The Unseen Hero: How Silicon Carbide Revolutionizes Laser Cutting Systems

Share

Laser cutting technology has become indispensable across a multitude of industries, from intricate electronics manufacturing to heavy industrial fabrication. The demand for higher precision, faster processing speeds, and unwavering reliability in laser cutting systems is perpetually on the rise. While the laser source itself often garners the most attention, the materials used to construct critical components within these systems play an equally vital, albeit often unseen, role. In this quest for optimal performance and durability, custom silicon carbide (SiC) products have emerged as a transformative material, quietly revolutionizing the capabilities of modern laser cutters. For engineers, procurement managers, and technical buyers in sectors like semiconductors, aerospace, and advanced manufacturing, understanding the impact of SiC is becoming increasingly crucial.

The operational environment of a laser cutter is demanding. Components are often subjected to intense thermal loads, high accelerations, and the need for exceptional dimensional stability. Traditional materials like aluminum or steel, while widely used, can exhibit limitations in thermal expansion, stiffness, or wear resistance, which ultimately cap the performance potential of the laser system. This is where the unique properties of technical ceramics, specifically silicon carbide, offer a significant leap forward. SiC’s ability to maintain its form and function under extreme conditions makes it an ideal candidate for manufacturing high-performance laser cutting components, leading to enhanced accuracy, longevity, and overall system efficiency. As industries push the boundaries of what laser cutting can achieve, the integration of advanced ceramics in laser systems, particularly custom-designed SiC parts, is no longer a niche consideration but a strategic imperative for achieving a competitive edge.

Why Silicon Carbide? Unpacking the Material Advantages for Laser Cutter Components

The choice of silicon carbide for critical laser cutter components is not arbitrary; it’s a decision rooted in a remarkable combination of physical and thermal properties that outperform conventional materials in several key aspects. For industrial laser parts subjected to dynamic stresses and fluctuating temperatures, SiC offers a compelling suite of advantages. Understanding these benefits is key for procurement professionals and engineers looking to source ceramic laser components that deliver tangible performance improvements.

One of the most significant attributes of SiC is its exceptional thermal management capability. It boasts high thermal conductivity, often comparable to or exceeding that of many metals, allowing it to dissipate heat rapidly. This is critical for components near the laser path or those experiencing friction from rapid movements. Simultaneously, SiC exhibits a very low coefficient of thermal expansion. This means that as temperatures change, SiC components expand or contract minimally, ensuring dimensional stability and maintaining the precise alignment necessary for accurate laser focusing and beam delivery. This combination is particularly vital for maintaining the focal point and path accuracy of the laser, directly impacting cut quality and consistency.

Another crucial factor is SiC’s outstanding stiffness-to-weight ratio. Silicon carbide is an incredibly stiff material, significantly more so than aluminum or steel. This high modulus of elasticity means that SiC components resist deformation under load, which is essential for components like support structures, gantries, or mirror mounts that undergo rapid acceleration and deceleration. Because SiC is also relatively lightweight (less dense than most metals), components can be designed for high stiffness without adding excessive mass. This translates to faster possible movement speeds, reduced inertia, and consequently, higher throughput for the laser cutting system.

Beyond thermal and mechanical superiority, SiC offers excellent wear resistance and chemical inertness. In environments where particulate matter or reactive gases might be present, SiC’s hardness and resistance to abrasion and corrosion ensure a longer operational lifespan for components like nozzles or protective windows. This durability reduces downtime for maintenance and replacement, contributing to a lower total cost of ownership.

To illustrate the comparison, consider the following table:

| Property | Silicon Carbide (Typical SSiC) | Aluminum (6061 Alloy) | Steel (Stainless 304) | Unit | Significance for Laser Cutters |

|---|---|---|---|---|---|

| Density | ~3.1-3.2 | ~2.7 | ~8.0 | g/cm³ | Lower mass for faster acceleration (advantageous for SiC) |

| Young’s Modulus (Stiffness) | >400 | ~69 | ~193-200 | GPa | Higher stiffness for better precision under dynamic loads (SiC excels) |

| Thermal Conductivity | 120-200 | ~167 | ~16.2 | W/(m·K) | Faster heat dissipation (SiC is very good) |

| Coeff. of Thermal Exp. | ~2.4-4.5 | ~23 | ~17 | 10−6/K | Minimal dimensional change with temperature (SiC excels) |

| Hardness (Knoop) | ~2500-2800 | ~107 (Brinell) | ~215 (Brinell) | – | Higher wear resistance (SiC excels) |

The data clearly shows why silicon carbide laser components are increasingly favored for applications demanding the utmost in precision, speed, and reliability. For businesses seeking wholesale technical ceramics or specialized OEM SiC components, these inherent material advantages translate directly into superior laser cutting performance and enhanced productivity.

