carbon Fiber-Reinforced SiC Matrix Composites (C/SiC) | Carbon fibers embedded in a SiC matrix. Matrix typically formed by liquid silicon infiltration (LSI) or CVI. |

|

High-performance brake discs (sports cars, aircraft), clutch components, hot press molds. |

Choosing the right grade involves a careful assessment of the operating environment (temperature, chemical exposure, mechanical loads) and economic considerations. For instance, while sintered SiC composites offer superior chemical and high-temperature resistance, reaction bonded SiC composites might be more cost-effective for complex shapes with slightly less demanding conditions. For ultimate toughness and high-temperature performance, SiC/SiC CMCs are unparalleled, albeit at a higher cost. Consulting with material experts is crucial to navigate these choices effectively.

Critical Design Considerations for Manufacturing SiC Composite Components

Designing components with Silicon Carbide (SiC) composites requires a different approach than with metals or plastics. The inherent properties of ceramics, even when enhanced in composite form, necessitate careful consideration during the design phase to ensure manufacturability, performance, and longevity. Overlooking these aspects can lead to suboptimal parts, increased costs, or premature failure.

Key design considerations for custom SiC parts include:

- Understanding Material Brittleness (Even in Composites): While SiC composites are tougher than monolithic SiC, they are still more brittle than most metals. Designs should aim to minimize stress concentrations. This means:

- Generous radii on internal and external corners. Sharp corners are major stress raisers.

- Avoiding sudden changes in cross-section. Gradual transitions are preferred.

- Distributing loads over larger areas to reduce localized stress.

- Manufacturing Process Limitations: The chosen manufacturing route (e.g., reaction bonding, sintering, CVI for CMCs) will impose certain geometric constraints.

- Near-Net Shape Capability: Some processes allow for complex shapes with minimal post-processing, while others may require significant grinding. Discuss achievable complexities with your supplier early on.

- Wall Thickness: Minimum and maximum wall thicknesses vary by process. Extremely thin walls can be fragile and difficult to produce uniformly, while overly thick sections might suffer from internal stresses or incomplete infiltration/sintering.

- Draft Angles: For processes involving molds, draft angles may be necessary for part removal.

- Shrinkage and Distortion: Sintering processes, in particular, involve significant shrinkage (typically 15-20%). This must be accounted for in the initial “green” body design. Non-uniform shrinkage can also lead to distortion, especially in complex or asymmetrical parts.

- Joining and Assembly: Joining SiC composite parts to each other or to other materials (like metals) can be challenging due to differences in thermal expansion coefficients and the non-weldable nature of ceramics.

- Mechanical fastening (bolts, clamps) is common but requires careful design to avoid point loads.

- Brazing or specialized adhesive bonding are options, requiring specific surface preparation and material compatibility.

- Consider integrated designs to minimize the number of joints.

- Thermal Management Design: If the component is for a thermal application (heat sink, heat exchanger), the design must optimize heat flow. Consider the anisotropic thermal conductivity of some fiber-reinforced composites and orient fibers accordingly.

- Tolerances and Machinability: SiC and its composites are extremely hard, making them difficult and costly to machine. Design parts to be as close to net shape as possible to minimize finishing operations like grinding or lapping. Specify realistic tolerances; tighter tolerances significantly increase cost.

- Surface Finish Requirements: Specify the required surface finish based on the application (e.g., for sealing surfaces, wear components, or optical applications). Different finishing processes achieve different Ra values.

- Impact Resistance: While tougher than monolithics, avoid designs that expose SiC composite components to direct, high-velocity impacts unless specifically designed for such loads (e.g., armor).

- Environmental Factors: Consider the full range of operating conditions – temperature extremes, thermal cycling, chemical environment, and potential for abrasion or erosion – as these will influence material grade selection and design details.

Early collaboration between the design engineer and the SiC composite manufacturer is paramount. This ensures that the design is optimized for both performance and manufacturability, leveraging the unique strengths of technical ceramics engineering to achieve the best possible outcome.

