Mastering Quality and Performance: The Indispensable Role of Silicon Carbide Testing Equipment

Share

In the demanding landscape of modern industry, the pursuit of materials that offer superior performance, durability, and efficiency is relentless. Silicon Carbide (SiC) has emerged as a frontrunner, a technical ceramic prized for its exceptional properties. From the heart of semiconductor manufacturing to the extreme conditions of aerospace engineering and high-temperature furnaces, custom SiC components are pivotal. However, to unlock the full potential of SiC and ensure the reliability of these critical parts, rigorous testing is not just recommended—it’s imperative. This is where silicon carbide testing equipment plays a crucial role, acting as the gatekeeper of quality and the enabler of innovation.

For engineers, procurement managers, and technical buyers in sectors like energy solutions, industrial manufacturing, and automotive (especially EV technology), understanding the nuances of SiC testing is paramount. It’s about guaranteeing that the custom SiC products specified and procured will perform flawlessly under the toughest conditions. This blog post delves into the world of SiC testing equipment, exploring its importance, the types of equipment available, key parameters evaluated, and how to navigate the selection process, ensuring that your SiC components meet the highest standards of quality and performance. As a key player in the SiC industry, Sicarb Tech leverages its deep understanding of SiC material science and production, including comprehensive testing and evaluation, to deliver superior custom SiC solutions.

Introduction – What is Silicon Carbide Testing Equipment and Why is it Crucial for Quality Assurance?

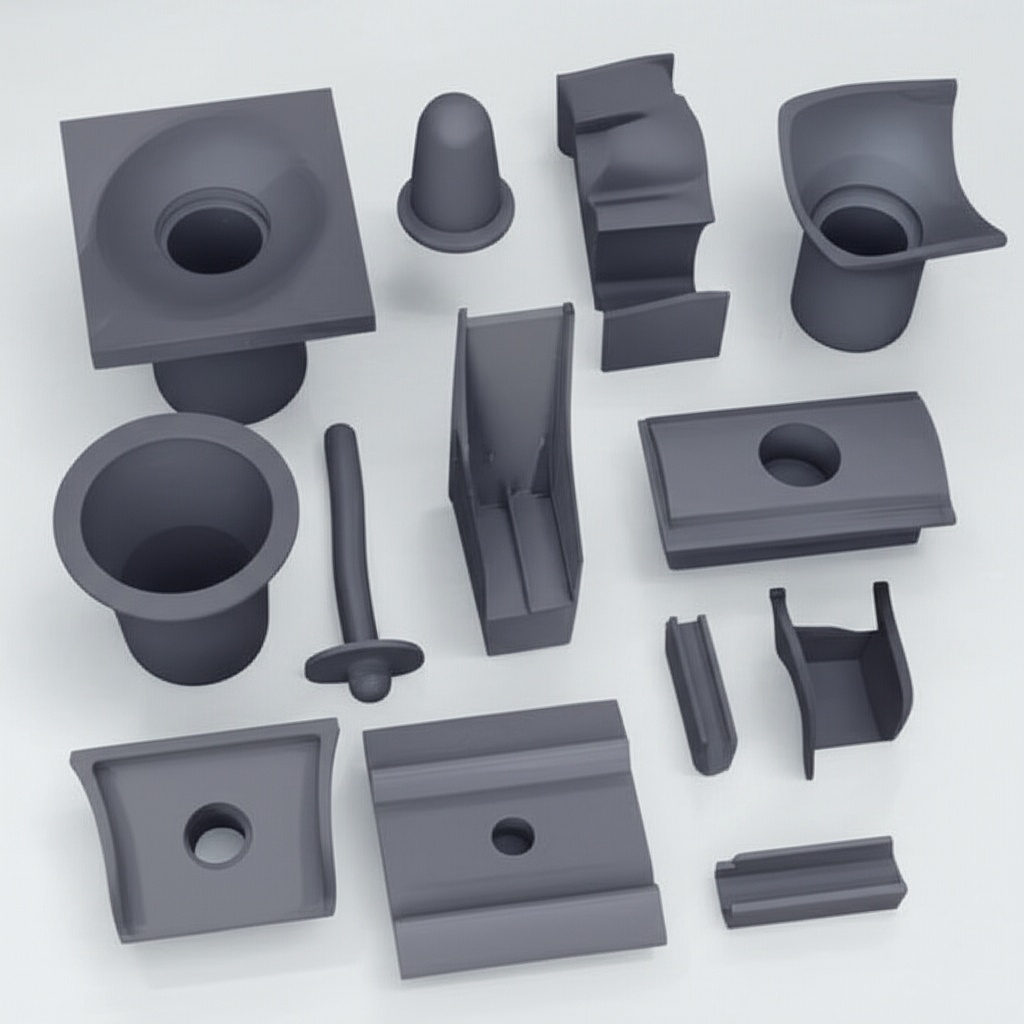

Silicon carbide testing equipment encompasses a range of specialized instruments and systems designed to evaluate the mechanical, thermal, electrical, and chemical properties of SiC materials and components. Given that SiC is often used in applications where failure is not an option, this equipment is vital for quality assurance (QA) and quality control (QC) at various stages – from raw material inspection and process validation during manufacturing to final product verification and in-service performance monitoring.

The criticality of this testing stems from the inherent nature of ceramic materials like SiC. While incredibly strong and resilient in many aspects, their performance can be significantly affected by minute flaws, variations in microstructure, or inconsistencies in the manufacturing process. For wholesale buyers, OEMs, and distributors relying on custom silicon carbide parts, robust testing provides the confidence that components will exhibit:

- Consistent Material Properties: Ensuring each batch of SiC meets the specified hardness, density, and purity.

- Reliable Performance: Validating that components can withstand the operational stresses, temperatures, and electrical loads of their intended application.

- Dimensional Accuracy: Confirming that parts adhere to strict design tolerances, crucial for complex assemblies.

- Longevity and Durability: Assessing resistance to wear, corrosion, and thermal shock, predicting lifespan in demanding environments.

In essence, SiC testing equipment underpins the reliability and safety of end-products. It helps manufacturers like those in Weifang City, the hub of China’s SiC customizable parts manufacturing, to refine their processes and enables end-users to integrate SiC components with assurance. Sicarb Tech, having played a significant role in the technological advancement of this region since 2015, understands that meticulous testing is inseparable from high-quality SiC production. Our expertise, backed by the Chinese Academy of Sciences, ensures that the SiC products sourced through us or manufactured with our technological support meet the most stringent quality benchmarks, partly due to a profound understanding of material characterization and testing.

Key Applications Requiring Rigorous SiC Testing – Industries and Use Cases

The exceptional properties of silicon carbide—high hardness, excellent thermal conductivity, superior wear resistance, chemical inertness, and high-temperature stability—make it a material of choice across a diverse range of demanding industrial applications. Consequently, rigorous testing of SiC components is non-negotiable in these sectors to ensure safety, reliability, and optimal performance. Industrial procurement professionals and technical buyers should be aware of these applications to appreciate the level of quality control required.