Key Silicon Carbide Components Optimizing Laser Cutter Precision and Durability

The theoretical advantages of silicon carbide truly shine when applied to specific components within a laser cutting system. By strategically replacing traditional materials with custom SiC parts for OEMs and end-users, manufacturers can unlock new levels of precision, speed, and operational lifespan. Let’s explore some key applications where SiC makes a significant difference:

SiC Laser Mirrors and Optics: Perhaps the most critical application of SiC in laser systems is in mirrors and optical mounts. SiC laser mirrors offer unparalleled thermal stability. The low coefficient of thermal expansion (CTE) coupled with high thermal conductivity means that even when subjected to high laser power, the mirror surface remains exceptionally flat and stable, preventing thermal lensing or distortion. This ensures the laser beam remains precisely focused and directed, which is paramount for fine-feature cutting and consistent quality. Sintered Silicon Carbide (SSiC) is often the preferred grade for these applications due to its high purity and polishability to achieve super-smooth surfaces (low Ra) essential for high reflectivity and minimal scatter. The lightweight nature of SiC also allows for faster scanning and beam delivery system movements.

SiC Optical Benches, Stages, and Gantries: The structural components that guide the laser head or support the workpiece demand extreme stiffness and vibrational damping. SiC optical benches and precision motion stages made from SiC provide a far more stable platform than their metallic counterparts. The high Young’s modulus of SiC minimizes deflections and vibrations, even during rapid accelerations and decelerations of the cutting head. This enhanced stability directly translates to higher cutting accuracy and the ability to maintain tight tolerances over large cutting areas. Furthermore, the lightweight nature reduces the inertial loads on the drive motors, potentially allowing for faster travel speeds and increased throughput.

Laser Nozzles and Protective Components: Laser nozzles, which direct the assist gas to the cutting point, operate in a harsh environment of high temperatures and ejected molten material. SiC nozzles offer superior wear resistance and can withstand higher temperatures than many metallic nozzles. This leads to longer nozzle life, reduced contamination of the cut, and more consistent gas flow dynamics. Similarly, SiC can be used for protective windows or shields in areas exposed to laser radiation or process byproducts, benefiting from its thermal shock resistance and chemical inertness.

Other Structural and Wear Parts: Beyond these primary applications, custom SiC components can be designed for various other structural elements or wear parts within a laser cutter where a combination of stiffness, thermal stability, and wear resistance is beneficial. This could include guide rails, bearing components, or specialized fixtures.

The integration of these high-precision SiC parts is a testament to the material’s versatility. Companies like Sicarb Tech, leveraging the extensive SiC manufacturing ecosystem in Weifang, China, are pivotal in providing these advanced ceramic material solutions. Their expertise ensures that the SiC components are not only materially superior but also manufactured to the exacting specifications required by the laser industry. By partnering with a knowledgeable SiC supplier, OEMs and technical buyers can confidently incorporate these advanced materials to push the performance envelope of their laser cutting systems.

Choosing the Right SiC Grade for Your Laser Application: A Guide for Engineers

Silicon carbide is not a monolithic material; it encompasses several grades, each with distinct manufacturing processes, microstructures, and resulting property profiles. Selecting the optimal SiC grade is critical for maximizing the performance and cost-effectiveness of SiC laser cutter components. This decision often involves balancing desired properties like thermal conductivity, density, porosity, and manufacturability against application-specific requirements and budget considerations. Engineers and procurement specialists sourcing technical ceramics should be familiar with the primary options.

Sintered Silicon Carbide (SSiC): The High-Purity Champion SSiC is produced by sintering fine SiC powder at very high temperatures (typically > 2000∘C), often with non-oxide sintering aids. The result is a dense, single-phase SiC material with exceptional hardness, high strength, excellent chemical inertness, and good thermal conductivity.

