Mastering Material Excellence: A Deep Dive into SiC Sintering Furnaces for High-Performance Industrial Applications

Share

Silicon Carbide (SiC) has emerged as a cornerstone material in industries demanding exceptional performance under extreme conditions. From the heart of semiconductor fabrication units to the demanding environments of aerospace and high-temperature industrial processes, custom SiC components offer unparalleled thermal conductivity, wear resistance, and chemical inertness. However, the journey to achieving these superior properties in SiC parts is critically dependent on one pivotal piece of equipment: the SiC sintering furnace. This blog post delves into the intricacies of SiC sintering furnaces, exploring their types, essential features, operational nuances, and the innovations shaping their future. For engineers, procurement managers, and technical buyers seeking high-quality custom silicon carbide products or advanced ceramic manufacturing equipment, understanding the role of these furnaces is paramount.

The Crucial Role of Sintering in Silicon Carbide Component Manufacturing

Sintering is a transformative thermal treatment process that densifies a powder compact into a solid, coherent mass, significantly below its melting point. For Silicon Carbide, a material renowned for its strong covalent bonds and lack of ductility, sintering is the key to unlocking its remarkable physical and mechanical properties. Without a precisely controlled sintering process, SiC powders would not achieve the density and microstructure required for demanding applications.

The primary goals of sintering SiC are:

- Densification: Reducing porosity and increasing the material’s density, leading to enhanced strength and hardness.

- Microstructure Development: Controlling grain size and distribution, which directly influences properties like fracture toughness and thermal shock resistance.

- Phase Purity: Ensuring the desired SiC polytype is formed and maintained, without undesirable secondary phases.

A SiC sintering furnace is engineered to provide the extreme temperatures (often exceeding 2000∘C) and controlled atmospheres (typically inert gases like argon or nitrogen, or vacuum) necessary for these transformations. The precision of these furnaces in maintaining temperature uniformity, executing complex heating and cooling profiles, and managing the atmospheric conditions directly dictates the final quality and performance of sintered silicon carbide (SSiC) components. Consequently, investment in high-quality industrial furnace solutions is a critical factor for manufacturers of technical ceramics.

Unveiling the Science: What Happens Inside a SiC Sintering Furnace?

The sintering of Silicon Carbide is a complex diffusional process. Due to SiC’s strong covalent bonding and low self-diffusion coefficients, achieving high densities typically requires very high temperatures and often the use of sintering aids or external pressure.

Several mechanisms can be at play during SiC sintering:

- Solid-State Sintering: This involves the diffusion of atoms through the crystal lattice and along grain boundaries. It typically requires very high temperatures (often >2100∘C) and fine, high-purity SiC powders. Non-oxide sintering aids like boron and carbon are commonly used to promote densification by modifying surface energies and grain boundary characteristics. Carbon helps remove silica (SiO2) from the surface of SiC particles, while boron enhances grain boundary diffusion.

- Liquid-Phase Sintering (LPS): In this method, additives are used that form a liquid phase at the sintering temperature. This liquid phase wets the SiC grains and provides a fast diffusion path, promoting particle rearrangement and densification at comparatively lower temperatures than solid-state sintering. Common additives include alumina (Al2O3) and yttria (Y2O3). The properties of LPS-SiC can be tailored by the choice and amount of additives.

- Reaction Sintering (or Reaction Bonding): While not strictly a “sintering” process in the traditional powder metallurgy sense for creating dense SiC from SiC powder alone, it’s a vital method for producing materials like Reaction-Bonded Silicon Carbide (RBSiC or SiSiC). Here, a porous carbon or SiC preform is infiltrated with molten silicon. The silicon reacts with the carbon (or fine SiC) to form new SiC in-situ, bonding the original SiC particles. This results in a dense composite material containing SiC and free silicon. The furnaces for this process must handle molten silicon and ensure complete infiltration.

Understanding these mechanisms is crucial for selecting the appropriate SiC sintering furnace and designing optimal firing profiles. The furnace must be capable of reaching the specific temperatures required for the chosen sintering route, maintaining them with high uniformity, and providing the correct atmospheric conditions to prevent oxidation or unwanted reactions. This precision is vital for producing custom SiC components for applications ranging from semiconductor wafer handling to kiln furniture in high-temperature processing.

