Powering Precision: The Essential Role of Custom Silicon Carbide in Vacuum Furnaces

Share

In the realm of high-performance industrial applications, the synergy between advanced materials and cutting-edge equipment is paramount. Vacuum furnaces, critical for processes demanding controlled atmospheres and extreme temperatures, rely heavily on components that can withstand these harsh conditions. Among the array of technical ceramics, silicon carbide (SiC) stands out as a material uniquely suited for these demanding environments. Its exceptional thermal conductivity, superior strength at high temperatures, and resistance to wear and chemical attack make custom silicon carbide products indispensable for optimizing vacuum furnace performance, longevity, and efficiency. This is particularly true for industries ranging from semiconductor manufacturing and aerospace to energy and industrial heat treatment, where precision and reliability are non-negotiable. As procurement managers, engineers, and technical buyers seek robust solutions, understanding the nuances of SiC and its application in vacuum furnaces becomes crucial for making informed decisions that impact operational excellence and cost-effectiveness.

The demand for custom silicon carbide components is driven by the need for tailored solutions that meet specific operational parameters. Standard off-the-shelf parts may not always suffice for the intricate and varied designs of modern vacuum furnaces. This is where specialized manufacturers, capable of producing bespoke SiC parts, play a vital role. These parts, including heating elements, thermocouple protection tubes, setters, beams, and liners, are engineered to enhance thermal uniformity, reduce contamination, and extend maintenance intervals, thereby boosting overall productivity. For wholesale buyers and OEMs, sourcing high-quality, application-specific SiC ceramics is key to delivering reliable and efficient industrial furnace systems.

The Indispensable Partnership: Silicon Carbide and Vacuum Furnace Technology

Vacuum furnaces are sophisticated pieces of equipment designed to perform heat treatment processes, sintering, brazing, and degassing in a controlled, oxygen-free (or low-oxygen) environment. This controlled atmosphere is crucial for preventing oxidation and contamination of the processed materials, which is particularly important in industries like semiconductor fabrication, aerospace component manufacturing, and medical device production. The core of a vacuum furnace’s capability lies in its ability to achieve and maintain high temperatures, often exceeding 1200∘C and sometimes reaching well above 2000∘C, while ensuring a stable vacuum level.

The operational environment within a vacuum furnace is incredibly demanding. Key challenges include:

- Extreme Temperatures: Materials used must maintain their structural integrity and mechanical properties at very high temperatures.

- Rapid Thermal Cycling: Components are often subjected to rapid heating and cooling rates, which can induce thermal shock and lead to material failure if not properly managed.

- Vacuum Integrity: Materials must have low outgassing characteristics to maintain the required vacuum levels and prevent contamination of the processed goods.

- Chemical Compatibility: Resistance to process gases, by-products, and the materials being treated is essential to avoid degradation and ensure a long service life.

- Mechanical Stress: Components like supports, hearths, and fixtures must bear significant loads at elevated temperatures without deforming or breaking.

Silicon carbide, with its remarkable portfolio of properties, directly addresses these challenges. Its high sublimation temperature, excellent thermal shock resistance, low vapor pressure, and chemical inertness make it an ideal candidate for constructing critical internal components of vacuum furnaces. Furthermore, the ability to customize SiC parts allows for designs that optimize heat distribution, gas flow, and mechanical support within the furnace chamber, leading to improved process outcomes and operational efficiency. This makes advanced SiC materials a cornerstone in the advancement of high-temperature vacuum furnace technology.

At Sicarb Tech, located in Weifang City, the heart of China’s silicon carbide manufacturing hub, we have been at the forefront of SiC production technology since 2015. Our deep understanding of material science, coupled with state-of-the-art manufacturing processes, allows us to provide custom SiC solutions that meet the stringent requirements of vacuum furnace applications worldwide. Leveraging the scientific prowess of the Chinese Academy of Sciences , SicSino is more than just a supplier; we are a technology partner dedicated to advancing the capabilities of industrial thermal processing equipment.

Unlocking Performance: Why Silicon Carbide is the Material of Choice for Vacuum Furnace Components

The selection of materials for vacuum furnace construction is a critical decision that directly impacts performance, reliability, and operational costs. While various refractory metals and ceramics are used, silicon carbide (SiC) consistently emerges as a superior choice for many critical components, particularly in applications demanding high temperatures, chemical stability, and wear resistance. The unique combination of properties inherent in SiC makes it an invaluable asset for engineers and procurement professionals aiming to enhance their high-temperature processing capabilities.

The advantages of using silicon carbide in vacuum furnaces are multifaceted:

- Exceptional High-Temperature Strength: Unlike many metals that soften significantly at elevated temperatures, SiC retains a high degree of mechanical strength even above 1400∘C. This allows for the design of robust structural components, such as SiC beams and supports, that can bear loads without sagging or deforming, ensuring the stability of the workload.

- Superior Thermal Conductivity: SiC exhibits excellent thermal conductivity, which is crucial for achieving uniform temperature distribution within the furnace hot zone. This leads to more consistent product quality and can reduce cycle times. SiC heating elements benefit greatly from this property, allowing for efficient energy transfer and rapid heating.

- Outstanding Thermal Shock Resistance: Vacuum furnace operations often involve rapid temperature changes. SiC’s low coefficient of thermal expansion and high thermal conductivity contribute to its exceptional resistance to thermal shock, preventing cracking and extending component life. This is particularly important for custom SiC furnace furniture that undergoes frequent cycling.