- Key Advantages for Laser Systems:

- Optical Applications: Its high purity and ability to be polished to extremely smooth surfaces make SSiC ideal for SiC laser mirrors and other optical components requiring high reflectivity and minimal scatter.

- Wear Resistance: Superior hardness translates to excellent performance in high-wear applications like nozzles or guide components.

- Thermal Stability: Good thermal conductivity and low CTE contribute to dimensional stability in thermally loaded parts.

- Considerations: Generally, SSiC is more expensive and can be more challenging to machine into highly complex shapes compared to some other grades.

Reaction-Bonded Silicon Carbide (RBSiC or SiSiC): The Versatile Workhorse Reaction-Bonded Silicon Carbide, also known as Silicon Infiltrated Silicon Carbide (SiSiC), is manufactured by infiltrating a porous preform of SiC grains and carbon with molten silicon. The silicon reacts with the carbon to form additional SiC, which bonds the original grains. The final material typically contains 8-15% free silicon.

- Key Advantages for Laser Systems:

- Complex Shapes: RBSiC/SiSiC is easier to form into large and complex net shapes with relatively tight tolerances, reducing the need for extensive post-machining. This makes it suitable for larger structural components like SiC optical benches or support arms.

- Good Thermal Conductivity: The presence of free silicon often enhances thermal conductivity compared to some other ceramics.

- Cost-Effectiveness: Generally more cost-effective for larger or more intricate parts than SSiC.

- Zero Porosity: Typically exhibits very low or zero porosity, which is beneficial for vacuum applications or when gas permeability is a concern.

- Considerations: The presence of free silicon limits its maximum service temperature (typically around 1350∘C−1380∘C) compared to SSiC. It may also be less resistant to certain aggressive chemical environments.

Other SiC Grades: While SSiC and RBSiC are the most common for laser system components, other grades like Nitride-Bonded SiC (NBSiC) or CVD-SiC (Chemical Vapor Deposited SiC) exist. CVD-SiC, for instance, offers ultra-high purity and exceptional thermal conductivity, making it suitable for very demanding optical or thermal management applications, though it comes at a premium cost.

The following table offers a simplified comparison for typical laser component considerations:

| Feature | Sintered SiC (SSiC) | Reaction-Bonded SiC (RBSiC/SiSiC) | Primary Benefit for Laser Applications |

|---|---|---|---|

| Purity | Very High (typically >98% SiC) | Contains free Silicon (8-15%) | SSiC for ultra-pure optical surfaces |

| Density | ~3.10 – 3.15 g/cm³ | ~3.02 – 3.10 g/cm³ | Both are lightweight, SSiC slightly denser |

| Max. Service Temperature | >1600∘C (in inert atm.) | ~1380∘C | SSiC for higher temperature exposure |

| Thermal Conductivity | Good to Excellent (120-180 W/mK) | Excellent (120-200 W/mK) | RBSiC can have an edge due to free Si; both good for thermal management. |

| Suitability for Optics | Excellent (highly polishable) | Fair (can be polished but may have limitations) | SSiC is the prime choice for SiC mirrors and high-quality optics. |

| Complex Shape Capability | More challenging, often requires machining | Excellent (net-shape forming possible) | RBSiC for complex structural parts like SiC stages or custom brackets. |

| Relative Cost | Higher | Moderate to Lower | RBSiC often more cost-effective for larger/complex parts. |

Precision Engineering: Design and Manufacturing Custom SiC Components for Laser Cutters

The exceptional properties of silicon carbide make it a highly desirable material for laser cutter components, but its inherent hardness and brittleness also present unique challenges in design and manufacturing. Achieving the required precision for custom SiC manufacturing, especially for intricate laser system design engineering, demands specialized knowledge, advanced precision ceramic machining techniques, and a collaborative approach between the designer and the SiC component manufacturer.

Design Considerations for Manufacturability: When designing SiC components, engineers must consider the “design for manufacturability” (DfM) principles specific to technical ceramics:

- Geometric Complexity: While grades like RBSiC allow for near-net-shape forming of complex geometries, overly intricate features, sharp internal corners, or very thin walls can increase manufacturing difficulty and cost. Generous radii and uniform wall thicknesses are generally preferred.

- Tolerances: SiC can be machined to very tight tolerances, but stricter tolerances significantly increase machining time and cost. Designers should specify the tightest tolerances only where functionally necessary.

