Revolutionizing High-Temperature Processing: The Definitive Guide to Custom Silicon Carbide Furnace Components

Share

In the realm of advanced industrial operations, high-temperature furnaces are the unsung heroes, enabling processes that are fundamental to manufacturing a vast array of products we rely on daily. From the intricate fabrication of semiconductor wafers to the robust heat treatment of aerospace components and the firing of technical ceramics, these furnaces must operate under extreme conditions with unwavering reliability. However, the intense heat, aggressive chemical atmospheres, and demanding thermal cycling inherent in these processes push traditional furnace materials like metals and conventional refractories to their absolute limits, often leading to premature failure, process contamination, and costly downtime. This is where the exceptional properties of advanced ceramics, particularly Silicon Carbide (SiC), come to the fore, revolutionizing furnace design and performance.

Silicon Carbide stands out as a material uniquely suited to the rigors of high-temperature environments. Its remarkable combination of high thermal conductivity, excellent thermal shock resistance, superior strength at elevated temperatures, and impressive chemical inertness makes it an ideal candidate for constructing critical furnace components. As industries continually strive for higher efficiencies, tighter process control, and longer operational lifespans for their thermal processing equipment, the demand for custom silicon carbide furnace components has surged. These bespoke parts, engineered to specific application requirements, are not just upgrades but essential elements for unlocking new levels of performance and reliability in industrial furnaces. The ability to tailor SiC components ensures optimal thermal management, structural integrity, and resistance to the specific challenges posed by each unique high-temperature process, making SiC an indispensable material in the modern industrial landscape.

Unpacking the Silicon Carbide Furnace: Key SiC Components and Their Functions

A high-performance silicon carbide furnace is more than just a heated chamber; it’s a sophisticated system where each component plays a critical role in achieving precise and efficient thermal processing. Many of these vital parts are increasingly manufactured from various grades of Silicon Carbide due to its unparalleled ability to withstand extreme conditions. Understanding these SiC furnace internals and their functions reveals why custom SiC solutions are paramount for optimizing furnace design and operation.

At the heart of many electrically heated furnaces are SiC Heating Elements. These components are responsible for generating the required thermal energy. Silicon carbide’s ability to operate at very high temperatures, often exceeding 1400∘C to 1600∘C, and its consistent electrical resistivity allow for stable and uniform heat generation. Common types include rod, helical, and U-shaped elements, each designed for specific furnace configurations and heating patterns. The advantage of SiC heating elements lies in their longevity, resistance to oxidation, and ability to provide rapid heating and cooling rates, contributing significantly to process efficiency.

For processes requiring controlled atmospheres or the transport of materials through the hot zone, SiC Process Tubes and Rollers are indispensable. SiC tubes, such as radiant tubes or muffle tubes, can encapsulate the process environment, protecting it from direct contact with heating elements or combustion byproducts, while efficiently transferring heat. This is crucial in semiconductor manufacturing and specialized chemical vapor deposition (CVD) processes. Similarly, SiC rollers are used in roller hearth kilns for transporting heavy loads like ceramic tiles or metal parts through the furnace at high temperatures, offering excellent wear resistance and minimal deformation under load.