- Excellent Chemical Inertness and Corrosion Resistance: Silicon carbide is highly resistant to attack from most acids, alkalis, and process gases commonly encountered in vacuum furnace environments. This minimizes contamination of the processed materials and prolongs the lifespan of SiC liners and process tubes.

- High Wear and Abrasion Resistance: For applications involving moving parts or contact with abrasive materials, the inherent hardness of SiC provides excellent wear resistance. This is beneficial for components like SiC nozzles and wear parts used in specific vacuum processes.

- Low Outgassing and Vapor Pressure: Maintaining a high-quality vacuum is essential. SiC has very low vapor pressure and minimal outgassing characteristics at high temperatures, contributing to a cleaner furnace environment and more stable vacuum levels. This makes it a preferred material over graphite in certain sensitive applications where carbon contamination is a concern.

- Electrical Properties: Depending on the grade and manufacturing process, SiC can be tailored to have specific electrical resistivity. This allows it to be used effectively as both an electrical insulator in some forms and as a resistive heating element in others (e.g., Globar-type SiC heaters).

The table below highlights a comparison of SiC with other common materials used in vacuum furnace construction:

| Property | Silicon Carbide (SiC) | Graphite | Molybdenum (Mo) | Alumina (Al2O3) |

|---|---|---|---|---|

| Max Use Temp. (approx.) | 1400−1800∘C (grade dep.) | >2000∘C (inert atm.) | 1900∘C (vacuum) | 1700∘C |

| Thermal Conductivity | High | Very High | High | Moderate |

| Thermal Shock Resistance | Excellent | Good | Moderate | Fair |

| Chemical Inertness | Excellent | Good (non-oxidizing) | Fair (oxidizes) | Good |

| Mechanical Strength (Hot) | Excellent | Decreases > 2500∘C | Good | Fair |

| Outgassing | Very Low | Moderate to High | Low | Low |

| Cost Factor | Moderate to High | Low to Moderate | High | Moderate |

While graphite offers higher temperature capabilities in inert atmospheres, SiC provides a better overall balance of properties, especially when considering mechanical strength at temperature, oxidation resistance (in air-containing leaks or process steps), and lower particle generation. For technical buyers focused on long-term operational efficiency and reduced maintenance downtime, investing in high-purity SiC components often yields significant returns. Sicarb Tech specializes in producing various grades of SiC, including Reaction-Bonded Silicon Carbide (RBSiC/SiSiC) and Sintered Silicon Carbide (SSiC), tailored for the demanding needs of vacuum furnace OEMs and end-users.

Key Silicon Carbide Components in Vacuum Furnaces: Applications and Advantages

The versatility and exceptional properties of silicon carbide (SiC) make it suitable for a wide array of critical components within vacuum furnaces. These components are engineered to enhance performance, improve energy efficiency, and extend the operational life of the furnace system. For procurement managers in industrial manufacturing and engineers in aerospace or semiconductor sectors, understanding these specific applications is key to leveraging the full potential of advanced ceramic materials.

Here are some of the primary SiC components used in vacuum furnaces and their distinct advantages:

- SiC Heating Elements:

- Application: Provide the primary source of heat within the furnace. Common types include rod, spiral, and U-shaped elements.

- Advantages: Capable of reaching very high temperatures (e.g., SSiC elements can operate efficiently up to 1600∘C or higher in controlled atmospheres). They offer long service life, high electrical stability, and excellent resistance to thermal shock and chemical attack. Compared to metallic elements, SiC heaters can often provide higher power densities and faster ramp rates. Custom SiC heating elements can be designed for optimal heat distribution in specific furnace geometries.

- SiC Beams, Supports, and Rollers:

- Application: Used to support the workload (products being heat-treated) within the furnace hot zone. This includes setter plates, crucibles, beams, and rollers in continuous furnaces.

- Advantages: High hot strength and creep resistance ensure that these structural components maintain their integrity under load at extreme temperatures, preventing sagging or distortion. This dimensional stability is crucial for precise positioning of the workload. Their excellent thermal shock resistance withstands rapid temperature changes during loading and unloading. Reaction-bonded SiC (RBSiC) is often favored for these applications due to its good strength and cost-effectiveness for complex shapes.

- SiC Thermocouple Protection Tubes:

- Application: Shield thermocouples from the harsh furnace environment (high temperatures, corrosive gases, and mechanical impact) to ensure accurate temperature measurement and prolong thermocouple life.

- Advantages: SiC tubes offer rapid thermal response due to good thermal conductivity, along with superior protection against chemical corrosion and erosion. They are gas-tight, preventing contamination of the thermocouple and the furnace atmosphere. High-purity SiC grades are essential here.

- SiC Furnace Liners, Tiles, and Muffles:

- Application: Used to line the furnace chamber, creating a durable and chemically resistant hot zone. Muffles can create a separately controlled atmosphere within the main furnace chamber.

- Advantages: Protect the underlying insulation and furnace shell from direct heat radiation, chemical attack, and wear. SiC liners contribute to better temperature uniformity and can reflect heat back to the workload, improving energy efficiency. Their non-contaminating nature is vital for high-purity processes.

- SiC Nozzles and Burner Components:

- Application: In vacuum furnaces that may also operate with controlled gas atmospheres or for specific processes like gas quenching or carburizing.

- Advantages: Exceptional wear resistance, high-temperature strength, and thermal shock resistance make SiC ideal for nozzles that direct gas flow or for components in burner systems that might be used for initial heating phases or specific reactive processes.