- Joining and Assembly: If the SiC component needs to be joined to other parts (metallic or ceramic), the design must accommodate suitable joining techniques (e.g., brazing, shrink-fitting, adhesive bonding) and account for differences in thermal expansion.

- Stress Concentrations: Given SiC’s brittle nature, designs should aim to minimize stress concentrations. This involves avoiding sharp corners, notches, and abrupt changes in cross-section. Finite Element Analysis (FEA) is often employed to identify and mitigate high-stress regions.

- Feature Integration: Consider integrating multiple functions into a single SiC component if feasible, as this can reduce assembly complexity and potential points of failure. However, this may also increase the complexity of the individual SiC part.

Manufacturing Processes: The manufacturing of custom SiC components typically involves several stages:

- Powder Preparation: Starting with high-quality SiC powders and appropriate additives.

- Forming: Shaping the powder into a green body. Common methods include:

- Pressing (Uniaxial, Isostatic): Suitable for simpler shapes and high-volume production.

- Slip Casting/Injection Molding: For more complex geometries.

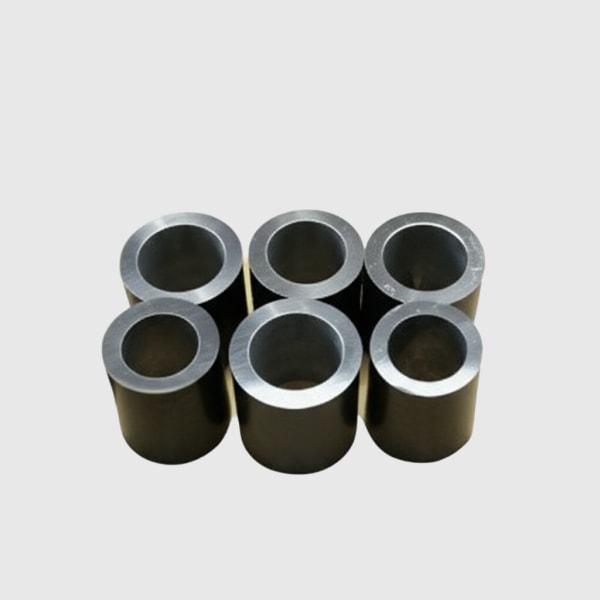

- Extrusion: For creating parts with uniform cross-sections, like rods or tubes.

- Green Machining: Machining the component in its “green” (pre-sintered) state. The material is much softer at this stage, making machining easier and less costly.

- Sintering/Reaction Bonding: Firing the green body at high temperatures to achieve densification and develop the final material properties.

- Hard Machining (Grinding, Lapping, Polishing): Due to SiC’s extreme hardness, final shaping and achieving tight tolerances or fine surface finishes require diamond grinding, lapping, and polishing. This is the most time-consuming and expensive part of the process for precision SiC machining. Electrical Discharge Machining (EDM) can also be used for certain conductive SiC grades.

The SicSino Advantage in Customization: This is where a supplier with deep technical expertise, like Sicarb Tech, becomes invaluable. Located in Weifang, a city accounting for over 80% of China’s SiC output, SicSino has been instrumental in advancing local SiC production technology since 2015. Backed by the Chinese Academy of Sciences National Technology Transfer Center, SicSino possesses a domestic top-tier professional team specializing in the customized production of silicon carbide products. They offer a comprehensive suite of services, including:

- Material and Process Expertise: Guidance on selecting the optimal SiC grade and manufacturing route.

- Design Support: Collaboration with customers to optimize designs for manufacturability and performance.

- Advanced Manufacturing Capabilities: Access to a wide array of forming and machining technologies.

- Integrated Process: From materials to finished products, ensuring quality control throughout.

By partnering with SicSino, businesses can confidently tackle the challenges of custom SiC fabrication, ensuring their laser cutter components meet the most demanding specifications for performance and reliability. Their commitment to providing higher-quality, cost-competitive SicSino custom SiC solutions makes them a strategic partner for OEMs and technical buyers worldwide.

Ensuring Peak Performance: Post-Processing, Coating, and Quality Assurance for SiC Laser Parts

Creating a precisely shaped silicon carbide component is a significant achievement, but for many demanding laser applications, particularly those involving optics or extreme precision, further post-processing, specialized coatings, and rigorous quality assurance are essential to unlock peak performance. These final steps transform a well-manufactured SiC blank into a highly functional SiC laser mirror, a precision SiC optical component, or a durable structural part ready for integration.