A Comparative Look: Key Types of SiC Sintering Furnaces

The choice of a SiC sintering furnace significantly impacts the properties of the final SiC product, as well as production efficiency and cost. Different furnace designs cater to specific sintering mechanisms and production scales.

| Furnace Type | Operating Principle | Typical Temperature Range (∘C) | Pressure Capability | Atmosphere | Common SiC Types Produced | Key Advantages | Key Considerations |

|---|---|---|---|---|---|---|---|

| Pressureless Sintering (PLS) Furnace | Sintering occurs at atmospheric pressure, relying on temperature and additives. | 2000−2400 | Atmospheric | Inert (Ar, N₂) | SSiC, some LPS-SiC | Relatively lower cost, suitable for complex shapes, high throughput potential | Higher sintering temperatures often needed, control of grain growth is critical |

| Gas Pressure Sintering (GPS) Furnace | Sintering under elevated inert gas pressure (typically up to 10 MPa or higher). | 1900−2300 | Moderate to High | Inert (Ar, N₂) | Dense SSiC, LPS-SiC | Improved densification, suppression of decomposition, finer microstructures | Higher equipment cost, more complex operation |

| Hot Pressing (HP) Furnace | Uniaxial pressure is applied to the SiC powder in a die at high temperature. | 1800−2200 | Very High | Inert, Vacuum | HP-SiC, some specialty SSiC | Achieves near-theoretical density, excellent mechanical properties | Limited to simple shapes, lower throughput, expensive |

| Hot Isostatic Pressing (HIP) Furnace | Isostatic gas pressure is applied to encapsulated parts at high temperature. | 1700−2100 | Very High | Inert (Ar) | Post-HIPed SSiC, LPS-SiC | Eliminates residual porosity, enhances properties of pre-sintered parts | High equipment cost, often a secondary process |

| Reaction Bonding Furnace | Infiltration of molten silicon into a porous preform. | 1450−1700 | Atmospheric/Vacuum | Vacuum, Inert | RBSiC (SiSiC) | Lower processing temperatures, near-net shaping, good thermal shock resistance | Presence of free silicon limits max operating temp and chemical resistance |

For many industrial applications requiring high-volume SiC components with good all-around properties, PLS and GPS furnaces are workhorses. GPS furnaces, in particular, offer a good balance of achieving high density and controlling microstructure for demanding applications like bearings, seals, and nozzles. Sicarb Tech, with its deep understanding of SiC production technologies, leverages advanced sintering furnaces to produce a wide array of custom silicon carbide products tailored to specific industrial needs. Their expertise in the Weifang SiC cluster allows them to optimize furnace selection and operation for superior component quality.

Anatomy of a Performer: Essential Features and Design Considerations for SiC Sintering Furnaces

A robust and reliable SiC sintering furnace is built with specific design features that ensure precise control over the demanding sintering environment. These features are critical for achieving consistent quality in technical ceramics and advanced materials engineering.

Key Furnace Components and Their Impact:

| Component | Material/Type Examples | Design Considerations & Impact on Sintering |

|---|---|---|

| Heating Elements | Graphite, Lanthanum Chromite (LaCrO3), Molybdenum Disilicide (MoSi2), SiC rods | Must withstand extreme temperatures and the furnace atmosphere. Graphite is common for very high temps (>2000∘C) in inert/vacuum. MoSi2 suitable up to 1800∘C in oxidizing/inert. Element placement affects temperature uniformity. |

| Insulation | Graphite felt, Carbon-Carbon Composite (CFC), Ceramic Fiber Boards/Blankets (Alumina, Zirconia) | Minimizes heat loss, improving energy efficiency and temperature stability. Must be compatible with high temperatures and furnace atmosphere (non-reactive). Multi-layer designs are common. |