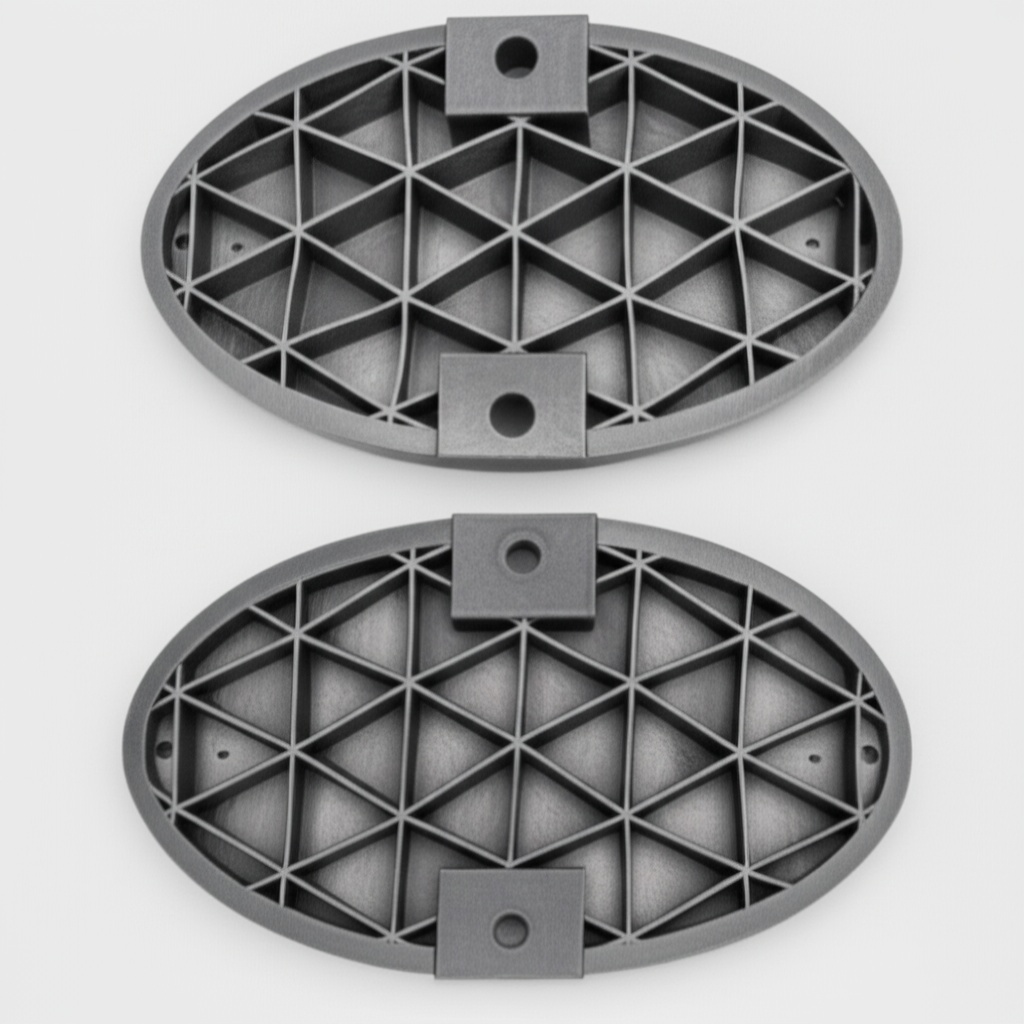

Structural integrity within the furnace at extreme temperatures is maintained by SiC Beams, Supports, and Kiln Furniture. These components, including plates, setters, posts, and complex assemblies, must bear significant loads without warping, sagging, or breaking. Kiln furniture made from SiC allows for denser packing of products, maximizing furnace throughput while ensuring even heat distribution and support. The high hot modulus of rupture and creep resistance of SiC are critical for these applications, far surpassing traditional ceramic or metallic options.

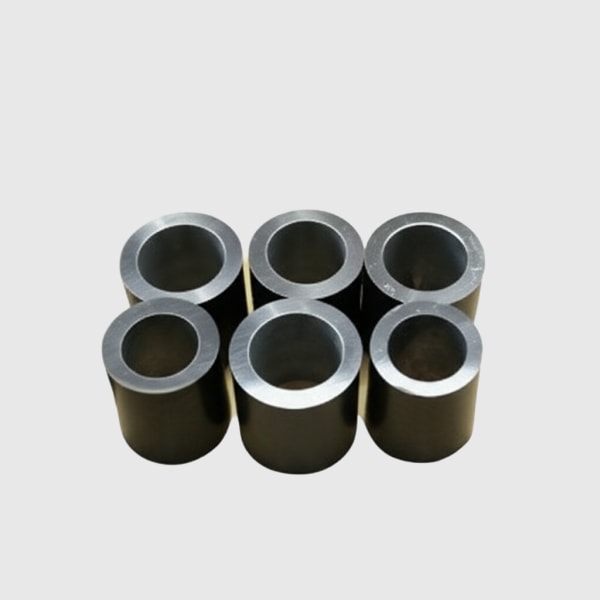

To protect the furnace’s insulation and outer shell from the harsh internal environment, and to contain the materials being processed, SiC Liners, Plates, and Crucibles are often employed. SiC liners provide a robust barrier against corrosive gases and molten materials. SiC plates can serve as hearth plates or baffles, while SiC crucibles are used for melting and holding non-ferrous metals or other reactive substances due to SiC’s excellent non-wetting properties and chemical stability.

The diverse functions and demanding operational conditions within a furnace mean that standard, off-the-shelf components are often insufficient. This is where custom silicon carbide parts become essential. Tailoring the geometry, grade of SiC, and surface finish of each component to the specific furnace design and process parameters can lead to significant improvements in thermal efficiency, product quality, and operational lifetime. For instance, custom-designed kiln furniture can optimize airflow and temperature uniformity around the processed parts, while bespoke heating elements can ensure precise heat distribution in complex furnace chambers. Companies like Sicarb Tech, leveraging their deep expertise in SiC technology, play a crucial role in providing these highly specialized, custom-engineered solutions to meet the evolving needs of high-temperature industries.