Post-Processing for Surface Perfection and Dimensional Accuracy:

- Grinding: After sintering or reaction bonding, SiC parts are typically diamond ground to achieve the primary shape and dimensional tolerances. This process removes any distortions from firing and brings the component closer to its final specifications.

- Lapping: For applications requiring very flat surfaces or extremely tight thickness tolerances, lapping is employed. This involves abrading the SiC surface against a flat plate with fine abrasive slurries, resulting in exceptional flatness and parallelism. SiC mirror polishing often begins with lapping stages.

- Polishing: To achieve the ultra-smooth surfaces necessary for optical components (e.g., mirrors with low scatter and high reflectivity) or for components requiring minimal friction, polishing is the final step. This uses progressively finer diamond abrasives to reduce surface roughness (Ra) to nanometer levels. The quality of polishing is critical for the efficiency and longevity of optical coatings for SiC.

- Edge Chamfering and Hole Finishing: Attention to detail, such as precise edge chamfering or finishing of internal bores, can be crucial for fit, assembly, and preventing stress concentrations.

Specialized Coatings for Enhanced Functionality: While SiC itself has excellent intrinsic properties, coatings can further enhance its performance in specific laser applications:

- Reflective Coatings: For SiC laser mirrors, metallic (e.g., gold, silver, aluminum) or dielectric coatings are applied to maximize reflectivity at specific laser wavelengths. The choice of coating depends on the laser type (e.g., CO2, Nd:YAG, fiber laser) and operating environment.

- Protective Coatings: In some cases, thin protective coatings might be applied to enhance resistance to specific chemical environments or to modify surface energy.

- Anti-Reflection (AR) Coatings: For transmissive SiC optics (less common but possible for certain IR applications), AR coatings can reduce reflection losses.

Quality Assurance and Metrology: Rigorous ceramic component testing and metrology are non-negotiable for high-performance SiC laser parts. This ensures that every component meets the stringent specifications.

- Dimensional Inspection: Using Coordinate Measuring Machines (CMMs), laser scanners, and other precision metrology tools to verify all critical dimensions, tolerances, and geometric features (GD&T).

- Surface Roughness and Flatness Measurement: Employing profilometers, interferometers, and atomic force microscopy (AFM) to quantify surface roughness (Ra, Rq) and flatness (e.g., λ/10, λ/20).

- Material Property Verification: Non-destructive testing (NDT) methods like ultrasonic testing can be used to check for internal flaws or inconsistencies. Density and porosity checks might also be performed.

- Optical Performance Testing: For mirrors and optics, reflectivity, scatter, and surface quality are tested according to industry standards.

Partnering for Excellence: Selecting Your Silicon Carbide Component Supplier for Laser Systems

The successful integration of custom silicon carbide components into advanced laser cutting systems hinges significantly on the capabilities and reliability of your SiC supplier. Choosing the right partner goes beyond simply sourcing a material; it involves finding a technical ceramics expert who can provide design support, material selection guidance, consistent quality, and dependable lead times. For OEMs and procurement professionals, this selection is a strategic decision impacting product performance, innovation cycles, and supply chain resilience.

When evaluating a potential SiC component supplier, consider the following key criteria:

- Technical Expertise and Experience:

- Does the supplier have a deep understanding of various SiC grades (e.g., SSiC, RBSiC/SiSiC) and their suitability for different laser applications?

- Can they offer design-for-manufacturability advice for complex OEM SiC components?

- Do they have a proven track record in the laser industry or similar high-tech sectors?

- Material Quality and Consistency:

- What are their raw material sourcing and quality control processes?

- Can they provide material certifications and lot traceability?

- Is there consistency in material properties from batch to batch?

- Customization and Manufacturing Capabilities:

- Do they possess the necessary forming, green machining, sintering/reaction bonding, and precision ceramic machining (grinding, lapping, polishing) technologies?

- Can they handle complex geometries and tight tolerances common in laser system components?

- Are they equipped for specialized post-processing like optical coating preparation?

- Quality Management Systems:

- Are they ISO certified or compliant with other relevant industry quality standards?

- What metrology and inspection equipment do they use?

- Can they provide comprehensive quality documentation and inspection reports?