Achieving Precision: Tolerance, Surface Finish & Dimensional Accuracy in SiC Composites

Precision is often a critical requirement for components made from Silicon Carbide (SiC) composites, especially in industries like semiconductor manufacturing, aerospace, and optics. Achieving tight tolerances, specific surface finishes, and high dimensional accuracy with these extremely hard materials demands specialized manufacturing and finishing techniques. Understanding the capabilities and limitations is key for both designers and procurement professionals.

Tolerances:

The achievable tolerances for SiC composite parts depend heavily on several factors:

- Manufacturing Process:

- Near-Net Shape Processes: Techniques like reaction bonding or some forms of sintering can produce parts close to final dimensions, with typical “as-fired” tolerances in the range of ±0.5% to ±1% of the dimension. Complex internal features might have looser tolerances.

- Machining-Intensive Processes: For very tight tolerances, post-sintering or post-infiltration grinding, lapping, and polishing are necessary.

- Part Size and Complexity: Larger and more complex parts are generally harder to control dimensionally during firing or infiltration, potentially leading to wider as-fired tolerances.

- Material Grade: Different SiC composite grades may exhibit varying degrees of shrinkage and stability during processing.

With precision grinding, standard achievable tolerances for SiC composites can be in the range of ±0.01 mm to ±0.05 mm (±0.0004″ to ±0.002″). For highly critical applications, even tighter tolerances, down to a few microns, can be achieved through specialized lapping and polishing, but this significantly increases cost and lead time.

Surface Finish:

The surface finish (Ra, roughness average) of SiC composite components is crucial for applications involving seals, bearings, fluid flow, or optical interfaces.

- As-Fired/As-Processed: Surfaces might have a roughness of Ra 1 µm to 5 µm or more, depending on the process and mold/tooling surface. This may be adequate for some kiln furniture or general structural parts.

- Grinding: Diamond grinding can achieve surface finishes typically in the range of Ra 0.2 µm to Ra 0.8 µm. This is common for many mechanical components.

- Lapping and Polishing: For ultra-smooth surfaces, lapping and polishing techniques using progressively finer diamond abrasives can achieve Ra values below 0.1 µm, and even down to Ra 0.01-0.02 µm for optical-grade finishes. These processes are time-consuming and require specialized equipment.

Dimensional Accuracy:

Dimensional accuracy refers to how closely the final part conforms to the nominal dimensions specified in the design. This encompasses not only linear tolerances but also geometric features like flatness, parallelism, perpendicularity, and cylindricity.

- Achieving high dimensional accuracy in SiC composites involves meticulous control over each manufacturing step, from powder preparation and green body formation to the firing/infiltration cycle and final machining.

- Advanced metrology equipment, such as Coordinate Measuring Machines (CMMs), optical comparators, and surface profilometers, is essential for verifying dimensional accuracy and surface finish.

Key Considerations for Procurement and Engineering:

- Specify Only What is Necessary: Over-specifying tolerances and surface finishes dramatically increases manufacturing costs and lead times due to the difficulty of machining SiC. Analyze the functional requirements of the part carefully.

- Consult with Supplier Early: Discuss your dimensional and surface finish requirements with your SiC composite supplier during the design phase. They can provide guidance on what is practically and economically achievable with their processes.

- Factor in Machining Costs: Remember that achieving tight tolerances on hard SiC composites is primarily a machining challenge. The more material that needs to be removed and the finer the finish, the higher the cost.

By understanding these aspects of precision, companies can effectively specify and procure SiC composite components that meet their performance needs without incurring unnecessary expenses.

Enhancing Performance: Post-Processing for SiC Composites

While as-manufactured Silicon Carbide (SiC) composite components possess many exceptional properties, various post-processing treatments can be applied to further enhance their performance, durability, or suitability for specific applications. These steps are often critical for meeting stringent operational demands and can range from precision machining to specialized surface treatments.

Common post-processing needs for SiC wear resistance and other performance enhancements include:

- Precision Grinding and Lapping:

- Purpose: To achieve tight dimensional tolerances, specific geometric features (flatness, parallelism), and desired surface finishes. SiC’s extreme hardness necessitates the use of diamond abrasives.