Here are some key industries and specific use cases where meticulous SiC testing is indispensable:

- Semiconductor Manufacturing:

- Wafer Handling and Processing Equipment: SiC components like wafer chucks, focus rings, and edge rings are used in plasma etch chambers and chemical vapor deposition (CVD) systems. Testing ensures dimensional stability, purity (to prevent contamination), and resistance to corrosive gases and high temperatures. Semiconductor-grade SiC demands the highest level of scrutiny.

- CMP (Chemical Mechanical Planarization): SiC polishing carriers and conditioning disks require testing for wear resistance and surface finish to ensure uniform wafer planarization.

- High-Temperature Processing:

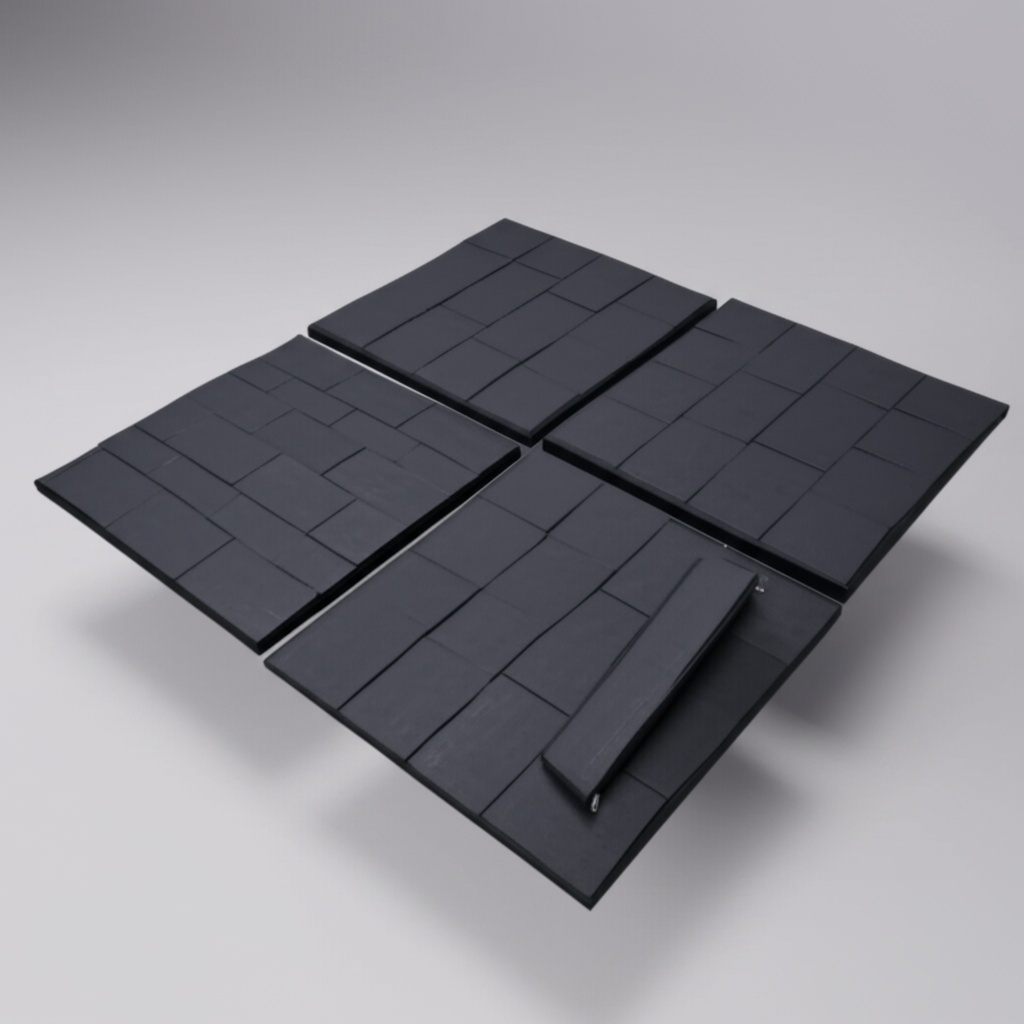

- Furnace Components: Kiln furniture, beams, rollers, thermocouple protection tubes, and burner nozzles made from SiC are used in industrial furnaces operating at extreme temperatures (e.g., for ceramics firing, metal heat treatment). Testing for thermal shock resistance, creep resistance, and high-temperature strength is critical.

- Heating Elements: SiC heating elements must be tested for electrical resistivity, stability at high temperatures, and resistance to oxidation to ensure efficient and long-lasting performance.

- Aerospace and Defense:

- Mirror Substrates: Lightweight SiC mirrors for telescopes and optical systems require testing for dimensional stability over wide temperature ranges, low thermal expansion, and polishability to achieve precise optical surfaces.

- Armor Components: SiC ceramics are used in ballistic protection. Testing for fracture toughness and impact resistance is vital.

- Nozzles and Thruster Components: Components exposed to high-velocity hot gases need testing for erosion resistance and thermal stability.

- Energy Sector:

- Power Electronics: SiC-based MOSFETs, diodes, and power modules are revolutionizing power conversion due to their high efficiency, switching frequency, and operating temperature capabilities. Rigorous electrical testing (breakdown voltage, on-state resistance, switching characteristics) and thermal cycling tests are essential for applications like EV inverters, solar power inverters, and industrial motor drives.

- Heat Exchangers: SiC tubes and plates in heat exchangers for corrosive and high-temperature environments require testing for thermal conductivity, pressure resistance, and chemical compatibility.

- Industrial Manufacturing and Wear Parts:

- Mechanical Seals and Bearings: Used in pumps and rotating equipment handling abrasive or corrosive fluids. Testing for wear resistance, friction coefficient, and chemical inertness is key.

- Nozzles for Abrasive Blasting or Fluid Handling: Require testing for erosion resistance and dimensional stability.

- Cutting Tools and Grinding Wheels: Though not always custom components in the same vein, the base SiC material undergoes stringent testing for hardness and toughness.

- Automotive (Beyond EV Power Electronics):

- Diesel Particulate Filters (DPFs): Porous SiC is used for DPFs. Testing focuses on porosity, filtration efficiency, and thermal shock resistance during regeneration cycles.

- Brake Discs: High-performance SiC ceramic matrix composites (CMCs) for brake discs require extensive testing for friction, wear, and thermal stability.