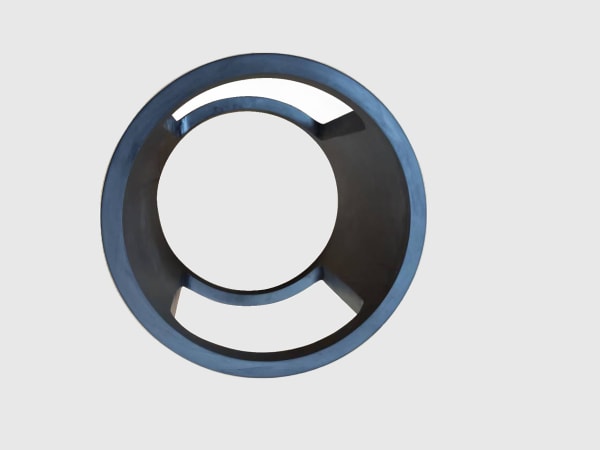

| Chamber/Hot Zone | High-purity graphite, CFC, Tungsten, Molybdenum | Must be robust, non-reactive with SiC or process gases at high temperatures. Design should promote uniform temperature distribution. Water-cooled steel vessel often encloses the hot zone. |

| Atmosphere Control System | Gas supply lines (Ar, N₂), vacuum pumps (roughing, diffusion, turbo), gas purification systems, oxygen sensors | Precise control of gas composition and pressure is vital. Prevents oxidation of SiC and heating elements. Vacuum systems help in outgassing and specific sintering routes. |

| Temperature Control System | Thermocouples (Type B, C, D), pyrometers, PID controllers, PLC systems | Accurate temperature measurement and control are paramount. Multi-zone heating with independent PID loops ensures temperature uniformity across the workload. Programmable controllers allow complex firing cycles. |

| Power Supply & Control | Thyristor (SCR) based power controllers, transformers | Provides stable and precisely controlled power to the heating elements. Step-down transformers are often needed for low-resistance graphite elements. |

| Safety Systems | Over-temperature protection, pressure relief valves, emergency stops, interlocks, gas leak detectors | Essential for protecting personnel and equipment given the high temperatures, pressures, and flammable gases (if used, e.g., hydrogen for debinding). |

Design Considerations for Optimal Performance:

- Temperature Uniformity: Achieving a consistent temperature across the entire SiC workload is crucial for uniform densification and microstructure. This is influenced by hot zone design, heating element placement, and insulation quality.

- Ramp Rate Control: The ability to precisely control heating and cooling rates is important to prevent thermal shock in SiC parts and to manage outgassing during debinding.

- Atmosphere Integrity: Maintaining a pure, controlled atmosphere (e.g., low ppm levels of oxygen and moisture) is critical, especially for sintering non-oxide ceramics like SiC.

- Degassing/Debinding Capability: Many SiC forming processes involve binders that must be removed before high-temperature sintering. The furnace should accommodate this, often with dedicated cycles and gas flow management to sweep away volatiles.

- Durability and Maintainability: Components must withstand harsh conditions. Easy access for maintenance of heating elements, thermocouples, and insulation is a practical necessity.

Procurement managers and engineers looking for silicon carbide manufacturing equipment should scrutinize these features to ensure the furnace meets their specific quality and production requirements for parts used in industries like semiconductors, aerospace, or high-temperature furnaces.

Maximizing Output: Optimizing the SiC Sintering Process with the Right Furnace

Owning a state-of-the-art SiC sintering furnace is only the first step; optimizing the sintering process itself is key to consistently producing high-quality custom SiC components. This involves careful planning, precise execution, and continuous monitoring.

Key aspects of process optimization include:

- Developing Precise Sintering Profiles:

- Heating Rates: Gradual heating, especially through critical temperature zones where binder burnout occurs or significant shrinkage begins, is essential to prevent cracking or deformation.

- Soak/Dwell Times: The duration for which the SiC parts are held at the peak sintering temperature. This allows for diffusion processes to complete, achieving target density and grain structure.

- Cooling Rates: Controlled cooling is equally important to prevent thermal shock, especially for larger or complex-shaped components. Annealing steps might be incorporated during cooling to relieve internal stresses.

- These profiles are highly dependent on the SiC grade (e.g., SSiC, LPS-SiC, RBSiC), part size, geometry, and the specific furnace characteristics.

- Binder Burnout (Debinding):

- If green SiC parts contain organic binders, these must be completely removed before reaching high sintering temperatures to avoid carbon contamination or defects.

- Furnaces often incorporate specific debinding stages with slow heating rates, specific atmospheric conditions (e.g., air, nitrogen, or vacuum), and adequate gas flow to carry away the binder decomposition products.

- The transition from debinding to sintering must be managed carefully.

- Atmosphere Management:

- For SSiC, an inert atmosphere (Argon or Nitrogen) is crucial to prevent oxidation. The purity of the gas is important.