Transformative Advantages: Why Custom Silicon Carbide Elevates Furnace Performance

The decision to incorporate custom Silicon Carbide components into furnace design and operation is driven by a compelling array of transformative advantages. These benefits extend beyond simple material substitution, fundamentally elevating furnace performance, efficiency, and longevity. For procurement managers, technical buyers, and engineers in sectors like semiconductor processing, aerospace manufacturing, and high-temperature industrial production, understanding these advantages is key to making informed decisions for their critical thermal processing equipment.

Exceptional Thermal Management: Silicon Carbide exhibits outstanding thermal properties crucial for furnace applications.

- High Thermal Conductivity: SiC materials possess significantly higher thermal conductivity compared to many other refractory materials. This allows for rapid and uniform heat distribution within the furnace, minimizing hot spots and ensuring consistent product processing. For example, SiC heating elements and radiant tubes can transfer heat more efficiently to the workload.

- Excellent Thermal Shock Resistance: Furnaces often undergo rapid temperature changes during startup, shutdown, or process cycling. SiC’s low thermal expansion coefficient and high thermal conductivity give it exceptional resistance to thermal shock, preventing cracking or spalling where other materials might fail. This is particularly vital for components like SiC kiln furniture and SiC burner nozzles.

Unmatched High-Temperature Stability and Strength: The ability to maintain structural integrity and mechanical properties at extreme temperatures is a hallmark of Silicon Carbide.

- SiC retains its strength at temperatures where many metals would soften or melt and other ceramics might deform. Reaction-bonded SiC (RBSiC/SiSiC) and Sintered SiC (SSiC) can be used in applications exceeding 1380∘C and 1650∘C respectively, with some specialized grades pushing even higher.

- This high hot strength ensures that SiC beams, supports, and rollers can bear substantial loads within the furnace without significant creep or deformation over extended periods, contributing to stable and reliable operation.

Superior Chemical Inertness and Corrosion Resistance: Industrial furnace atmospheres can be highly aggressive, featuring corrosive gases, molten materials, or reactive process byproducts.

- Silicon Carbide is inherently resistant to a wide range of acids, alkalis, and oxidizing environments. This chemical inertness prevents contamination of the processed materials and extends the life of furnace components such as SiC liners, tubes, and crucibles.

- In applications like aluminum smelting or chemical processing, SiC’s resistance to attack by molten metals and corrosive vapors is a significant advantage.

Enhanced Durability and Operational Lifetime: The combination of high-temperature strength, thermal shock resistance, wear resistance, and corrosion resistance translates directly into longer-lasting furnace components.

- Custom SiC wear parts within a furnace, such as guides or nozzles, can significantly outlast those made from conventional materials, reducing the frequency of maintenance and replacement.

- Longer component life means less furnace downtime, higher productivity, and a lower total cost of ownership over the furnace’s lifespan. This is a critical consideration for OEMs and distributors looking to offer robust and reliable furnace systems.

Energy Efficiency: The unique properties of SiC also contribute to more energy-efficient furnace operations.

- Rapid heating capabilities due to high thermal conductivity can shorten cycle times.

- The ability to operate at higher temperatures can sometimes intensify processes, leading to greater throughput for a given energy input.

- Lighter SiC kiln furniture, compared to traditional cordierite or mullite, means less thermal mass to heat, saving energy with each firing cycle.

By choosing custom silicon carbide solutions, industries can harness these advantages to their fullest, leading to more efficient, reliable, and cost-effective high-temperature processing. Sicarb Tech specializes in partnering with businesses to develop these tailored SiC components, ensuring that furnace performance is not just maintained but significantly enhanced.

Selecting the Optimal Silicon Carbide Grade for Your Furnace Application

Not all Silicon Carbide is created equal, and the selection of the optimal SiC grade is a critical decision that directly impacts the performance, longevity, and cost-effectiveness of furnace components. Different manufacturing processes result in SiC materials with varying microstructures, purities, and, consequently, distinct physical and thermal properties. Engineers and procurement professionals must consider the specific operating conditions of their furnace—such as maximum temperature, thermal cycling severity, chemical environment, and mechanical stress—to choose the most suitable grade.

Here’s an overview of common SiC grades used in furnace applications and their typical characteristics:

- Reaction Bonded Silicon Carbide (RBSiC or SiSiC – Silicon Infiltrated SiC): This is one of the most widely used types of SiC for furnace parts. It is produced by infiltrating a porous preform of SiC grains and carbon with molten silicon. The silicon reacts with the carbon to form additional SiC, which bonds the original grains, and any remaining pores are filled with metallic silicon.