The following table summarizes key SiC applications and the critical testing parameters:

| Industry Sector | SiC Component Examples | Key Testing Parameters | Why Testing is Critical |

|---|---|---|---|

| Semiconductor | Wafer chucks, focus rings, CMP carriers | Purity, dimensional stability, wear resistance, electrical resistivity, thermal conductivity | Prevent wafer contamination, ensure process uniformity, and equipment longevity |

| High-Temperature | Kiln furniture, burner nozzles, heating elements | Thermal shock resistance, creep resistance, high-temperature strength, oxidation resistance, electrical stability | Ensure furnace reliability, energy efficiency, and safety at extreme temperatures |

| Aerospace & Defense | Mirrors, armor, rocket nozzles | Dimensional stability, thermal expansion, fracture toughness, impact resistance, erosion resistance | Mission-critical performance, structural integrity under harsh conditions |

| Energy (Power Electronics) | MOSFETs, diodes, power modules | Breakdown voltage, on-state resistance (R_DS(on)), switching speed, thermal impedance, reliability under cycling | Ensure efficiency, prevent device failure in high-power, high-frequency applications |

| Industrial Wear Parts | Mechanical seals, bearings, nozzles | Wear resistance, hardness, friction coefficient, chemical inertness, erosion resistance | Maximize operational life, reduce downtime, and maintain process integrity |

| Automotive | Diesel Particulate Filters (DPFs), high-performance brakes | Porosity, filtration efficiency, thermal shock resistance (DPF); friction, wear, thermal stability (brakes) | Meet emissions standards, ensure vehicle safety and performance |

Why Invest in Advanced SiC Testing Equipment? – Benefits for Manufacturers and End-Users

Investing in, or partnering with suppliers who utilize, advanced silicon carbide testing equipment offers substantial benefits for both manufacturers of SiC components and the end-users who integrate them into their systems. For procurement managers and technical buyers, understanding these benefits reinforces the value of sourcing from suppliers who prioritize robust quality control and material characterization.

Benefits for SiC Component Manufacturers:

- Enhanced Product Quality and Consistency:

- Advanced testing allows for tighter control over manufacturing processes, leading to more consistent material properties and component dimensions. This reduces batch-to-batch variability, a critical factor for OEMs requiring reliable SiC wholesale supplies.

- Early detection of defects or deviations from specifications prevents substandard products from reaching customers, safeguarding the manufacturer’s reputation.

- Process Optimization and Yield Improvement:

- Data from testing equipment can provide valuable insights into how different process parameters (e.g., sintering temperature, pressure, raw material purity) affect the final product. This enables manufacturers to optimize their processes for higher yields and reduced waste.

- For instance, understanding the impact of specific impurities on electrical performance can lead to adjustments in raw material sourcing or purification steps.

- Accelerated Research and Development (R&D):

- When developing new SiC grades or custom components with unique geometries, advanced testing equipment is indispensable for characterizing new materials and validating designs quickly and accurately.

- This speeds up the innovation cycle, allowing manufacturers to bring new custom SiC solutions to market faster.

- Reduced Manufacturing Costs in the Long Run:

- While the initial investment in testing equipment can be significant, it often leads to long-term cost savings by minimizing scrap rates, reducing rework, preventing costly field failures, and improving overall production efficiency.

- Meeting Stringent Industry Standards and Customer Specifications:

- Many industries, such as aerospace, automotive, and semiconductor, have rigorous standards (e.g., ASTM, ISO, SEMI) that SiC components must meet. Advanced testing equipment ensures compliance and provides the necessary documentation.

- It also allows manufacturers to confidently meet the specific and often demanding requirements of technical procurement professionals.

Benefits for End-Users (Engineers, OEMs, System Integrators):

- Increased Reliability and Lifespan of End-Products:

- Using SiC components that have undergone thorough testing significantly reduces the risk of premature failure in the final application. This leads to more reliable systems, longer operational life, and reduced warranty claims.

- For example, an EV manufacturer using well-tested SiC power modules can expect better inverter reliability and longevity.

- Improved System Performance and Efficiency:

- Precisely characterized SiC components perform as expected, contributing to the overall efficiency and performance of the system. For instance, SiC with consistently low electrical resistance (R_DS(on)) in power devices directly translates to lower energy losses.

- Reduced Risk of System Downtime and Maintenance Costs:

- Reliable components mean fewer unexpected breakdowns, leading to less system downtime and lower maintenance expenses. This is particularly crucial in industrial manufacturing and energy generation, where downtime can be extremely costly.

- Greater Confidence in Design and Innovation:

- Engineers can design systems with greater confidence when they know the SiC components they are using have been rigorously tested and meet precise specifications. This allows for more ambitious designs and the adoption of SiC in even more demanding applications.

- Simplified Incoming Quality Control (IQC):

- While end-users may still perform some IQC, sourcing from suppliers with robust testing regimes can reduce the burden and complexity of their own inspection processes.

- Stronger Supplier Partnerships:

- Working with suppliers like Sicarb Tech, who prioritize and invest in advanced testing and leverage a deep scientific understanding from the Chinese Academy of Sciences, fosters trust and leads to stronger, more collaborative partnerships focused on quality and innovation. Our role in developing the SiC industry in Weifang includes embedding such quality-centric approaches.

The investment in advanced SiC testing is not merely an operational expense; it’s a strategic imperative that drives quality, innovation, and reliability throughout the SiC value chain. It ensures that technical ceramics suppliers can confidently stand behind their products, and end-users can build systems that push the boundaries of performance.

Types of Silicon Carbide Testing Equipment and Their Functions – Mechanical, Thermal, Electrical, and Non-Destructive Testing (NDT)

To comprehensively evaluate silicon carbide and ensure its suitability for demanding applications, a variety of testing equipment is employed. These instruments are designed to assess specific properties under controlled conditions. Technical buyers and engineers specifying custom SiC components should have a general understanding of these test categories to appreciate the depth of quality control involved.

The main categories of SiC testing equipment include:

Mechanical Testing Equipment: This equipment evaluates the material’s response to applied forces, determining its strength, hardness, and resistance to fracture.

- Universal Testing Machines (UTMs):

- Function: Used for tensile, compressive, flexural (bending), and shear strength testing. For SiC, flexural strength (e.g., 3-point or 4-point bend tests) is commonly measured due to its brittle nature.

- Parameters Measured: Flexural strength (Modulus of Rupture – MOR), compressive strength, tensile strength (less common for bulk ceramics but important for fibers/composites), Young’s modulus (stiffness).

- Importance: Ensures the SiC component can withstand mechanical loads expected in its application without fracturing or deforming excessively.

- Hardness Testers:

- Function: Measure the resistance of SiC to localized plastic deformation (indentation or scratching). Common methods include Vickers and Knoop hardness tests.

- Parameters Measured: Hardness value (e.g., HV, HK). SiC is one of the hardest known materials.

- Importance: Critical for wear-resistant applications like seals, nozzles, and bearings.

- Fracture Toughness Testers:

- Function: Determine the material’s ability to resist crack propagation. Methods like Single Edge Notched Beam (SENB) or Chevron Notch are used.

- Parameters Measured: Fracture toughness (K_IC).

- Importance: Indicates the material’s tolerance to pre-existing flaws, vital for structural reliability.

- Impact Testers (e.g., Charpy, Izod):

- Function: Assess the material’s ability to withstand sudden, high-rate loading. While less common for monolithic ceramics than for metals, it’s relevant for some SiC applications, especially composites.

- Parameters Measured: Impact energy absorbed.

- Importance: Relevant for applications prone to sudden impacts or shocks.

- Wear and Friction Testers (Tribometers):

- Function: Evaluate the wear rate and coefficient of friction of SiC against itself or other materials under various conditions (load, speed, lubrication, temperature). Pin-on-disk or ball-on-flat configurations are common.

- Parameters Measured: Wear volume/rate, coefficient of friction.