- Lead Time, Scalability, and Supply Chain Reliability:

- What are their typical lead times for custom components?

- Can they scale production to meet your volume requirements, both for prototyping and series production?

- How do they manage their supply chain to ensure reliability, especially for critical raw materials?

- Cost-Effectiveness:

- While cost is a factor, it should be balanced against quality, reliability, and technical support. The lowest price is not always the best value for high-performance components.

- Customer Support and Communication:

- Are they responsive to inquiries and proactive in communication?

- Can they provide ongoing technical support throughout the product lifecycle?

Sicarb Tech: Your Trusted Partner in Custom Silicon Carbide

For businesses seeking a reliable and highly capable silicon carbide China supplier, Sicarb Tech stands out as a compelling choice. Situated in Weifang City, the epicenter of China’s SiC customizable parts manufacturing, SicSino embodies the region’s industrial strength while elevating it with cutting-edge technology and a commitment to global standards.

SicSino’s distinct advantages include:

- Strong Backing and Expertise: As part of the Chinese Academy of Sciences (Weifang) Innovation Park and collaborating closely with the National Technology Transfer Center of the Chinese Academy of Sciences , SicSino leverages unparalleled scientific, technological capabilities, and a rich talent pool. This connection ensures access to the latest advancements in SiC materials science and processing.

- Proven Technology Transfer: Since 2015, SicSino has been introducing and implementing advanced SiC production technology, aiding over 10 local enterprises in achieving large-scale production and technological upgrades. This demonstrates their deep understanding of the entire SiC value chain.

- Comprehensive Customization Support: They possess a wide array of technologies, covering material development, process design, component manufacturing, and detailed measurement & evaluation. This integrated approach enables them to meet diverse and complex customization needs for SicSino custom products.

- Reliable Quality and Supply Assurance: With a top-tier professional team and a robust local manufacturing network, SicSino offers higher-quality, cost-competitive customized SiC components. Their commitment to quality is unwavering, ensuring that parts meet stringent international specifications.

- Full-Spectrum Services (Turnkey Projects): Beyond component supply, SicSino is also committed to assisting clients in establishing their own specialized SiC production facilities. They can provide technology transfer, factory design, equipment procurement, installation, commissioning, and trial production support – a unique offering that underscores their profound expertise.

By choosing Sicarb Tech as your OEM SiC partner, you gain access not just to superior SiC components, but to a wealth of knowledge and a commitment to fostering technological advancement in the advanced ceramics industry. Their ability to bridge cutting-edge research with industrial-scale production makes them a reliable and forward-looking supplier for demanding laser system applications.

Frequently Asked Questions (FAQ) about Silicon Carbide in Laser Cutters

As engineers and procurement specialists explore the integration of silicon carbide into their laser cutting systems, several common questions arise. Addressing these queries can help clarify the benefits and practical considerations of using this advanced ceramic material.

Q1: Can Silicon Carbide components be used with all types of lasers (e.g., CO2, Fiber, Nd:YAG)? A1: Yes, silicon carbide’s excellent thermal and mechanical properties make its components, particularly mirrors and structural elements, beneficial across a wide range of laser types. For SiC laser optics, the specific grade of SiC (often SSiC for its polishability) and any applied optical coatings will be optimized for the laser’s wavelength and power. For example, SiC mirrors can be coated for high reflectivity in the far-infrared for CO2 lasers or in the near-infrared for fiber and Nd:YAG lasers. The inherent thermal stability of SiC is advantageous regardless of the laser source, as it helps maintain optical alignment and component integrity under varying thermal loads. Sicarb Tech can assist in selecting or developing SiC components suitable for specific laser wavelengths and operating conditions.

Q2: What are the primary cost implications of using custom Silicon Carbide components compared to traditional materials like aluminum or specialized steels? A2: Custom silicon carbide components generally have a higher upfront cost compared to standard metallic parts. This is due to the more complex and energy-intensive raw material processing, forming, and particularly the diamond machining required for precision SiC machining due to its extreme hardness. However, it’s crucial to consider the total cost of ownership (TCO).

- Performance Gains: SiC parts can lead to higher laser cutter throughput (due to increased speed and precision), better cut quality, and the ability to process more demanding materials.

- Longevity and Durability: Superior wear resistance and thermal stability mean SiC components often last significantly longer, reducing replacement frequency and downtime.