- Properties: Good mechanical strength, excellent thermal shock resistance, high thermal conductivity, and good wear resistance. The presence of free silicon (typically 8-15%) limits its maximum service temperature to around 1380∘C, as silicon melts above this point. It is relatively cost-effective to produce in complex shapes.

- Typical Furnace Applications: Kiln furniture (beams, setters, plates, posts), rollers, burner nozzles, radiant tubes, and wear-resistant liners.

- Sintered Silicon Carbide (SSiC): SSiC is produced by sintering fine SiC powder at very high temperatures (typically above 2000∘C) with the aid of sintering additives (e.g., boron and carbon). This process results in a fine-grained, high-purity SiC material with minimal or no free silicon.

- Properties: Extremely high strength and hardness (maintained at high temperatures), excellent corrosion resistance against both acidic and alkaline environments, superior wear resistance, and a very high maximum service temperature (often exceeding 1650∘C). It is generally more expensive than RBSiC due to the more demanding manufacturing process.

- Typical Furnace Applications: High-performance kiln furniture, components for semiconductor processing furnaces (e.g., wafer boats, process tubes), thermocouple protection tubes, crucibles for aggressive melts, and applications requiring extreme purity and wear resistance.

- Nitride Bonded Silicon Carbide (NSiC): NSiC is formed by bonding SiC grains with silicon nitride (Si3N4). This creates a material with a good balance of properties.

- Properties: Good thermal shock resistance, good mechanical strength, and resistance to molten non-ferrous metals like aluminum. Its thermal conductivity is generally lower than RBSiC or SSiC.

- Typical Furnace Applications: Kiln furniture, components for aluminum and other non-ferrous metal contact applications, and parts requiring good thermal cycling capabilities.

- Recrystallized Silicon Carbide (R-SiC or RSiC): This grade is produced by firing high-purity SiC grains at very high temperatures (around 2500∘C), causing them to bond together without the need for secondary bonding phases or sintering aids. It often has a degree of controlled porosity.

- Properties: Very high purity, excellent thermal shock resistance, and high-temperature stability. Its strength is generally lower than SSiC or RBSiC due to its typically porous nature.

- Typical Furnace Applications: High-temperature kiln furniture (especially where thermal mass needs to be minimized and rapid heating/cooling is desired), setters, and some specialized heating elements.

The following table provides a comparative overview of these key SiC grades:

| Property | Reaction Bonded SiC (RBSiC/SiSiC) | Sintered SiC (SSiC) | Nitride Bonded SiC (NSiC) | Recrystallized SiC (R-SiC) |

|---|---|---|---|---|

| Max. Service Temp. | ∼1380∘C | >1650∘C | ∼1450∘C | ∼1650∘C |

| Thermal Conductivity | High | Very High | Moderate | Moderate to High |

| Thermal Shock Resistance | Excellent | Good to Very Good | Excellent | Excellent |

| Flexural Strength | High | Very High | Moderate to High | Moderate |

| Corrosion Resistance | Good | Excellent | Good | Very Good (Purity) |

| Relative Cost | Moderate | High | Moderate to High | High |

| Key Features | Complex shapes, cost-effective | Extreme purity & strength | Molten metal resistance | High purity, low mass |

Sicarb Tech offers a comprehensive portfolio of these SiC grades, including RBSiC (SiSiC), SSiC, and R-SiC, ensuring the perfect material match for your specific furnace requirements. Our selections are backed by the advanced technological capabilities and robust talent pool of the Chinese Academy of Sciences . Situated in Weifang City, the hub of China’s silicon carbide customizable parts manufacturing, SicSino is uniquely positioned to provide expert guidance and high-quality materials tailored to your high-temperature applications.

Choosing the right grade involves a careful analysis of the application’s demands versus the material’s properties and cost. Consulting with experienced SiC suppliers like Sicarb Tech can help navigate these choices, leading to optimized furnace performance and longevity.

Critical Design and Engineering Insights for Custom SiC Furnace Components

The successful implementation of Silicon Carbide components in high-temperature furnaces extends beyond material selection; it heavily relies on meticulous design and engineering practices. While SiC offers a host of superior properties, its inherent characteristics as an advanced ceramic—notably its hardness and brittleness compared to metals—necessitate specialized design considerations. Collaborating with an experienced SiC manufacturer from the early design stages can prevent costly mistakes and ensure that the final components deliver optimal performance and durability.