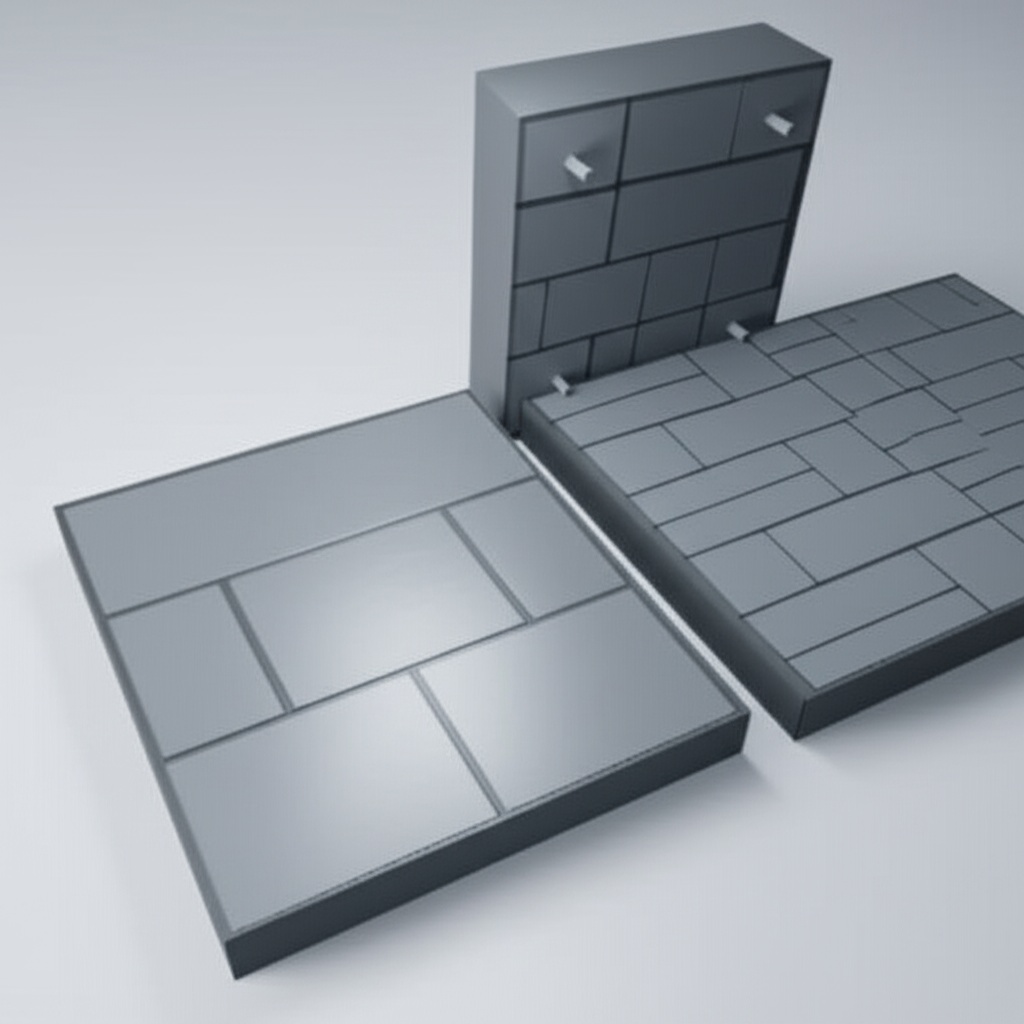

- SiC Setter Plates and Trays:

- Application: Flat components used to hold and separate products during heat treatment.

- Advantages: Provide a stable, flat surface that resists warping at high temperatures. Their good thermal conductivity promotes uniform heating of the product. They are durable and can withstand repeated thermal cycling. Custom SiC setters can be designed with specific patterns or features to accommodate unique product geometries.

The table below summarizes the key SiC components and their primary benefits in vacuum furnace applications:

| SiC Component | Primary Benefit(s) in Vacuum Furnaces | Recommended SiC Type(s) |

|---|---|---|

| Heating Elements | High operating temperature, long life, energy efficiency | SSiC, ReSiC (Recrystallized) |

| Beams, Supports, Rollers | High hot strength, creep resistance, thermal shock resistance | RBSiC (SiSiC), SSiC |

| Thermocouple Protection Tubes | Accurate temperature sensing, corrosion resistance, thermocouple longevity | SSiC, RBSiC (dense) |

| Furnace Liners/Tiles | Hot zone protection, temperature uniformity, chemical inertness | RBSiC, SSiC |

| Nozzles/Burner Components | Wear resistance, high-temperature stability, thermal shock resistance | SSiC, RBSiC |

| Setter Plates/Trays | Dimensional stability, uniform heating, durability | RBSiC, SSiC, Nitride-Bonded |

Sicarb Tech, with its comprehensive understanding of SiC material science and advanced ceramics manufacturing, excels in producing these diverse components. Our facility in Weifang, the hub of China’s silicon carbide industry, is equipped to handle complex customizations, ensuring that OEMs and industrial buyers receive SiC parts perfectly matched to their vacuum furnace designs and process requirements. We focus on delivering high-quality, cost-competitive custom silicon carbide components that drive performance and reliability in your high-temperature applications.

Optimizing Vacuum Furnace Performance with Custom SiC Designs

Standard, off-the-shelf silicon carbide components can serve many purposes, but to truly unlock the peak performance and efficiency of a vacuum furnace, custom SiC designs are often essential. The specific geometry of the furnace, the nature of the thermal processes, the type of workload, and the desired throughput all influence the optimal design of internal SiC components. Tailoring these parts allows engineers to address unique challenges and achieve superior results in high-temperature industrial applications.