- For Reaction-Bonded SiC (RBSiC), vacuum or a controlled atmosphere is used during silicon infiltration to ensure proper wetting and reaction.

- Monitoring oxygen levels and dew point within the furnace can provide critical process feedback.

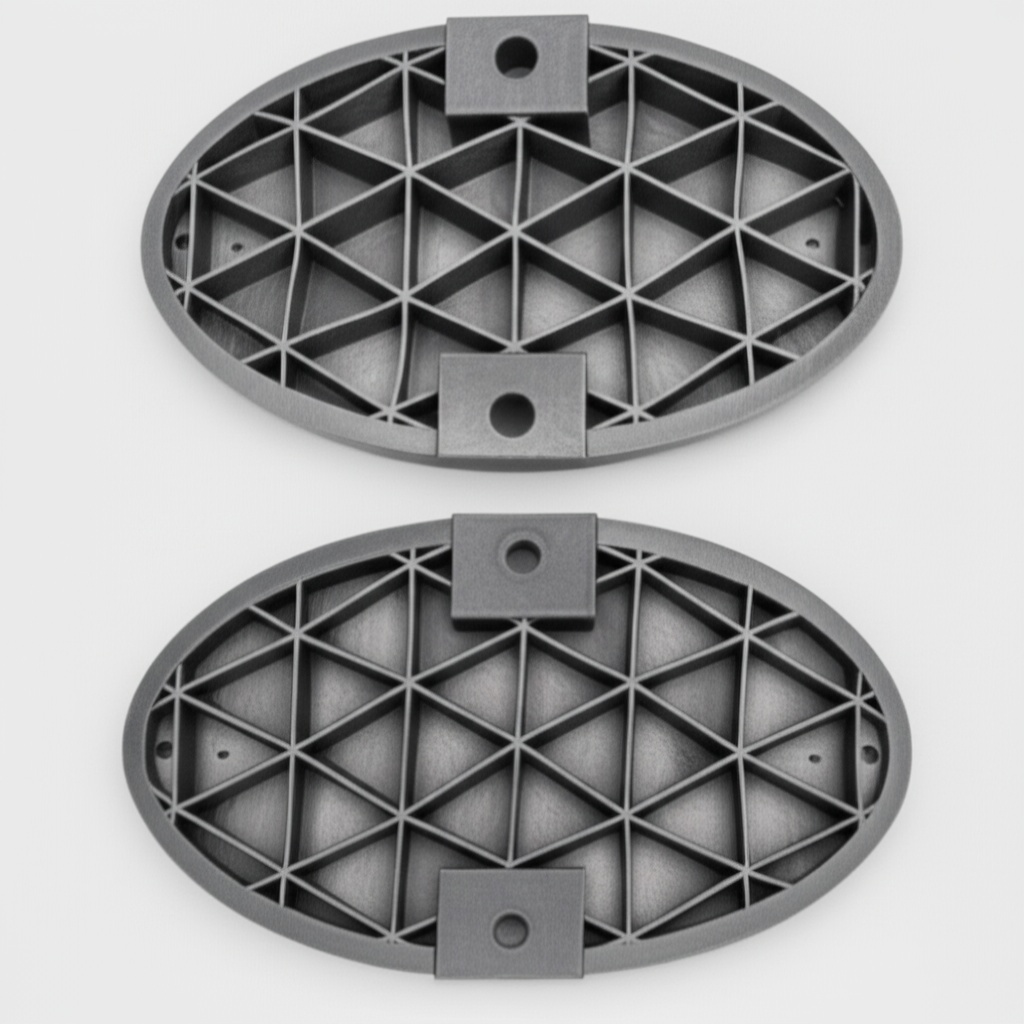

- Loading and Supports:

- Proper arrangement of parts within the furnace ensures uniform heating and gas flow.

- The choice of setter plates and supports (often high-purity graphite or SiC itself) is critical as they must be stable at high temperatures and not react with the SiC parts.

- Monitoring and Data Logging:

- Modern SiC sintering furnaces are equipped with sophisticated Programmable Logic Controllers (PLCs) and Human-Machine Interfaces (HMIs) that allow for precise programming of sintering cycles.