Designing for Manufacturability with SiC’s Unique Properties:

- Hardness and Brittleness: SiC is extremely hard, which contributes to its excellent wear resistance but also makes it challenging and costly to machine after sintering or reaction bonding. Designs should aim to minimize complex machining operations in the densified state. Features like sharp internal corners, very thin sections, or abrupt changes in thickness can act as stress concentrators and should be avoided or carefully managed with generous radii and smooth transitions.

- Forming Processes: SiC components are typically formed from powders using techniques like slip casting, extrusion, iso-static pressing, or injection molding before the high-temperature bonding or sintering process. The chosen forming method can influence design possibilities, dimensional accuracy, and cost. For example, extrusion is suitable for long, uniform cross-sections like tubes and rods, while slip casting or iso-static pressing can produce more complex shapes.

Geometric Considerations:

- Wall Thickness: While SiC boasts high strength, excessively thin walls can be prone to damage during handling, installation, or due to thermal stresses. Conversely, overly thick sections can lead to longer heating/cooling times and potentially higher internal stresses. An optimal balance, guided by thermal and mechanical analysis, is crucial.

- Complex Shapes: Modern manufacturing techniques allow for the production of intricate SiC components. However, complexity often translates to higher tooling costs and potentially increased manufacturing challenges. The design should be as simple as the function allows, without compromising performance.

- Stress Concentration Points: As mentioned, sharp corners, notches, and small holes can become points of high stress, particularly under thermal cycling. Designs should incorporate fillets and radii to distribute stress more evenly. Finite Element Analysis (FEA) is often employed to identify and mitigate high-stress regions in complex SiC furnace parts.

Thermal Expansion Compatibility: SiC components are often part of a larger furnace assembly, interacting with materials like metals, other ceramics, or insulation.

- Silicon Carbide has a relatively low coefficient of thermal expansion (CTE). When designing SiC parts that interface with materials having different CTEs (e.g., metallic frames or supports), adequate allowances for differential expansion and contraction must be incorporated to prevent mechanical stress and failure during temperature changes. This might involve using expansion joints, flexible seals, or carefully designed mounting systems.

Joining and Sealing SiC Components: In many furnace applications, SiC components need to be joined to each other or to other materials, or they must provide a gas-tight seal.

- Direct joining of SiC parts can be achieved through specialized ceramic brazing, diffusion bonding, or by using SiC-based cements, though these methods often have temperature or atmospheric limitations.

- Mechanical clamping or interference fits, designed with thermal expansion in mind, are common.

- For sealing, O-rings (for lower temperature sections) or specialized high-temperature gaskets and packing materials might be used in conjunction with carefully designed flange surfaces on the SiC components.

Leverage the expertise of Sicarb Techs domestic top-tier professional team for collaborative design and optimization of your custom SiC furnace parts. Our integrated process, which spans from materials science and process engineering to detailed component design, measurement, and evaluation technologies, ensures innovative and practical solutions tailored to your specific furnace needs. Backed by the Chinese Academy of Sciences , we assist clients in navigating the complexities of SiC design, ensuring manufacturability and optimal performance in demanding industrial environments. Early engagement with SicSino can help translate your functional requirements into robust and efficient SiC component designs, maximizing the benefits of this advanced ceramic material.

Precision Matters: Tolerance, Surface Finish, and Post-Processing for SiC Furnace Internals

The performance and longevity of Silicon Carbide components within a high-temperature furnace are not solely determined by the material grade and design geometry. The achievable dimensional tolerances, the quality of the surface finish, and any necessary post-processing treatments play a crucial role in ensuring optimal functionality, efficiency, and reliability. For technical buyers and engineers specifying custom SiC furnace internals, understanding these aspects is vital for achieving the desired outcomes in applications ranging from semiconductor wafer processing to precision heat treatment.

Achievable Dimensional Tolerances for Custom SiC Furnace Components: The manufacturing process for SiC parts (e.g., pressing, casting, sintering) inherently involves some dimensional changes and variability.

- As-Fired Tolerances: Components used “as-fired” (i.e., without subsequent machining) will have broader tolerances. These are typically acceptable for applications like general kiln furniture (beams, plates) where very high precision is not the primary concern. Typical as-fired tolerances might be in the range of ±1% to ±2% of the dimension, or a minimum of ±0.5mm to ±1mm, depending on the size and complexity.

- Machined Tolerances: For applications demanding higher precision, such as mating parts, seals, or components used in semiconductor equipment, SiC can be diamond-ground after sintering. This allows for much tighter tolerances, often in the range of ±0.01mm to ±0.05mm, and in some specialized cases, even tighter. However, machining SiC is a costly and time-consuming process due to its extreme hardness.