Design considerations for custom SiC products in vacuum furnaces are critical for manufacturability, longevity, and functional effectiveness:

- Geometry and Complexity: While SiC can be formed into complex shapes, certain limitations exist depending on the manufacturing method (e.g., slip casting, extrusion, isopressing, reaction bonding, sintering). Early collaboration between the furnace designer and the SiC manufacturer, like Sicarb Tech, is crucial. We can advise on design modifications that maintain functionality while improving manufacturability and reducing costs. For instance, minimizing sharp internal corners or excessively thin sections can prevent stress concentrations and improve the robustness of custom SiC furnace furniture.

- Wall Thickness and Uniformity: Appropriate wall thickness is vital for mechanical strength, especially for load-bearing components like SiC beams and tubes. However, overly thick sections can reduce thermal shock resistance and increase material costs. Achieving uniform wall thickness is also important for consistent heating and stress distribution.

- Stress Points and Load Distribution: Identifying potential stress concentration points in the design is critical. Features like holes, notches, or abrupt changes in cross-section must be carefully considered. Designs should aim to distribute mechanical and thermal stresses as evenly as possible. For custom SiC support structures, this might involve incorporating fillets, ribs, or optimized support points.

- Thermal Management: Custom designs can significantly impact thermal uniformity and efficiency. For example, the placement and design of SiC heating elements can be optimized to direct heat precisely where it’s needed, reducing cold spots and improving temperature consistency across the workload. The design of SiC radiant tubes or muffles can also be tailored for specific heating profiles.

- Gas Flow Dynamics: In vacuum furnaces that utilize process gases for quenching, carburizing, or other reactive processes, the design of SiC components like gas inlet nozzles, baffles, or plenums can be customized to ensure optimal gas flow patterns, enhancing process efficiency and product uniformity.

- Interfacing with Other Materials: Consideration must be given to how SiC components will interface with other materials in the furnace, such as metallic supports or insulation. Differences in thermal expansion coefficients need to be accommodated to prevent stress buildup and potential failure. Custom mounting solutions or expansion joints may be required.

- Manufacturability and Cost: While complex designs are possible, they often come with higher manufacturing costs and potentially longer lead times. It’s a balance between ideal performance and practical, cost-effective production. Our team at SicSino works closely with clients to achieve designs for industrial SiC ceramics that are both high-performing and economically viable.

Engineering Tips for Custom SiC Design:

- Engage Early with Your SiC Supplier: Discuss your application and design concepts with experts like SicSino at the initial stages. Our experience in custom SiC fabrication can provide invaluable insights.

- Simplify Where Possible: Avoid unnecessary complexity if a simpler design can achieve the desired function.

- Consider the Manufacturing Process: The choice of SiC grade (RBSiC, SSiC, etc.) will influence design possibilities.

- Finite Element Analysis (FEA): For critical or complex components, FEA can be used to simulate thermal and mechanical stresses, helping to optimize the design and predict performance.

- Prototyping: For novel designs, creating prototypes can be beneficial for testing and validation before committing to large-scale production.

By leveraging custom-designed SiC components, technical buyers and engineers can achieve significant improvements in their vacuum furnace operations, including enhanced temperature uniformity, reduced cycle times, longer component life, and lower energy consumption. Sicarb Tech is dedicated to providing this level of customization, backed by the robust scientific and technological capabilities of the Chinese Academy of Sciences and our extensive experience within Weifang’s dynamic SiC industry.

Selecting the Right Grade of Silicon Carbide for Your Vacuum Furnace Application

Silicon carbide is not a one-size-fits-all material. It is available in several grades, each manufactured differently and possessing a unique set of properties that make it more suitable for specific applications within a vacuum furnace. Choosing the correct grade of SiC is paramount for ensuring optimal performance, longevity, and cost-effectiveness of your technical ceramic components. Procurement professionals and engineers must understand these distinctions to specify the most appropriate material for their high-temperature furnace systems.

The most common grades of silicon carbide used in industrial applications, including vacuum furnaces, are:

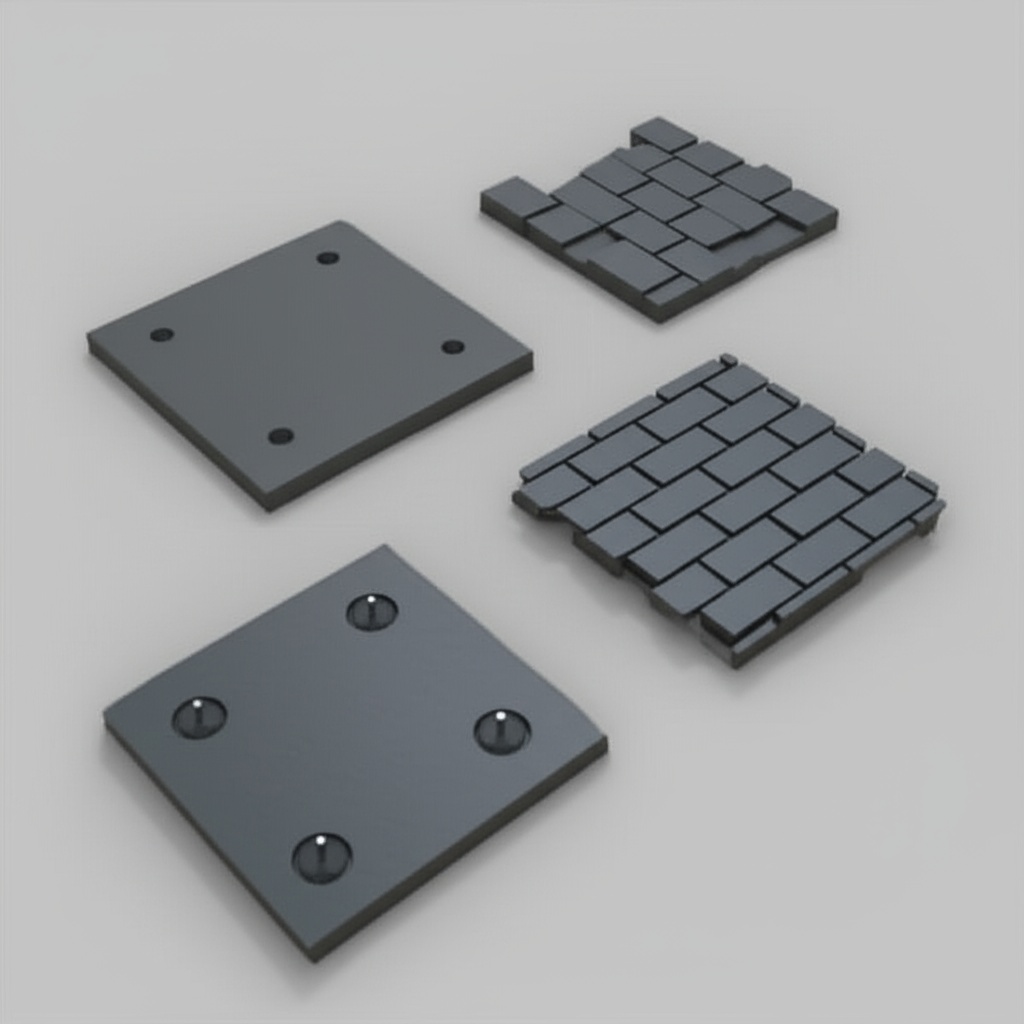

- Reaction-Bonded Silicon Carbide (RBSiC or SiSiC – Silicon Infiltrated Silicon Carbide):

- Manufacturing: Produced by infiltrating a porous preform, typically made of SiC grains and carbon, with molten silicon. The silicon reacts with the carbon to form new SiC, which bonds the original SiC grains. Some free silicon (typically 8-15%) remains in the final microstructure.

- Properties:

- Excellent thermal conductivity.

- Good wear resistance and high hardness.

- High strength, maintained up to the melting point of silicon ( 1410∘C).

- Good thermal shock resistance.

- Relatively easy to form into complex shapes with good dimensional accuracy.

- Cost-effective for larger and more intricate components.

- Vacuum Furnace Applications: Ideal for structural components like beams, rollers, plates, nozzles, thermocouple protection tubes, and larger furnace fixtures where operating temperatures generally stay below 1350−1380∘C. Often chosen for custom SiC furnace furniture.

- Considerations: The presence of free silicon limits its maximum service temperature. It may not be suitable for applications where silicon reactivity is a concern.

- Sintered Silicon Carbide (SSiC):

- Manufacturing: Produced by sintering fine SiC powder at very high temperatures (>2000∘C) with the aid of sintering additives (e.g., boron and carbon). This results in a dense, single-phase SiC material (typically >98% SiC).

- Properties:

- Superior high-temperature strength (maintains strength up to 1600−1800∘C).

- Excellent corrosion and chemical resistance, even against aggressive chemicals.

- High hardness and wear resistance.

- Good thermal shock resistance, though typically slightly less than RBSiC due to higher Young’s modulus.

- Higher purity than RBSiC.

- Vacuum Furnace Applications: Preferred for the most demanding applications, including high-temperature heating elements, critical wear parts, thermocouple tubes in highly corrosive environments, and components requiring maximum chemical purity and strength at temperatures above 1400∘C. Suitable for advanced SiC components in semiconductor processing.

- Considerations: Generally more expensive than RBSiC and can be more challenging to produce in very large or highly complex shapes.

- Nitride-Bonded Silicon Carbide (NBSiC):

- Manufacturing: SiC grains are bonded by a silicon nitride (Si3N4) phase.

- Properties:

- Good thermal shock resistance.

- Good resistance to wetting by molten non-ferrous metals.

- Moderate strength.

- Vacuum Furnace Applications: Less common for general vacuum furnace components but can be used for specific applications like handling molten metals or where its particular combination of properties is advantageous. Often used for kiln furniture in other industries.

- Recrystallized Silicon Carbide (ReSiC / R-SiC):

- Manufacturing: High-purity SiC grains are fired at very high temperatures (>2300∘C) causing them to bond together without additives or a secondary bonding phase. This results in a porous structure with interconnected SiC crystals.

- Properties:

- Excellent thermal shock resistance due to porosity and strong grain-to-grain bonding.

- Very high service temperature (up to 1650∘C or higher).

- Good chemical stability.

- Lower mechanical strength compared to dense SiC grades.

- Vacuum Furnace Applications: Used for applications where extreme thermal cycling is prevalent and high mechanical strength is not the primary concern, such as some types of kiln furniture, setters, and radiant heating tubes. Less common for load-bearing structural parts in high-vacuum environments due to porosity unless specifically designed.