- Continuous monitoring and logging of key parameters like temperature (multiple zones), pressure, gas flow rates, and power consumption are vital for process control, quality assurance (traceability), and troubleshooting.

- Furnace Maintenance Best Practices:

- Regular inspection and replacement of heating elements, thermocouples, and insulation.

- Leak checking of the furnace chamber and gas supply lines.

- Cleaning the hot zone to remove contaminants.

- Calibration of sensors and controllers.

- A proactive maintenance schedule minimizes downtime and ensures consistent furnace performance, which is critical for OEM ceramic components suppliers.

By meticulously controlling these parameters, manufacturers can optimize for desired material properties such as density, hardness, strength, and thermal conductivity. This level of control is particularly important for producing high-performance SiC components used in challenging environments like chemical processing equipment or advanced armor systems.

Sicarb Tech: Your Trusted Partner for Advanced SiC Sintering Solutions and Custom Components

Navigating the complexities of SiC sintering and sourcing high-quality components or production technology requires a knowledgeable and reliable partner. This is where Sicarb Tech stands out. Located in Weifang City, the undisputed hub of China’s silicon carbide customizable parts manufacturing—a region accounting for over 80% of the nation’s total SiC output—SicSino has been a pivotal force since 2015. We have been instrumental in introducing and implementing advanced SiC production technology, empowering local enterprises to achieve large-scale production and significant technological advancements.

Why Partner with SicSino?

- Unparalleled Expertise: As part of the Chinese Academy of Sciences (Weifang) Innovation Park and backed by the National Technology Transfer Center of the Chinese Academy of Sciences , SicSino leverages the formidable scientific capabilities and talent pool of the Chinese Academy of Sciences. This unique position allows us to bridge the gap between cutting-edge research and practical industrial application.

- Comprehensive Technological Know-How: Our domestic top-tier professional team specializes in the customized production of silicon carbide products. We possess a wide array of technologies, encompassing material science, process engineering, design optimization, and meticulous measurement & evaluation. This integrated approach, from raw materials to finished products, enables us to meet diverse and demanding customization needs.

- High-Quality, Cost-Competitive Custom SiC Components: Thanks to our optimized processes and deep understanding of SiC sintering furnace technology, we deliver superior custom silicon carbide parts. Whether you require components for semiconductors, aerospace, energy, or industrial manufacturing, SicSino ensures products that meet stringent quality standards while remaining cost-competitive. Our support has already benefited over 10 local enterprises, enhancing their production capabilities.

- Technology Transfer and Turnkey Solutions: For businesses looking to establish their own SiC production capabilities, SicSino offers comprehensive technology transfer services. This isn’t just about selling equipment; it’s about providing a full-range “turnkey project” solution. This includes:

- Factory design tailored to your specific needs.

- Procurement of specialized equipment, including advanced SiC sintering furnaces.

- Professional installation and commissioning.

- Comprehensive training and trial production support. This ensures an effective investment, reliable technology transformation, and a guaranteed input-output ratio, empowering you to own a professional SiC products manufacturing plant.

SicSino’s Offerings: A Snapshot

| Service/Product Category | Description | Key Benefits for B2B Buyers |

|---|---|---|

| Custom SiC Components | Manufacturing of Reaction-Bonded SiC (RBSiC/SiSiC), Sintered SiC (SSiC), and other grades to precise customer specifications. | High-performance parts, tailored properties (wear resistance, thermal shock), reliable supply chain, access to Weifang SiC cluster advantages, cost-effectiveness. |

| SiC Production Technology Transfer | Full turnkey solutions for setting up SiC manufacturing plants, including furnace selection, process know-how, and operational training. | Own your production, secure IP, reduce long-term costs, leverage Chinese Academy of Sciences expertise, reliable technology, faster ramp-up to production, support from an experienced partner. |

| Consultancy and Technical Support | Expert advice on SiC material selection, component design, process optimization, and troubleshooting for SiC manufacturing. | Solve complex challenges, improve existing processes, innovate new products, access to leading SiC knowledge base, ensure quality and efficiency in your technical ceramic operations. |

By choosing SicSino, you are not just selecting a supplier; you are gaining a strategic partner committed to advancing your capabilities in the realm of silicon carbide. We stand as a testament to the innovation and manufacturing prowess concentrated in Weifang, ready to deliver reliable quality and supply assurance for your industrial SiC application needs.