Surface Finish Options and Their Impact on Performance: The surface finish of SiC components can significantly influence their interaction with the furnace environment and the products being processed.

- As-Fired Surface: This is the natural surface resulting from the sintering or reaction-bonding process. It is often suitable for many structural applications. The roughness (Ra) can vary depending on the SiC grade and manufacturing method.

- Ground Surface: Grinding produces a smoother, more precise surface than as-fired. This is often required for dimensional accuracy and can also reduce the likelihood of particle shedding, which is critical in clean environments like semiconductor furnaces. Typical Ra values after grinding can range from 0.4μm to 1.6μm.

- Lapped/Polished Surface: For applications requiring ultra-smooth, non-porous surfaces, such as seals, bearings, or some optical components (though less common for furnace internals), lapping and polishing can achieve Ra values below 0.1μm. This can also enhance corrosion resistance in certain environments.

Post-Processing Techniques: Beyond basic shaping and finishing, several post-processing steps can be employed to enhance the performance or meet specific application requirements of SiC furnace parts:

- Grinding and Lapping: As mentioned, these are primarily used to achieve tight dimensional tolerances and specific surface finishes.

- Sealing: For porous SiC grades like some R-SiC or if gas-tightness is critical for RBSiC components in certain atmospheres, a sealing process might be applied. This could involve impregnating the surface with glass-formers or applying a dense SiC coating (e.g., CVD SiC).

- Specialized Coatings: Applying a thin layer of another material, often high-purity CVD SiC or other ceramics, can further enhance properties like oxidation resistance, chemical inertness, or reduce outgassing. This is particularly relevant for SiC components in semiconductor manufacturing equipment.

- Edge Chamfering/Radiusing: To reduce the risk of chipping on sharp edges, which can be points of weakness for brittle ceramics, edges are often chamfered or radiused.

The following table illustrates typical tolerances and surface finishes achievable for SiC furnace components:

| Feature | As-Fired Condition | Ground Condition | Lapped/Polished Condition |

|---|---|---|---|

| Dimensional Tolerance | ±1−2% (or ±0.5−1mm) | ±0.01−±0.05mm (typical) | Even tighter, application-specific |

| Surface Roughness (Ra) | Varies (e.g., 1.6−6.3μm) | 0.4−1.6μm (typical) | <0.1μm (typical) |

| Primary Benefit | Cost-effective | Precision, improved surface | Ultra-smooth, high purity surface |

| Common Use | General kiln furniture | Mating parts, precise locations | Seals, specific semiconductor parts |

Sicarb Tech possesses a comprehensive suite of technologies, including advanced material processing, precision design capabilities, and meticulous measurement & evaluation techniques. This integrated approach allows us to deliver custom silicon carbide furnace components that meet stringent tolerance and surface finish requirements. Our expertise, nurtured since 2015 through technology implementation and support for local enterprises in the Weifang SiC hub, ensures that your components are manufactured to the highest standards of quality and precision, suitable for even the most demanding high-temperature industrial applications.

By carefully specifying and controlling these parameters, manufacturers can ensure that their SiC furnace components deliver the expected performance, contributing to process stability, product quality, and overall operational excellence.

Sourcing High-Quality SiC Furnace Components: Overcoming Challenges with a Strategic Partner

Sourcing specialized components like custom Silicon Carbide furnace parts presents unique challenges for procurement managers, engineers, and OEMs. While the material offers undeniable advantages for high-temperature industrial furnaces, ensuring consistent quality, managing lead times, dealing with the complexity of custom designs, and controlling costs associated with hard ceramic machining requires careful supplier selection and a strategic partnership.

Common Procurement Challenges:

- Ensuring Material Quality and Consistency: The performance of SiC components is heavily dependent on the purity of raw materials, the manufacturing process, and quality control. Variations can lead to premature failure. Verifying a supplier’s material certifications, quality management systems (e.g., ISO 9001), and traceability is crucial.

- Managing Lead Times: Custom SiC components are not typically off-the-shelf items. The manufacturing process, involving powder preparation, forming, high-temperature sintering/bonding, and potentially precision machining, can result in lead times ranging from several weeks to months. Effective project planning and communication with the supplier are essential.

- Complexity of Custom Designs: Translating a functional requirement into a manufacturable and cost-effective SiC component design requires expertise in ceramic engineering. Suppliers must have the capability to review and optimize designs, or even co-develop them.

- Cost of Machining Hard Ceramics: As SiC is extremely hard, any post-sintering machining (grinding, lapping) is expensive and adds to the component cost and lead time. Designs should be optimized to minimize machining where possible.