The following table provides a general comparison of these primary SiC grades for vacuum furnace applications:

| Feature | RBSiC (SiSiC) | SSiC | NBSiC | ReSiC (R-SiC) |

|---|---|---|---|---|

| Max. Service Temp. | 1380∘C | 1600−1800∘C | 1400∘C | 1650∘C+ |

| Thermal Conductivity | Very Good | Good | Moderate | Good |

| Strength @ High Temp. | Good (up to Si melt point) | Excellent | Moderate | Fair |

| Thermal Shock Resistance | Excellent | Good | Very Good | Excellent |

| Chemical Resistance | Good (Si can be reactive) | Excellent | Good | Very Good |

| Relative Cost | Moderate | High | Moderate | Moderate to High |

| Porosity | Low (due to Si fill) | Very Low (Dense) | Moderate | Moderate to High |

| Typical Use Cases | Beams, supports, nozzles, plates | Heating elements, wear parts, high-purity applications | Molten metal contact, some setters | Extreme thermal cycling, setters |

Sicarb Tech: Your Partner for High-Performance SiC Vacuum Furnace Solutions

In the demanding world of high-temperature vacuum furnace technology, the quality and reliability of silicon carbide components are paramount. Choosing the right supplier is as critical as selecting the right material grade. Sicarb Tech stands as a premier partner for companies seeking custom silicon carbide products, leveraging a unique combination of advanced technology, strategic location, and a commitment to customer success.

Rooted in China’s SiC Heartland: SicSino is strategically situated in Weifang City, Shandong Province, which is widely recognized as the hub of China’s silicon carbide customizable parts manufacturing. This region hosts over 40 SiC production enterprises, accounting for more than 80% of the nation’s total output. Since 2015, SicSino has been instrumental in introducing and implementing advanced SiC production technology, fostering large-scale production and technological advancements within this vibrant industrial cluster. We haven’t just been a participant; we’ve been a catalyst and witness to the growth and development of the local SiC industry.

Leveraging the Strength of the Chinese Academy of Sciences : operates under the umbrella of the Chinese Academy of Sciences (Weifang) Innovation Park, an entrepreneurial park with close ties to the National Technology Transfer Center of the Chinese Academy of Sciences . This national-level innovation platform integrates research, technology transfer, venture capital, and incubation services. This unique backing provides SicSino with unparalleled access to the robust scientific and technological capabilities and talent pool of the Chinese Academy of Sciences. We serve as a crucial bridge, facilitating the seamless integration and commercialization of cutting-edge scientific achievements into practical, high-performance SiC products.

Unmatched Customization and Quality Assurance: Our core strength lies in our domestic top-tier professional team specializing in the customized production of silicon carbide products. We have a proven track record, with over ten local enterprises benefiting from our technologies. SicSino possesses a comprehensive suite of technologies, encompassing:

- Material Technology: Deep understanding of different SiC grades (RBSiC, SSiC, R-SiC, etc.) and their optimal application.

- Process Technology: Advanced forming, firing, and finishing techniques for complex geometries.

- Design Technology: Expertise in co-designing components with customers for optimal performance and manufacturability in vacuum furnace environments.

- Measurement & Evaluation Technology: Rigorous quality control to ensure every component meets stringent specifications.

- Integrated Process from Materials to Products: A holistic approach that ensures quality and efficiency at every stage.

This integrated capability allows us to meet diverse customization needs, offering higher-quality, cost-competitive customized silicon carbide components directly from the heart of China’s SiC manufacturing base. We are committed to providing reliable quality and supply assurance for wholesale buyers, technical procurement professionals, OEMs, and distributors globally.

Beyond Components: Turnkey Technology Transfer: SicSino’s commitment to the SiC industry extends beyond component supply. For businesses looking to establish their own specialized SiC production capabilities, we offer comprehensive technology transfer services. This includes:

- Professional silicon carbide production technology.

- Full-range turnkey project services:

- Factory design

- Procurement of specialized equipment

- Installation and commissioning

- Trial production support

This unique offering enables clients to build their own professional SiC products manufacturing plant with minimized investment risk, reliable technology transformation, and a guaranteed input-output ratio. This is particularly valuable for industrial manufacturing enterprises seeking to vertically integrate or establish local SiC production.

Why Partner with SicSino for Your Vacuum Furnace SiC Needs?

- Access to Leading SiC Technology: Benefit from Chinese Academy of Sciences -backed innovations.

- Expert Customization: Components tailored to your precise vacuum furnace specifications.

- Strategic Sourcing: Direct access to China’s SiC manufacturing hub for cost-effectiveness.

- Quality and Reliability: Rigorous quality control and a commitment to excellence.

- Comprehensive Support: From design consultation to potential technology transfer.

- Experienced Team: Decades of collective experience in SiC materials and applications.

For engineers designing next-generation vacuum furnaces or procurement managers seeking reliable, high-performance SiC heating elements, furnace furniture, or structural parts, Sicarb Tech offers a partnership built on expertise, innovation, and a deep commitment to quality. We empower your operations with silicon carbide solutions that deliver superior performance and lasting value.

Addressing Common Challenges in Utilizing SiC for Vacuum Furnaces

While silicon carbide (SiC) offers a multitude of advantages for vacuum furnace applications, like any advanced material, it comes with its own set of considerations and potential challenges. Understanding these and knowing how to mitigate them is crucial for engineers and operators to maximize the lifespan and performance of SiC furnace components. Collaborating with an experienced supplier like Sicarb Tech can provide valuable insights and solutions to overcome these hurdles.