- Process: Grinding typically uses diamond wheels to remove material and shape the part. Lapping involves using a loose diamond abrasive slurry between the part and a lap plate to achieve very fine surface finishes and high flatness.

- Benefit: Critical for components like seals, bearings, semiconductor wafer chucks, and optical elements where precision is paramount.

- Polishing:

- Purpose: To achieve an ultra-smooth, often mirror-like surface finish, minimizing friction, wear, or light scattering.

- Process: A finer version of lapping, using extremely fine diamond particles or other specialized polishing compounds.

- Benefit: Essential for optical components, high-performance bearings, and some medical device applications.

- Edge Chamfering/Radiusing:

- Purpose: To remove sharp edges which can be prone to chipping in brittle materials like SiC composites, and to reduce stress concentrations.

- Process: Can be done via grinding or specialized tooling.

- Benefit: Improves handling safety, component robustness, and durability by preventing crack initiation.

- Cleaning:

- Purpose: To remove any contaminants, machining residues, or particulates from the surface, especially crucial for high-purity applications like semiconductor processing or medical devices.

- Process: May involve ultrasonic cleaning in specialized solvents, deionized water rinses, and controlled drying environments.

- Benefit: Ensures component purity and prevents contamination in sensitive processes.

- Sealing/Impregnation:

- Purpose: Some SiC composites, particularly certain grades of Reaction-Bonded SiC or those with inherent porosity, might be sealed or impregnated to reduce permeability, enhance chemical resistance, or improve mechanical properties.

- Process: Involves infiltrating the pores with materials like resins, glass, or other ceramics. For example, free silicon in RB-SiC essentially fills pores.

- Benefit: Reduces gas/liquid permeability, improves resistance to chemical attack, and can increase strength.

- Coatings:

- Purpose: To add functionalities not inherent to the base SiC composite, such as enhanced oxidation resistance at very high temperatures (e.g., environmental barrier coatings – EBCs for SiC/SiC CMCs), improved biocompatibility, or specific tribological properties.

- Process: Techniques include Chemical Vapor Deposition (CVD), Physical Vapor Deposition (PVD), or slurry coatings followed by heat treatment.

- Benefit: Extends the operational range and lifespan of SiC composites in extremely harsh environments or provides specialized surface properties. For instance, an EBC can protect SiC fibers in a CMC from oxidation and water vapor attack in gas turbine engines.

- Annealing/Heat Treatment:

- Purpose: To relieve internal stresses induced during manufacturing or machining, or to modify the microstructure for specific properties.

- Process: Controlled heating and cooling cycles in specific atmospheres.

- Benefit: Can improve mechanical stability and consistency of the material.

The selection of appropriate post-processing steps is driven by the final application requirements and the specific grade of SiC composite used. Careful planning and execution of these processes are vital to realizing the full potential of these advanced materials and often require specialized expertise and equipment.

Navigating Challenges in SiC Composite Fabrication and Use

Despite their superior properties, Silicon Carbide (SiC) composites present certain challenges in their fabrication and application. Understanding these hurdles is essential for engineers and manufacturers to effectively design, produce, and implement SiC composite components, ensuring optimal performance and reliability. Mitigating these challenges often involves careful material selection, design optimization, and specialized manufacturing expertise.

Common challenges and strategies to overcome them include:

- Brittleness and Fracture Toughness:

- Challenge: While composites (especially fiber-reinforced CMCs) are significantly tougher than monolithic SiC, they are still more brittle than metals. Susceptibility to catastrophic failure from impact or flaws can be a concern.

- Mitigation:

- Employ toughening mechanisms like fiber reinforcement (e.g., SiC/SiC CMCs), whisker reinforcement, or duplex microstructures.

- Design components to minimize stress concentrations (e.g., rounded corners, gradual thickness changes).

- Implement rigorous quality control and non-destructive testing (NDT) to detect cr

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.