- Supplier Reliability and Technical Support: A reliable supplier offers not just components, but also technical support, application knowledge, and problem-solving capabilities. This is especially important for novel or demanding applications.

The Weifang SiC Hub Advantage: For businesses sourcing SiC components, looking towards established manufacturing hubs can offer significant advantages. Weifang City in China has emerged as a major global hub for silicon carbide customizable parts manufacturing. This region is home to over 40 SiC production enterprises of various sizes, collectively accounting for more than 80% of China’s total SiC output. This concentration creates a rich ecosystem of expertise, skilled labor, and specialized ancillary services, fostering innovation and competitive pricing.

However, navigating this landscape to find a truly reliable partner requires diligence. This is where Sicarb Tech distinguishes itself. We have been instrumental in this ecosystem, introducing and implementing advanced silicon carbide production technology since 2015. Our efforts have assisted numerous local enterprises in achieving large-scale production and significant technological advancements in their product processes. As a witness to the emergence and ongoing development of the local SiC industry, SicSino acts as a beacon of quality and innovation.

Operating under the platform of the national technology transfer center of the Chinese Academy of Sciences through the Chinese Academy of Sciences (Weifang) Innovation Park, SicSino capitalizes on the robust scientific, technological capabilities, and talent pool of the Chinese Academy of Sciences. This backing allows us to offer unparalleled reliable quality and supply assurance. We possess a domestic top-tier professional team specializing in the customized production of silicon carbide products. Our support has benefited over 10 local enterprises, and our wide array of technologies—encompassing material science, process engineering, design optimization, and comprehensive measurement & evaluation—enables us to meet diverse customization needs. This synergy allows us to provide higher-quality, cost-competitive customized silicon carbide components directly from the heart of China’s SiC industry.

Strategic Partnership for Global Needs: Beyond supplying custom components, Sicarb Tech is committed to fostering global SiC capabilities. For international businesses looking to establish their own specialized SiC production facilities, SicSino offers comprehensive technology transfer for professional silicon carbide production. This includes a full range of turnkey project services: from initial factory design and procurement of specialized equipment to installation, commissioning, and trial production. This unique offering empowers companies worldwide to develop their own SiC manufacturing plants with a more effective investment, reliable technology transformation, and a guaranteed input-output ratio.

By partnering with a knowledgeable and well-integrated supplier like Sicarb Tech, businesses can effectively overcome the challenges of sourcing custom SiC furnace components, ensuring access to high-quality products, technical expertise, and a stable supply chain rooted in one of the world’s leading SiC manufacturing centers.

Frequently Asked Questions (FAQ) about Silicon Carbide Furnaces and Components

Engineers, procurement managers, and technical buyers often have specific questions when considering Silicon Carbide for their furnace applications. Here are some common queries with concise, practical answers:

What is the maximum operating temperature for SiC components in a furnace? The maximum operating temperature depends heavily on the specific grade of Silicon Carbide used.

- Reaction Bonded Silicon Carbide (RBSiC or SiSiC), containing free silicon, is generally limited to about 1380∘C (2516∘F). Above this temperature, the free silicon begins to melt, compromising the material’s integrity.

- Sintered Silicon Carbide (SSiC), being a high-purity material, can typically operate at much higher temperatures, often up to 1650∘C (3002∘F) or even higher in specific non-oxidizing atmospheres or for short durations. Some specialized grades can push this limit further.

- Nitride Bonded SiC (NSiC) and Recrystallized SiC (R-SiC) also offer high-temperature capabilities, generally falling between RBSiC and SSiC, often in the 1400∘C to 1650∘C range depending on the exact composition and application environment. It’s crucial to consult material datasheets and supplier recommendations for the specific grade and operating atmosphere.

How long do SiC heating elements or furnace furniture typically last? The lifespan of SiC components like heating elements and kiln furniture is highly variable and depends on several factors:

- Operating Temperature and Cycling: Higher temperatures and frequent, rapid thermal cycling will generally shorten lifespan.

- Furnace Atmosphere: Corrosive or oxidizing atmospheres can degrade SiC components over time. The specific chemistry of the process environment plays a significant role.

- Mechanical Stress and Load: Overloading kiln furniture or improperly supporting components can lead to premature failure.

- SiC Grade: Higher purity and denser grades like SSiC often exhibit longer lifespans in aggressive conditions compared to RBSiC, though RBSiC offers excellent service in many applications.