The Horizon of Heat: Innovations and Future Trends in SiC Sintering Furnace Technology

The field of SiC sintering furnace technology is continuously evolving, driven by the demand for higher performance SiC components, improved energy efficiency, and greater process control. These advancements are crucial for OEMs, wholesale buyers, and distributors who rely on cutting-edge advanced ceramics.

Key Innovations and Future Directions:

- Enhanced Energy Efficiency:

- Improved Insulation Materials: Development of novel insulation with lower thermal conductivity and higher temperature resistance to minimize heat loss.

- Optimized Heating Element Design: More efficient heating elements and power control systems that reduce energy consumption per cycle.

- Heat Recovery Systems: Integration of systems to recover waste heat, potentially for pre-heating combustion air (if applicable) or other plant processes. This focus on sustainability and operational cost reduction is a significant driver for industrial furnace solutions.

- Advanced Automation and Smart Controls (Industry 4.0):

- Predictive Maintenance: AI-powered analytics to predict furnace component failures, allowing for proactive maintenance and minimizing downtime.

- Adaptive Process Control: Systems that can automatically adjust sintering parameters in real-time based on sensor feedback to ensure optimal outcomes and compensate for variations.

- Remote Monitoring and Control: Enabling off-site monitoring and adjustments, improving operational flexibility and expert access.

- Big Data Analytics: Collecting and analyzing vast amounts of sintering data to identify trends, optimize recipes, and improve overall equipment effectiveness (OEE).

- Furnaces for Larger and More Complex Geometries:

- As applications for SiC expand, so does the need for larger monolithic components or parts with intricate designs.

- Future furnaces will feature larger hot zones with even better temperature uniformity and advanced support structures to handle such components without distortion or cracking.

- Hybrid and Novel Sintering Technologies:

- Microwave Sintering: Offers potential for rapid heating and energy savings, though scaling for industrial SiC production presents challenges.

- Spark Plasma Sintering (SPS) / Field Assisted Sintering Technology (FAST): While often used for R&D and small, high-value parts, ongoing research aims to scale these rapid consolidation techniques for broader industrial use, offering unique microstructures and potentially lower sintering temperatures.

- Combination Furnaces: Equipment capable of performing multiple process steps (e.g., debinding, sintering, and gas pressure application) in a single cycle to improve efficiency.

- Reduced Environmental Impact:

- Cleaner combustion systems (for gas-fired variants, though less common for high-temp SiC sintering which is often electric).

- Improved abatement systems for any process off-gases.

- Focus on using materials with lower environmental footprints in furnace construction.

These trends indicate a future where SiC sintering furnaces are not just heating chambers but sophisticated, intelligent systems integral to the advanced materials engineering workflow. For businesses involved in silicon carbide procurement, staying abreast of these developments can offer a competitive edge in sourcing or producing next-generation SiC components. SicSino is committed to integrating such advancements, ensuring our clients benefit from the latest in ceramic manufacturing equipment and processes.

Frequently Asked Questions (FAQ) about SiC Sintering Furnaces

Navigating the specifics of SiC sintering furnaces can raise many questions for technical buyers, engineers, and procurement professionals. Here are answers to some common queries:

- What is the typical sintering temperature range for Silicon Carbide? The sintering temperature for SiC varies significantly depending on the specific type of SiC and the sintering method.

- Sintered Silicon Carbide (SSiC) typically requires temperatures between 2000∘C and 2400∘C for pressureless sintering, and slightly lower (1900∘C−2300∘C) for gas pressure sintering.

- Liquid Phase Sintered SiC (LPS-SiC) can be sintered at temperatures ranging from 1750∘C to 2100∘C, depending on the additives used.

- Reaction Bonded SiC (RBSiC or SiSiC) involves silicon infiltration at temperatures around 1450∘C−1700∘C, above the melting point of silicon. The furnace must be capable of achieving and uniformly maintaining these demanding temperatures.

- What type of atmosphere is generally required for SiC sintering? An inert atmosphere is crucial for most SiC sintering processes to prevent oxidation of the silicon carbide and the furnace components (especially graphite heating elements and insulation).

- Argon (Ar) is commonly used due to its inertness and availability.

- Nitrogen (N₂) can also be used, particularly for nitride-bonded SiC or certain SSiC grades, but care must be taken as it can react with SiC at very high temperatures to form silicon nitride.