- Importance: Essential for mechanical seals, bearings, and other tribological applications.

Thermal Testing Equipment: This category focuses on how SiC behaves under varying temperatures and its ability to conduct or resist heat.

- Dilatometers:

- Function: Measure the dimensional changes (expansion or contraction) of SiC as a function of temperature.

- Parameters Measured: Coefficient of Thermal Expansion (CTE).

- Importance: Crucial for applications involving temperature cycling or joining SiC to other materials with different CTEs, to prevent stress and failure.

- Thermal Conductivity Analyzers (e.g., Laser Flash Apparatus – LFA):

- Function: Measure the rate at which heat is conducted through the SiC material.

- Parameters Measured: Thermal conductivity, thermal diffusivity, specific heat capacity.

- Importance: Vital for heat sinks, heat exchangers, furnace components, and power electronic substrates where efficient heat dissipation or retention is required.

- Differential Scanning Calorimeters (DSC) and Differential Thermal Analyzers (DTA):

- Function: Monitor heat flow to/from a sample compared to a reference as temperature changes. Used to detect phase transitions, oxidation onset, and specific heat.

- Parameters Measured: Transition temperatures, heats of reaction/transition, specific heat capacity.

- Importance: Helps understand thermal stability, oxidation behavior, and material purity.

- Thermogravimetric Analyzers (TGA):

- Function: Measure changes in mass of a sample as a function of temperature or time in a controlled atmosphere.

- Parameters Measured: Mass loss/gain (due to oxidation, decomposition).

- Importance: Assesses thermal stability and resistance to oxidation or chemical reactions at high temperatures.

- Thermal Shock Testing Equipment:

- Function: Subjects SiC components to rapid temperature changes (e.g., quenching from high temperature to room temperature) to evaluate their resistance to cracking.

- Parameters Measured: Number of cycles to failure, critical temperature difference (DeltaT_c).

- Importance: Essential for applications like kiln furniture, crucibles, and DPFs that experience rapid heating and cooling.

Electrical Testing Equipment: For SiC used in electrical and electronic applications, particularly semiconductors, these tests are critical.

- Resistivity/Conductivity Meters (e.g., Four-Point Probe, Van der Pauw method):

- Function: Measure the electrical resistance or conductance of the SiC material.

- Parameters Measured: Electrical resistivity, conductivity.

- Importance: Key for SiC heating elements (conductivity) and semiconductor substrates/devices (controlled resistivity).

- Dielectric Strength Testers / High Voltage Testers:

- Function: Determine the maximum electric field strength that SiC can withstand without electrical breakdown.

- Parameters Measured: Dielectric strength (breakdown voltage).

- Importance: Crucial for insulators, capacitors, and high-voltage SiC power devices.

- Semiconductor Parameter Analyzers / Curve Tracers:

- Function: Characterize the current-voltage (I-V) and capacitance-voltage (C-V) behavior of SiC semiconductor devices (diodes, MOSFETs).

- Parameters Measured: Threshold voltage, on-state resistance (R_DS(on)), leakage current, breakdown voltage, switching characteristics (rise time, fall time, switching losses with additional circuitry like double-pulse testers).

- Importance: Fundamental for qualifying SiC power electronic devices for EV inverters, solar converters, and industrial drives. Source 1.1 highlights modular SiC device evaluation kits that allow for comprehensive system-level testing, including double-pulse tests and power buck/boost converter tests.

- Hall Effect Measurement Systems:

- Function: Determine carrier concentration, mobility, and type (n-type or p-type) in semiconducting SiC.

- Parameters Measured: Carrier density, carrier mobility, Hall coefficient.

- Importance: Essential for R&D and quality control of SiC semiconductor materials.

Non-Destructive Testing (NDT) Equipment: NDT methods inspect SiC components for internal or surface flaws without damaging the part.

- Ultrasonic Testing (UT) Equipment:

- Function: Uses high-frequency sound waves to detect internal defects like cracks, voids, porosity, and inclusions. Can also measure thickness.

- Parameters Measured: Location, size, and type of defects.

- Importance: Widely used for quality control of structural SiC components, ensuring internal integrity. Fraunhofer IKTS is mentioned as a specialist in ultrasonic testing (Source 8.2).

- X-ray Radiography / Computed Tomography (CT) Equipment:

- Function: Uses X-rays to create images of the internal structure of SiC components, revealing density variations, pores, cracks, and foreign inclusions. CT provides 3D reconstructions.

- Parameters Measured: Internal defect detection, dimensional analysis.

- Importance: Provides detailed internal inspection, valuable for complex shapes and critical components. X-ray diffraction can also be used for phase analysis and residual stress measurement (Source 7.1).

- Dye Penetrant Testing (DPT) / Liquid Penetrant Inspection (LPI):

- Function: A surface inspection method that reveals surface-breaking cracks or porosity by applying a colored or fluorescent dye.

- Parameters Measured: Presence and extent of surface defects.

- Importance: Simple and effective for detecting surface flaws on non-porous SiC.

- Acoustic Emission (AE) Testing Equipment:

- Function: Detects high-frequency stress waves generated by active crack growth or material deformation under stress.

- Parameters Measured: AE event counts, energy, amplitude.

- Importance: Can be used for in-situ monitoring of structural health or during proof testing. Fraunhofer IKTS also specializes in acoustic emission analysis (Source 8.2).

- Infrared Thermography (IRT):

- Function: Maps surface temperature variations, which can indicate subsurface defects, delaminations, or variations in thermal properties.

- Parameters Measured: Temperature profiles, thermal anomalies.

- Importance: Useful for detecting flaws that affect thermal transport and for monitoring components in thermal cycling tests.

The choice of testing equipment depends on the specific type of SiC (e.g., sintered, reaction-bonded, CVD SiC), the intended application, and the properties that are most critical for performance. Sicarb Tech, by collaborating with the Chinese Academy of Sciences and numerous SiC manufacturers in Weifang, has access to and understanding of a wide array of these testing methodologies. This ensures that the custom SiC products we help develop or source are thoroughly evaluated, meeting the complex needs of technical procurement professionals and engineers globally. Our capabilities extend to providing measurement and evaluation technologies as part of our comprehensive service.

Critical Parameters in SiC Component Evaluation – Ensuring Performance and Reliability

Evaluating silicon carbide components involves measuring a range of critical parameters that directly influence their performance, reliability, and lifespan in specific applications. Engineers designing with SiC and procurement specialists sourcing custom SiC parts must understand these parameters to ensure the components meet the demanding requirements of their end-use environment. These parameters are derived from the mechanical, thermal, electrical, and chemical properties of the material.

Here’s a breakdown of critical parameters evaluated during SiC testing:

Mechanical Properties:

- Flexural Strength (Modulus of Rupture – MOR):

- Definition: The maximum stress a material can withstand before fracturing when subjected to bending. Typically measured via 3-point or 4-point bend tests.

- Importance: Crucial for structural components like kiln furniture, beams, and plates that bear loads. A higher MOR indicates greater resistance to breaking under stress.

- Hardness:

- Definition: Resistance to localized surface deformation, indentation, or scratching (e.g., Vickers, Knoop).