- Reduced Maintenance: The stability and durability of SiC can lead to lower maintenance requirements for the laser system. When these factors are considered, the initial investment in custom SiC parts can be offset by improved productivity and reduced operational costs over the system’s lifespan. SicSino, leveraging the efficient manufacturing ecosystem in Weifang, strives to offer cost-competitive high-quality SiC components.

Q3: How does Sicarb Tech handle highly complex or novel custom SiC component requests for laser systems? A3: Sicarb Tech is specifically geared towards handling diverse and complex customization needs. Their approach involves:

- In-depth Consultation: Their team of experts works closely with clients to understand the specific application requirements, operating conditions, and performance goals for the custom SiC laser components.

- Material and Design Expertise: Leveraging their strong connection with the Chinese Academy of Sciences and their own extensive experience, they provide guidance on the optimal SiC grade, component design for manufacturability, and potential performance trade-offs.

- Integrated Technology Platform: SicSino possesses a wide array of technologies covering material science, process engineering, design, and advanced measurement & evaluation. This allows them to develop tailored solutions from the ground up if necessary.

- Prototyping and Iteration: They can facilitate rapid prototyping and work through iterative design improvements to achieve the desired outcome.

- Access to Weifang SiC Hub: Being at the heart of China’s SiC industry, they can draw upon a vast network of specialized capabilities while ensuring stringent quality oversight. For novel or particularly challenging designs, SicSino’s R&D capabilities and their commitment to being an innovation partner, not just a parts supplier, make them well-suited to tackle such projects. They aim to provide not just components but complete ceramic material solutions.

Q4: What are the typical lead times for custom SiC components for laser cutting equipment? A4: Lead times for custom silicon carbide products can vary significantly based on several factors:

- Complexity of the Part: More intricate designs with tighter tolerances will generally require longer manufacturing times.

- SiC Grade: Some grades may have longer raw material processing or sintering cycles.

- Quantity Ordered: Small prototype runs may have different lead times than larger production volumes.

- Required Post-Processing: Extensive machining, lapping, polishing, or specialized coating requirements will add to the lead time.

- Current Order Backlog: Supplier capacity at the time of order. Generally, lead times can range from a few weeks for simpler, smaller components to several months for highly complex, large, or high-volume orders. It is crucial to discuss lead time expectations early in the procurement process. Sicarb Tech works to provide realistic lead time estimates and strives for efficient production planning to meet customer deadlines, benefiting from the agile and large-scale production capacity within the Weifang SiC cluster. They encourage early engagement to facilitate smoother project timelines.

Conclusion: The Enduring Value of Custom Silicon Carbide in Demanding Industrial Environments

The integration of custom silicon carbide components into laser cutting systems represents a significant technological advancement, pushing the boundaries of precision, speed, and reliability in a multitude of industrial applications. From the demanding environments of semiconductor manufacturing and aerospace to high-volume industrial fabrication, the superior thermal stability, exceptional stiffness-to-weight ratio, and remarkable wear resistance of SiC offer tangible benefits that directly translate into enhanced productivity and improved end-product quality.

The journey from raw SiC powder to a precisely engineered laser system component is complex, requiring deep material science knowledge, advanced manufacturing techniques, and meticulous quality control. This is where the choice of a proficient and reliable supplier becomes paramount. Companies like Sicarb Tech, strategically positioned within China’s primary silicon carbide production hub in Weifang and fortified by the scientific prowess of the Chinese Academy of Sciences, are pivotal in making these advanced ceramic solutions accessible. Their commitment extends beyond mere component supply; they offer comprehensive customizing support, from material selection and design optimization to sophisticated post-processing and even technology transfer for establishing specialized SiC production facilities.

For engineers designing next-generation laser systems, procurement managers seeking robust wholesale technical ceramics, and OEMs aiming to elevate their equipment’s performance, silicon carbide offers a compelling value proposition. While the initial investment may be higher than conventional materials, the long-term benefits of reduced downtime, enhanced operational efficiency, and superior component lifespan underscore the strategic wisdom of incorporating high-precision SiC parts. As industries continue to demand more from their processing equipment, the role of advanced materials like silicon carbide, supplied by expert partners such as SicSino, will only continue to grow in importance, solidifying its status as an essential element in the landscape of high-performance industrial technology.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.