- Vacuum conditions are often employed during the initial heating stages for outgassing and are essential for processes like producing RBSiC to facilitate silicon infiltration. High purity of the process gas (low oxygen and moisture content) is critical.

- How does the choice of sintering furnace impact the final properties of SiC components? The sintering furnace has a profound impact.

- Temperature Capability and Uniformity: Directly affect densification, grain growth, and phase purity. Non-uniform temperatures lead to inconsistent properties within a part or batch.

- Pressure Capability (for GPS, HP, HIP): Higher pressure can lead to greater densification, finer microstructures, and improved mechanical properties like strength and hardness.

- Atmosphere Control: Prevents unwanted reactions (like oxidation) that degrade SiC properties. The ability to switch between vacuum and inert gas is also vital for certain processes.

- Ramp Rate and Profile Control: Influences residual stresses, risk of cracking, and the effectiveness of binder removal. Ultimately, a well-chosen and properly operated furnace is key to achieving the desired wear resistance, thermal conductivity, electrical resistivity, and mechanical strength in custom SiC products.

- Can Sicarb Tech provide custom SiC sintering furnaces or help set up a complete SiC production line? Yes, absolutely. SicSino offers comprehensive solutions beyond just supplying custom SiC components. We provide:

- Technology Transfer: We can assist you in establishing your own specialized SiC production facility. This includes providing the technology for professional silicon carbide production.

- Turnkey Projects: Our services cover the full spectrum, from factory design and procurement of specialized equipment (including tailored SiC sintering furnaces suited to your specific product needs) to installation, commissioning, and trial production support. We aim to ensure your investment is effective, technology transformation is reliable, and your input-output ratio is guaranteed.

- What are some common challenges in SiC sintering, and how can they be addressed with the right furnace and expertise? Common challenges include:

- Achieving Full Densification: SiC’s covalent bonding makes it difficult to sinter. Additives, high temperatures, and sometimes pressure (as in GPS or HP furnaces) are needed. A furnace with precise temperature and atmosphere control is vital.

- Controlling Grain Growth: Excessive grain growth can degrade mechanical properties. Optimized sintering profiles (temperature, time) and appropriate sintering aids, managed within a capable furnace, help control this.

- Binder Removal Defects: Incomplete or too rapid binder burnout can cause cracks, voids, or carbon contamination. Furnaces with dedicated debinding cycles and good atmosphere flow are essential.

- Thermal Shock/Cracking: Due to SiC’s brittleness, controlled heating and cooling rates, achievable with programmable furnace controllers, are critical.

- Atmosphere Purity: Contamination from oxygen or moisture can lead to undesirable reactions. High-integrity furnace chambers and gas purification systems mitigate this. SicSino’s expertise in both SiC materials and ceramic manufacturing equipment allows us to help clients overcome these challenges, whether through supplying optimized components or providing the technology and furnaces for their own production.

Conclusion: The Foundation of Excellence in Silicon Carbide

The SiC sintering furnace is more than just a piece of heating equipment; it is the heart of the Silicon Carbide manufacturing process, a critical enabler that transforms SiC powder into high-performance technical ceramics. The precision, control, and capability of these furnaces directly determine the quality, consistency, and ultimate performance of SiC components used across a spectrum of demanding industrial applications, from semiconductor processing parts to wear components in heavy industry.

As industries continue to push the boundaries of material performance, the demand for high-quality, custom silicon carbide products will only grow. Choosing the right sintering technology, and by extension, the right furnace, is a strategic decision that impacts not only product quality but also manufacturing efficiency and cost-effectiveness.

At Sicarb Tech, we pride ourselves on our deep understanding of SiC materials science and our expertise in advanced sintering technologies. Whether you are seeking a reliable supplier of wholesale SiC components, require bespoke parts for a unique application, or are looking to establish your own SiC production capabilities with a turnkey SiC plant, SicSino is your trusted partner. Rooted in the innovative environment of the Weifang SiC cluster and backed by the scientific prowess of the Chinese Academy of Sciences, we are committed to delivering excellence and driving the future of silicon carbide. We invite engineers, procurement managers, and technical buyers to connect with us to explore how our advanced SiC solutions can elevate your projects and contribute to your success.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.