- Importance: Essential for wear parts such as mechanical seals, nozzles, bearings, and grinding media. SiC is known for its extreme hardness.

- Fracture Toughness (K_IC):

- Definition: A measure of the material’s resistance to crack propagation from a pre-existing flaw.

- Importance: Indicates the material’s ability to tolerate defects without catastrophic failure. Higher fracture toughness is desirable for reliability, though SiC is inherently a brittle material.

- Young’s Modulus (Modulus of Elasticity):

- Definition: A measure of the material’s stiffness or resistance to elastic deformation under tensile or compressive stress.

- Importance: Determines how much a component will deflect under a given load. Important for applications requiring high rigidity, like precision instrument components or mirror substrates.

- Density and Porosity:

- Definition: Density is mass per unit volume. Porosity refers to the volume fraction of pores within the material.

- Importance: Affects mechanical strength (higher density/lower porosity generally means higher strength), thermal conductivity, and chemical resistance. Critical for applications like vacuum chucks (low porosity) or filters (controlled porosity).

- Wear Rate & Coefficient of Friction:

- Definition: Wear rate quantifies material loss due to friction or erosion. The coefficient of friction indicates the resistance to sliding motion between surfaces.

- Importance: Paramount for tribological applications (seals, bearings) to ensure long life and low energy loss.

Thermal Properties:

- Thermal Conductivity (lambda or k):

- Definition: The ability of a material to conduct heat.

- Importance: High thermal conductivity is vital for heat sinks, heat exchangers, and power electronic substrates to dissipate heat effectively. Low thermal conductivity is needed for thermal insulation. SiC generally has high thermal conductivity (Source 4.1).

- Coefficient of Thermal Expansion (CTE):

- Definition: The fractional change in size (length, area, or volume) per unit change in temperature.

- Importance: Critical when SiC is joined to other materials or undergoes significant temperature cycling. Mismatched CTEs can induce stress and lead to failure. SiC has a relatively low CTE.

- Thermal Shock Resistance:

- Definition: The ability of a material to withstand rapid changes in temperature without cracking or failing.

- Importance: Essential for components like kiln furniture, crucibles, rocket nozzles, and diesel particulate filters that experience abrupt heating or cooling.

- Maximum Use Temperature / Creep Resistance:

- Definition: The highest temperature at which SiC can operate continuously without significant degradation or deformation (creep) under load.

- Importance: Defines the operational limits for high-temperature applications like furnace parts and heating elements.

- Emissivity:

- Definition: The effectiveness of a material’s surface in emitting energy as thermal radiation.

- Importance: Relevant for applications involving radiative heat transfer, such as SiC heating elements or components in vacuum furnaces.

Electrical Properties (especially for semiconductor and electronic applications):

- Electrical Resistivity / Conductivity:

- Definition: Resistivity is the material’s opposition to the flow of electric current. Conductivity is the reciprocal.

- Importance: Ranges from highly resistive (insulators) to semiconducting (power devices) to moderately conductive (heating elements), depending on the SiC grade and doping.

- Dielectric Strength:

- Definition: The maximum electric field a material can withstand without experiencing electrical breakdown.

- Importance: Critical for insulating components in high-voltage systems and for the gate oxide in SiC MOSFETs. SiC has a dielectric strength about ten times that of silicon (Source 1.1).

- On-State Resistance (R_DS(on)) (for SiC MOSFETs):

- Definition: The electrical resistance between the drain and source terminals when the MOSFET is fully turned on.

- Importance: A key performance metric for power switches; lower R_DS(on) means lower conduction losses and higher efficiency (Source 5.1, 6.1).

- Breakdown Voltage (V_BR):

- Definition: The maximum voltage that a semiconductor device (diode or transistor) can block in its off-state before breakdown occurs.

- Importance: Determines the voltage rating of the power device.

- Switching Characteristics (e.g., rise time, fall time, switching energy):

- Definition: Parameters that describe how quickly a power device can switch between on and off states, and the energy lost during these transitions.

- Importance: SiC devices are valued for their fast switching speeds, enabling higher frequency operation and smaller passive components (Source 1.1, 5.1).

- Carrier Mobility and Concentration (for semiconducting SiC):

- Definition: Mobility is how quickly charge carriers (electrons or holes) can move through the material under an electric field. Concentration is the number of charge carriers per unit volume.

- Importance: Fundamentally affects the conductivity and performance of SiC semiconductor devices.

Chemical and Other Properties:

- Chemical Resistance / Corrosion Resistance:

- Definition: The ability of SiC to resist degradation from exposure to acids, alkalis, molten salts, and other corrosive agents at various temperatures.

- Importance: Essential for components used in chemical processing, wet etching, and harsh industrial environments.

- Purity:

- Definition: The absence of unwanted elements or compounds.

- Importance: Extremely critical for semiconductor applications where even trace impurities can affect electrical performance. Also important for applications where leaching is a concern.

- Surface Finish / Roughness (R_a):

- Definition: A measure of the texture of a material’s surface.

- Importance: Affects friction, wear, sealing capability, optical reflectivity, and the ability to bond with other materials.

- Dimensional Tolerances & Geometric Accuracy:

- Definition: The allowable deviation from specified dimensions and geometric forms.

- Importance: Crucial for interchangeability of parts and proper fit in assemblies.

The following table provides a quick reference for some of these key parameters and their significance for SiC components:

| Parameter Category | Parameter | Unit(s) | Significance for SiC Components |

|---|---|---|---|

| Mechanical | Flexural Strength (MOR) | MPa, psi | Load-bearing capacity in bending (e.g., beams, plates) |

| Hardness (Vickers) | HV, GPa | Resistance to wear, scratching, indentation (e.g., seals, nozzles) | |

| Fracture Toughness (K_IC) | MPa·m<sup>1/2</sup> | Resistance to crack propagation, material toughness (structural reliability) | |

| Young’s Modulus | GPa, psi | Stiffness, resistance to elastic deformation (precision components) | |

| Thermal | Thermal Conductivity | W/(m·K) | Heat dissipation (heat sinks, power electronics) or insulation |

| Coefficient of Thermal Expansion (CTE) | ppm/°C, 10<sup>-6</sup>/K | Dimensional stability with temperature changes, compatibility with other materials | |

| Thermal Shock Resistance | DeltaT_c (°C), cycles | Ability to withstand rapid temperature changes (e.g., kiln furniture) | |

| Electrical | Electrical Resistivity | Omegacdotcm, Omegacdotm | Determines insulating, semiconducting, or conducting behavior |

| Dielectric Strength | MV/cm, kV/mm | Insulating capability under high voltage (e.g., insulators, power devices) | |

| On-State Resistance (R_DS(on)) (MOSFETs) | m$\Omega$, Omega | Conduction losses in power switching applications | |

| Chemical | Chemical/Corrosion Resistance | Qualitative / Rate of degradation | Durability in harsh chemical environments (e.g., chemical processing equipment) |

| General | Density | g/cm<sup>3</sup>, kg/m<sup>3</sup> | Affects mechanical, thermal properties; indicator of densification |

| Porosity | % volume | Influences strength, permeability, thermal properties (e.g., filters vs. dense structural parts) | |

| Surface Roughness (R_a) | $\mu$m, nm | Affects friction, wear, sealing, optical properties |

Achieving Precision in SiC Testing – Calibration, Standards, and Best Practices

Achieving precise and reliable results from silicon carbide testing equipment is paramount for ensuring the quality and performance of SiC components. Imprecise measurements can lead to incorrect material assessments, flawed component designs, and ultimately, failure in application. This section highlights the importance of calibration, adherence to recognized standards, and the implementation of best practices in the SiC testing laboratory. For technical procurement professionals and OEMs, understanding these aspects helps in evaluating a supplier’s commitment to quality assurance.