Common challenges and mitigation strategies include:

- Brittleness and Fracture Toughness:

- Challenge: SiC is a ceramic material and is inherently more brittle than metals. It has lower fracture toughness, meaning it can be susceptible to cracking or chipping if subjected to sudden impacts, high localized stresses, or excessive mechanical shock during handling, installation, or operation.

- Mitigation Strategies:

- Careful Design: Avoid sharp corners and stress concentrators. Incorporate fillets and radii in designs. Ensure even load distribution. Sicarb Tech assists in designing for manufacturability and robustness.

- Proper Handling and Installation: Train personnel on correct procedures for handling and installing SiC components. Avoid dropping or banging parts. Use appropriate mounting fixtures that accommodate thermal expansion without imposing undue stress.

- Controlled Thermal Ramps: While SiC has excellent thermal shock resistance, extremely aggressive heating or cooling rates, especially for very large or complex parts, can still pose a risk. Program furnace controllers for smooth, controlled temperature changes where feasible.

- Grade Selection: Some SiC grades (e.g., certain RBSiC formulations or ReSiC) can offer better effective toughness or thermal shock resistance for specific profiles.

- Machining Complexity and Cost:

- Challenge: Due to its extreme hardness, machining SiC after firing (sintering or reaction bonding) is difficult, time-consuming, and expensive. It typically requires diamond tooling and specialized grinding techniques.

- Mitigation Strategies:

- Near-Net-Shape Manufacturing: Utilize forming processes (e.g., slip casting, isopressing, extrusion) that produce parts as close to the final desired dimensions as possible (“green machining” before firing is also an option). This minimizes the need for extensive post-firing machining. SicSino specializes in net-shape forming of SiC.

- Design for Manufacturability: Design components with machining requirements in mind. Simplify geometries where possible if tight tolerances are not globally needed. Specify tolerances only where critical.

- Supplier Expertise: Partner with suppliers like SicSino who have advanced machining capabilities and experience in minimizing machining costs through optimized processes for technical ceramics.

- Thermal Expansion Mismatch:

- Challenge: When SiC components are assembled with metallic parts (e.g., supports, flanges, electrical connectors) or other ceramics with different coefficients of thermal expansion (CTE), temperature changes can induce significant stresses at the interface, potentially leading to failure.

- Mitigation Strategies:

- Flexible Mounting: Design mounting systems that allow for differential expansion and contraction. This can include using spring-loaded fixtures, flexible connectors, or high-temperature gasketing materials.

- Graded Interfaces: In some advanced applications, functionally graded materials can be used to transition between materials with different CTEs, although this is complex and costly.

- Material Selection: Where possible, select interfacing materials with CTEs closer to that of SiC, or design the SiC component to accommodate the known expansion of the mating part.

- Oxidation at Very High Temperatures in Specific Atmospheres:

- Challenge: While generally resistant to oxidation due to the formation of a protective silica (SiO2) layer, under certain extreme conditions (e.g., very high temperatures >1600−1700∘C in the presence of oxygen or water vapor, or in “active oxidation” regimes at lower temperatures with low oxygen partial pressures), the SiO2 layer can become volatile (SiO gas), leading to material degradation. This is more of a concern for non-vacuum or partial vacuum processes with specific gas chemistries.

- Mitigation Strategies:

- Grade Selection: SSiC generally offers better oxidation resistance at higher temperatures than RBSiC (due to the absence of free silicon).

- Atmosphere Control: Ensure proper vacuum levels or controlled inert gas atmospheres to minimize oxidizing species.

- Protective Coatings: In some specialized cases, coatings can be applied to enhance oxidation resistance, though this adds complexity and cost.

- Operational Limits: Understand and operate within the recommended temperature and atmospheric limits for the specific SiC grade.

- Cost of High-Purity or Complex Components:

- Challenge: High-purity grades like SSiC and complex custom designs can be more expensive than standard components or other refractory materials.

- Mitigation Strategies:

- Value Engineering: Work with the supplier to optimize designs for cost-effectiveness without compromising essential performance. SicSino focuses on cost-competitive custom SiC solutions.

- Lifecycle Cost Analysis: Consider the total cost of ownership. While initial costs might be higher, the longer lifespan, reduced downtime, and improved process efficiency of high-quality SiC often lead to lower overall operational costs.

- Strategic Sourcing: Leveraging suppliers in manufacturing hubs like Weifang, where SicSino is based, can provide access to more competitive pricing due to economies of scale and specialized local expertise.

By proactively addressing these potential challenges through careful design, material selection, and collaboration with knowledgeable suppliers, users can fully harness the exceptional benefits of silicon carbide in their vacuum furnace operations. Sicarb Tech is committed to supporting its clients not only with high-quality SiC parts for industrial furnaces but also with the technical expertise to overcome application-specific challenges, ensuring successful and reliable performance.

Frequently Asked Questions (FAQ) about SiC in Vacuum Furnaces

Engineers, procurement managers, and technical buyers often have specific questions when considering silicon carbide (SiC) for their vacuum furnace applications. Here are answers to some common queries:

1. What is the maximum operating temperature for SiC components in a vacuum furnace?

The maximum operating temperature for SiC components depends heavily on the specific grade of silicon carbide and the furnace atmosphere.

- Reaction-Bonded Silicon Carbide (RBSiC or SiSiC): Generally limited to around 1350∘C to 1380∘C due to the presence of free silicon, which begins to melt above this range. In highly controlled, pure vacuum or inert atmospheres, slightly higher temperatures might be tolerated for short periods, but sustained operation above the silicon melting point will lead to degradation.