- Proper Handling and Maintenance: Avoiding mechanical shock and following recommended operational guidelines can extend life. With appropriate selection and operation, SiC heating elements can last for thousands of hours, and SiC kiln furniture can endure many firing cycles. However, specific lifetime predictions require a detailed understanding of the application. Many users report lifespans from 1 to 5 years or more for structural SiC parts, depending on the intensity of use.

What are the primary cost drivers for custom SiC furnace parts? Several factors influence the cost of custom Silicon Carbide furnace components:

- SiC Grade: High-purity grades like SSiC are generally more expensive than RBSiC due to more complex raw materials and processing.

- Complexity of Design: Intricate shapes, tight tolerances, and features requiring extensive machining significantly increase costs. The initial tooling cost for custom shapes is also a factor.

- Size of the Component: Larger parts require more raw material and may necessitate larger, more specialized manufacturing equipment.

- Machining and Finishing: As SiC is very hard, any grinding, lapping, or polishing operations are time-consuming and add substantially to the cost. Minimizing post-sintering machining is key to cost control.

- Order Volume: Larger production runs can distribute setup and tooling costs over more units, potentially reducing the per-unit price.

- Quality and Testing Requirements: Specialized testing or certification requirements can also add to the cost. Sicarb Tech leverages its position in the Weifang SiC hub and its advanced technological processes to offer cost-competitive custom solutions without compromising quality.

Can SiC components be repaired if damaged within a furnace? Generally, repairing cracked or broken Silicon Carbide components is very difficult and often not feasible or recommended, especially for critical applications.

- SiC is a brittle ceramic, and cracks tend to propagate. Attempts to patch or weld SiC usually don’t restore the original strength or integrity, particularly for high-temperature structural use.

- For some very large or complex structures, specialized cements might be used for minor repairs in lower-stress areas, but this is application-specific and should be approached with caution.

- The best approach is to focus on proper design, material selection, and operational procedures to prevent damage in the first place. Replacement of damaged components is the standard practice.

How does Sicarb Tech ensure the quality of its custom SiC furnace products? Sicarb Tech places a strong emphasis on quality throughout the entire manufacturing lifecycle:

- Material Expertise: Leveraging the scientific backing of the Chinese Academy of Sciences , we have a deep understanding of SiC material science, ensuring appropriate grade selection and raw material quality.

- Advanced Process Control: We have implemented advanced SiC production technologies and support local partner enterprises in maintaining high standards in their manufacturing processes, from powder preparation to final sintering and finishing.

- Integrated Technology Platform: Our capabilities include design, material processing, sophisticated measurement, and evaluation technologies. This allows for rigorous quality checks at each stage.

- Experienced Team: Our domestic top-tier professional team specializes in customized SiC production, bringing years of experience to ensure product quality and performance.

- Collaborative Approach: We work closely with our clients to understand their specific needs and application challenges, ensuring the final product is fit for purpose and meets or exceeds expectations. By combining these elements, SicSino is committed to delivering high-quality, reliable custom SiC furnace components.

Conclusion: The Enduring Value of Custom Silicon Carbide in Demanding Industrial Furnaces

In the ever-evolving landscape of industrial manufacturing and high-technology processing, the demand for materials that can perform reliably under extreme conditions is relentless. Silicon Carbide has unequivocally established itself as a cornerstone material for constructing and optimizing high-temperature furnaces across a multitude of sectors. Its unique combination of exceptional thermal conductivity, superior high-temperature strength, outstanding thermal shock resistance, and robust chemical inertness provides a value proposition that is increasingly indispensable for engineers, procurement managers, and technical buyers.

The true potential of this advanced ceramic is most effectively unlocked through custom silicon carbide solutions. Tailoring the grade, design, and finish of SiC components—be it intricate SiC heating elements, robust SiC kiln furniture, precise SiC process tubes, or durable SiC liners—allows for the fine-tuning of furnace performance to meet specific process requirements. This customization leads to enhanced energy efficiency, improved product quality, extended operational lifecycles, and ultimately, a lower total cost of ownership. As industries push the boundaries of temperature, throughput, and process control, the role of custom SiC components will only continue to grow in significance.

Choosing the right partner for these specialized components is paramount. Sicarb Tech, strategically located in Weifang, the heart of China’s SiC manufacturing industry, and backed by the formidable technological resources of the Chinese Academy of Sciences, stands ready to meet these demanding needs. With a proven track record of technological innovation, a commitment to quality, and comprehensive capabilities spanning from material science to custom component design and even turnkey factory solutions, SicSino is more than just a supplier; we are a dedicated partner in advancing your high-temperature processing capabilities. By embracing custom Silicon Carbide, industries can ensure their furnaces are not just meeting today’s challenges but are also well-equipped for the demands of tomorrow.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.