Calibration of Testing Equipment:

Calibration is the process of comparing the measurements made by an instrument to a known standard (traceable to national or international standards) to ensure its accuracy.

- Why it’s Crucial:

- Accuracy: Ensures that the test results are a true reflection of the SiC material’s properties.

- Consistency: Allows for comparable results over time and between different pieces of equipment or laboratories.

- Reliability: Builds confidence in the test data used for quality control, design validation, and material certification.

- Frequency: Calibration should be performed regularly according to the equipment manufacturer’s recommendations, industry standards, or internal quality procedures. The frequency may also depend on the usage of the equipment and the criticality of the measurements.

- Procedures:

- Use certified reference materials (CRMs) or calibrated artifacts.

- Follow standardized calibration procedures (e.g., ISO/IEC 17025 guidelines for testing and calibration laboratories).

- Maintain detailed calibration records, including dates, standards used, results before and after adjustment, and the technician who performed the calibration.

- Equipment Requiring Calibration: Virtually all SiC testing instruments, including:

- Universal Testing Machines (load cells, extensometers, displacement sensors).

- Hardness testers (indenters, load application systems).

- Thermal analyzers (temperature sensors, heat flow sensors).

- Electrical measurement systems (voltmeters, ammeters, LCR meters).

- Dimensional measurement tools (micrometers, calipers, CMMs).

Adherence to Testing Standards:

Standardized test methods ensure that tests are performed consistently and that results are comparable across different organizations and locations.

- Key Standards Organizations:

- ASTM International (formerly American Society for Testing and Materials): Publishes numerous standards for testing ceramics and advanced materials, including SiC. Examples:

- ASTM C1161: Flexural Strength of Advanced Ceramics at Ambient Temperature.

- ASTM C1327: Vickers Indentation Hardness of Advanced Ceramics.

- ASTM E1461: Thermal Diffusivity of Solids by the Flash Method.

- ISO (International Organization for Standardization): Develops international standards. Examples:

- ISO 14704: Fine ceramics (advanced ceramics, advanced technical ceramics) – Test method for flexural strength of monolithic ceramics at room temperature.

- ISO 18754: Fine ceramics (advanced ceramics, advanced technical ceramics) – Determination of fracture toughness of monolithic ceramics at room temperature by the single-edge V-notch beam (SEVNB) method.

- EN (European Standards): Standards adopted by European standardization bodies. Example:

- EN 843 series: Advanced technical ceramics – Monolithic ceramics – Mechanical properties at room temperature (covering flexural strength, modulus, hardness, fracture toughness). (Source 13.1)

- JIS (Japanese Industrial Standards): Often used, particularly for materials and components originating from or supplied to Japan.

- SEMI Standards: Specifically for the semiconductor industry, covering materials, equipment, and processes.

- ASTM International (formerly American Society for Testing and Materials): Publishes numerous standards for testing ceramics and advanced materials, including SiC. Examples:

- Benefits of Using Standards:

- Comparability: Allows for meaningful comparison of data from different sources.

- Reproducibility: Ensures that tests can be repeated with similar results.

- Clarity: Provides clear guidelines on test specimen preparation, test procedures, data analysis, and reporting.

- Quality Assurance: Forms a basis for quality agreements between suppliers and customers. DGUV (Source 7.1) mentions a standard method for measuring SiC in respirable dusts, highlighting how specific standards are developed for various SiC-related evaluations.

Best Practices in SiC Testing:

Beyond formal calibration and standards, several best practices contribute to precision in SiC testing:

- Proper Specimen Preparation:

- Machining and surface finishing of SiC test specimens must be done carefully to avoid introducing flaws (e.g., chips, cracks) that can affect test results, especially for mechanical tests. Diamond tooling and precise grinding/polishing are often required.

- Specimen dimensions and geometry must strictly adhere to the requirements of the chosen test standard.

- Controlled Test Environment:

- Maintain stable temperature and humidity in the testing laboratory, as these can influence some material properties and instrument performance.

- Minimize vibrations, especially for sensitive measurements like hardness testing or high-precision dimensional analysis.

- Operator Training and Competency:

- Ensure that personnel operating the testing equipment are well-trained on the specific instruments and test procedures.

- Regular competency assessments and ongoing training are important.

- Method Validation and Verification:

- Before implementing a new test method or piece of equipment, validate its performance to ensure it provides accurate and reliable results for SiC materials.

- Regularly verify method performance using control samples or CRMs.

- Meticulous Record Keeping:

- Maintain comprehensive records of all tests, including specimen identification, test conditions, raw data, calculations, results, and any deviations from standard procedures.

- This traceability is crucial for quality audits and troubleshooting.

- Regular Equipment Maintenance:

- Follow the manufacturer’s guidelines for routine maintenance of testing equipment to ensure it remains in optimal working condition.

- Understanding Material Behavior:

- Recognize that SiC is a brittle material, and its mechanical properties can be highly sensitive to surface flaws and stress concentrations. This understanding informs test setup and data interpretation.

- Be aware of the different polytypes of SiC (e.g., alpha-SiC, beta-SiC) and grades (e.g., sintered, reaction-bonded) as they can exhibit different properties and may require specific testing considerations.

- Statistical Analysis of Data:

- For properties that show inherent variability (common in ceramics), test multiple specimens and use appropriate statistical methods to analyze the data and report results (e.g., mean, standard deviation, Weibull statistics for strength).

Sicarb Tech recognizes that precision in testing is fundamental to delivering high-quality custom SiC solutions. Our collaboration with the Chinese Academy of Sciences instills a rigorous, scientific approach to all aspects of SiC technology, including material characterization and quality assurance. We work with Weifang’s leading SiC enterprises, promoting these best practices and ensuring that their SiC testing services and internal QC processes meet global expectations. For technical buyers and OEMs, this commitment translates into greater confidence in the advanced ceramic components sourced through our network. Our support to local enterprises includes enhancing their measurement and evaluation technologies, which directly contributes to the precision of their SiC product testing.

Interpreting Test Data and Reporting – From Raw Data to Actionable Insights for SiC Components

Collecting data using sophisticated silicon carbide testing equipment is only the first step. The true value lies in the accurate interpretation of this raw data and its transformation into actionable insights. This process is crucial for manufacturers to optimize their production, for engineers to validate their designs, and for procurement professionals to make informed purchasing decisions regarding custom SiC products. Clear and comprehensive reporting is essential for communicating these findings effectively.