- Sintered Silicon Carbide (SSiC): Can typically operate at much higher temperatures, often up to 1600∘C to 1800∘C, and in some cases even higher for specialized grades in very clean, inert, or vacuum environments. SSiC offers excellent strength retention and stability at these elevated temperatures.

- Recrystallized Silicon Carbide (ReSiC): Can also be used at very high temperatures, often up to 1650∘C or more, particularly valued for its thermal shock resistance.

It’s crucial to consult with your SiC supplier, like Sicarb Tech, to determine the appropriate grade and its specific temperature limitations for your vacuum furnace’s operating conditions and atmosphere. Factors like ramp rates, cycle duration, and presence of reactive gases also play a role.

2. How does the cost of SiC components compare to other materials like graphite or molybdenum for vacuum furnaces?

The cost comparison is nuanced and depends on the specific component, its complexity, size, and the grade of material:

- Graphite: Generally, graphite is less expensive than most SiC grades, especially for simpler shapes and larger components. However, graphite can outgas more, may not be suitable for all atmospheres (can react with certain materials or introduce carbon contamination), and typically has lower mechanical strength than SiC, especially in thinner sections or at points of stress.

- Molybdenum (Mo): Molybdenum is a refractory metal and is typically significantly more expensive than most grades of SiC and graphite. While it offers excellent high-temperature strength in vacuum or reducing atmospheres, it oxidizes readily in the presence of even trace amounts of oxygen, requiring very high vacuum integrity or hydrogen atmospheres. Machining molybdenum can also be costly.

- Silicon Carbide (SiC):

- RBSiC (SiSiC): Offers a good balance of performance and cost, often being more cost-effective than SSiC for larger or more complex shapes where its temperature limit is acceptable. It is generally more expensive than graphite but can be less expensive than molybdenum.

- SSiC: Is a premium grade and typically the most expensive among common SiC types due to the higher processing temperatures and finer raw materials. However, its superior performance (higher temperature capability, better chemical resistance, higher purity) can justify the cost in demanding applications, potentially leading to longer life and reduced overall operational costs compared to frequent replacement of cheaper materials.

When evaluating costs, it’s essential to consider the total cost of ownership (TCO), which includes initial price, component lifespan, maintenance requirements, impact on process yield and quality, and potential downtime. Custom SiC components from a knowledgeable supplier like SicSino, even if initially more expensive than some alternatives, can offer better long-term value in many high-temperature industrial applications due to their durability and performance.

3. Can SiC components be repaired if they are damaged in a vacuum furnace?

Repairing damaged silicon carbide components is generally very difficult and often not feasible or economically viable, especially for cracks or significant fractures. SiC is a brittle ceramic, and attempts to weld or patch it typically do not restore its original strength or integrity, particularly for high-stress or high-temperature applications within a vacuum furnace.

- Minor Chips or Surface Damage: Sometimes, minor chips on non-critical surfaces might be ground or smoothed out, but this depends heavily on the location and extent of the damage and whether it compromises the component’s function or structural integrity.

- Cracks or Fractures: These are usually non-repairable. A cracked SiC heating element, for instance, will likely have altered electrical properties and be prone to complete failure. A cracked structural beam will lose its load-bearing capacity.

- Devitrification or Surface Degradation: In some cases of surface chemical attack or degradation, if it’s very superficial, some level of re-surfacing might be technically possible but is rarely practical.

Prevention is key:

- Proper design to minimize stress concentrations.

- Careful handling and installation.

- Operating the furnace within the specified limits for the SiC components.

- Choosing the right SiC grade for the application’s thermal and chemical environment.

If a custom SiC part is damaged, replacement is the most common and reliable solution. Working with a supplier like Sicarb Tech ensures access to timely replacements and expert advice on preventing future damage through optimized design or material selection for your SiC furnace equipment. We also help analyze failures to recommend improvements.

Conclusion: Elevating Industrial Processes with Custom Silicon Carbide

The relentless pursuit of efficiency, precision, and reliability in demanding industrial environments necessitates the use of materials that can push the boundaries of performance. Custom silicon carbide has firmly established itself as a cornerstone material for vacuum furnaces, enabling operations at higher temperatures, with greater chemical stability, and superior mechanical robustness. From SiC heating elements that deliver uniform and efficient heat, to durable SiC furnace furniture that withstands extreme thermal cycling and mechanical loads, the contributions of this advanced ceramic are undeniable.

For technical buyers, engineers, and OEMs in sectors like semiconductors, aerospace, energy, and high-temperature manufacturing, partnering with a knowledgeable and capable SiC supplier is crucial. Sicarb Tech, situated in Weifang, the epicenter of China’s SiC industry, and backed by the formidable research capabilities of the Chinese Academy of Sciences, offers more than just components. We provide tailored solutions, deep material expertise, and a commitment to quality that translates into tangible benefits for your operations: enhanced productivity, reduced downtime, and improved end-product quality. Our ability to deliver high-quality, cost-competitive custom silicon carbide components and even facilitate turnkey SiC production technology transfer makes us a unique and valuable partner in the global advanced ceramics market.

By understanding the diverse grades of SiC, embracing optimized design principles, and choosing a supplier dedicated to innovation and customer success, industries can continue to leverage the exceptional properties of custom silicon carbide to drive progress and achieve new levels of performance in their most critical thermal processes.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.