Transforming Raw Data into Meaningful Information:

- Data Processing and Calculation:

- Raw output from testing machines (e.g., load vs. displacement, voltage vs. current, temperature changes) needs to be processed according to standardized formulas or software algorithms to derive the specific material properties. For example, flexural strength is calculated from the fracture load, specimen geometry, and test span.

- Software integrated with modern testing equipment often automates these calculations, but understanding the underlying principles is vital.

- Statistical Analysis:

- Due to the inherent variability in ceramic materials like SiC, properties such as strength are often statistical in nature. Testing multiple samples (e.g., 5-30 specimens for flexural strength) is common.

- Mean, Standard Deviation, Coefficient of Variation: These provide a measure of the average property value and its scatter.

- Weibull Statistics: Often used for analyzing the strength of brittle materials like SiC. The Weibull modulus (m) is a key parameter indicating the distribution of flaw sizes – a higher ‘m’ signifies greater reliability and less scatter in strength.

- Confidence Intervals: Provide a range within which the true property value is likely to lie.

- Comparison with Specifications and Standards:

- The derived properties are compared against internal quality control limits, customer specifications, or requirements outlined in industry standards (e.g., ASTM, ISO).

- This step determines if the SiC material or component passes or fails the quality criteria.

- Graphical Representation:

- Plotting data (e.g., stress-strain curves, strength distributions, property vs. temperature graphs) can help visualize trends, identify anomalies, and facilitate easier interpretation.

- For instance, a Weibull plot graphically represents strength data and helps determine the Weibull modulus.

Key Considerations in Interpreting SiC Test Data:

- Understanding Material Behavior:

- Recognize that SiC’s brittle nature means failure is often catastrophic and initiated by small flaws. This impacts how strength data is interpreted (probabilistic rather than deterministic).

- Consider the specific grade of SiC (e.g., SSiC, RBSiC, CVD-SiC) as their microstructures and typical property ranges differ. For example, RBSiC contains free silicon, which can affect its high-temperature properties and chemical resistance compared to SSiC.

- Identifying Outliers and Anomalies:

- Statistical methods can help identify data points that deviate significantly from the rest. Investigate whether outliers are due to testing errors, specimen defects, or actual material variability.

- Correlation with Microstructure:

- Often, test results are correlated with microstructural analysis (e.g., using Scanning Electron Microscopy – SEM) to understand the relationship between grain size, porosity, phase distribution, and the measured properties. Fractography (analysis of fracture surfaces) is crucial for understanding failure origins in mechanical tests.

- Environmental and Test Condition Effects:

- Always consider the conditions under which the test was performed (temperature, atmosphere, loading rate) as these can significantly influence SiC properties. For example, the strength of some SiC grades may decrease at very high temperatures due to oxidation or creep.

- Relating to Application Requirements:

- The most critical aspect of interpretation is to assess whether the measured properties meet the demands of the intended application. A certain flexural strength might be adequate for one application but insufficient for another requiring higher stress tolerance.

Effective Reporting of SiC Test Results:

A comprehensive test report is the formal record of the testing process and its outcomes. It should be clear, concise, accurate, and contain all relevant information for the end-user.

Essential Elements of a SiC Test Report:

- Identification:

- Report title, unique report number, date of issue.

- Information about the testing laboratory (name, address, accreditation if any).

- Customer information (if applicable).

- Sample Description:

- Clear identification of the SiC material or component tested (e.g., batch number, part number, material grade – Reaction Bonded Silicon Carbide, Sintered Silicon Carbide, etc.).

- Source of the material/component.

- Number of specimens tested.

- Description of specimen preparation (machining, surface finish).

- Test Method and Equipment:

- Reference to the specific test standard used (e.g., ASTM C1161).

- Identification of the testing equipment used (manufacturer, model, serial number).

- Date of the last calibration for critical equipment.

- Test Conditions:

- Environmental conditions during the test (e.g., temperature, humidity).

- Specific test parameters (e.g., loading rate, test temperature, atmosphere).

- Test Results:

- Clear presentation of the measured data, including individual values for each specimen and statistical summaries (mean, standard deviation, Weibull modulus where applicable).

- Use of tables and graphs to present data effectively.

- Units of measurement clearly stated.

- Example from Source 3.1 shows an evaluation of SiC MOSFET key parameters such as I_DM, R_on, rise/fall time, turn-on/off delay, and minimum pulse width, noting discrepancies between experimental data and datasheet values. This level of detail in reporting is crucial.

- Statement of Conformance/Non-Conformance (if applicable):

- A clear statement of whether the material/component meets the specified requirements.

- Observations and Interpretations:

- Any unusual observations during testing.

- Brief interpretation of the results in the context of the material and application (optional but often helpful).

- Notes on any deviations from the standard test procedure.

- Signature and Authorization:

- Signature of the technician/engineer who performed the test and the person authorizing the report.

The table below illustrates how different test data points might be interpreted for actionable insights:

| Raw Data/Test Result | Interpretation | Potential Actionable Insight for SiC Component |

|---|---|---|

| Low average Flexural Strength | Material may not meet mechanical load requirements. Possible issues with porosity, large grains, or internal flaws. | Review sintering process; improve powder quality; redesign component to reduce stress; consider a higher strength SiC grade. |

| High Weibull Modulus for Strength | Material exhibits consistent strength with a narrow distribution of flaws; indicates good process control and higher reliability. | Continue current manufacturing practices; potentially allows for less conservative design safety factors (with caution). |

| High Thermal Conductivity | Material is effective at dissipating heat. | Suitable for heat sink applications or power electronic substrates. Confirm consistency across batches. |

| R_DS(on) higher than specified | SiC MOSFET will have higher conduction losses, reducing system efficiency and potentially leading to overheating. | Reject batch; investigate wafer processing issues (doping, contact formation); review device design. |

| Unexpected peak in DSC curve | Indicates a phase change, reaction, or presence of impurity that was not anticipated at that temperature. | Investigate raw material purity; analyze material composition (e.g., using XRD or EDS); assess impact on high-temperature stability. |

| Cracking during Thermal Shock | Material has insufficient resistance to rapid temperature changes for the given DeltaT. | Modify component design to reduce thermal stresses; select a more thermal shock-resistant SiC grade (e.g., one with optimized microstructure or lower CTE); adjust operational heating/cooling rates. |

Sicarb Tech, leveraging its connection with the Chinese Academy of Sciences and its role in Weifang’s SiC industry, emphasizes the importance of not just testing, but also skilled interpretation and clear reporting. Our expertise in SiC material science and customized production processes ensures that test data is translated into genuine product improvements and reliable performance for our clients. We facilitate access to comprehensive testing and evaluation technologies, helping wholesale buyers and OEMs gain a deeper understanding of the technical ceramic components they procure.

Frequently Asked Questions (FAQ) about SiC Testing Equipment

Q1: What are the most critical tests for SiC components intended for high-temperature structural applications like kiln furniture?

A1: For high-temperature structural applications such as SiC beams, SiC plates, and SiC rollers used as kiln furniture, the most critical tests include:

- Flexural Strength (Modulus of Rupture – MOR) at Elevated Temperatures: This determines the load-bearing capacity of the SiC component at its intended operating temperature, not just at room temperature.

- Creep Resistance: Measures the material’s ability to resist slow deformation under a constant load at high temperatures over extended periods. This is vital for long-term dimensional stability.

- Thermal Shock Resistance: Assesses the component’s ability to withstand rapid temperature changes without cracking, which is common during heating and cooling cycles in furnaces.

- Oxidation Resistance: Evaluates how well the SiC material resists chemical degradation (oxidation) in the furnace atmosphere at high temperatures, which can affect its strength and lifespan.

- Coefficient of Thermal Expansion (CTE): Important for understanding how the component will expand and contract, and for ensuring compatibility with other materials in the furnace structure. For these applications, Reaction-Bonded Silicon Carbide (RBSiC or SiSiC) and Sintered Silicon Carbide (SSiC) are common choices, and their specific high-temperature characteristics need careful evaluation.

Q2: How does Non-Destructive Testing (NDT) help in ensuring the quality of custom SiC parts, especially for critical applications like semiconductor processing equipment?

A2: Non-Destructive Testing (NDT) is crucial for custom SiC parts in critical applications like semiconductor processing (e.g., SiC chucks, SiC focus rings) for several reasons:

- Internal Flaw Detection: Techniques like Ultrasonic Testing (UT) and X-ray Computed Tomography (CT) can detect internal defects such as voids, cracks, or inclusions that are not visible on the surface but could compromise the component’s integrity or performance (e.g., leading to particle generation or uneven heating). Source 8.1 and 8.2 discuss the role of NDT.

- Purity and Homogeneity Assessment: While not directly measuring chemical purity, NDT can sometimes reveal density variations or inclusions that might indicate contamination or lack of homogeneity, which is critical for preventing wafer contamination.

- Dimensional Verification of Internal Features: For complex custom parts, CT scanning can verify internal dimensions and features that are otherwise difficult to measure.

- 100% Inspection Capability: NDT methods can often be applied to every component (100% inspection) rather than just a sample, which is vital for applications where a single failure can be catastrophic or extremely costly.

- Ensuring Structural Integrity without Damage: As the name suggests, NDT does not damage the part, allowing for thorough inspection without compromising the component’s usability. This ensures that only high-quality, defect-free technical ceramic components are used in sensitive semiconductor manufacturing processes. Sicarb Tech understands the stringent requirements of the semiconductor industry and can facilitate access to SiC components that have undergone appropriate NDT evaluations to ensure they meet these exacting standards.

Q3: If we are sourcing SiC power modules for EV inverters, what are the key electrical parameters we should look for in test reports, and what kind of equipment is used to measure them?

A3: When sourcing SiC power modules for Electric Vehicle (EV) inverters, the test reports should highlight several key electrical parameters critical for performance, efficiency, and reliability. These are typically measured using semiconductor parameter analyzers, curve tracers, specialized power cycling testers, and double-pulse testers:

- On-State Resistance (R_DS(on)): Lower R_DS(on) means lower conduction losses and better efficiency. The report should specify R_DS(on) at different operating temperatures and currents (Source 5.1, 6.1).

- Breakdown Voltage (V_BR): Ensures the device can withstand the high voltages present in EV drivetrains without failure.

- Switching Characteristics (t<sub>on</sub>, t<sub>off</sub>, E<sub>on</sub>, E<sub>off</sub>): These are turn-on time, turn-off time, turn-on switching energy, and turn-off switching energy. Fast switching with low energy loss is a key advantage of SiC, leading to higher inverter efficiency and the potential for smaller passive components (Source 1.1).

- Threshold Voltage (V_GS(th)): The gate-source voltage at which the MOSFET begins to conduct. Consistency is important for reliable gate driving.

- Leakage Currents (I<sub>GSS</sub>, I<sub>DSS</sub>): Gate leakage current and drain leakage current when the device is off. Low leakage is crucial for minimizing standby power loss.

- Thermal Resistance/Impedance (R<sub>thJC</sub>): Junction-to-case thermal resistance, indicating how effectively heat can be removed from the SiC die. Lower values are better for thermal management (Source 5.1).

- Short-Circuit Withstand Time: The ability of the device to survive a short-circuit event for a specified duration.

- Reliability Data (e.g., from Power Cycling, High-Temperature Reverse Bias – HTRB tests): While not single parameters, data from these tests indicate the module’s robustness and expected lifetime under automotive stress conditions. Modular SiC device evaluation kits, as mentioned in Source 1.1, are often used to perform many of these critical tests, including double-pulse testing for switching characteristics and continuous power tests to evaluate thermal performance and efficiency. Sicarb Tech, with its focus on advanced SiC applications, can help connect you with suppliers who provide comprehensive testing and detailed reporting for SiC power modules tailored to the demanding automotive sector.

Conclusion – The Unwavering Value of Rigorous SiC Testing for Industrial Excellence

In the realm of high-performance materials, silicon carbide stands out for its remarkable combination of properties, making it indispensable across a spectrum of demanding industries. However, the journey from raw SiC powder to a reliable, high-performing custom SiC component is paved with meticulous manufacturing processes and, crucially, comprehensive testing. As we’ve explored, silicon carbide testing equipment and the rigorous evaluation it enables are not mere afterthoughts but fundamental pillars supporting the quality, reliability, and innovation that SiC promises.

For engineers, technical procurement professionals, OEMs, and distributors, understanding the significance of SiC testing—from mechanical strength and thermal stability to electrical performance and internal integrity—is key to making informed decisions. It ensures that the SiC technical ceramics integrated into critical systems, whether in semiconductor fabs, aerospace vehicles, high-temperature industrial furnaces, or EV power electronics, will deliver the expected performance and longevity.

The benefits are clear: enhanced product quality, improved system reliability, reduced risk of failure, and the ability to push the boundaries of technological advancement. Adherence to international standards, diligent equipment calibration, and best practices in data interpretation and reporting are hallmarks of a quality-conscious SiC supplier.

Sicarb Tech is deeply committed to this ethos of quality and precision. Situated in Weifang City, the heart of China’s SiC customizable parts manufacturing, and backed by the formidable scientific and technological capabilities of the Chinese Academy of Sciences , we have been instrumental in elevating the production and technological standards of the local SiC industry. Our unique position allows us to offer access to a network of specialized SiC factories, all benefiting from our expertise in material science, process optimization, and, critically, advanced measurement and evaluation technologies. We don’t just connect you with suppliers; we ensure that the custom SiC components you procure are of the highest quality, backed by thorough testing and a deep understanding of material performance.

Whether you require intricately designed SSiC parts, robust RBSiC kiln furniture, or high-purity SiC for semiconductor applications, Sicarb Tech is your trusted partner. We provide not only higher-quality, cost-competitive customized SiC components from China but also offer comprehensive technology transfer services for those looking to establish their own specialized SiC production facilities. Our commitment to rigorous testing and quality assurance is unwavering, ensuring that the silicon carbide you source through us contributes directly to your industrial excellence and competitive edge.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.